Fall Final Presentation November 30, 2004 MAVerick Solutions Todd Adkins Leroy Cohen Jr. Adam...

-

Upload

daniel-milo-griffith -

Category

Documents

-

view

220 -

download

3

Transcript of Fall Final Presentation November 30, 2004 MAVerick Solutions Todd Adkins Leroy Cohen Jr. Adam...

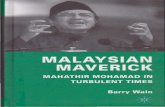

Fall Final Fall Final PresentationPresentation

November 30, 2004November 30, 2004

MAVerick SolutionsMAVerick Solutions

Todd AdkinsTodd Adkins

Leroy Cohen Jr.Leroy Cohen Jr.

Adam HollrithAdam Hollrith

Brian MooreBrian Moore

OVERVIEWOVERVIEW

ObjectivesWing ConceptsDeployment MechanismsDesign AnalysisCost AnalysisCurrent WorkFuture Work

ObjectivesObjectives

Design and fabricate component technology that will provide a MAV the capability to collapse/fold all wing surfaces along the body of the fuselage

Assess current materials and technologies that will maximize subsystem performance and minimize size and weight (i.e. composites, plastic actuators)

Demonstrate final concept design at Eglin AFB

Furnish final report documenting project objective, approach, results, budget analysis for hardware used, and conclusions/recommendations

SpecificationsSpecificationsParameters Specifications

Wing Dimensions 6” wingspan, 3-4” width

Deploy/Retract time interval 1-3 seconds

Fuselage dimensions 1-1.5 in. diameter x-sec., 4-6 in. lengthLanding System No

Wing/On-board Power Source 10-12 V

MAV recoverable Yes

Wing Material Carbon Fiber

System Weight 100-200 gm

Vehicle Velocity < 25 mph

MAV control Remote

Fuselage Material Carbon fiber

Stowed DimensionsMAV cross section must fit in 3"

diameter tube, Wings may not extend past tips of fuselage

Activation DevicesMicro Servos, Micro Actuators,

Micro Motors, Springs

System PackagingAll mechanical and structural

components to be contained within a single module

System ModuleTo be easily implemented into the

existing MAV fuslage

Wing ConceptsWing Concepts

Concept #1

Involves a pair of wings that fold along the sides of the fuselage Pros- Compact design

Cons- Complicated deployment path- Multiple driving mechanisms- Two separately moving wings

Wing ConceptsWing Concepts

Concept #2

Involves a one-piece, rotating wing Pros- Simple deployment- Compact design- One rotating mechanism- One-piece wing design

Cons- Concentrated stress on single support- Possible interference with tail of MAV

Wing ConceptsWing Concepts

Concept #3

Involves a bi-wing design that will allow for greater lift capabilities and improved glide slope

Pros- Greater lift capabilities than concept 2- One-piece wing design- Central rotating mechanism

Cons- Possible wing interference- Greater weight

Wing ConceptsWing Concepts

Concept #4

Comprised of a two-wing system that simply rotates into deployment The wings overlap on the top of the vehicle fuselage while stowed Pros- Simple and quick deployment- Compact design

Cons- Interference caused by overlapping wings- Two wing attachment points

Wing ConceptsWing Concepts

Concept #5

Comprised of one central connection between the wings and the fuselage Both wings will rotate from the same point Pros- Central rotation point- Compact design- Simple and quick deployment

Cons- Interference from overlapping wings- Relatively more complex concentric shafts

Actuator DeploymentActuator Deployment

Linkage DeploymentLinkage Deployment

Gear Set DeploymentGear Set Deployment

Design Analysis - Lift and DragDesign Analysis - Lift and Drag

Lift Force (N) vs. Velocity of MAV (mph) Coefficient of Lift

0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 250

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

FL_1 VMAV N

FL_1.25 VMAV N

FL_1.5 VMAV N

FL_1.75 VMAV N

FL_2.0 VMAV N

VMAV

mph

CL_2.0 3

CL_1.75 2.5

CL_1.5 2.0

Need to be above (0.981 N) ------->CL_1.25 1.5

CL_1 1

FL WMAV

FL 0.981N

Lift Force must be equal to 0.981 N for MAV to fly

Design Analysis - Lift and DragDesign Analysis - Lift and Drag

Coefficient of Drag

0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 251 10

10

0.04

0.08

0.12

0.16

0.2

0.24

0.28

0.32

0.36

0.4

Momentwings_1 VMAV N cm

Momentwings_2 VMAV N cm

Momentwings_3 VMAV N cm

Momentwings_4 VMAV N cm

Momentwings_5 VMAV N cm

VMAV

mph

CD_5 0.05Max. Moment --------->

CD_4 0.04

CD_3 0.03

CD_2 0.02

CD_1 0.01

Moment on Wings (N*cm) vs. Velocity of MAV (mph)

