Fabrication of an overdenture - Toledo,...

Transcript of Fabrication of an overdenture - Toledo,...

Fabrication of an overdentureusing retentive anchorsP R O S T H E T I C S

Disclaimer of liabilityThe Straumann® dental implant is part of an overall concept and mayonly be used in conjunction with the associated original componentsand instruments according to Institut Straumann AG’s instructions andrecommendations.

Use of products made by third parties in conjunction with theStraumann® Dental Implant System will void any warranty or otherobligation, expressed or implied, of Straumann.

Instruction as to application of our products takes place verbally, inwriting, by electronic media, or in hands-on training corresponding tostate of the art at the time of introduction of the product. The user ofStraumann products has the duty to determine whether or not anyproduct is suitable for a particular patient and circumstance.Straumann disclaims any liability, expressed or implied, and shall haveno responsibility for any direct, indirect, punitive or other damages,arising out of or in connection with any errors in professional judgmentor practice in the use or installation of Straumann products.

The user is also obliged to study the latest developments of theStraumann® Dental Implant System and its applications regularly.

Please noteThe descriptions given are insufficient to allow immediate use of theStraumann® Dental Implant System. Guidance in the handling of theseinstruments by a doctor experienced in their use is stronglyrecommended.

ValidityUpon publication of this brochure, all previous versions aresuperseded.

AvailabilityNot all products listed in this brochure are available in all countries.

CautionOur products must be secured against aspiration when used intraorally(e.g. use of a throat pack is recommended).

DeliveryFederal law restricts these devices to sale by or on the order of adentist or physician.

Units per packageUnless stated otherwise, there is one unit in each package.

DocumentationYou can obtain detailed instructions on the Straumann® Dental ImplantSystem from your Straumann representative.

DefinitionSLA® = Sand-blasted, Large grit, Acid-etched

Copyright and trademarksStraumann documents may not be reprinted or published, in whole or part,without the written authorization of Institut Straumann AG. Straumann®

Dental Implant System, SLA®, and synOcta® are registered trademarksof Institut Straumann AG, Switzerland.

Description of the symbols on labels and instructions for use

Lot/batch number

Article number

Sterile by gamma irradiation

Non-sterile

Do not use on patients

Do not reuse

Protect from exposure to strong light or heat

Refer to instructions for use

Use before expiration date

Colored warning labelsYELLOW ➡ CAUTION: In case of danger or unsafe

handling that might cause slight bodily injury or damage to property.

ORANGE ➡ WARNING: In case of danger that mightcause severe bodily injury or death.

RED ➡ DANGER: In case of danger that may cause immediate severe bodily injury or death.

LOT

REF

RSTER I L E

IMPORTANT NOTES

STER I L E

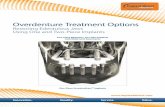

Planning principles and recall appointments 2

Introduction 3

Fabrication of a new full lower denture with metal reinforcement 4and two Elliptical Matrices

Fabrication of a new full lower denture with metal reinforcement 9and two titanium matrices

Modification of an existing full lower denture in an 15implant-borne retentive anchor denture with Elliptical Matrices

Relining of an implant-borne retentive anchor denture 17

Instructions for dentists and dental technicians

Table of contents

Straumann is the exclusive industrial

partner of the ITI (International Team for

Implantology) in the areas of research,

development, and education.

1

2

Planning principlesImplant-borne full dentures requirethorough planning of the surgical andtechnical procedures. The number andpositions of the implants as well as thedesign of the denture and occlusionshould take the anatomical, functional,and hygienic aspects into account. The static/dynamic conditions governthe selection of the retentive units(Besimo, 1993).

Recall appointmentsHybrid dentures with resilient retentionunits must be examined at intervals of approximately 3 months to ensureharmful excursions of the denture areeliminated in their early stages (possiblemethods: relining, activating/replacingthe matrix, checking the occlusion).In cases of poor oral hygiene, the patientshould undergo thorough scaling andpolishing, as well as re-instruction andmotivation to maintain the necessary highlevel of oral hygiene. If the patient is co-operative, the interval between check-ups can be increased.

Planning

Retentive anchors are not foruse in the following applications:

– Combined tooth-/implant-bornerestorations

– Use of more than two implants per jaw

– In conjunction with attachmentsexhibiting a different degree of resilience

– If the implants are not vertical to theocclusal plane

– In cases where the implants have beenpositioned in the arch in such a way asto prevent a tangential axis of rotation

– In unfavorable ridge situations

Description/FunctionThe retentive anchor abutment works inconjunction with the movable attachments.Retentive units that permit rotary movementof the denture in one or more directionsand/or vertical translational movementsare termed mobile units.

