FABRICATING POLYMER NANOSTRUCTURES WITH CONTROLLED ... · 1 FABRICATING POLYMER NANOSTRUCTURES WITH...

Transcript of FABRICATING POLYMER NANOSTRUCTURES WITH CONTROLLED ... · 1 FABRICATING POLYMER NANOSTRUCTURES WITH...

1

FABRICATING POLYMER NANOSTRUCTURES

WITH CONTROLLED MORPHOLOGY:

DIFFERENT TOP-DOWN APPROACHES

Ignacio Martín-Fabiani

Instituto de Estructura de la Materia, IEM-CSIC, Madrid, Spain

Motivation

POLYMERS

• High molecular weight (more than 1000 atoms and

up to millions)

• Carbon-based

• Unique internal structure: amorphous and crystalline

phases coexist

FlexibilityLow cost

Durability Light weight

Functionality

2

Natural

Synthetic

~ 10-5 - 10-6 m

Spherulites

~ 10-8 m

Crystalline lamellae

~ 10-9 m

Unit cell

• Glass transition temperature (Tg)

Motivation

POLYMERS

NANOSTRUCTURATION

• Laser Induced Periodic Surface Structures (LIPSS)

• Nanoimprint Lithography (NIL)

• Imprinting of Optical Near Fields (ONFs)

• Melt Wetting of Nanoporous Templates

APPLICATIONS

Flexibility

Low cost DurabilityLight weight

Functionality

Photovoltaics

Electronics

Photonics

• Feasibility of nanostructuration methods in polymers

• Appropiate characterization techniques

• Optimization of the process/nanostructures

• Understanding of the physics that lie underneath

Plasmonics

LET´S GO!

Preparation and characterization of polymer thin films

𝜔a 𝜔a

PTT

PC

PET

Spin coating of a PTT/TFA solution (20 g/l)

on a Si substrate

10 x 10 μm2 5 x 5 μm2

Atomic Force Microscopy (tapping mode) Absorbance

Good absorbance only in the near UV range

190 nm < λ < 400 nmRugosity 1,1 ± 0,5 nm

Film thickness 147 ± 25 nm

Preparation and characterization of polymer thin films

Tg = 44ºC ; Tm = 232 ºC

Laser Induced Periodic Surface Structures (LIPSS)

5

Laser light 𝜃

Original surface

LIPSS

𝑛

𝐿

𝐻

• Interference between incident and reflected

light generates ripples with period L~λ

• It involves a feedback effect and thus pulse

repetition

• Rugosity plays a relevant role

• Can we assess the structural order of LIPSS on polymer films?

• Is it possible to optimize LIPSS formation with laser parameters?

Bolle, M.; Lazare, S., Appl. Surf. Sci. 1993, 69 (1-4), 31-37 Csete, M.; Bor, Z., Appl. Surf. Sci. 1998, 133 (1-2), 5-16

𝐿 =𝜆

𝑛 − 𝑠𝑒𝑛𝜃

Nd:YAG laser (λ = 266 nm)

Linearly polarized

τ = 6ns ; f = 10 Hz

Nnormal incidence (θ = 0⁰)

𝐿 =𝜆

𝑛 − 𝑠𝑒𝑛𝜃=

𝜆

𝑛

Fluence dependence

(Energy of a single pulse over a

determined area integrated over time,

mJ/cm2)

Number of pulses dependence

Laser Induced Periodic Surface Structures (LIPSS)

Irradiation of polymer thin films

Open questions

Characterization

AFM in tapping mode

100 300 1200 6000

4 mJ/cm2 9 mJ/cm213 mJ/cm25 mJ/cm2

Dependence with number of pulses for a fixed fluence F = 7 mJ/cm2

Dependence with fluence for a fixed number of pulses (600)

Martin-Fabiani, I.; Rebollar, E.; Perez, S.; Rueda, D. R.; Garcia-Gutierrez, M. C.; Szymczyk, A.; Roslaniec, Z.; Castillejo, M.; Ezquerra, T. A., Langmuir 2012, 28 (20), 7938-7945.

