EXJ_14A99 jeep xj service manual

Transcript of EXJ_14A99 jeep xj service manual

-

7/29/2019 EXJ_14A99 jeep xj service manual

1/38

FUEL SYSTEM2.5L DIESEL ENGINE

CONTENTS

page page

FUEL DELIVERY SYSTEM2.5L DIESEL ENGINE . . . . . . . . . . . . . . . . . . . . . 2

FUEL INJECTION SYSTEM2. 5L DIESEL ENGINE . . . . . . . . . . . . . . . . . . . . 23

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . 1

GENERAL INFORMATION

INDEX

page page

GENERAL INFORMATIONFUEL REQUIREMENTS2.5L DIESEL . . . . . . . . . 1

FUEL SHUTDOWN SOLENOID . . . . . . . . . . . . . . 1

GENERAL INFORMATION

FUEL SHUTDOWN SOLENOIDThe fuel shutdown solenoid is controlled and

operated by the MSA.Th e f u el sh u t d ow n (sh u t -of f ) solen oid is u sed t o

electrically shut off t he diesel fuel supply to t he high-pr es su re f uel i nject i on p um p. Th e s ol en oi d i s

mounted to the rear of the injection pump.

The solenoid controls start ing and stopping of the

e n gin e r e ga r d le ss of t h e p osit ion of t h e a cce le r a t o r

p ed a l . Wh e n t h e ig n it ion (k ey ) sw it ch is O F F, t h e

solenoid is shut off and fuel flow is not allowed to the

f u el in je ct ion p u m p. Wh e n t h e k ey is p la ced in t h e

ON or START posit ions, fuel supply is allowed a t the

injection pump.

FUEL REQUIREMENTS 2.5L DIESELPr e m iu m q u a li t y d ie se l f u e l w it h a m in im u m C e t -a n e r a t in g o f 50 o r h ig h e r is r e q u ir e d .

XJ FUEL SYSTEM 2.5L DIESEL ENGINE 14 - 1

-

7/29/2019 EXJ_14A99 jeep xj service manual

2/38

FUEL DELIVERY SYSTEM2.5L DIESEL ENGINE

INDEX

page page

DESCRIPTION AND OPERATIONFUEL DRAIN TUBES . . . . . . . . . . . . . . . . . . . . . . 6

FUEL FILTER/WATER SEPARATOR . . . . . . . . . . . 3FUEL GAUGE SENDING UNIT . . . . . . . . . . . . . . . 3FUEL HEATER . . . . . . . . . . . . . . . . . . . . . . . . . . . 6FUEL HEATER RELAY . . . . . . . . . . . . . . . . . . . . . 7FUEL INJECTION PUMP . . . . . . . . . . . . . . . . . . . 4

FUEL INJECTORS . . . . . . . . . . . . . . . . . . . . . . . . 4FUEL SHUTDOWN SOLENOID . . . . . . . . . . . . . . 3FUEL SYSTEM PRESSURE WARNING . . . . . . . . 2FUEL TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

FUEL TANK MODULE . . . . . . . . . . . . . . . . . . . . . 3FUEL TUBES/LINES/HOSES AND CLAMPS

LOW-PRESSURE TYPE . . . . . . . . . . . . . . . . . . 5HIGH-PRESSURE FUEL LINES . . . . . . . . . . . . . . 6

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 2QUICK-CONNECT FITTINGSLOW PRESSURE

TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5DIAGNOSIS AND TESTING

AIR IN FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . 10FUEL HEATER RELAY TEST . . . . . . . . . . . . . . . 10FUEL INJECTION PUMP TEST . . . . . . . . . . . . . . 11FUEL INJECTOR / NEEDLE MOVEMENT

SENSOR TEST . . . . . . . . . . . . . . . . . . . . . . . . 11

FUEL INJECTOR TEST . . . . . . . . . . . . . . . . . . . 10FUEL SHUTDOWN SOLENOID TEST . . . . . . . . . 12

FUEL SUPPLY RESTRICTIONS . . . . . . . . . . . . . 11GENERAL INFORMATION . . . . . . . . . . . . . . . . . . 7

HIGH-PRESSURE FUEL LINE LEAK TEST . . . . . 12VISUAL INSPECTION . . . . . . . . . . . . . . . . . . . . . . 7

SERVICE PROCEDURESAIR BLEED PROCEDURES . . . . . . . . . . . . . . . . 12FUEL INJECTION PUMP TIMING . . . . . . . . . . . . 13

REMOVAL AND INSTALLATIONACCELERATOR PEDAL . . . . . . . . . . . . . . . . . . . 13AIR CLEANER ELEMENT . . . . . . . . . . . . . . . . . . 13FUEL DRAIN TUBES . . . . . . . . . . . . . . . . . . . . . 14

FUEL FILTER/WATER SEPARATOR . . . . . . . . . . 14FUEL HEATER . . . . . . . . . . . . . . . . . . . . . . . . . . 15FUEL HEATER RELAY . . . . . . . . . . . . . . . . . . . . 15FUEL INJECTION PUMP . . . . . . . . . . . . . . . . . . 15

FUEL INJECTORS . . . . . . . . . . . . . . . . . . . . . . . 19FUEL LEVEL SENSOR . . . . . . . . . . . . . . . . . . . . 15FUEL RESERVOIR MODULE . . . . . . . . . . . . . . . 21FUEL TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

HIGH-PRESSURE LINES . . . . . . . . . . . . . . . . . . 22SPECIFICATIONS

FUEL INJECTOR FIRING SEQUENCE . . . . . . . . 22FUEL SYSTEM PRESSURE . . . . . . . . . . . . . . . . 22FUEL TANK CAPACITY . . . . . . . . . . . . . . . . . . . 22

IDLE SPEED . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

DESCRIPTION AND OPERATION

INTRODUCTIONThis Fuel Delivery section will cover components

n ot con t r ol le d b y t h e P C M . F or com p on en t s con -

t r o lle d by t h e PC M, r e f e r t o t h e F u e l I n je ct io n S y s-

tem2.5L Diesel Engine section of this group.

Th e f u e l h e a t e r r e la y , f u el h e a t e r a n d f u el g a u g e

a r e n ot op er a t e d by t h e P C M. Th e se com p on e n t s a r e

controlled by the ignit ion (key) switch. All other fuel

sy st e m e le ct r ica l com p on e n t s n e ce ssa r y t o op er a t e

t h e e n g in e a r e co n t r o lle d o r r e g u la t e d by t h e PC M.

