Final Hydrolic Bending Bending Machine

-

Upload

avinash-jadhav -

Category

Documents

-

view

303 -

download

0

Transcript of Final Hydrolic Bending Bending Machine

-

8/12/2019 Final Hydrolic Bending Bending Machine

1/39

HYDRAULIC BENDINGMACHINE

ACKNOWLEDGEMENT

It gives us immense pleasure to represent the report on

HYDRAULIC BENDING MACHINE. We like to express our heart full

thanks, gratitude and appreciation to our guide Prof. A.A. PATIL sir for this

timel, careful and valua!le guidance "ith constant inspiration.

We take this opportunit to offer our sincere thanks to #. $.

%. of &echanical %epartment Prof. PATIL P.'. and principal of our college

Prof. %($ ).). for providing us help in course of our pro*ect report.

We "ould also like to thank him for sharing his kno"ledgeon this su!*ect ,"ithout him the completion of this pro*ect seemed impossi!le.

Last !ut not the least ,"e "ould like to thank the almight

god "ho made us capa!le of "ithstanding all the difficulties that occurred

during the completion of this pro*ect.

1

-

8/12/2019 Final Hydrolic Bending Bending Machine

2/39

HYDRAULIC BENDINGMACHINE

CONTENTS

CHAPTER

NO:-

TOPIC PAGE

NO:-+. IT-$%/TI$ 0

1. /$)T-/TI$ 2 W$-3I4 5

0. W$-3I4 $6 #7%-ALI/ 'A/3 +8

9. %()I4 +0

:. P-$/()) )#((T) 18

5. APPLI/ATI$ 15

;. A%

-

8/12/2019 Final Hydrolic Bending Bending Machine

3/39

HYDRAULIC BENDINGMACHINE

INTRODUCTION

3

-

8/12/2019 Final Hydrolic Bending Bending Machine

4/39

HYDRAULIC BENDINGMACHINE

&an device of mechanical are !ased on hdraulic

po"er. #draulic device uses principles of fluid static and fluid kinematics are

used for either storing the hdraulic energ and then transmitting "hen

needed or maintaining the hdraulic energ several times and transmitting

the same.

In all such machines, po"er is transmitted "ith the

help of a fluid, "hich ma !e "ater or oil. $ur mechanism is used in industrial

fitting and maintaining department, in automo!ile garage or in industrial

"orkshop.

$ur pro*ect is used for reducing manufacturing cost

and saving time and also to reduce maintaining cost or a manufacturing cost.

#ere "e manufacture a light "eight 2 eas to handle

machine so that ou can carr an "here into the shop. It is also simple for

assem!ling and disassem!ling.

HYDRAULIC JACKING SYSTEM:-

#draulic *acking sstem is ver eas "orking and gets

result ver fast. In hdraulic *acking 1 tons, 0 tons, : tons,+8 tons, +1 tons, is

standard part and availa!le in market.

4

-

8/12/2019 Final Hydrolic Bending Bending Machine

5/39

HYDRAULIC BENDINGMACHINE

We have used 0 tons *acking sstem. This sstem lifts 0

tons of load .In our pro*ect re@uiring !ending load of :88 "hich "ill !e more

than sufficient for fine "ork.

#draulic energ is mainl used for "orking a hdraulic

*acking sstem. ?ut in our mechanism this energ is used for !ending pipe.

$ur machine is used in industrial fitting and as plum!ing

instrument. $ur pro*ect is used for reducing manufacturing cost and also to

save time thus reducing manufacturing and fitting time.

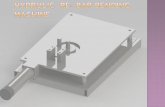

(Fig. 1) HYDRAULIC BENDING M/C

5

-

8/12/2019 Final Hydrolic Bending Bending Machine

6/39

-

8/12/2019 Final Hydrolic Bending Bending Machine

7/39

HYDRAULIC BENDINGMACHINE

CONSTRUCTION WORKING.