• Period close to the wavelength

• Height increases with number of pulses

• There is a strong dependence of morphology with laser parameters

Is it possible to optimize

LIPSS formation with laser

parameters?

Laser Induced Periodic Surface Structures (LIPSS)

7

Grazing Incidence Small Angle X-ray Scattering (GISAXS)

Correlations parallel to the

sample plane

𝑞𝑧 =2𝜋

𝜆𝑠𝑒𝑛𝛼𝑖 + 𝑠𝑒𝑛𝛼

𝑞𝑦 =2𝜋

𝜆𝑠𝑒𝑛𝜔𝑐𝑜𝑠𝛼

Correlations perpendicular to

the sample plane

• Allows characterizing submicrometric

films

• Reflection geometry is extremely

sensitive to surface features

• By changing the incidence angles

different depths within the sample can

be probed

• Powerful tool to characterize

nanostructures

DESY, Hamburg (Germany)

BW4 beamline (Doris ring)

λ = 0.14 nm

MARR CCD pixel size 79.1 x 79,1 µm2

αi ≈ 0.4⁰

Muller-Buschbaum, P., Analytical and Bioanalytical Chemistry 2003, 376 (1), 3-10

Detector

Sample

αi

αi

ω

αf

Incident beam

hh’ α=0

qy

qz

m

m’ ω=0

Grazing Incidence Small Angle X-Ray Scattering

8

LL+ΔL1 L

L-ΔL2

• The probability of finding the next

box at a distance L is determined

by a Gaussian function

𝑝 𝑥 =1

𝜎 2𝜋𝑒𝑥𝑝 −

(𝑥 − 𝐿)2

2𝜎2

Hosemann, R., Zeitschrift Fur Physik 1950, 128, 465-492 Lazzari, R., Journal of Applied Crystallography 2002, 35, 406-421

Paracrystalline lattice

IsGISAXS software – Freeware

http://ln-www.insp.upmc.fr/axe4/Oxydes/IsGISAXS/isgisaxs.htm

• Central geometrical parameters

determined by AFM, assuming

a variation

𝜎𝑅

𝑅~

𝜎𝐻

𝐻~0.1

𝑔 = 𝜎/𝐿

• Paracrystalline distortion parameter

𝑔 = 0 Crystalline lattice

𝑔 → ∞ Disordered system

Local monodisperse aproximation (LMA) (monodisperse domains that interfere incoherently

between them)

𝑑Σ

𝑑Ω 𝑞 =< 𝐹 2> 𝑆 𝑞 α 𝐼𝑠𝑐𝑎𝑡𝑡𝑒𝑟𝑒𝑑

Distorted Wave Born Approximation (DWBA)(4 contributions to the form factor)

GISAXS modeling of nanostructures

Dependence with number of pulses for a fixed fluence F = 7 mJ/cm2

AFM

100

Modelling

300

6000

300

6000

100

GISAXS

100

300

6000

Cut at α = 0.2 ⁰

Laser Induced Periodic Surface Structures (LIPSS)

10

Optimum

LIPSS formation

𝑔 = 𝜎/𝐿

Paracrystalline distortion

parameter

𝑔 = 0 Crystalline lattice

𝑔 → ∞ Disordered system

• LIPSS generated by ns laser pulses can be described as paracrystalline 1D lattices

• Optimum value of the number of pulses for a fixed frequency!

• GISAXS and AFM information are in agreement and complement each other

Laser Induced Periodic Surface Structures (LIPSS)

9 mJ/cm2

13 mJ/cm2

9 mJ/cm2

13 mJ/cm2

AFM

5 mJ/cm2

GISAXS

5 mJ/cm2

Modelling

5 mJ/cm2

9 mJ/cm2

13 mJ/cm2

Dependence with fluence for a fixed number of pulses (600)

Cut at α = 0.2 ⁰

Laser Induced Periodic Surface Structures (LIPSS)

12

• Structural order of LIPSS improves with increasing fluency!

