EXPERIMENTAL DESIGN PROJECT - The University of Akron : UA Home

Transcript of EXPERIMENTAL DESIGN PROJECT - The University of Akron : UA Home

EXPERIMENTAL DESIGN PROJECT

By Carlos A. Barrios and Neissa M. Pinzon

THE UNIVERSITY OF AKRON April 23, 2004

EXPERIMENTAL DESIGN PROJECT

1. Goals and Expectations Paper towels are one of the most important tools in America, not only for kitchen purposes but in all kind of cleaning tasks. Nowadays, there are several brands of paper towels claiming to be better in strength and absorbency, but sometimes it is not easy to believe that they are as good as they say in their advertisements. The purpose of our experiment is to test the resistance of three different brands of paper towels currently known as leading brands using different type of liquids, which are often use at home. We expect to find that there is a real difference among the brands and a difference in resistance depending on the liquid that is imposed to the towel. 2. Description of the experiment 2.1. Response Variable The response variable in this experiment is the time (in seconds) that takes one towel to break after adding one type of liquid when holding two weights (discs). 2.2. Factors In this study the chosen factors were brand of paper towel and type of liquid. These factors are fixed because their levels were deliberately and specifically selected. Factor A: Brand of paper towel. Three levels: Bounty, Brawny and Scott, since they are top brands in the market. Factor B: Type of Liquid. Three levels: Water, vegetable oil and orange juice were assigned because they are common spilled liquids in the kitchen. 2.3. Other factors Weights. For our experiment we used two weight discs, each one of 1¼ lb. This factor was maintained constant during the whole experiment. This means that we put two discs in each towel for each run.

Temperature. The temperature of the liquid might have a difference in the resistance of the towel, but this factor does not have a relevant meaning in this study. The temperature was maintained constant during the experiment. For this purpose we use a thermometer and we measured the temperature of the liquid before adding it into the towel. The temperature for all the liquids in all the runs was 20 C. Brand of liquid. We used just one brand of orange juice (Premium Orange Juice) and one brand of vegetable oil (Italica). There could be an effect on the resistance of the towel if we decide to test different brands of liquids, but this is not the purpose of this study. As a result we used the same type of juice and oil that made this factor constant during the experiment. Amount of liquid. The amount of liquid added to the towel might have an effect in the study, because if the amount of liquid used increased the resistance might decrease due to the weight of the liquid. This factor was held constant by measuring and using the same amount of liquid in each run. This amount was a half of cup (125 cm3). 2.4. Experimental Protocol Name of the design: 3 x 3 factorial in a CRD with three replicates. Experimental units: Square paper towels. They are mainly composed of cellulose (a natural polymer extracted from trees) and reinforced with some additives to improve resistance. Randomization scheme: One roll of each brand was bought. From each roll we took 9 towels and mixed them in a bag. Then we made three labels for each level of the other factor as W (water), O (oil) and J (orange juice). After that we randomly took one label from the liquids bag and assigned it to one paper towel from the towels bag. We repeated the same procedure with the other two brands. The schematic is presented in the next page. Experimental procedure: Well dry discs were placed on the towel; one person put her hand under the towel to hold the discs before the liquid was added. Then one of the team members held the paper towel from its edges, while the other group member started the chronometer and added the liquid (125 cm3). When the towel was ripped completely the timer was stopped and the response variable was registered. Then the discs were well cleaned and properly dried to repeat the experiment with the corresponding towel and liquid. (See appendix for pictures)

Randomization Scheme:

Paper Brand Liquid1 Bounty Water2 Bounty Oil3 Bounty Oil4 Bounty Water5 Bounty Juice6 Bounty Water7 Bounty Oil8 Bounty Juice9 Bounty Juice10 Browny Oil11 Browny Water12 Browny Juice13 Browny Juice14 Browny Oil15 Browny Water16 Browny Juice17 Browny Oil18 Browny Water19 Scott Oil20 Scott Juice21 Scott Water22 Scott Oil23 Scott Juice24 Scott Water25 Scott Oil26 Scott Juice27 Scott Water

3. Data analysis The following table shows the results for each run. The analysis was carried out using MINITAB software. The response variable is time (in seconds).