In our machine there are mainl four parts. This parts are stated !elo"B

+. ?ase Plate

1. )upporter Plate

0. pper Plate

9. Locking Plate

1. BASE PLATE :-

The Plate is used for mounting purpose. We drill 9 holeCs

to cutter side and also 9 holeCs in center for mounting *acking sstem as "ell as

"e "eld the *acking sstem to the !ase plate.

(Fig. !) BASE PLATE

7

-

8/12/2019 Final Hydrolic Bending Bending Machine

8/39

HYDRAULIC BENDINGMACHINE

!. SUPPORTER PLATE :-

)upporter plate is mounted on !ase plate "ith help of !oltCs.

These plate is standing on ?ase plate. This plates

forms a support for the plates. it also holds the pipe "hich is to !e !end.

(Fig. ") SUPPORTER PLATE

". UPPER PLATE :-

pper Plate is mounted on supported plate. These plate is

mounted on upper side. pper plate !alances the pro*ect and get po"er for

!ending.

8

-

8/12/2019 Final Hydrolic Bending Bending Machine

9/39

HYDRAULIC BENDINGMACHINE

#. MIDDLE PLATE :-

Locking plate is mounted !et"een supporter plates !

using !olt. Locking plate is used for holding the pipe or shaft these plate gets

eas "orking.

9

-

8/12/2019 Final Hydrolic Bending Bending Machine

10/39

-

8/12/2019 Final Hydrolic Bending Bending Machine

11/39

HYDRAULIC BENDINGMACHINE

WORKING OF HYDRAULIC JACK

1$%&'i*+, ,ig

!*&'i*+, ,ig

1) 1ST CYLINDER WORKING:

The hdraulic *ack is a device for lifting heav load !

the application of much smaller effort. It is !ased on pascalCs la", "hichstates that intensit of pressure is transmitted e@uall in all directions through

a mass of fluid at rest.

It consists of clinder DfixedE in "hich the piston slides.

The lo"er end of the piston carries a mova!le plate "hich moves up 2 do"n

"ith the piston the upper 2 lo"er stationar plate are *oined ! column.

When li@uid under high pressure is supplied to the

clinder, the piston moves up"ard 2 applies tremendous pressure De@ual to

the product intensit of pressure supplied 2 area of the ramE on an material

placed on it.

!) !ND CYLINDER WORKING :-

When the piston approaches the end of itCs stroke in

the direction of force, itCs force of fluid into the drilled passage. 6lo" of fluidpast the needle value is restricted so that the piston velocit is reduced. This

prevents the piston from striking the clinder end. The slo"ing of the piston

motion is called deceleration.

6luid entering the connecting part of the rod end passes

directl ! the lip of the cushion seal 2 applies energ at the face of the piston

11

-

8/12/2019 Final Hydrolic Bending Bending Machine

12/39

HYDRAULIC BENDINGMACHINE

for !ringing the ram !ack in position, the fluid from clinder is taken out

su!se@uentl the ram in over up ! the action at return "eights.

To raise the main ram rapidl, fluid is pumped The smaller

inner ram, called *ack ram, has a greater area than the lip of the main ram.

/linders 2 rams are often !uilt as an integer part of a

machine slide or press element.

(@ual pressure through out the circuit provides a sta!iliFing

influence in the main ram assists the reiteration of this ram.

In all such machines po"er is transmitted "ith the help of afluid "hich man !e a li@uid "e can use !ut mostl oil is po"erful means that

"hen choosing a hdraulic fluid, the follo"ing factors must !e considered

spread of operation, surrounding atmospheric conditions, economic

conditions, availa!ilit of replacement fluid, re@uired pressure level, temp.

-ange, contamination possi!ilities, cost of mission lines in "hich the fluid is

used safel to operates and expected service life.

#draulic fluids have specific characteristic that can affect

the associated components. i.e. seals, coaching, parking and diaphragms

must !e made !e of a material that "ill not deteriorate in association "ith the

"orking fluid.