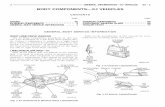

FUEL SYSTEM PRESSURE WARNING

WARNING: HIGHPRESSURE FUEL LINES DELIVERDIESEL FUEL UNDER EXTREME PRESSURE FROMTHE INJECTION PUMP TO THE FUEL INJECTORS.THIS MAY BE AS HIGH AS 45,000 KPA (6526 PSI).

USE EXTREME CAUTION WHEN INSPECTING FOR

HIGHPRESSURE FUEL LEAKS. INSPECT FORHIGHPRESSURE FUEL LEAKS WITH A SHEET OF

CARDBOARD (Fig. 1). HIGH FUEL INJECTIONPRESSURE CAN CAUSE PERSONAL INJURY IFCONTACT IS MADE WITH THE SKIN.

FUEL TANKTh e f u el t a n k a n d t a n k m ou nt i ng u sed w i t h t h e

d ie se l p o w e r e d e n g in e is t h e sa m e a s u se d w it h g a s-

oline powered models, although the fuel tank moduleis different.

T h e f u e l t a n k c o n t a i n s t h e f u e l t a n k m o d u l e a n d

tw o rollover va lves. Two fuel lines a re routed t o the

fuel tank module. One line is used for fuel supply to

the fuel filter/wa ter separa tor. The other is used t o

r e t u r n e x ce ss f u el ba ck t o t h e f u el t a n k .

The fuel tank module contains the fuel gauge elec-

trical sending unit . An electrical fuel pump is notused with the diesel engine.

14 - 2 FUEL SYSTEM 2.5L DIESEL ENGINE XJ

-

7/29/2019 EXJ_14A99 jeep xj service manual

3/38

FUEL TANK MODULEAn e le ct r ic f u el p u m p is n ot a t t a ch e d t o t h e f u el

t a n k m od u le f or d ie se l p ow e r ed e ng in es . F u el i s

siphoned by the fuel injection pump.

Th e f u e l t a n k m od u le is in st a l le d in t h e t op o f t h e

fuel tank. The fuel tank module contains the follow-

ing components:

Fuel reservoir

A separate in-tank fuel filter Electric fuel gauge sending unit

Fuel supply line connection

Fuel return line connection

FUEL GAUGE SENDING UNITTh e f u e l g a u g e se n d in g u n it is a t t a ch e d t o t h e sid e

of the fuel pump module. The sending unit consists of

a f loa t , a n a r m , a n d a va r ia ble r e sist or ( t r a ck). Th e

track is used to send an electrical signal used for fuel

gauge operation.

As the fuel level increases, the float and arm move

up. This decreases the sending unit resistance, caus-

in g t h e P C M t o se n d a sign a l t o t h e f u el g a u g e on t h ei ns t r um en t pa n el t o r ea d f ul l. As t h e f uel l ev el

d ecr ea s es , t h e f loa t a n d a r m m ov e d ow n . Th is

i n cr ea s e s t h e s en d in g u n it r es is t a n ce , ca u s i ng t h e

P C M t o sen d a sig n a l t o t h e f u el g a u g e o n t h e in st r u -

m e n t p a n e l t o r e a d e m p t y .

FUEL FILTER/WATER SEPARATORThe fuel filter/wa ter separ at or a ssembly is located

in the engine compartment near the strut tower (Fig.

2).

Th e com bin a t ion f u el f i lt e r /w a t e r se pa r a t o r p r o-

t e ct s t h e f u el in je ct ion p u m p by h e lp in g t o r e m ove

w a t e r a n d co n t a m in a n t s f r o m t h e f u e l . Mo ist u r e co l-

lects a t the bottom of the filter/separa tor in a plastic

bowl.

The fuel filter/wa ter separa tor assembly conta ins

t h e f ue l f il t er, f ue l h e a t e r e le me nt , a n d f u el d r a i n

valve.

F o r in f or m a t io n o n t h e f u el h e a t e r, r e fe r t o F u e lH e a t e r in t h is g r o u p .

Re f e r t o t h e m a in t e n a n ce sch e d u le s in G r o u p 0 in

this manual for the recommended fuel filter replace-

ment intervals.

For periodic draining of water from the bowl, refer

to Fuel Filter/Wat er Separa tor Removal/Insta llat ion

in this group.

FUEL SHUTDOWN SOLENOIDThe fuel shutdown solenoid is controlled and

operated by the MSA.Th e f u el sh u t d ow n (sh u t -of f ) so le n oid is u sed t o

electrically shut off th e diesel fuel supply to t he high-p res su r e f uel i nject i on pu m p. Th e s ol en oi d i s

mounted to the rear of the injection pump.

The solenoid controls start ing and stopping of the

e n g in e r e ga r d le ss of t h e p osit ion of t h e a cce le r a t o r

p ed a l . Wh e n t h e ig n it ion (k ey ) sw it ch is O F F, t h e

solenoid is shut off and fuel flow is not allowed to the

f u el in je ct ion p u m p. Wh e n t h e k ey is p la ced in t h e

ON or START posit ions, fuel supply is allowed a t the

injection pump.

Fig. 1 Typical Fuel Pressure Test at Injector Fig. 2 Fuel Filter/Water Separator Location

XJ FUEL SYSTEM 2.5L DIESEL ENGINE 14 - 3

DESCRIPTION AND OPERATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

4/38

FUEL INJECTION PUMPThe fuel injection pump is a mecha nical distr ibu-

t o r t y p e, B o sch V P36 se r ie s (F ig . 3). A g e a r on t h e

en d of t h e i nject i on pu m p s h a ft m es h es w i t h t h e

d riv e g ea r a t t h e fr on t of en gin e. Th e pu mp is

m ech a n i ca l l y t i m ed t o t h e e ng in e. Th e M S A c a n

m a k e a d ju st m en t s t o t h e t im in g of t h e i nject i onpump.