Tissue Brand Liquid Time (sec)1 Bounty Water 34 2 Bounty Water 39 3 Bounty Water 39 4 Bounty Orange Juice 156 5 Bounty Orange Juice 201 6 Bounty Orange Juice 170 7 Bounty Oil 927 8 Bounty Oil 1081 9 Bounty Oil 1053 10 Brawny Water 3 11 Brawny Water 2 12 Brawny Water 2 13 Brawny Orange Juice 2 14 Brawny Orange Juice 6 15 Brawny Orange Juice 4 16 Brawny Oil 391 17 Brawny Oil 430 18 Brawny Oil 388 19 Scott Water 1 20 Scott Water 2 21 Scott Water 1 22 Scott Orange Juice 2 23 Scott Orange Juice 2 24 Scott Orange Juice 1 25 Scott Oil 228 26 Scott Oil 235 27 Scott Oil 225

The data was inputted to MINITAB as a Factorial Design. The results are shown in the following pages.

Factorial Design Factors (2): Brand and liquid Levels (3,3): Bounty, Brawny and Scott; Water, orange juice and oil Response variable: Time before ripping (sec) Runs: 27 Replicates: 3 Two-way ANOVA: Time (sec) versus Brand, Liquid Analysis of Variance for Time (se Source DF SS MS F P Brand 2 570769 285384 327.26 0.000 Liquid 2 1593995 796997 913.95 0.000 Interaction 4 528446 132111 151.50 0.000 Error 18 15697 872 Total 26 2708906 Individual 95% CI Brand Mean -----+---------+---------+---------+------ Bounty 411.1 (-*-) Brawny 136.4 (-*-) Scott 77.4 (-*-) -----+---------+---------+---------+------ 100.0 200.0 300.0 400.0 Individual 95% CI Liquid Mean -+---------+---------+---------+---------+ Oil 550.9 (-*) Orange J 60.4 (*) Water 13.7 (*) -+---------+---------+---------+---------+ 0.0 150.0 300.0 450.0 600.0 Analysis of Means Rows: Brand Columns: Liquid Oil Orange J Water All Bounty 3 3 3 9 1020.33 175.67 37.33 411.11 82.03 23.03 2.89 462.79 Brawny 3 3 3 9 403.00 4.00 2.33 136.44 23.43 2.00 0.58 200.26 Scott 3 3 3 9 229.33 1.67 1.33 77.44 5.13 0.58 0.58 113.95

Oil Orange Juice Water

ScottBrawnyBounty

1000

500

0

Brand

Liquid

Mea

n

Interaction Plot - Data Means for Time (sec)

Brand Liquid

Bounty

Brawny

Scott Oil

Orange

Juice

Water

0

120

240

360

480

Tim

e (s

ec)

Main Effects Plot - Data Means for Time (sec)

All 9 9 9 27 550.89 60.44 13.67 208.33 362.55 87.19 17.82 322.78

Now, the data was analyzed using each of the 2-factor interactions as one factor. The results are shown in the following pages.

Tissue Brand/Liquid Time (sec) 1 Bo/W 34 2 Bo/W 39 3 Bo/W 39 4 Bo/J 156 5 Bo/J 201 6 Bo/J 170 7 Bo/O 927 8 Bo/O 1081 9 Bo/O 1053

10 Br/W 3 11 Br/W 2 12 Br/W 2 13 Br/J 2 14 Br/J 6 15 Br/J 4 16 Br/O 391 17 Br/O 430 18 Br/O 388 19 S/W 1 20 S/W 2 21 S/W 1 22 S/J 2 23 S/J 2 24 S/J 1 25 S/O 228 26 S/O 235 27 S/O 225

Bounty Brawny Scott

WaterOrange JuiceOil

1000

500

0

Liquid

Brand

Mea

n

Interaction Plot - Data Means for Time (sec)

One-way ANOVA: Time (sec) versus B/L Analysis of Variance for Time (se Source DF SS MS F P B/L 8 2693209 336651 386.05 0.000 Error 18 15697 872 Total 26 2708906 Individual 95% CIs For Mean Based on Pooled StDev Level N Mean StDev --+---------+---------+---------+---- Bo/J 3 175.7 23.0 (*) Bo/O 3 1020.3 82.0 (*) Bo/W 3 37.3 2.9 (*) Br/J 3 4.0 2.0 (*) Br/O 3 403.0 23.4 (*-) Br/W 3 2.3 0.6 (*) S/J 3 1.7 0.6 (*) S/O 3 229.3 5.1 (-*) S/W 3 1.3 0.6 (*) --+---------+---------+---------+---- Pooled StDev = 29.5 0 300 600 900 Tukey's pairwise comparisons Family error rate = 0.0500 Individual error rate = 0.00252 Critical value = 4.96 Intervals for (column level mean) - (row level mean) Bo/J Bo/O Bo/W Br/J Br/O Br/W S/J S/O Bo/O -929.2 -760.1 Bo/W 53.8 898.4 222.9 1067.6 Br/J 87.1 931.8 -51.2 256.2 1100.9 117.9 Br/O -311.9 532.8 -450.2 -483.6 -142.8 701.9 -281.1 -314.4 Br/W 88.8 933.4 -49.6 -82.9 316.1 257.9 1102.6 119.6 86.2 485.2 S/J 89.4 934.1 -48.9 -82.2 316.8 -83.9 258.6 1103.2 120.2 86.9 485.9 85.2 S/O -138.2 706.4 -276.6 -309.9 89.1 -311.6 -312.2 30.9 875.6 -107.4 -140.8 258.2 -142.4 -143.1 S/W 89.8 934.4 -48.6 -81.9 317.1 -83.6 -84.2 143.4 258.9 1103.6 120.6 87.2 486.2 85.6 84.9 312.6