• GISAXS and AFM information are in agreement and complement each other

Laser Induced Periodic Surface Structures (LIPSS)

13

Laser Induced Periodic Surface Structures (LIPSS)

Formation mechanism𝜕2𝑇(𝑥, 𝑡)

𝜕𝑥2− 𝑎2

𝜕𝑇 𝑥, 𝑡

𝜕𝑥=

𝛼

𝜅𝑃 𝑡 exp −αx 𝐹0

Rebollar, E.; Perez, S.; Hernandez, J. J.; Martin-Fabiani, I. et al. Langmuir 2011, 27, 5596-5606.

Solving numerically the heat equation in one dimension:

The Raman spectra of irradiation samples remain

unaffected except for a slight oxidation in the case

of high number of pulses

• The maximum temperatures reached on the

surface of the polymer film are around 87 -

203 ⁰C.

• These temperatures are well above Tg and

below Tm, suggesting that a reorganization

of material takes place in the formation of

LIPSS (no ablation).

14

Laser Induced Periodic Surface Structures (LIPSS)

Au-coated polymer LIPSS as Surface-Enhanced

Raman Scattering (SERS) substrates

Rebollar, E. et al. Phys. Chem. Chem. Phys. 2012, 14, 15699-15705.

Thinner Au coatings yield higher

enhancements

Linear relationship between analyte

concentration and Raman intensity

PTT LIPSS Au-coated LIPSS

Pulsed Laser Deposition

Nd:YAG laser

λ = 213 nm; τ = 15 ns

Ν = 10 Hz

The presence of metallic nanoparticles can

enhance dramatically the Raman intensity

A SERS enhancement of an

order of magnitude is obtained

• These hybrid substrates require a small

amount of gold

• They benefit from the light weight,

flexibility and durability of polymeric

materials

• The linear relationship of the Raman

intensity with analyte concentration is

advantageous for potential application

in sensors

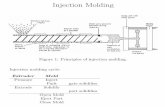

Nanoimprint Lithography (NIL)

15

PressNanoimprint Lithography (NIL)

• Lithographic process which involves the

transfer of nanometric motifs from a hard

mold to a soft substrate

• Requires the use of white rooms

• The transfer is optimized when motifs in

the mold are protruding from the

substrate.

Wet etchingOptic Lithography

16

Fabricación del molde I: mesa

Si wafer

UV light

Resist

Mask

HNO3

HF

H2O

Nanoimprint Lithography (NIL)

Fabrication of a mesa-type structure

17

Fabricación del molde I: mesa

Wafer

Resist

Nanoimprint Lithography (NIL)

Fabrication of a mesa-type structure

AFM

Height ≈ 650 nm

(2) e-beam lithography

(4) Removal of

redundant resist

and metal

(3) Development

+ Metalization

PMMA

Si

(1) spin- coating

e-e-

SF6C4F8 O2

(5) Reactive Ion Etching (6) Mold

300 nm

300 nm

Nanoimprint Lithography (NIL)

Fabrication of motifs on the mesa structure

Nanoimprint Lithography (NIL)

Silanization process: Avoids sticking of the polymer

to the Si mold

TFOCS

60nm

200 x 200 µm2

Mesa

Si mold

• GISAXS arc-like pattern

• Radius depends on αi

• Spacing 300 nm

LET´S IMPRINT!

300 nm

SEM AFM

60 nm100 nm

Qin, D.; Xia, Y. N.; Whitesides, G. M. Nat. Protoc. 2010, 5, 491-502.