Th e in je ct ion p u m p con t a in s t h e f u el sh u t d ow n

solenoid, fuel temperature sensor, control sleeve sen-

so r , f u e l q u a n t i t y a ct u a t o r a n d t h e f u e l t im in g so le -

noid (Fig. 3).In the electronically controlled injection pump, the

p u m p p lu n g e r w o r k s t h e sa m e a s t h e p u m p p lu n g e r

in a mechanically controlled injection pump, but the

a m o un t of f ue l a n d t h e t i m e t h e f ue l i s i n ject e d i s

con t r ol le d b y t h e v eh i cl es M S A, i n st e a d of b y a

mecha nical governor assembly. A solenoid controlled

by the MSA is used in place of the mechanical gover-

nor a ssembly, a nd it moves a control sleeve inside the

pu mp t h a t r eg ula t es t h e a m ou nt of fu el b ein g

injected. There is no mecha nical connection between

the accelerator pedal an d the electronically controlled

in je ct ion p u m p. I n st e a d , a sen sor con n e ct e d t o t h e

a cce le r a t o r p ed a l se n ds a sig n a l t o t h e MS A t h a t r e p-

r e se n t s t h e a ct u a l p o sit io n o f t h e a cce le r a t o r p e d a l .

Th e M S A u ses t h is i npu t , a l on g w i t h i np ut f rom

ot h e r se n sor s t o m ove t h e con t r o l s le eve t o d e liver

the a ppropriat e a mount of fuel. This syst em is known

a s Dr ive-B y-Wire.

Th e a ct u a l t im e t h a t t h e f u e l is d e liver e d is ve r y

important to the diesel combustion process. The MSA

monitors outputs from the engine speed sensor (fly-

wheel posit ion in degrees), and the fuel injector sen-

s or (m ech a n i ca l m ov em en t w i t h in t h e # 1 cy l in d er

f u el in je ct o r ). O u t pu t s f r om t h e Acceler a t o r P e d a l

P osit ion se n sor, e n gin e sp ee d se n sor (e n g in e r p m )

and engine coolant temperature sensor are also used.

Th e MS A w il l t h e n com p a r e i t s se t va lu es t o t h e se

outputs to electrically adjust the amount of fuel t im-

in g (a m o u n t of a d va n ce ) w it h in t h e in je ct ion p u m p.

This is referred to as Closed Loop opera tion. TheMSA monitors fuel t iming by comparing its set value

to when the injector #1 opens. If the value is greater

t h a n a p re set v a l ue a f a u lt w i l l b e se t .

Act u a l e le ct r ic f u el t im in g (a m o u n t of a d va n ce ) is

accomplished by the fuel t iming solenoid mounted to

the bottom of the injection pump (Fig. 3). Fuel timing

will be adjusted by the MSA, which controls the fuel

timing solenoid.

An o ve r f lo w va lve is a t t a ch e d in t o t h e f u e l r e t u r n

lin e a t t h e r e a r of t h e f u el in je ct ion p u m p (F ig . 3).

This va lve serves t wo purposes. One is to ensure th at

a ce r t a in a m o u n t o f r e sid u a l p r e ssu r e is m a in t a in e d

w i t h in t h e p um p w h e n t h e e ng in e i s s w i t ch ed of f.T h is w il l p r e ve n t t h e f u e l t im in g m e ch a n ism w it h in

t h e in je ct ion p u m p f r om r e t u r n in g t o i t s z er o p o si-

t ion. The other purpose is to allow excess fuel to be

r et u r n ed t o t h e f u el t a n k t h r ou g h t h e f ue l r e t u rn

line. The pressure values w ithin t his va lve are preset

a n d ca n n o t be a d ju st e d .

Th e f u el in je ct ion p u m p su pp lies h ig h p r essu r e

fuel of a pproximat ely 45,000 kP a (6526 psi) to ea ch

in je ct o r in p r ecise m e t er e d a m o u n t s a t t h e cor r e ct

t ime.

F or m ech a n i ca l i n ject i on p um p t i m in g , r ef er t o

F u e l I n je ct ion P u m p Tim in g in t h e S e r vice P r oce-

dures section of this group.

FUEL INJECTORSF u e l d r a in t u be s (F ig . 4) a r e u se d t o r o u t e e x ce ss

f uel b a ck t o t h e ov er fl ow v a lv e a t t h e r e a r of t h e

injection pump. This excess fuel is then returned to

t h e f u e l t a n k t h r o u g h t h e f u e l r e t u r n l in e .

Th e in je ct o r s a r e con n e ct e d t o t h e f u el in je ct ion

p um p b y t h e h i gh pr es s ur e f u el l in es . A s e pa r a t e

in je ct o r is u sed f or e a ch of t h e f ou r cyl in d e r s. An

in je ct o r con t a in in g a se n sor (F ig . 5) is u sed on t h e

cylinder number one injector. This injector is called

instrumented injector #1 or needle movement sensor.

I t i s u s ed t o t e ll t h e M S A w h e n t h e # 1 i n je ct or s

i n t er n a l s pr in g -l oa d e d v a l ve s ea t h a s b ee n f or ce d

open by pressurized fuel being delivered to t he cylin-

d e r, w h ich is a t t h e e n d o f i t s com p r ession st r ok e.

When the instrumented injectors valve seat is force

open , i t s en d s a s m a ll v ol t a ge s pi ke pu ls e t o t h e

MSA. This tells the MSA that cylinder #1 is f ir ing. I t

is not used with the other three injectors.

F u el en t e rs t h e i n je ct or a t t h e f ue l i n l et (t op of

injector) and is routed to the needle valve bore. When

fuel pressure rises to approximat ely 15,00015,800

Fig. 3 Fuel Injection Pump

14 - 4 FUEL SYSTEM 2.5L DIESEL ENGINE XJ

DESCRIPTION AND OPERATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

5/38

kPa (21752291 psi), the needle valve spring tension

is over com e . Th e n e ed le va lve r ise s a n d f u el f low st h r ou g h t h e s pr a y h ol es i n t h e n oz z le t i p i n t o t h e

com bu st ion ch a m ber. Th e p r essu r e r e q u ir e d t o l i ft

the needle valve is the injector opening pressure set-

t ing. This is referred to a s the pop-off pressure set-

t ing.

Fuel pressure in the injector circuit decreases aft er

injection. The injector needle valve is immediately

clo se d by t h e n e e d le va lve sp r in g a n d f u e l f lo w in t o

t h e com bu st ion ch a m be r is s t op pe d . Ex h a u st g a se s

a r e p r eve nt e d f r om e n t er in g t h e in je ct o r n oz z le by

the needle valve.

A cop pe r w a s h e r (g a s k et ) i s u s ed a t t h e b a s e o f

e a ch in je ct o r (F ig . 5) t o p r even t com bu st ion g a se s

from escaping.