The mobile connector shortens the leverarm of the tilting forces exerted on theimplant. The implants must always beplaced at an angle of 90° to the occlusalplane to ensure that they are loadedaxially. Precisely designed occlusalsurfaces – balanced occlusion withfreedom-in-centric (Geering et al., 1993)– and optimum design of the denturefitting surface also influence the stability ofthe denture and the distribution of themasticatory forces (Worthington et al.,1992). We recommend that a newdenture always be fabricated as part ofthe treatment plan or after the provision ofimplants (Mericske-Stern, 1988).

Indications for retentiveanchors– Use with Standard implants Ø 4.1 mm,

RN (Regular Neck)

– Resilient anchorage in the edentulousmaxilla and mandible in conjunctionwith two implants to ensure the degreesof freedom

– Insufficient space available (in suchcases, bars often cause the anteriorsection to be extended too far linguallythus restricting the space available forthe tongue and impeding its function)

– In cases of severely tapering anteriorarches and/or jaws (Geering et al.,1993)

IntroductionPurposes of anchors:

– Securing the prosthesis againstexcursive forces and those which woulddislodge the saddles

– Distribution of shear forces

– To transfer the masticatory forces asaxially as possible from the denture tothe implant

3

Retentive anchor

Taking an impression of the retentive anchor

The impression is taken with an elastomericimpression material (polyvinylsiloxane orpolyether rubber) directly over the anchor,without any impression components.

Important: In view of its low resistanceto tearing, a hydrocolloid is not suitablefor this application.

From left to right: Driver (046.069) with “R.A.” marking(“Retentive Anchor”), retentive anchor abutment(048.439), and transfer pin (048.109-1).

“Patient” initial situationEdentulous lower jaw with two Standardimplants Ø 4.1 mm, RN (Regular Neck)replacing the canines with retentiveanchor abutments (048.439).

Important: To ensure that the retentiveanchors function properly over a longperiod of time, the implants must beplaced as parallel as possible to oneanother and vertical to the occlusal planeto create a tangential axis of rotation.

The retentive anchor has a square neck toaccommodate the driver. It is inserted intothe implant with a force of 35 Ncm.Measured from the upper edge of theimplant shoulder, the retentive anchor is3.4 mm high.

4

3.4 mm

RN = Regular Neck (implants that havea 4.8 mm restorative platform)

Fabrication of a new full lower denture with a metal reinforcement and two Elliptical Matrices

To ensure stability, the production andintegration of a metal reinforcement inthe full lower denture is recommended.Sufficient space must be left for securingthe matrices.

The teeth should be set up using theocclusal concept for full dentures.

Producing the modelTransfer pins are positioned in theimpression and the cast is produced inspecial, type 4 (DIN 13911) hardplaster. The impression of the retentiveanchor provides the square/sphericalstud of the transfer pin with sufficientretention in the impression.

5

Elliptical Matrix

The principle of function of theElliptical Matrix:The Elliptical Matrix is used for the fixationof removable resilient full dentures onStraumann implants in conjunction withthe retentive anchor. It consists of atitanium housing (pure titanium grade 4)with a gold lamella retention insert(Elitor®; Au 68.6%, Ag 11.8%, Cu10.6%, Pd 4.0%, Pt 2.5%, Zn 2.5%, Ir <1%). The insert is screwed into thetitanium housing.

Retentive anchor

Titanium housing

Lamella retention insert

When there is insufficient space, thewings of the titanium housing can bemodified individually. However, a minimumdiameter of 3.6 mm must be maintainedin order to ensure the retention of thehousing in the resin.

6

Adjusting the retentive forceThe screwdriver (046.154) is required foractivating, deactivating, and removingthe lamella retention insert. The instrumentis pushed with the correct alignment intothe lamella retention insert as far as it willgo. The retentive force is adjusted byrotation (increased by turning clockwiseand reduced in the opposite direction).The initial retention force is approximately200 g, which is also the minimum thatcan be set. The maximum retention forceis approximately 1400 g. The lamellaretention insert must not project out of thehousing. If retention is lost, the insert canbe replaced without having to remove thetitanium housing from the denture.

** Slight deviations from these average values are possible due to the unavoidablemanufacturing tolerances of the lamella retention insert and retentive anchor. If signs of wear are evident on the retentive anchor, the retention force may no longer apply, and the retentive anchor must be replaced.

Caution:Always begin with the presetretention force of 200 g. (matrix assupplied) and adjust it accordinglybased on the patient’s comfort leveland clinical requirements.

The connection between tightening angle and retention force:

90˚ = 700 g. 270˚ = 300 g.