12

-

8/12/2019 Final Hydrolic Bending Bending Machine

13/39

HYDRAULIC BENDINGMACHINE

(Fig.#) WORKING OF HYDRAULIC 0ACK

13

-

8/12/2019 Final Hydrolic Bending Bending Machine

14/39

HYDRAULIC BENDINGMACHINE

DESIGN

1. DESIGN OF MIDDLE PLATE :-

#ere "e have selected 58 mm x 088 mm and no" "e

have to find out the thickness of the plate re@uiring to sustain the force :88.

ThereforeG &aximum !ending moment at center of plate isB

H 6 x +:8mm

D6Hforce acted on plateG +:8mmH i.e. distance at "hich force is

applied at centre of plateE

H :88 x +:8mm

H ;:888 .mm

middle plate is made up of 08 /= &.). material "hose 7ield strength of

tension

D)tE H 988 mmJ

14

-

8/12/2019 Final Hydrolic Bending Bending Machine

15/39

HYDRAULIC BENDINGMACHINE

o" ,"orking stress DK!E

H & MMMM. De@ no.+E

Where & H ?ending moment

H )ectional modulus

also ,DK!E H )t 6.). H 9881

H 188 mmJ

Where B 6.). N 6actor of )afet.

H D58tJE5Hsectional modulus

Putting all these values in e@uation + "e getG

DK !E H &

188 H;:888D58tJE5

t H >.9= mm.

)o that the thickness should !e +8 mm.

15

-

8/12/2019 Final Hydrolic Bending Bending Machine

16/39

HYDRAULIC BENDINGMACHINE

O O

P O

O

(Fig.) MIDDLE PLATE

!. DESIGN OF BOTTOM PLATE.

&aximum !ending moment at center of plate

H :88 x +1:mm

D6Hforce acted on plateG +1:mmH i.e. distance at "hich

force is applied at centre of plateE

H 51:88 .mm

Plate %imensions are

988 mm length x +:8 mm "idth

16

-

8/12/2019 Final Hydrolic Bending Bending Machine

17/39

HYDRAULIC BENDINGMACHINE

?ottom Plate made up of 08 /= &.).material

"hose 7ield strength of tension D)tE H 988 mmJ

o" ,"orking stress DK!E

H & MMMM. De@ no.1E

Where & H ?ending moment

H )ectional modulus

We kno"

also ,DK!E H )t 6.). H 9881

H 188 mmJ Where B 6.). N 6actor of )afet.

H D58tJE5Hsectional modulus

Putting all these values in e@uation 1 "e getG

DK!E H &

188 H51:88D+:8tJE5

t H >.=9 mm.

)o that the thickness should !e +8 mm.

17

-

8/12/2019 Final Hydrolic Bending Bending Machine

18/39

HYDRAULIC BENDINGMACHINE

(Fig.2) BASE PLATE

". DESIGN OF SUPPORTER PLATE :-

)upporter plate has direct tension on it

K H 6A BBBBBBBDe@ no. 0E

Where, 6 H 6orce H :88

A H /) area of supporter plate

Therefore percentage ield strength of plate is

Q )t 6.). H 9880

18

-

8/12/2019 Final Hydrolic Bending Bending Machine

19/39

HYDRAULIC BENDINGMACHINE

H +00.00 mmJ

and /) area of supporter plate is

A H tJ B+8 t

Putting all these values in e@uation 0

K H 6A

+00.00 H :88 tJ B +8 t

tJ B +8 tR :88 +00.00

tJ H +8t N 0.;: H 8

t H +8.1:

t H +8 mm

therefore "e have selected thickness of +8 mm

19

-

8/12/2019 Final Hydrolic Bending Bending Machine

20/39

HYDRAULIC BENDINGMACHINE

(Fig.3) SUPPORTER PLATE

Top plate doesnCt carries an force. It is *ust for holding support.