Fuel injector firing sequence is 1342.

FUEL TUBES/LINES/HOSES AND CLAMPS

LOW-PRESSURE TYPEAlso refer to the proceeding section on QuickCon-

nect Fit t ings.

I n sp ect a l l h ose con n e ct ion s su ch a s cla m p s, cou -

p lin g s a n d f i t t in g s t o m a k e su r e t h e y a r e se cu r e a n d

l ea k s a r e n ot p re sen t . Th e com p on en t s h ou ld b e

replaced immediately if there is any evidence of deg-

r a d a t io n t h a t co u ld r e su lt in f a i lu r e .

Never at tempt to repair a plastic fuel line/tube or a

quickconnect fitt ing. Replace complete line/tube a s

necessary.

Avoid conta ct of a ny fuel t ubes/hoses with other

ve h icle com p on e n t s t h a t cou ld ca u se a br a sion s or

scu f fin g . B e su r e t h a t t h e f u el l in e s/t u bes a r e p r op -e rl y r ou t ed t o p re ve nt p in ch i ng a n d t o a v oi d h ea t

sources.

The lines/tubes/hoses a re of a special const ruction.

If it is necessary to replace these lines/tubes/hoses,

use only original equipment type.

T h e h o se cla m p s u se d t o se cu r e t h e r u bbe r h o se s

a r e of a sp ecia l r ol le d e d ge con st r u ct ion . Th is con -

s t r u ct i on i s u s ed t o p rev en t t h e e dg e o f t h e cl a m p

f r om cut t in g in t o t h e h ose . O n ly t h e se r o lled e d ge

t y p e c la m p s m a y b e u s ed i n t h i s s y s t em . A ll ot h er

t y p es of cl a m ps m a y cu t i n t o t h e h o se s a n d ca u s e

fuel leaks.

Wh er e a r u bb er h os e i s joi ned t o a m et a l t u be

(s t a k ed ), d o n ot a t t e m pt t o r ep a ir. R ep la c e e nt i r e

line/tu be a ssem bly.

U s e n ew or i gi n a l e qu i pm en t t y p e h o s e cl a m ps .

Tighten hose clamps to 2 Nm (20 in. lbs.) torque.

QUICK-CONNECT FITTINGS LOW PRESSURETYPE

Different types of quick-connect fit t ings ar e used t o

attach various fuel system components. These are: a

sin g le -t a b t y p e, a t w o -t a b t y p e o r a p la st ic r e t a in er

ring type (Fig. 6). Refer to Quick-Connect Fit t ings in

t h e Re m ova l/I n st a l la t io n se ct ion f or m or e in for m a -tion.

CAUTION: The interior components (o-rings, spac-ers) of quick-connect fitting are not serviced sepa-rately, but new pull tabs are available for sometypes. Do not attempt to repair damaged fittings or

fuel lines/tubes. If repair is necessary, replace thecomplete fuel tube assembly.

Fig. 4 Fuel Injectors and Drain Tubes

Fig. 5 Fuel Injector Sensor

XJ FUEL SYSTEM 2.5L DIESEL ENGINE 14 - 5

DESCRIPTION AND OPERATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

6/38

HIGH-PRESSURE FUEL LINES

CAUTION: The highpressure fuel lines must beheld securely in place in their holders. The lines

cannot contact each other or other components. Donot attempt to weld highpressure fuel lines or torepair lines that are damaged. Only use the recom-mended lines when replacement of highpressure

fuel line is necessary.

H ig h p r essu r e f u el l in e s d elive r f u el u n d er p r es-

su r e of u p t o a p p r ox im a t e ly 45,000 k P a (6526 p si)

f r om t h e in je ct ion p u m p t o t h e f u el in je ct o r s. Th e

l in es e xp a n d a n d con t r a c t f r om t h e h i gh p re ss u r e

fuel pulses generated during the injection process. All

h ig h p r e ssu r e f u e l l in e s a r e o f t h e sa m e le n g t h a n d

i n si d e d i a m et e r. C or r ect h i gh pr es s ur e f u el l in e

u s a g e a n d i n st a l l a t i on i s cr i t ica l t o s m oot h e ng in e

operation.

WARNING: USE EXTREME CAUTION WHENINSPECTING FOR HIGHPRESSURE FUEL LEAKS.INSPECT FOR HIGHPRESSURE FUEL LEAKS WITH

A SHEET OF CARDBOARD. HIGH FUEL INJECTIONPRESSURE CAN CAUSE PERSONAL INJURY IFCONTACT IS MADE WITH THE SKIN.

FUEL DRAIN TUBESThese rubber tubes are lowpressure type.

S o m e e x ce ss f u el is con t in u a lly ve n t e d f r om t h e

fuel injection pump. Dur ing injection, a sma ll a mount

of f uel f low s pa s t t h e i nject or n oz zl e a n d i s n ot

i n je ct e d i n t o t h e com b us t i on ch a m b er. Th i s f u el

d r a in s in t o t h e f u e l d r a in t u be s (F ig . 7) a n d ba ck t o

t h e t e e ba n jo f it t in g , w h ich is con n e ct e d t o t h e sa m e

l in e a s t h e ov er f low v a l ve , w h i ch a l l ow s a v a r i a b le

q u a n t i t y t o r et u r n t o t h e f u el t a n k . Th e ov er f low

v a lv e i s ca l ib ra t e d t o open a t a pr es et pr es su re.

Excess fuel not required by the pump to maintain them i ni m um p um p ca v i t y p res s ur e i s t h e n r et u r n ed

t h r ou g h t h e o v er f low v a l ve a n d on t o t h e f ue l t a n k

t h r ou g h t h e f u el r e t u r n l in e .

FUEL HEATERThe fuel heater is used to prevent diesel fuel from

w a x in g d u ri ng col d w e a t h er oper a t ion . Th e f uel

h ea t e r i s l oca t e d i n t h e b ot t om p la s t i c b ow l of t h e

fuel filter/wa ter separa tor (Fig. 8).