(1.54 lb) (0.66 lb)

0˚ = 1,400 g. (3.08 lb) 360˚ = 200 g. (0.44 lb)

(tightened as far as it will go) (delivery condition)

180˚ = 500 g. (1.10 lb)

Clockwise rotation =

increase retention force

Counterclockwise rotation =

decrease retention force

7

Screwdriver (046.154)

Unscrewed lamella retention insert

Finished denture

Before curing the matrix into the denture,the lamella should be tightened justenough so that it remains stable on theretentive anchor during processing.

Important:When trying the denture in the patient,always start with the lowest retentionforce. The retention force is adjusted byrotating the lamella retention insert andmust be done in small increments until thedesired retention force is obtained.Otherwise, excessive retention forces maycause difficulties when removing thedenture from the mouth.

8

The titanium matrix (048.450) consists ofa titanium alloy (Ti-6Al-4V), hardness HV5Vickers 350–385. The titanium matrix isavailable preassembled and consists ofthe following individual components:housing, spring ring, threaded top (fromleft to right).

“Patient” initial situationEdentulous lower jaw with two Standardimplants Ø 4.1 mm, RN (Regular Neck)replacing the canines with retentiveanchor abutments (048.439).

Model starting situation (procedureidentical as previously described for“Fabrication of a full lower denture withmetal reinforcement and two EllipticalMatrices”).

9

Fabrication of a new full lower denture with metal reinforcementand two titanium matrices

Unlike the Elliptical Matrix, the titaniummatrix makes use of a spring ring with adefined extraction force of700–1,100 g. If retention is lost, thespring ring can be replaced.

To replace the spring ring, the threadedtop on the titanium matrix is unscrewedcounter-clockwise using the correspondingscrewdriver (048.452), and the springring is changed.

The threaded top is then screwed back inplace hand-tight.

10

Method ABefore positioning the matrices on thetransfer pins in the model, the originalhousing is unscrewed and replaced witha plastic threaded mounting ring(048.454V4). The undercuts are blockedout with wax. The plastic ring is 3/100mm wider in diameter than the titaniummatrix housing and acts as a spacer forit. This prevents too tight a fit of thetitanium threaded ring on the polymerisedacrylic. After polymerisation, the threadedmounting ring is replaced by the titaniumhousing once more.

The titanium matrices canbe polymerised into place asfollows:

11

Threadedmounting ring

Block-out wax

Housing Threaded top Threadedmounting ring

Method BThe denture is polymerised with specialacrylic spacers only (048.451V4). First,the undercuts are blocked out with wax.Once the denture is ready, the spacersare removed and the dentist canpolymerise the titanium matrices into placedirectly in the patient’s mouth. The spacersare also used to produce the model forthe metal reinforcement.

12

Spacer

Block-out wax

Method CBefore being positioned on the edge ofthe threaded ring, the titanium matrix mustbe coated with a thin film of die spacer.This ensures that the housing can bereleased later without excessive forcebeing exerted.

Important: With all three methods, thetitanium matrices (or spacers) must alsoalways be positioned on the transfer pinswith their axes aligned (parallel to thepath of insertion) and the undercutsblocked out.

The finished denture with titaniummatrices integrated in the metalframework.

Important: Once the denture iscomplete, it must be checked to ensureno acrylic has penetrated the matrix. Todo this, the housing should be removedand the inner configuration with thespring should be cleaned.

13

Removal of titanium matrixfrom an existing dentureTo replace an entire titanium matrix, thehousing and spring ring must first beremoved. The tip of a special extractor(048.453) is then heated over a Bunsenburner and screwed into the threadedtop. The top can then be withdrawn fromthe acrylic denture.

14

The retentive anchor abutments are insertedinto the implants with a force of 35 Ncm.The existing denture is then hollowed out inthe region of the anchors. The openingcreated allows the acrylic to flow in andaround the matrices. The Elliptical Matricespositioned on the retentive anchors must nottouch the denture after hollowing.

Polymerisation of the EllipticalMatrix in the patient’s mouthafter implantation andosseointegration:

The existing full lower denture prior tomodification.

15

Modification of an existing full lower denture in an implant-borneretentive anchor denture with Elliptical Matrices

After positioning the Elliptical Matrices onthe retentive anchors, a small piece ofrubber dam is placed over the matrices toblock out the undercut created betweenthe lower edge of the matrix and theabutment. This prevents the acrylic fromflowing into the internal matrixconfiguration, which could lead to“locking” the denture in the patient’smouth.

Important: The matrices must bealigned (parallel to the path ofinsertion).The prepared denture is then fixed in themouth and the acrylic is flowed throughthe perforation.

The modified denture with the polymerisedElliptical Matrices.