20

Nanoimprint Lithography (NIL)

Polymer replicaSi mold

52 nm300 nm

60 nm

150 ºC 40 bar

5 minC

• Scattered intensity in the vertical direction

300 nm

60 nm100 nm

150 ºC 40 bar

5 minC

• AFM images shows regions where the effective

length of the motifs is reduced

Nanoimprint Lithography (NIL)

(⁰)

(⁰)

(⁰)

(⁰) (⁰)

(⁰)

(⁰)

(⁰)

ModelingGISAXSAFM

200 μm

150 μm

1 μm(⁰)

(⁰)(⁰)

(⁰)

LIPSS

Polymer replica

Si mold

Effective length of

the motifs decreases

22

Nanoimprint Lithography (NIL)

W/R = 1000

W/R = 100

W/R = 10

(⁰)

(⁰)

(⁰)

(⁰)

(⁰) (⁰)

(⁰)

(⁰)(⁰)

(⁰)

(⁰)

(⁰)

(⁰)

(⁰)

(⁰)

Rueda, D. R.; Martin-Fabiani, I.; Soccio, M. et al. J. Appl. Crystallogr. 2012, 45, 1038-1045.

Form FactorGISAXS Interference function

The transition from an arc-like pattern, characteristic of polymer

grating replicas fabricated by NIL, to a fringe pattern,

characteristic of LIPSS, is determined by a reduction of the

effective length of the motifs

Cut at ω = 0 ⁰

Imprinting the Optical Field dispersed by a dielectric microsphere

Nanostructuring with Optical Near Fields (ONFs)

pfw

b

sin1fwpa

pbw

sin1bwpr

θ

Shadow region

Far field approximation

• CD and DVD optical systems

(phase change memories)

• Microscopy (SNOM)

• Sensors

• Materials processing

Vicinity of the sphere

Period in the

backward direction Period in the

forward direction

Optical Near Fields

allow to overcome the

diffraction limit

(≈ λ/2)

Kuehler, P. et al. Small 2009, 5, 1825-1829.

Carried out in several inorganic materials:

silicon, amorphous silica, aluminium oxide,

Ge2Sb2Te5…

Never in

polymers!

It is possible to visualize

or imprint structures with

resolution of λ/2 or

smaller

Applications

Laser light

θLaser light

Ablation hole The sphere can be considered a point scatterer

100 µm

Nanostructuring with Optical Near Fields (ONFs)

1. Sample preparation: spin-coating of SiO2 microspheres (ϕ = 4.6 µm) on PTT

polymeric thin films

2. Irradiation: single pulse from an excimer laser ArF at normal incidence (θ = 0⁰) or

θ = 54⁰. Fluences around 300-350 mJ/cm

3. Characterization of the irradiated zone

θ = 0⁰, F=300mJ/cm2

OM AFM

Dendritic morphology!

GIWAXS Raman Spectroscopy

Crystallinity hints?

Increased fluorescence

Might be related to parallel

arrangement of phenyl

rings in PTT

Some incipient

shoulders

corresponding to

Bragg peaks

appear

Luo, W.-a. et al. Macromolecules 2008, 41, 7513-7518.

150x150 µm2 10x10 µm2

θ = 54⁰, F = 350 mJ/cm2

100 µm

107 nm

Asymptotical

value in the

far field

sin1bwp

Nanostructuring with Optical Near Fields (ONFs)

• Near-field induced topography modulation

extends over the entire film thickness.

• Regions of local fluence enhancement

correspond to topographic regions below the

initial film surface

• Values of the period tend to reach the

asymptotical value predicted in the far field

25 x 25 μm2

L1L2

25 x 25 μm2

Zoom in the

backscattering

region

Nanostructuring with Optical Near Fields (ONFs)

10 nm

0 nm

10 nm

0 nm

Formation mechanism: patterning of GST single pulse from an excimer laser ArF

Fluences around 75 mJ/cm2

Topographic contrast originates from the

different density of both phases, the amorphous

one being lower yielding to an elevation of the

amorphous regions over the crystalline film (no

ablation)

θ = 54⁰, F = 75 mJ/cm2

Raman spectroscopy

Siegel, J. et al. Appl. Phys. 2008, 023516.1-7

Under these irradiation conditions PTT

presents chemical stability

Melt wetting of nanoporous AAO membranes

27

Zhang, M. F.; Dobriyal, P.; Chen, J. T.;

Russell, T. P.; Olmo, J.; Merry, A. Nano Lett.