20

-

8/12/2019 Final Hydrolic Bending Bending Machine

21/39

HYDRAULIC BENDINGMACHINE

PROCESS SHEET

21

-

8/12/2019 Final Hydrolic Bending Bending Machine

22/39

HYDRAULIC BENDINGMACHINE

Part ame B )PP$-T(- PLAT(

Part St B 1

Part Wt B 5 3g

Part )iFe B :88 x +88 x +8mm

)r.

o

$peration &achine Tool Time

+. /utting the

material as our

re@uired siFe

4as /utting mc 4as oFFle +:min

1. At one side tap

&= siFe t"o

hole

%rilling mc R

tapping

manuall

%rilling ?it ;.:

mm manual

operated tap &=

+: min

0. %rilling 0: mm

at length 088

mm

Lathe mc 0: mm %rilling ?it +: min

9. %rilling +8 mm

at +8mm length

at another end

%rilling mc %rilling ?it +8mm : min.

Part name B TOP PLATE

Part St B +

Part Wt B 0 3g.

22

-

8/12/2019 Final Hydrolic Bending Bending Machine

23/39

HYDRAULIC BENDINGMACHINE

Part )iFe B 088 x +88 x +8 mm

)r.

o

$peration &achine Tool Time

+. /utting the

material as our

re@uired siFe

4as /utting mc 4as oFFle +:min

1. Tapping & =

siFe at ?oth end

in length of

+:mm

%rilling ;.: mm 2

manuall operated

tap &= siFe

%rilling ?it ;.:

mm 2 & = tap

+: min

Part name B FI4ING PLATE

Part St B 1

Part Wt B 9 3g.

23

-

8/12/2019 Final Hydrolic Bending Bending Machine

24/39

HYDRAULIC BENDINGMACHINE

Part )iFe B 58 x 088 x +8 mm

)r.

o

$peration &achine Tool Time

+. /utting the material as our

re@uired siFe

4as /utting mc 4as

oFFle

+:min

1. & = siFe tapping at length

of +8mm as ?oth side.

%rilling ?it ;.: mm 2

manuall operated

tap &= siFe

%rilling

?it ;.:

mm 2

& = tap

08 min

08 min

0. At ?ottom side t"o &= tap

at length =8 mm

%rilling ?it ;.: mm 2

manuall operated

tap &= siFe

%rilling

?it ;.:

mm 2

& = tap

08 min

Part name :- MIDDLE PLATE

Part siFe B +18 x : x 18mm

Part Wt B 8.1: 3g.

Part St B 1

24

-

8/12/2019 Final Hydrolic Bending Bending Machine

25/39

HYDRAULIC BENDINGMACHINE

)r.

o

$peration &achine Tool Time

+. /utting the

material as our

re@uired siFe

Po"er #acksa" mc #acksa" ?lade +8 min

1. %rilling t"o hole

at same length

%rilling mc %rilling tap +8

mm

: min

Part name B BOTTOM PLATE

Part Wt B 0 3g.

Part St B

Part siFe B 988 x +:8 x +8mm

25

-

8/12/2019 Final Hydrolic Bending Bending Machine

26/39

HYDRAULIC BENDINGMACHINE

)r.

o

$peration &achine Tool Time

+. /utting the material

as our re@uired siFe

4as cutting mc 4as noFel +8 min

1. %rilling 6our hole at

+8mm

%rilling mc %rilling ?it +8

mm

+8

min

26

-

8/12/2019 Final Hydrolic Bending Bending Machine

27/39

HYDRAULIC BENDINGMACHINE

APPLICATION

(1) INDUSTRIAL APPLICATION :-

In Industrial application, !ending pipe or

27

-

8/12/2019 Final Hydrolic Bending Bending Machine

28/39

HYDRAULIC BENDINGMACHINE

shaft to for re@uired condition. thus saving time and get the

process fast.

(!) HOME APPLIED USE :-

In home applied get plum!ing pipe !end. )o get

save plum!ing cost and these leakage pro!lem is minimum.

(") AUTOMOBILE INDUSTRIES :-

In automo!ile industries remove the shaft

!ending or !ending a shaft.