The element inside the heater assembly is made of

a P osit ive Temperat ure Coefficient (P TC) m at erial,

a n d h a s p o w e r a p p lie d t o i t by t h e f u e l h e a t e r r e la y

anytime the ignit ion key is in the on posit ion. PTC

m a t e r ia l h a s a h ig h r e sist a n ce t o cu r r e n t f lo w w h e n

it s t e m p e r a t u r e is h ig h , w h ich m e a n s t h a t i t w il l n o t

g e n e r a t e h e a t w h e n t h e t e m p e r a t u r e is a bo ve a ce r -

t a in va lu e . W h e n t h e t e m p e r a t u r e is be lo w 7C (45

F), the resistance of the PTC element is lowered, and

a llow s cur r e n t t o f low t h r o ug h t h e f u el h e a t e r e le-

m e nt w a r m i n g t h e f ue l. Wh en t h e t e m pe ra t u r e i s

a b ov e 29 C (85 F ), t h e P TC el em en t s r es is t a n ce

r ises, a n d cur r e n t f low t h r o ug h t h e h e a t e r e lem e n t

stops.

Voltage to operate the fuel heater is supplied from

the ignit ion (key) switch and through the fuel heater

r e la y . Re f er t o t h e f ol low in g F u e l H e a t e r Re la y f or

Fig. 6 Plastic Retainer Ring-Type Fitting

Fig. 7 Fuel Drain Tubes

14 - 6 FUEL SYSTEM 2.5L DIESEL ENGINE XJ

DESCRIPTION AND OPERATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

7/38

a d d it ion a l in f or m a t ion . The fuel heater and fuelheater relay are not controlled by the Power-train Control Module (ECM).

C u r r e n t d r a w f o r t h e h e a t e r e le m e n t is 150 w a t t s

at 14 volts (DC).

FUEL HEATER RELAYVoltage to operate the fuel heater is supplied from

t h e i gn i t ion (k ey ) s w i t ch t h r ou g h t h e f u el h ea t e r

relay. The PCM or MSA is not used to control

this relay.T h e f u e l h e a t e r r e l a y i s l o c a t e d i n t h e P D C . T h eP D C is loca t e d n e xt t o t h e ba t t e r y in t h e e n g in e com -

p a r t m en t . F or t h e l oca t i on of t h e r el a y w i t h in t h e

PD C , r e f e r t o la be l o n PD C co ve r .

DIAGNOSIS AND TESTING

GENERAL INFORM ATIONThis section of the group will cover a general diag-

nosis of diesel engine fuel system components.

Diagnostic Trouble Codes: Re fe r t o O n -B o a r d

D ia g n o st ics in G r o u p 25, Em ission C o n t r ol S y st e mfor a list of Dia gnostic Trouble Codes (DTCs) for cer-

tain fuel system components.

Th e P C M a n d MS A m us t be t es ted w it h t he

D R B I I I s ca n t ool . Th e D R B I I I s h ou ld b e t h e f ir s t

s t ep i n a n y d i a g nos is of en g in e p er f or m a n ce com -

plaints. Refer to the 1997 ZJ /ZG 2.5L Diesel P ower-

t r a i n D i a g n os t i c P r o ce du r es m a n u a l f or d ia g n os is

and testing of the diesel engine control system.

VISUAL INSPECTIONA visual inspection for loose, disconnected, or in cor-

rectly routed wires and hoses should be made before

a t t e m pt i n g t o d i a g nos e or s er v ice t h e d ie se l f ue l

injection system. A visual check will help find these

con d it ion s. I t a lso sa ve s u n n e ce ssa r y t e st a n d d ia g -

nostic t ime. A thorough visual inspection of the fuelinjection system includes the following checks:

(1) B e su r e t h a t t h e ba t t e r y co n n e ct io n s a r e t ig h t

and not corroded.

(2) B e s ur e t h a t t h e 60 w a y con n ect or i s f ul ly

e n g a g e d w it h t h e PC M (F ig . 9) .

(3) B e s ur e t h a t t h e 68 w a y con n ect or i s f ul ly

engaged with the MSA (Fig. 10).

(4) Ve r if y t h a t t h e e le ct r ica l con n e ct ion s f or t h e

ASD relay are clean and free of corrosion. This relay

i s l o c a t e d i n t h e P D C . F o r t h e l o c a t i o n o f t h e r e l a y

w it h in t h e PD C , r e f e r t o la be l o n PD C co ve r .

(5) Ve r if y t h a t t h e e le ct r ica l con n e ct ion s f or t h e

fuel heater relay ar e clean an d free of corrosion. This

r e l a y i s l o c a t e d i n t h e P D C . F o r t h e l o c a t i o n o f t h e

r e la y w it h in t h e PD C , r e f e r t o la be l o n PD C co ve r .

(6) Be sure the electrical connectors at the ends of

t h e g low p lu g s (F ig . 11) a r e t ig h t a n d f r ee of cor r o-

sion.

(7) B e su r e t h a t t h e e le ct r ica l con n e ct ion s a t t h e

glow plug relay are t ight and not corroded. The glow

p lu g r e la y is lo ca t e d in t h e e n g in e co m p a r t m e n t o n

the leftinner fender (Fig. 12).

(8) I n sp ect t h e st a r t e r m o t or a n d st a r t e r so le n oid

connections for t ightness an d corrosion.

Fig. 8 Fuel Heater Temperature Sensor and ElementLocation

Fig. 9 PCM LocationTypical

XJ FUEL SYSTEM 2.5L DIESEL ENGINE 14 - 7

DESCRIPTION AND OPERATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

8/38

(9) Ve r if y t h a t t h e F u e l I n ject ion P u m p e le ct r ica l

connector is f irmly connected. Inspect the connector

f or cor r os ion or d a m a g e d w i r es . Th e s ol en oi d i s

mounted to the rear of the injection pump (Fig. 13).

(10) Verify that the fuel heater electrical connector

is f ir m ly a t t a ch e d t o t h e f i l t e r bo w l a t t h e bo t t o m o f

the fuel filter/wa ter separ at or. Inspect the connector

for corrosion or damaged wires.(11) Ve r if y t h a t t h e e le ct r ica l p ig t a i l con n e ct o r

(sensor connector) (Fig. 14) for the fuel injector sen-

sor is f irmly connected to the engine wiring harness.

Inspect the connector for corrosion or damaged wires.

This sensor is used on the #1 cylinder injector only.

(12) I n sp ect f or e xh a u st sy st e m r e st r ict ion s su ch

a s p in ch ed e xh a u st p ip es or a colla p se d or p lu g g ed

muffler.

(13) Ve r if y t h a t t h e h a r n e ss con n e ct o r is f ir m ly

con n e ct e d t o t h e ve h icle sp ee d se n sor (F ig . 15) or

(Fig. 16).