Using the balanced design option, we can get the expected mean squares, as follows, ANALYSIS OF VARIANCE (BALANCED DESIGN) Factor Type Levels Values Brand fixed 3 Bounty Brawny Scott Liquid fixed 3 Oil Orange Juice Water Source Variance Error Expected Mean Square for Each Term component term (using restricted model) 1 Brand 4 (4) + 9Q[1] 2 Liquid 4 (4) + 9Q[2] 3 Brand*Liquid 4 (4) + 3Q[3] 4 Error 872.0 (4)

We also wanted to check the contrasts:

Brand Liquid C1 C2 C3 C4 C5 C6 C7 C8 MeansBounty Water 0 2 -1 1 0 -2 0 2 175.70Bounty Orange Juice 0 2 -1 -1 0 -2 0 -2 1020.30Bounty Oil 0 2 2 0 0 4 0 0 37.30Brawny Water 1 -1 -1 1 -1 1 1 -1 4.00Brawny Orange Juice 1 -1 -1 -1 -1 1 -1 1 403.00Brawny Oil 1 -1 2 0 2 -2 0 0 2.30Scott Water -1 -1 -1 1 1 1 -1 -1 1.70Scott Orange Juice -1 -1 -1 -1 1 1 1 1 229.30Scott Oil -1 -1 2 0 -2 -2 0 0 1.30

C C C C C C C C177 1825 -1752.2 -1471.2 -174 -1612 -171.4 -1062.6

SSC's 15664.5 555104 511701 1082215 7569 216545 22033 282280

SSbrand 570769SSliquid 1593916

SSinteraction 528427SSTrts 2693112

These results agree with the results obtained using one-way Anova.

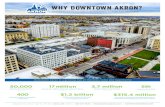

4. Results F test: For the brands: Fo= 327.26 > F 0.05, 2,18= 3.55 The F test is showing that there are significant differences among the brands in terms of the time before braking. For the liquids: Fo= 913.95 > F 0.05, 2,18= 3.55 There are significant differences among the liquids that were used in this study. For the interaction: Fo= 151.5 > F 0.05, 4,18= 2.93 There is an interaction in this study between brand and liquid. From the plot we can see that the best combination is Bounty and vegetable oil. From the One-way Analysis of variance: Fo= 386.05 > F 0.05, 8,18= 2.51 The F test is showing that there are significant differences among the brands and liquids in terms of the time before ripping. 5. Conclusions and Suggestions We found that the brand of paper towel had an important effect in the resistance of the towels. We can also conclude that the liquid used in each run affected differently the strength of the towel. F tests proved that there is a significant difference between brands and liquid used to test the resistance of the paper towels. From the plots and respective p-values we can conclude that there is an interaction between brand of paper towel and liquid used, the best combination is Bounty and Vegetable Oil and the worst is Scott and Water.

The results showed that vegetable oil presented the highest times in the ripping test. This could be explained from the solubility of cellulose (composing material of the fibers of the paper towel) in a non-polar liquid as oil. The fibers really do not like the oily environment and remain strongly attached. On the other hand, the fibers can re-arrange their orientation in presence of water, because both substance (fibers and water) are polar. This makes the towels less resistant in the presence of water. Bounty is definitely better in terms of resistance, but as a suggestion it may be interesting to test the absorbency of each brand using different liquids and also test the effect of the temperature of the liquid on the resistance of the towel. By mere coincidence, we found an article about this topic (it will be published on May 2004) comparing different properties of paper towels and their results on strength properties showed that Bounty towels are the strongest (please see appendix).

Three different brands of paper towels were tested: Bounty, Scott and Brawny. TV. advertisements says that Bounty s is the best in terms of resistance …Will be it true? Three different liquids were tested: Water (a polar liquid), orange juice (an acid polar liquid) and vegetable oil (a non-polar liquid: dislike water)

Measurement materials and weights

The Team performing the experiment

Source: Real Simple – May 2004