Maximum Torque on Wings@ Maximum Velocity (25mph)

TorqueWings 0.376N cm

Torque Provided by Servo (UsingLowest Torque from Servos Chosen)

TorqueServo 4.3 oz in( ) g

TorqueServo 3.036N cm

Design Analysis – LinkagesDesign Analysis – Linkages

0 10 20 30 40 50 60 70 80 90170

180

190

200

210

220

230

240

250

260

270

280

4 in deg

in

deg

4 0deg( ) 270deg

4 90deg( ) 180deg

Design Analysis – LinkagesDesign Analysis – Linkages

0 9 18 27 36 45 54 63 72 81 90135

137

139

141

143

145

147

149

151

153

155155

135

3 in deg

900 in

deg

0.2 0.25 0.3 0.35 0.4 0.45 0.5 0.550.15

0.11

0.064

0.021

0.021

0.064

0.11

0.15.15

0.15

P y in in

0.55.20 P x in in

Design Analysis – GearsDesign Analysis – Gears

Teeth on pinion/gear

Np 22 Ng 33

Gear Ratio

mG

Ng

Np

mG 1.5

Diameter of pinion

dp

Np

pd

dp 0.183in

Diameter of gear

dg

Ng

pd

dg 0.275inTorque on pinion shaft

Tp .0376N cmrp 0.092in

Bending - Stress

b_pinion 206.05psi b_gear 191.827psi

Safety Factors

Nb_pinion 53.628 Nb_gear 57.604

Servos Cost AnalysisServos Cost Analysis

Servos Weight Torque Speed Supply Voltage Dimension CostBlue Arrow 3.9g 0.31 kg*cm 0.12sec/60deg 4.8V 19.6mm x 17.6mm x 8mm 16.95$ Cirrus CS 4.4g 1.30 kg*cm 0.10sec/60deg 4.8V 18mm x 7.5mm x 15.7mm 29.99$ Micro JST 3.0g 0.50 kg*cm 0.12sec/60deg 4.8V 20mm x 6mm x 6mm 49.99$

HE 490 4.8g 0.72 kg*cm 0.08sec/60deg 4.8V 20mm x 7mm x 16mm 19.95$ Hitec HS-55 7.9 g 1.10 kg*cm 0.17sec/60deg 4.8V 23mm x 12mm x 24mm 16.49$

BA-TS 4.3g 0.40 kg*cm 0.12sec/60deg 4.8V 19.6mm x19.6mm x 8mm 14.50$

Blue Arrow Cirrus CS Micro JST HE 490 Hitec HS-55 BA-TS

Connectors & Rods Connectors & Rods Cost AnalysisCost Analysis

Rod Material Type Diameter Weight Cost Round Carbon Fiber Carbon Fiber Round .02 in - .125 in 0.27g - 11.0g $1.50 - $3.50Flat Carbon Fiber Carbon Fiber Flat .02 in - .09 in 2.2g - 17.7 g $2.15 - $8.00Micro Pushrod System Aluminum Round 0.32 in N/A $4.95K-Mac Fiberglass Rod Fiberglass Round .125 in - .375 in N/A $4.26 - $7.76

Connector Material Type Diameter Weight Cost Mini E/Z Connector Aluminum Round N/A 0.25g $2.49Micro Horns Plastic L shape 0.5 in N/A $1.00

Gears Cost AnalysisGears Cost Analysis

Material Number of teeth Pressure Angle Face Width PriceAcetal 22 20 deg 0.187 8.29$ Nylon 24 20 deg 0.375 2.09$

2024 Aluminum 22 20 deg 0.125 12.98$ 303 Stainless Steel 22 20 deg 0.125 14.38$

Pro-E DrawingsPro-E Drawings

Pro-E DrawingsPro-E Drawings

Pro-E DrawingsPro-E Drawings

Current WorkCurrent Work

Incorporate Fuselage from Sponsor

Compile component order list

Continue researching component material

Future WorkFuture Work

Construct several prototypes of the MAV

Test the deployment systems

Operations Manual

Webpage

Final Report

Open House

SummarySummary

ObjectivesWing ConceptsDeployment MechanismsDesign AnalysisCost AnalysisCurrent WorkFuture Work

ReferencesReferences

http://www.eflightdesigns.com/cgi-bin/products.cgi?CAT=23

http://www.nyblimp.com/superior/carbon-rods.htm

http://www.robotcombat.com/marketplace_carbonfiber.html

http://www.stevensaero.addr.com/e-flight_servos.html

http://www.hobbypeople.net/gallery/877815.asp

http://www.nyltite.com/L20.html

https://sdp-si.com/eStore/

http://www.nyblimp.com/superior/DB.htm

QUESTIONS ???QUESTIONS ???