2006, 6, 1075-1079.

Garcia-Gutierrez, M.-C.; Linares, A.; Hernandez,

J. J.; Rueda, D. R.; Ezquerra, T. A.; Poza, P.;

Davies, R. J. Nano Lett. 2010, 10, 1472-1476.0

1D confinement

Length scales imposed

by external geometry

Length scales imposed by

internalcooperativity

Competition

• Electrospinning

• Self-assembly

• Nanoporous templates

2D confinement

• Crystalline unit cell

• Chain folding

• Size of crystalline lamellae

• Pore diameter

• Pore depth

• Pore density

Versus

Bulk

Restricting dimensions

Under these conditions interesting effects may arise!

Shin, K.; Xiang, H. Q.; Moon, S. I.; Kim, T.;

McCarthy, T. J.; Russell, T. P. Science 2004, 306, 76-76.

28

500 nm

Disordered

AAO membranes

500 nm

TOP – Pore size ~ 20 nm

BOTTOM – Pore size ~ 200 nm

0

N2

PTT

/nanocomposite

film

(200 µm thick)

AAO membrane

Melt wetting

1h at 253 ºC

Semicrystalline

nanorods

Cooling @ 3ºC/min

Solving AAO in NaOH

Are you sure they are crystalline?

Are they oriented?Let´s check it!

Poly (trimethylene terephthalate)

(PTT)

Tg = 44ºC ; Tm = 232 ºC

PTT/SWCNTs nanocomposite (0.5 % weight

concentration)

Prepared by in-situ polimerization

SWCNTs: diameter 0.6 – 1.4 nm

Melt wetting of nanoporous AAO membranes

X-Ray Microdiffraction setup

29

ESRF (Grenoble)ID13 Microfocus beamline

λ = 0,09951 nm

1 µm beam diameter

FReLoN detector

Transmission geometry

Scan

direction

Residualfilm

Infiltrated AAO

template

Interface

XBeam orthogonal to the

slide plane

Step scan (1 µm resolution)

We record a 2D diffraction pattern

each single micrometer containing

WAXS and SAXS information

WAXS

SAXS

• Crystallographic

planes

• Orientation

• Orientation of

crystalline

lamellae

• Long spacing

Bulk

002

010

01210201-2

Wide Angle X-Ray Scattering (WAXS)

30

Main nanopore axis

Bulk

002

01001-2012

102

Inside AAO

01001-2

012102

0kl reflections concentrated in the meridian

in both infiltrated PTT and nanocomposite!!

Triclinic unit cella=0.46nm ; b=0.61 nm ; c

=1.86 nm ; α=97.5º ; β=92.1º ;

γ =110º

Wang, B. J et al.

Polymer 2001, 42, 7171-

7180.

a

c

b

PTT

PTT/SWCNTsInside AAO

01001-2

012102

a-axis lies in the equator, b and

c can rotate

ac

b

a-axis is the radial

growth direction for

PTT spherulites!

Ho, R. M. et al.

Macromolecules

2000, 33, 7529-

7537.

Steinhart, M. et al.. Phys. Rev. Lett. 2006, 97.

Kinetic selection

Wide Angle X-Ray Scattering (WAXS)

31

Bulk Interface Inside AAOFull Width at Half

Maximum of the 102

reflection

102

Azimutal integration

Crystalline orientation

• Orientation improves with pore depth!

