Final Presentation

-

Upload

shyam-curtiz -

Category

Documents

-

view

75 -

download

0

Transcript of Final Presentation

SATHYABAMA UNIVERSITY

JeppiarNagar ,Chennai – 600 019

DESIGN PROJECT-REPORT

NAME OF THE STUDENTS :

SHYAM SUNDAR. S

SUNIL ANTONY ROY

SHEIK HUSSAIN

SHEIK HASAN

KEERTHIVAASAN

REGISTER NO

2926191

2926190

2926189

NAME OF THE PROJECT: DESIGN OF 200 SEATER

CIVIL PASSENGER AIRCRAFT

DEPARTMENT : AERONAUTICAL ENGINEERING

Certified That Is a Bonafide Project Report Carried Out On

DESIGN OF 200 SEATER CIVIL PASSENGER AIRCRAFT BY

SHYAM SUNDAR. S

SUNIL ANTONY ROY

SHEIK HUSSAIN

SHEIK HASAN

KEERTHIVAASAN

of VII Semester AERONAUTICAL (B.E) during the year 2012-2013

STAFF MEMBER INCHARGE :

INTERNAL EXAMINER :

EXTERNAL EXAMINER :

HEAD OF DEPARTMENT : (H.O.D)

ACKNOWLEDGEMENT

We would like to extend our heart filled thanks to Prof. BSM AUGUSTINE

(HEAD OF THE DEPARTMENT) for giving us his able support and encouragement.

At this point of time we must emphasis on the point that this design

Project would not have been possible without the highly informative and

Valuable guidance by Mr.Selvakumar, whose vast knowledge and experience

Has made us go about this project with great ease. We take great pleasure In extending our gratitude to him.

It is worth mentioning about my team mates, friends and colleagues of the

Aeronautical department, for extending their kind help whenever the

Necessity arose. Thank you one and all.

ABSTRACTAircraft come into being for a number of reasons .New aircrafts may be introduced because of new technology or new requirements. Aircrafts were put to use in carrying Passengers. In the mid 1940’s aircraft manufacturers were designing and building Passenger aircraft. The statics prove that by 2020 there will be a huge demand of CIVIL PASSENGER aircraft. This high demand for Passenger aircraft is the reason that lead to the innovative concept of designing a next generation Passenger aircraft. The following project aims at providing the whole design aspects of 200 seater Passenger aircraft.

CONTENT

Ex.No Name of the experiment

1 Introduction

2 Design Cycle

3 Aircraft Specifications

4 Characteristics Graph Plots

5 Overall Weight Estimation of Aircraft

6 Thrust Calculation

7 Airfoil Selection

8 Wing Selection

9 Drag and Lift Estimation

10 Performance Characteristics

Tail Design and Control surface Sizing

11 Structural Analysis

12 Three Views of Aircraft

13 Design Summary

14 Conclusion

15 Bibliography

ABBREVIATIONS

Ρ Density Of Airµ Dynamic ViscosityΛ Tapered RatioΒ Turning AngleΦ Gliding AngleA.R Aspect RatioB Wing SpanC Chord Of The Airfoil

Chord At RootChord At Tip

¯C Mean Aerodynamic ChordCD Drag Coefficient

Specific Fuel ConsumptionCL Lift CoefficientD DragE EnduranceE Oswald EfficiencyG Acceleration Due To GravityL Lift

Lift To Drag Ratio At LoiterLift To Drag Ratio At Cruise

M Mach Number Of AircraftR Range

Radius Of TurnRe Reynolds NumberR/C Rate Of ClimbS Wing AreaT Thrust

Velocity At Cruise Velocity At Stall

Crew WeightEmpty Weight Of AircraftWeight Of FuelPayload Of AircraftOverall Weight Of Aircraft

W/S Wing Loading

1. INTRODUCTION

MILITARY TRANSPORT-HISTORY

Aircraft were put to use carrying cargo in the form of air mail as early as 1911. The earliest "true" cargo aircraft is arguably the World War II German design, the AradoAr 232. Most other forces used freighter versions of airliners in the cargo role as well, most notably the C-47 Skytrain version of the Douglas DC-3, which served with practically every allied nation. . Post war Europe also served to play a major role in the development of the modern air cargo and air freight industry during what became known as the "Cold War. In the years following the war era a number of new custom-built cargo aircraft were introduced, often including some "experimental" features. For instance, the US's C-82 Packet featured a removable cargo area, while the C-123 Provider introduced the now-common upswept tail with a drop-down loading and unloading ramp.