28

-

8/12/2019 Final Hydrolic Bending Bending Machine

29/39

HYDRAULIC BENDINGMACHINE

AD5ANTAGES DISAD5ANTAGE

AD5ANTAGES :-

29

-

8/12/2019 Final Hydrolic Bending Bending Machine

30/39

HYDRAULIC BENDINGMACHINE

+E (as handling

1E Lo" maintenance

9E (as /onstruction

:E )mall space mounting

5E o damage

;E (as maintenance

DISAD5ANTAGE :-

+E ot used in an D?ig pipeE siFe pipe or shaft.

1E ot used in on construction moment.

3) )iFe "ill !e selected.

30

-

8/12/2019 Final Hydrolic Bending Bending Machine

31/39

-

8/12/2019 Final Hydrolic Bending Bending Machine

32/39

HYDRAULIC BENDINGMACHINE

0E Also the cross section differs "ith increase in plunger heightto a certain limit then it starts to !reaks "ith more increase inheight of plunger.

9E The maximum !end "hich can !e occurred is ;: to >8 degrees.

32

-

8/12/2019 Final Hydrolic Bending Bending Machine

33/39

HYDRAULIC BENDINGMACHINE

FURTHER MODIFICATION

In further modification "e can provide sliding sstem to locking plate.

%ue to "e can o!tain height as per re@uirement.

Also "e can provide "heel !elo" the !ase plate due to handling

!ecome eas.

33

-

8/12/2019 Final Hydrolic Bending Bending Machine

34/39

HYDRAULIC BENDINGMACHINE

#draulic !ending machine "e can also used for another application

like !earing press fitting in sheet metal.

34

-

8/12/2019 Final Hydrolic Bending Bending Machine

35/39

HYDRAULIC BENDINGMACHINE

COST ESTIMATION

COST OF MATERIAL

&aterial Wt -ate 3g Total

Top Plate 0 3g -s 98 -s +18

35

-

8/12/2019 Final Hydrolic Bending Bending Machine

36/39

HYDRAULIC BENDINGMACHINE

?ottom Plate 0 3g -s 98 -s +18

)upporter Plate

5 3g -s 98 -s 198

Locking Wt 8.1: 3g -s 98 -s +8

6ixing Plate 9 3g -s 98 -s +58

Total Wt +5.1: 3g B -s 5:8

COST FOR MACHINING

&achine used sing time -ate hr Total

4as cutting mc + hr ++8 -s ++8.88

Lathe mc +: &in +18 -s 08.88

%rilling machine 1 hrs. +18 -s 198.88Po"er #acksa"

machine

+: min +:8 -s 98.88

Tapping mc + hr 188 -s 188.88

Total -s 518.88

COST FOR STANDARD PART

-ateB

A&( $6 )TA%A-% PA-T) T$TAL

ut 2 ?olt D8.: 3gE -sB 98.88

#draulic !ottle *ack -sB +:88.88

Welding -sB 988.88

Painting -sB 088.88

Transport -sB 188.88

Total -sB 1998.88

36

-

8/12/2019 Final Hydrolic Bending Bending Machine

37/39

HYDRAULIC BENDINGMACHINE

TOTAL PRO0ECT COST B

/ost of material R /ost for machine R /ost for std. part

H 5:8.88R 518.88 R1998.88

H 0;+8.88

T$TAL P-$'(/T /$)T

H -) 0;+8.88

37

-

8/12/2019 Final Hydrolic Bending Bending Machine

38/39

HYDRAULIC BENDINGMACHINE

BIBLIOGRAPY

+. &A/#I( %()I4

D a E -.). 3hurmi gupta

D ! E ?handri '.%.

1. W$-3)#$P T(/#$L$47

D a E ).3. #a*ra choudhar

D ! E -aghuvanshi -.

-

8/12/2019 Final Hydrolic Bending Bending Machine

39/39

HYDRAULIC BENDINGMACHINE

3olkata.

9. &AT(-IAL T(/#$L$47

D a E &aha*an &.).

:. &AT(-IAL #A%?$$3

D a E Tata &c 4ra" hill pu!.

5. &A/#I( T$$L %()I4 #A%?$$3.

D a E Tata &c 4ra" hill pu!.