• Template has been filled completely

Increase of intensity related to:

• Augmented amount of

material

• Increase in orientation

AAO vs SWCNTs

32

Do the SWCNTs

enter the pores?

Yes, they do!

Ma, Y.; Hu, W. B.; Hobbs, J.; Reiter, G. Soft Matter 2008, 4, 540-543

Slippery walls

Sticky walls

Obtained

ac

b

Expected : Shish – Kebab?

SWCNT

Main polymer chain paralell to

the AAO wall (edge-on)

Main polymer chain orthogonal

to the AAO wall (flat-on)

Polymer melts – Low surface energy

AAO – High surface energy

The formation of flat-on lamellae is

favored by the strong polymer-AAO

interaction

This interaction, toguether with the

kinteic selection, prevails over the

templating features of the SWCNTs

Small Angle X-Ray Scattering (SAXS)

33

Main nanopore axis

PTT

PTT/

SWCNTs

Residual film Infiltrated AAO

Scan direction

Isotropic Edge-onEdge-on +

Flat-on No long spacing

No long spacing4-point

patterns

(shish-kebab)

Slight increase in flat-on

population

(SWCNTS alignment with

the pores)

70 µm away 25 µm away 5 µm away

Model for PTT

34

Edge-on/ flat-

on lamellae

WAXS

002

010

01-2

012 102

Bulk polymer Flow zone Interface

010

01-2 012 102

WAXS

ac

b

Confinement zone

IsotropicEdge-on

lamellae

SA

XS

Kinetic selection AAO-polymer interactionMartin-Fabiani, I. et al. ACS Applied Materials & Interfaces 2013, 5, 5324-5329.

Conclusions

35

Conclusions

• It has been proven that controlled nanostructuration of

polymeric materials can be achieved by using laser light

(LIPSS and imprinting of ONF), NIL and melt wetting of

nanoporous AAO membranes.

• It was demonstrated that nanosecond laser pulses can be used

in order to obtain LIPSS on polymer thin films. In addition, it

has been proven that the characterization of LIPPS in real

space by AFM can be complemented with the corresponding

characterization in the reciprocal space by GISAXS.

• It was shown that numerical modeling of the GISAXS

diagrams of LIPSS structures provides a description of them

in terms of one-dimensional paracrystalline lattice of

parallelepipeds. In addition to this, the study of the

dependence of the paracrystalline distortion parameter has

allowed determining the values of laser fluence and number

of pulses that optimize LIPSS formation.

• The potential of hybrid gold-polymer LIPSS as SERS

substrates has been proven.

Conclusions

36

Conclusions

• Hard silicon mold nanogratings have been imprinted on polymeric

thin films by NIL, fabricating successfully their replicas in the

polymer.

• Numerical modeling of the GISAXS diagrams has allowed

concluding that the transition from an arc-like pattern,

characteristic of polymer grating replicas fabricated by NIL, to a

fringe pattern, characteristic of LIPSS, is determined by a

reduction of the effective length of the motifs.

• The nanostructuration by imprinting of ONF has been applied

for the first time on a polymeric material. Structuration by ONF

takes place by polymer ablation and the nature of the laser used

determines the appearance of dendritic structures on the polymer

film surface.

• It has been proven that the one-dimensional confinement of

PTT in AAO nanopores induces the growth axis of the crystalline

lamellae to align with the main axis of the nanopores.

• The template effect of the SWCNTs in the crystallization process

of polymer nanocomposites is inhibited by the one-dimensional

confinement in AAO membranes.

Acknowledegements

37

Acknowledgements

Soft and Polymeric Matter group• T.A. Ezquerra

• A. Linares

Collaborators• E.Rebollar (IQFR-CSIC)

• J. Siegel (IO-CSIC)

• F. Pérez-Murano (

• J. Boneberg

38

Thanks for your attention!

Soft and Polymeric Matter grouphttp://www.iem.cfmac.csic.es/fmacro/softmatpol/