(14) Ve ri fy t u r boch a r g er w a s t e g a t e op er a t i on .

Re f e r t o G r o u p 11, Ex h a u st S y st e m a n d I n t a k e Ma n -ifold Group for information.

(15) Ve r if y t h a t t h e h a r n e ss con n e ct o r is f irm ly

connected to t he engine coolan t temperature sensor.

Th e se n sor is loca t e d on t h e sid e o f cy l in d e r h e a d

near the rear of fuel injection pump (Fig. 17).

(16) C h e ck f or a ir in t h e f u e l sy st e m . Re f er t o t h e

Air Bleed Procedure.

(17) I n spe ct a l l f u el su pp ly a n d r e t u r n l in es f or

signs of leakage.

Fig. 10 MSA LocationTypical

Fig. 11 Glow Plug Connector

Fig. 12 Glow Plug Relay Location

Fig. 13 Fuel Shutdown Solenoid Location

14 - 8 FUEL SYSTEM 2.5L DIESEL ENGINE XJ

DIAGNOSIS AND TESTING (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

9/38

(18) B e su r e t h a t t h e g r ou n d con n e ct ion s a r e t ig h t

a n d f r ee of cor r osion . Re fe r t o G r ou p 8, Wir in g f orlocations of ground connections.

(19) I n spe ct t h e a ir clea n e r e le m en t (f i lt e r ) f or

restrictions.

(20) B e su r e t h a t t h e t u r bo ch a r g e r o u t p u t h o se is

p r op er ly con n e ct e d t o t h e ch a r g e a ir cooler (in t er -

cooler ) in le t t u be. Ve r if y t h a t t h e ch a r g e a ir cooler

output h ose is properly connected to t he cooler a nd

the intake manifold. Refer to Group 11, Exhaust Sys-

t e m a n d I n t a k e Ma n if o ld f o r in f o r m a t io n .

(21) B e su r e t h a t t h e va cu u m h o ses t o t h e va cu u m

p u m p a r e con n e ct e d a n d n ot lea k in g . Th e va cu u m

pump is located in the front of engine (internal) andis driven from the crankshaft gear (Fig. 18). Discon-

n e ct t h e h o se a n d ch e ck f o r m in im u m va cu u m f r o m

t h e p u m p . Re f e r t o G r o u p 5, B r a k e S y st e m f o r sp e c-

ifications an d procedures.

(22) B e s u r e t h a t t h e a c ce ss or y d r iv e b el t i s n ot

damaged or slipping.

(23) Verify there is a good connection at the engine

sp e e d se n so r . Re f e r t o t h e F u e l I n je ct io n S y st e m in

t h is se ct ion f or loca t ion of t h e e n g in e sp ee d se n sor

location.

Fig. 14 Fuel Injector Sensor

Fig. 15 Vehicle Speed Sensor2 Wheel Drive

Fig. 16 Vehicle Speed Sensor4 Wheel Drive

Fig. 17 Engine Coolant Temperature SensorLocation

XJ FUEL SYSTEM 2.5L DIESEL ENGINE 14 - 9

DIAGNOSIS AND TESTING (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

10/38

(24) Verify there is a good connection at the Boost

P r e ss ur e S e n sor, w h ich i s a pa r t of t h e a i r i nt a k e

assembly.

AIR IN FUEL SYSTEMAir w il l e n t er t h e f u el sy st e m w h e n eve r t h e f u el

su pp ly l in e s, f u el f i lt e r /w a t e r se pa r a t o r, f u el f il t e r

bowl, injection pump, highpressure lines or injectors

are removed or disconnected. Air will also enter thef u el s y s t em w h e n ev er t h e f u el t a n k h a s b ee n r u n

empty.

Air t r a p p e d in t h e f u e l sy st e m ca n r e su lt in h a r d

start ing, a rough running engine, engine misfire, low

power, excessive smoke and fuel knock. After service

i s per for m ed , a i r m u st b e b led f rom t h e s y st em

before start ing the engine.

I n s p e c t t h e f u e l s y s t e m f r o m t h e f u e l t a n k t o t h e

in je ct o r s f or loose con n e ct ion s. L e a k in g f u el is a n

indicat or of loose connections or defective sea ls. Air

ca n a lso e n t e r t h e f u e l sy st e m be t w e e n t h e f u e l t a n k

a n d t h e i n je ct i on p um p . I n s p ect t h e f ue l t a n k a n d

f u e l l i n e s f o r d a m a g e t h a t m i g h t a l l o w a i r i n t o t h esystem.

F o r a ir blee d in g , r e fe r t o Air B le ed P r oce d ur e in

the Service Procedures section of this group.

FUEL HEATER RELAY TESTT h e f u e l h e a t e r r e la y is lo ca t e d in t h e Po w e r D is-

tribution Center (PDC). Refer to RelaysOperation/

Testing in F uel Injection S yst em section of this gr oup

for test procedures.

FUEL INJECTOR TESTThe fuel injection nozzles, locat ed on t he engine

cy lin d er h e a d , sp r a y f u el u n d er h ig h p r e ssu r e in t o

t h e i n di vi du a l com b us t i on ch a m b er s . P r e s s ur iz ed

fuel, delivered by the fuel injection pump, unseats a

sp r in g -loa d e d n e ed le va lve in sid e t h e in je ct o r, a n d

the fuel is a tomized a s it escapes t hrough the injectoropening into the engines combustion chamber. If the

f u el in je ct o r d oe s n ot op er a t e p r op er ly, t h e e n g in e

may misfire, or cause other driveability problems.

A leak in the injection pumptoinjector highpres-

su r e f u el l in e ca n ca u se m a n y o f t h e sa m e sy m p t o m s

as a malfunctioning injector. Inspect for a leak in the

h ig h p r essu r e l in e s bef or e ch eckin g f or a m a lf u n c-

tioning fuel injector.

WARNING: THE INJECTION PUMP SUPPLIESHIGHPRESSURE FUEL OF UP TO APPROXI-MATELY 45,000 KPA (6526 PSI) TO EACH INDIVID-

UAL INJECTOR THROUGH THE HIGHPRESSURELINES. FUEL UNDER THIS AMOUNT OF PRESSURECAN PENETRATE THE SKIN AND CAUSE PER-SONAL INJURY. WEAR SAFETY GOGGLES ANDADEQUATE PROTECTIVE CLOTHING. AVOID CON-

TACT WITH FUEL SPRAY WHEN BLEEDING HIGHPRESSURE FUEL LINES.