The Military Air Transport Service (MATS) was activated under United States Air Force Major General William H. Tunner, in order to harness interservice efforts more efficiently. It was an amalgamation of Navy and Army air transport commands, jointly placed by the Department of Defense under the control of the newly created United States Air Force (USAF) as what is known as today today as a Unified Combatant Command.

During World War II, the Army Air Force's needs were looked after by the Air Transport Command which focused on transportation of troops and supplies, also organized by Tunner. With the end of World War II, the United States Army Air Force Air Transport Command found itself in limbo. Senior USAAF authorities considered ATC to be a wartime necessity that was no longer needed, and expected its civilian personnel, including former airline pilots, to return to their peacetime occupations.

The DOD believed it should have its own air transport service and decided that ATC should become the Military Air Transport Service (MATS), supported by the Air Force, even though not listed as a formal military mission. . A detachment of VR-7 was also stationed at Tachikawa Air Base, Japan. Also Air Force pilots flew MATS Navy planes, just as Naval aviators could be found piloting Air Force transport aircraft.

It was first published in French by the Institute du Transport Aérien in 1998 and received very favorable reviews. There is no aspect of mail or cargo transport by air that has not been thoroughly researched and documented by Allaz, from the

first brief transport of animals by balloon in France in 1783 to the vast global networks of the integrated express carriers in the 21st century. As a true scholar, he fits his narrative into the larger framework of political, military, economic and aviation history. This book should stand for years as the definitive work on the history of air cargo and airmail, and will be of immense value to the academic community, to the air cargo industry, the postal services, and to the general public.

2. DESIGN CYCLE

WHAT IS DESIGN?

From analytical disciplines such as aerodynamics, structures, etc. An aircraft Designer needs to be well versed in these and many other specialities, but will actually Spends little time in performing such analysis in all but the smallest companies. Instead the designer’s time is spent in doing something called “design”, creating the geometric description of the thing to be built.

To the uninitiated design: looks a lot like “drafting”, finally the designers product is a drawing. However the designer’s work is mostly mental. The product of design involves a lot of hard work and knowledge by the designer. Design is not just a layout, but also the analytical should be modified to better meet the requirements.

DESIGN PROJECT PROCESS

Aircraft design is a compromise between many competing factors and constraints. It is important to recognise these and to understand the influence of each on the aircraft on the aircraft configuration. The process (e.g. mass estimations aerodynamic assessments and performance predictions) involves the coordination of many different specialist departments. Each of these work on the overall design but have a divided responsibility between the effectiveness of the aircraft and the professional objectives of their speciality.

It is necessary to understand the way in which each of the main departments Interacts on the definition of the design.

In real time –those involved in design can never quite agree as to where the design process begins. Design is an iterative effort, as shown in the “design wheel” Requirements are set by prior design trade studies. Concepts are developed to meet requirements. Design analysis frequently points out toward new concepts and technologies, which can initiate a whole new design effort. However a particular design is begun, all of these activities are equally important in producing a good aircraft concept.

DESIGN WHEEL

Sizing and Trade

Studies

Requirements

Design Analysis

Design Concept

PHASES OF AIRCRAFT DESIGN

Aircraft design can be divided into 3 phase, as

1. Conceptual design2. Preliminary design3. Detail design

CONCEPTUAL DESIGN

It is a very fluid process. New ideas emerge as design is investigated in ever increasing detail. Each time the latest design is analyzed and sized, it must be redrawn to reflect the new gross weight, fuel weight, wing size, engine size and other changes.

PRELIMINARY DESIGN

It commences when the major changes are over. The big question is whether to use a card or an aft tail have been resolved. The configuration arrangement can be expected to remain, although minor revisions may occur. At some point late in preliminary design, even minor changes are stopped when a decision is made to freeze the configuration.

The ultimate objective during preliminary design is to ready the company for the detail design stage, also called full-scale development. Thus the end of the preliminary design usually involves a full-scale development proposal.