16

After relining, the matrices should bechecked for acrylic that may have flowedinto them and for their functionality. It mustalso be possible to activate/deactivate theElliptical Matrices. After polymerisation,the Elliptical and titanium matrices areopened with the relevant screwdriver andthe internal configuration is cleaned.

Important: These measures are vital toensure the optimum function of therelined, implant-borne retentive anchordenture. If the function of the matrix isimpeded, this can damage theimplant/anchor.

Hybrid dentures with retentive anchorsshould be checked at approximatelythree-month intervals to eliminatedamaging denture movements byappropriate measures at an early stage.If the alveolar ridge resorbs after aprolonged wearing time, the denture maysink. This leads to a loss of resilience ofthe matrices and so to greater stress onthe retentive anchor/implants. Reliningthen becomes necessary.

Relining is carried out directly over theretentive anchors. Care should be takento ensure that the denture is sittingcorrectly (retentive anchor/matrixconnection). The dental technician thenpositions the transfer pins (048.109-1) inthe Matrices (titanium or Elliptical matrix)in the denture and produces the reliningmodel (see page 5, Producing themodel).

Relining of an implant-borne retentive anchor denture

17

Abutments and laboratory parts Instruments Abutments and laboratory parts Instruments

Retentive anchor048.439

Ratchet046.119

Torque control device046.049

Driver for retentive anchor046.069

Retentive anchor048.439

Ratchet046.119

Torque control device046.049

Driver for retentive anchor046.069

Transfer pin048.109-1

Transfer pin048.109-1

Elliptical matrix048.456

Screwdriver046.154

Titanium matrix048.450

Spacer048.451V4

Threaded mountingring048.454V4

Screwdriver 048.452

Screwdriver046.154

Replacement spring rings048.455V4

Screwdriver 048.452

Extractor048.453

Inse

rtio

n of

abu

tmen

tsIm

pres

sion

tran

sfer

Fabr

icat

ion

of d

entu

reIn

sert

ion

of f

inal

rest

orat

ion

18

Retentive anchor with Elliptical Matrix Retentive anchor with titanium matrix

Recommended choice of implant Standard implant Ø 4.1 mm or 4.8 mm, RN (Regular Neck)

V4 = 4 components per pack

Edentulous: retentive anchor

Case presentation:Courtesy of G. S. Solnit, DDS, MSBeverly Hills, CA

19

1

2

3

4

20

Art. No Article Dimension Material

048.439 Retentive anchor abutment Height 3.4 mm Titanium

046.069 Retentive anchor driver Length 19.0 mm Stainless steel

048.109-1 Transfer pin forretentive anchor

Length 18.0 mm Stainless steel

Elliptical Matrix with adjustable retention

048.456 Elliptical Matrix Height 3.2 mmØ 3.6 mm

Elitor®/titanium

048.457 Spare lamella retention insert Height 2.6 mm Elitor®

046.154 Screwdriver Length 37.0 mm Stainless steel

Titanium matrix with defined retention

048.450 Titanium matrix forretentive anchor

Height 3.1 mm Titanium alloy

048.451V4 Spacer fortitanium matrix

Height 3.5 mm Plastic

048.452 Screwdriver fortitanium matrix

Length 60.0 mm Stainless steel/anodized aluminum

048.453 Extractor fortitanium matrix

Length 100.0 mm Stainless steel

048.454V4 Threaded mounting ringfor titanium matrix

Height 2.2 mm Plastic

048.455V4 Spacer for 048.450 Stainless steel

Product Overview

Retentive anchors

Mericske-Stern R.Clinical evaluation of overdenturerestorations supported byosseointegrated titanium implants: aretrospective study.Int J Oral Maxillofac Implants1990;5:375– 83.

Mericske-Stern R.Forces on implants supporting overdentures: a preliminary study ofmorphologic and cephalometricconsiderations.Int J Oral Maxillofac Implants1993;8:254–63.

Mericske-Stern R, Steinlin-Schaf-fer T, Marti P, Geering AH.Periimplant mucosal aspects of ITIimplants supporting overdentures. A 5 year longitudinal study.Clin Oral Implants Res 1994;5: 9–18

Worthington P, Brånemark PI.Advanced osseointegration surgery: applications in themaxillofacial region. Chicago: Quintessence; 1992.

21

References

Straumann products are CE marked

LIT 065 7/04 Printed in USA

International Headquarters

Institut Straumann AGCH-4437 WaldenburgSwitzerlandPhone 011 41 61 965 11 11Fax 011 41 61 965 11 01www.straumann.com

National Distributor

Straumann USA, Inc.Reservoir Place1601 Trapelo RoadWaltham, MA 02451Phone 800/448 8168

781/890 0001Fax 781/890 6464www.straumannusa.com