WARNING: DO NOT BLEED AIR FROM THE FUELSYSTEM OF A HOT ENGINE. DO NOT ALLOW FUEL

TO SPRAY ONTO THE EXHAUST MANIFOLD WHENBLEEDING AIR FROM THE FUEL SYSTEM.

To determine wh ich fuel injector is ma lfunctioning,

run the engine a nd loosen t he highpressure fuel line

n u t a t t h e in je ct o r (F ig . 19). L ist en f or a ch a n g e in

engine speed. If engine speed drops, the injector was

op er a t i n g n or m a l ly. I f e ng in e s pee d r em a i n s t h e

same, the injector may be malfunctioning. After test-

i ng , t i gh t en t h e l in e n u t t o 30 N m (22 f t . l bs .)

t o r q u e. Te st a l l in je ct o r s in t h e sa m e m a n n e r on e a t

a t im e .

Once an injector has been found to be malfunction-

in g , r e m o ve i t f r o m t h e e n g in e a n d t e st i t . Re f e r t o

th e Removal/Ins ta llat ion section of this group for pro-

cedures.After the injector has been removed, install it to a

b en ch mou n t i n je ct or t e st e r. R ef er t o op er a t i n g

instructions supplied with tester for procedures.

The opening pressure or pop pressure should be

15,00015,800 kP a (21752291 psi). I f th e fuel injec-

tor needle valve is opening (popping) to early or to

lat e, replace the injector.

Fig. 18 Vaccum Pump at Front of Engine

14 - 10 FUEL SYSTEM 2.5L DIESEL ENGINE XJ

DIAGNOSIS AND TESTING (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

11/38

FUEL INJECTOR / NEEDLE MOVEMENT

SENSOR TESTTh e n e ed le m o vem e n t se n sor is u sed on ly on t h en u m ber 1 cy lin d e r f u el in je ct o r (F ig . 20). I t is n ot

used on the injectors for cylinders number 2, 3, or 4.

Testing the needle m ovement sensor requires t he

u se of a D R B S ca n t ool . R e fer t o t h e P o w er t r a inD ia g n o st ic P r oced u r es m a n u a l f or a d d it ion a l in f or -

m a t io n .

FUEL INJECTION PUMP TESTThe injection pump is not to be serviced or

the warranty may be voided. If the injectionpump requires service, the complete assemblymust be replaced.

I n cor r e ct in je ct ion p u m p t im in g (m e ch a n ica l or

e le ct r ica l) ca n ca u se p oor p er f or m a n ce, e xce ssive

smoke and emissions and poor fuel economy.

A defective fuel injection pump, defective fuel tim-

ing solenoid or misadjusted mechanical pump timing

ca n ca u se st a r t in g p r oblem s or p r even t t h e e n gin e

f r o m r e vvin g u p . I t ca n a lso ca u se :

En g in e su r g e a t id le

Rough idle (warm engine)

Low power Excessive fuel consumption

P oor performa nce

Low power

B la ck sm o ke f r o m t h e e x h a u st

B lu e or w h it e f og l ik e e xh a u st

Incorrect idle or maximum speed

Th e e le ct r o n ica l ly con t r o lled f u el p u m p h a s n o

m e ch a n ica l g over n or l ik e old er m e ch a n ica l ly con -

t r o lled f u el p u m ps. D o n ot r e m ove t h e t o p cover of

t h e f ue l p u m p, or t h e s cr ew s f a s t en i ng t h e w i r in g

p i g t a i l t o t h e s i d e o f t h e p u m p . The warranty ofthe injection pump and the engine may be void

if those seals have been removed or tamperedwith.

FUEL SUPPLY RESTRICTIONS

LOWPRESSURE LINESRestricted or P lugged supply lines or fuel filter can

ca u se a t im in g f a u lt t h a t w il l ca u se t h e E C M t o op er -

a t e t h e e n gi ne i n a L im p H om e m od e. S e e t h e

i n t r od u ct i on of t h e F u el I n ject i on S y s t em i n t h i s

group for more informa tion on t he Limp Home mode.

Fuel supply line restrict ions can cause start ing prob-

lem s a n d p r even t t h e e n gin e f r om r e vvin g u p . Th e

s t a r t i n g p rob le m s i n cl ud e; l ow p ow e r a n d b lu e orwh ite fog like exhaust . Test all fuel supply lines for

r e st r ict ion s or block a g e . F lu sh or r e pla ce a s n e ce s-

sa r y . B le e d t h e f u e l sy st e m o f a ir o n ce a f u e l su p p ly

line has been replaced. Refer to the Air Bleed Proce-

dure section of this group for procedures.

HIGHPRESSURE LINESRestricted (kinked or bent) highpressure lines can

ca u se st a r t in g p r oblem s, p oor e n gin e p er f or m a n ce

a n d bla ck sm ok e f r om e xh a u st .

Ex a m in e a l l h ig h p r essu r e l in es f or a n y d a m a g e.

E a c h r a d iu s on ea c h h ig h p res su r e l in e m u st b e

sm o o t h a n d f r e e o f a n y be n d s o r k in k s.

Replace damaged, restricted or leaking highpres-

sure fuel lines with the correct replacement line.

CAUTION: The highpressure fuel lines must beclamped securely in place in the holders. The linescannot contact each other or other components. Donot attempt to weld highpressure fuel lines or to

repair lines that are damaged. Only use the recom-mended lines when replacement of highpressurefuel line is necessary.

Fig. 19 Typical Inspection of Fuel Injector

Fig. 20 Needle Movement Sensor Location

XJ FUEL SYSTEM 2.5L DIESEL ENGINE 14 - 11

DIAGNOSIS AND TESTING (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

12/38

FUEL SHUTDOWN SOLENOID TESTRefer to 1997 ZJ /ZG 2.5L Diesel P owertrain Dia g-

n ost ic Ma n u a l f or t h e F u e l S h u t d o w n S o le n oid t e st .

HIGH-PRESSURE FUEL LINE LEAK TESTH i g h pr es s ur e f ue l l in e l ea k s ca n ca u s e s t a r t i n g

problems and poor engine performa nce.