DETAIL DESIGN

Assuming a favorable decision for entering full-scale development, the detailing phase beings in which the actual pieces to be fabricated are deigned. For example, during conceptual and preliminary desing the wing box will be desinged and analyzed as a whole. During detail desing, that whole will be broken down into

individual ribs, spars, and skins, each of which must be separately desinged and analyzed.

The third phase of the desing process (detail design) starts when a decision to build the aircraft has been taken. In this phase, all the detail of the aircraft are translated into drawings, manufacturing instructions and supply requests (subcontractor agreements and purchase orders). Progressively, throughout this phase, these instructions are released to the manufacturers.

Another important part of detail design is called production design.Specialists determine how the airplane will be fabricated, starting with the smallest and simplest subassemblies and building up to final assembly process .production designers frequently wish to modify the design for case of manufacture; are inevitable, but the design must still meet the original requirements. Detail design ends with fabrication of the aircraft. Frequently the fabrication begins on part of the aircraft before the entire detail-design effort is completed.

3. COMPARISON OF AIRCRAFTS

WING SPECIFICATION

Name of AircraftWing Span

(m) Wing Area (m²) Height (m)

Boeing 757 - 200 38.05 181.25

Boeing 727 - 200 32.92 153.3

Boeing 767 - 200 47.57 283.35

Airbus A321 - 200 34.1 122.6

Airbus A 340 59.06 361.6

Tupolev Tu - 204SM 41.8 184.2

Ilyushin iI - 96 - 300 60.11 350

Lockheed L - 1011 - 500 50.09 329McDonnell Douglas DC -

10 - 30 50.4 367.7

Douglas DC - 8 - 5143.41 257.4

WEIGHT SPECIFICATION

Name of Aircraft Empty Weight (kg)Fuel

Weight (kg) Max. TakeOff Weight (kg) PayLoad

Boeing 757 - 200 57,180 31156.4 115,665 32755

Boeing 727 - 200 38,700 22630 86,600 28620

Boeing 767 - 200 81,230 66262.1 179,170 61470

Airbus A321 - 200 48,500 53,874 93,440 42000

Airbus A 340 129000 113179.2 275015 45915

Tupolev Tu - 204SM 40,125 26,061 105,000 23,000

Ilyushin II - 96 - 300 120,400 131400 250,000 40000

Lockheed L - 1011 - 500 111,000 82328.67 231,332 38585

McDonnell Douglas DC - 10 - 30 120,742 64944.45 259,459 39500

Douglas DC - 8 - 51 120,532 64719.61 90,500 40000

POWERPLANT SPECIFICATION

Name of AircraftName of Engine

No. of Engine

Thrust Power Name of Engine

Boeing 757 - 200 Turbofan 2 325.6two Pratt & Whitney

PW2037

Boeing 727 - 200 Turbofan 2 207 3 Pratt & Whitney JT8D-15

Boeing 767 - 200 Turbofan 2 563.2two Pratt & Whitney

PW4062

Airbus A321 - 200 Turbofan 2 147 IAE V2500 series

Airbus A 340 Turbofan 2 616 SNECMA CFM56-5C2

Tupolev Tu - 204SM Turbofan 2 157 Aviadvigatel PS-90A2

Ilyushin II - 96 - 300 Turbofan 4 156.96 Aviadvigatel PS-90A9

Lockheed L - 1011 - 500 Turbofan 3 222 Rolls-Royce RB.211-524BMcDonnell Douglas DC - 10 -

30 Turbofan 3 227 GE CF6-50C

Douglas DC - 8 - 51 Turbofan 4 80.06 Pratt & Whitney JT3D - 1

PERFORMANCE SPECIFICATION

Name of AircraftRange (km) Service Ceiling (m)

Cruise Speed (kms/hr)

