Fabrication of Capsules with Angle Dependent Gold shims for Hohlraum Drive Symmetry Correction

description

Transcript of Fabrication of Capsules with Angle Dependent Gold shims for Hohlraum Drive Symmetry Correction

Fabrication of Capsules with Angle Dependent Gold shims for Hohlraum Drive Symmetry Correction

A. Nikroo1, J. Pontelandolfo1, A.Z. Greenwood1, J.L. Stillwell2, D. Callahan3

1 General Atomics2 University of California, Berkeley3 Lawrence Livermore National Laboratory

15th International Symposium on Heavy Ion Fusion

PPPLPrinceton, New JerseyJune 7-11, 2004

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

Thickness, µm

150100500

Polar angle, deg

Work performed under General Atomics Internal R&D program

Innovation in target design and fabrication can be used to compensate for drive asymmetry

• In the HIF hybrid target, most of the energy is deposited behind a shine shield

– Radiation flows around the shield and results in a bright source around the shield

– This causes a large P4 asymmetry

• The P4 asymmetry can be corrected using a shim to remove excess radiation

• Initial examination of this concept was done on a target shot in SNL’s double ended Z-pinch

Shims can be used to fix asymmetries in all indirect drive targets (heavy ion, laser, z-pinch)

equator XY

Au shim

Ge-CH

Z-axis

Summary of angle dependent gold shim fabrication process

• Ge-CH mandrels were made using well developed ICF capsule fabrication techniques

• Gold shim coating was deposited by magnetron sputtering

• Using masks patterned coatings were produced

• Coatings on flats were used as initial guidelines

• Gold thicknesses on shells were determined by x-ray transmission (contact radiography)

• Profile similar to desired profile was produced

• Adjustments to process is necessary to obtain desired profile

The decomposable mandrel technique was used to fabricate Ge-CH shells

• Process allows fabrication of shells with:

• Desired diameter (~ 5 mm)• Wall thickness (~ 20-30 µm)• Sphericity (>99.9%)• Wall thickness uniformity (<0.2 µm)• Dopant content (germanium- ~ 2 at.%)

DecomposableMandrel:

(GDP)Poly-a-methylstyrene(PAMS)

Glow discharge Polymer coating

Final Ge-CH shell

HeatCoat

High aspect ratio- fragile

0.8

0.7

0.6

0.5

0.4

0.3

Au thickness, µm

18013590450

Angle, deg

-2 -1 0 1 2r, mm

The desired gold shim profile was a combination of P2 and P4 Legendre polynomials

• The relative contribution of P2 and P4 needed to be an adjustable parameter

• Shim coating process had to be flexible enough to accommodate such changes:

• Use of multiple masks• Adjustment of mask-shell distance

f θ 0s .s 14P θ .2 2P θ

3

Desired shim profile for this experiment was:

XZ Projection

vs. polar angle

Designed to zero out P2, P4 double ended Z-pinch asymmetry

Gold coating was deposited using physical vapor deposition via magnetron sputtering

• Sputtering provides an important processing knob

• Background argon pressure determines mean free path of gold atoms

• Affects scattering and deposition pattern of gold atoms

• Masks were used to pattern gold coating

Au target

MotorGe-CH mandrel

VacuumChamber

Spi

nnin

g P

anxyzMicro-manipulator

Ar+ Impact

-500 V

Sputter system

Mask

Combination of coatings through two different masks could be used to obtain different profiles

• Aluminum plate with precision milled slots was used as mask

• Varying slot dimension varied coating profile

• Single and double slot masks could be combined to fine tune pattern

0.6

0.4

0.2

0.0

Thickness, µm

3210-1-2

Distance from center, mm

Single

Double

10

2.31

1.08

51.

085

7.5

2.2

5

Coatings on flat substrates

Combination mask

Gold coating pattern could also be changed by varying the mask-substrate distance

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

Thickness, µm

-3 -2 -1 0 1 2 3

Distance from center, mm

Movable mask

1mm

2mm

• For a given mask the separation between mask and substrate could be changed

• Coatings spread with separation of mask from substrate

• This allowed obtaining various profiles by adjusting mask-substrate distance

Coatings on flats

The desired profile could be produced on flats very closely

0.8

0.7

0.6

0.5

0.4

0.3

Thickness, µm

-2 -1 0 1 2

Distance from center, mm

Desired

Actual

• Coatings using:

• ~ 2mm mask-substrate distance• 0.8* single slot + 1.0 double slot

produced desired pattern on flats

• Coatings on shells were likely to be deficient near the poles• This, however, was used as a starting point for producing the shim on shells• Coating rate on shells needed to be determined

Characterization of coatings on shells provided a difficult challenge

• Interferometry or profilometry were not possible

• X-ray transmission detected by contact radiography was readily available and used:

• Convolution of x-ray source, coating, x-ray film signal was calibrated on flats • X-ray signals was linear for the range of interest• Uncoated shell signal was subtracted• Shell signal was corrected for cord length in ZX projection• Data near poles suffers from saturation due to large cord length

Coatings on flat substrates were used to calibrate x-ray transmission signal

• Coatings through single and double slots on flats were measured by interferometry

• Coatings were duplicated on thin CH film (~ zero substrate signal)

• X-ray signals were recorded using various tube voltage and exposure times

• The settings that led to highest x-ray vs. interferometry linearity were used for measuring shells

• It also allowed thickness determination on shells

1.5

1.0

0.5

0.0

Thickness, µm

420-2

Distance from center, mm

Single mask coating

8 bit digitized line out

Interfer

X-ray

2.0

1.5

1.0

0.5

0.0

Thickness by x-ray, µm

2.01.51.00.50.0

Thickness by Interferomretry , µm

X-ray signal was linear in most of the range of interest

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

Cord length, µm

-2 -1 0 1 2

Distance from center, mm

• X-ray signal measures projection of shells thickness on ZX plane

• Cord length for desired profile is ~ 0.5-1.2 µm

• X-ray signal is linear vs. thickness for this range

• Proper exposure and source voltage settings are required!

• Region of linearity could be changed by changing settings

ZX profile cord length of desired profile

Shells were precisely positioned under the masks

• Shells were mounted on ~ 200 µm tungsten stalks

• Stalk was attached to motor shaft with wobble of < ~ 50 µm

• Interferometer was used to determine position of top of shell to < 1 µm

• Measuring microscope was used for lateral position determination (~1 µm)

• XYZ micrometer stage was used to move mask over shells to within ~ 2 µm

Tungsten stalk

Shell mountingfor coating

1.0

0.8

0.6

0.4

0.2

0.0

Thickness, µm

-2 -1 0 1 2

Distance from center, mm

X-ray signal from shells coated through single mask was used to determine coating thickness

• Single slot pattern on shell was very similar to that on flats• X-ray exposure settings were changed for these thinner coatings

Uncoated shell

Au coated shellflat

shell

ZX thickness projection

X-ray signals from double slot mask indicated lower rate near equator

• Coatings using double slot mask were thicker near equator and thinner at the poles than expected from flat data

• Shell curvature and larger distance between poles and mask are responsible

• Data analyzed after shells were delivered for shots

• We will make adjustments for next series

Au coated shell

0.5

0.4

0.3

0.2

0.1

0.0

Thickness, µm

-2 -1 0 1 2

Distance from center, mm

flat

shell

ZX thickness projection

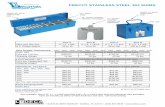

A profile similar to the desired profile was produced on target shells

• Final profile was not exactly as desired on shells delivered for shots

• Coating near equator was thicker than desired- would it reverse P2 asymmetry?

• Coating near poles was thinner

• Adjustment of the double slot mask is needed

• Shells were assembled and shot at SNL

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

Thickness, µm

150100500

Polar angle, deg

P2 symmetry was reversed in shot on SNL Z-pinch as expected

desired

actual

We hope to simulate process using Monte Carlo simulation to obtain better predictive capability

• Direct Monte Carlo simulation program DS2V of G. Bird

• Initially determine gold atom distribution near masks

• Use that distribution to simulate coating under masks as function of distance on flat and spherical substrates

We have produced angle dependent gold shim targets

• This innovative target can compensate for driver asymmetry

• Targets were produced using ICF target fabrication infrastructure at General Atomics

• Gold coating thickness could be patterned by coating shells through:

• Various masks • Adjusting mask-substrate distance

• The desired pattern was nearly produced

• However, adjustments are needed to faithfully produce desired profile

• Other characterization techniques also need to be examined in the future