Max. Speed

Boeing 757 - 200 7,240 12,810 850 935

Boeing 727 - 200 4020 10,700 915 1010

Boeing 767 - 200 12250 11885 850 900

Airbus A321 - 200 5,950 12,000 828 871

Airbus A 340 14800 12500 890 930

Tupolev Tu - 204SM 4,000 12100 850 900

Ilyushin II - 96 - 300 11,500 13,100 870 900

Lockheed L - 1011 - 500 9899 13100 972 1131

McDonnell Douglas DC - 10 - 30 10620 12802 908 982

Douglas DC - 8 - 51 8171 13,055 946 1035

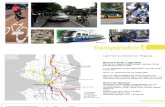

4. CHARACTERISTIC GRAPHS:

CRUISE SPEED VS RANGE

CRUISE SPEED VS MAXIMUM SPEED

820 840 860 880 900 920 940 960 9800

200

400

600

800

1000

1200

Maximum Speed

Maximum Speed

CRUISE SPEED VS SERVICE CEILING

820 840 860 880 900 920 940 960 9800

2,000

4,000

6,000

8,000

10,000

12,000

14,000

16,000

Range

Range

820 840 860 880 900 920 940 960 9800

2,000

4,000

6,000

8,000

10,000

12,000

14,000

Service Ceiling

Service Ceiling

CRUISE SPEED VS ASPECT RATIO

820 840 860 880 900 920 940 960 9800

2

4

6

8

10

12

Aspect Ratio

Aspect Ratio

CRUISE SPEED VS WING LOADING

820 840 860 880 900 920 940 960 9800

100

200

300

400

500

600

700

800

900

Wing Loading

Wing Loading

5. OVERALL WEIGHT ESTIMATION OF AIRCRAFT:

The structural design, the complexity of the load distribution through a redundant structure, and the large number of sophisticated systems in an aircraft, makes weight estimation a difficult and precarious task.

When the detail design drawings are complete, the weight engineer calculates the weight of each and every part, thousands of them, and adds them all up, and calculates the weight. But in the beginning phase of the design processes, this cannot be accomplished because there are neither detailed drawings of the aircraft nor the various details of the aircraft.

And so some approximations are made and the overall weight is eventually estimated.

The overall weight W0 is given by the formula

W0 = Wcrew+ Wpayload+ Wfuel+ Wempty (1)

In the above equation fuel weight and empty weight can be expressed in terms of overall weight.

So (1) becomes

W0 = Wcrew+ Wpayload+Wf.W0 + We. W0 (2) W0W0

On simplifying further we have,

W0 = (Wcrew+ Wpayload)/(1- Wf – We) (3) W0W0

Calculation

First Approximation

Wcrew

Number of crew = 4

(Each weighing 70 kg and having 30 Kg of luggage)

Therefore Wcrew = 4×100×9.81 =3924N

Wpayload

The payload for 130 seater aircraft from the reference of Airbus A400M and Boeing C 17

Wpayload= 57259.5

Substituting the assumed Values in the Equation (3)

W 0=3924+57259

1−907699.61993146.7

−1003563

1993146.7

w0=611385

1−0.455−0.503

W 0=14567500N

Second Approximation

W f

W 0

=¿

Where Wx = W1 × W2 × W3 × W4 × W5 (4)

W0W0 W1 W2 W3 W4

The five terms on the right hand side are

Fractions of takeoff, climb, cruise loiter and landing interrelated with each other and the overall weight.

1- Take Off2- Climb3- Cruise4- Loiter5- Landing

From the table (Raymer Pg 13)

W1= 0.970W0

W2 = 0.985W1

W5 = 0.995

W4

W3= e(-RC/VL/D)

W2

W4= e(EC/L/D)

W3

R- Range of the aircraft

C- Specific Fuel Consumption

V- Cruise Velocity

L/D- Lift to drag ratio

R of AirBus A400M is 4482km

C is 0.5 for high bypass Turbofan

V of Airbus A400M is 828.8Kmph

L/D is 14.7 during cruise

Therefore W 3

W 2

=e¿−4482×0.5

828.8×14.7

W 3

W 2

=0.831

Similarly,

W 4

W 3

=e−5.40× 0.4

16

W 4

W 3

=0.873

Substituting the above values in Equation (4)

W x

W 0

=0.970×0.985×0.831×0.873×0.995

W x

W 0

=0.689

Hence

W f

W 0

=1.06(1−0.689)

W f

W 0

=0.329

Substituting the above results in Equation (3)

W 0=3924+57259.5

1−0.329−0.503

W 0=364187.5

Third Approximation

W e

W 0

=AW 0c K

K is 1 for fixed sweepA is 0.93

And we have found that W0 =364187.5

W e

W 0

=0.93×364187.7−0.07

W e

W 0

=0.379

Substituting the above results in Equation (3)

W 0=611835

1−0.329−0.379

W 0=2095325.34

The Overall Weight of the Aircraft is 2095325.34