WARNING: DUE TO EXTREME FUEL PRESSURES OF

UP TO 45,000 KPA (6526 PSI), USE EXTREME CAU-

TION WHEN INSPECTING FOR HIGHPRESSURE FUEL

LEAKS. DO NOT GET YOUR HAND, OR ANY PART OF

YOUR BODY NEAR A SUSPECTED LEAK. INSPECT

FOR HIGHPRESSURE FUEL LEAKS WITH A SHEET

OF CARDBOARD. HIGH FUEL INJECTION PRESSURE

CAN CAUSE PERSONAL INJURY IF CONTACT IS

MADE WITH THE SKIN.

S t a r t t h e en g in e. M ov e t h e ca r d boa r d ov er t h e

highpressure fuel lines a nd check for fuel spray ontothe cardboard (Fig. 21). I f a highpressure line con-

n e ct io n is le a k in g , ble e d t h e sy st e m a n d t ig h t e n t h e

connection. Refer to the Air Bleed Procedure in this

group for procedures. Replace damaged, restricted or

l ea k i n g h i gh pr es s ur e f u el l in es w i t h t h e cor r ect

replacement line.

CAUTION: The highpressure fuel lines must beclamped securely in place in the holders. The lines

cannot contact each other or other components. Donot attempt to weld highpressure fuel lines or torepair lines that are damaged. Only use the recom-mended lines when replacement of highpressure

fuel line is necessary.

SERVICE PROCEDURES

AIR BLEED PROCEDURES

AIR BLEEDING AT FUEL FILTERA certain amount of air may become trapped in the

f u el sy st e m w h e n f u e l sy st e m com p on e n t s a r e se r -vice d o r r e p la ce d . B le e d t h e sy st e m a s n e e d e d a f t e r

fuel system service according to the following proce-

dures.

WARNING: DO NOT BLEED AIR FROM THE FUELSYSTEM OF A HOT ENGINE. DO NOT ALLOW FUELTO SPRAY ONTO THE EXHAUST MANIFOLD WHEN

BLEEDING AIR FROM THE FUEL SYSTEM.

S o m e a ir e n t e r s t h e f u e l sy st e m w h e n t h e f u e l f i l-

t e r or in je ct ion p u m p su p p ly l in e is ch a n g ed . Th is

sm a ll a m o u n t o f a ir is ve n t e d a u t o m a t ica l ly f r o m t h e

injection pump through the fuel drain manifold tubesif t h e f i l t er w a s ch a n g e d a ccor d in g t o in st r u ct ion s.

En su r e t h e bow l of t h e f u el f i lt e r /w a t e r se pa r a t o r is

full of fuel.

I t m a y be n e ce ssa r y t o m a n u a lly ble e d t h e sy st e m

if :

The bowl of the fuel filter/wa ter separ at or is not

partially filled before installat ion of a new filter

The injection pump is replaced

Highpressure fuel line connections are loosened

or lines replaced

I n it ia l en gi ne s t a rt u p or s ta r t u p a f ter a n

extended period of no engine operat ion

Ru n n in g f u e l t a n k e m p t y

FUEL INJECTION PUMP BLEEDING(1) I f t h e f u el in je ct ion p u m p h a s bee n r e pla ced ,

a i r s h ou ld b e b led a t t h e ov er fl ow v a lv e b ef or e

a t t e m p t in g t o st a r t e n g in e .

(a ) L o os en t h e ov er f low v a l ve (F i g. 22) a t t h e

rear of the injection pump.

(b) Pla ce a t o w e l be lo w t h e va lve .

WARNING: WHEN CRANKING THE ENGINE TOBLEED AIR FROM THE INJECTION PUMP, THEENGINE MAY START. PLACE THE TRANSMISSION

IN NEUTRAL OR PARK AND SET PARKING BRAKEBEFORE ENGAGING THE STARTER MOTOR.

CAUTION: Do not engage the starter motor formore than 30 seconds at a time. Allow 2 minutesbetween cranking intervals.

Fig. 21 Typical Fuel Pressure Test at Injector

14 - 12 FUEL SYSTEM 2.5L DIESEL ENGINE XJ

DIAGNOSIS AND TESTING (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

13/38

(2) C r a n k t h e e n g in e f or 30 s e con d s a t a t i m e t o

a l low a ir t r a p p ed in t h e in ject ion p u m p t o ve n t ou t

the fuel injector dra in t ubes. Continue this procedure

until the engine sta rts. Observe t he previous WARN-

I N G a n d C AU T I O N .

(3) Tighten overflow valve.

HIGHPRESSURE FUEL LINE BLEEDING

WARNING: THE INJECTION PUMP SUPPLIES HIGH-PRESSURE FUEL OF APPROXIMATELY 59,000 KPA(8,557 PSI) TO EACH INDIVIDUAL INJECTOR

THROUGH THE HIGHPRESSURE LINES. FUELUNDER THIS AMOUNT OF PRESSURE CAN PENE-TRATE THE SKIN AND CAUSE PERSONAL INJURY.WEAR SAFETY GOGGLES AND ADEQUATE PRO-

TECTIVE CLOTHING AND AVOID CONTACT WITHFUEL SPRAY WHEN BLEEDING HIGHPRESSUREFUEL LINES.

WARNING: DO NOT BLEED AIR FROM THE FUEL

SYSTEM OF A HOT ENGINE. DO NOT ALLOW FUELTO SPRAY ONTO THE EXHAUST MANIFOLD WHENBLEEDING AIR FROM THE FUEL SYSTEM.

Bleed air from one injector at t ime.

(1) L oose n t h e h ig h p r essu r e f u el l ine f it t in g a t

the injector (Fig. 23).

(2) C r a n k t h e en g in e u n t i l a l l a i r h a s b ee n b l ed

f r o m t h e l in e . Do not operate the starter motorfor longer than 30 seconds. Wait 2 minutesbetween cranking intervals.

(3) S t a r t t h e e ng in e a n d b le ed on e i n je ct or a t a

t ime until the engine runs smoothly.

FUEL INJECTION PUMP TIMING

Refer to R emoval/Inst alla t ion a nd Adjusting F uelP u m p Tim ing in t h is G r ou p .

REMOVAL AND INSTALLATION

ACCELERATOR PEDAL

REMOVAL(1) Disconnect electrical connector.

(2) Rem ove a cce le r a t o r p ed a l m o un t in g br a cke t

nuts. Remove accelerator pedal assembly.

INSTALLATION(1) P l a ce a c ce le ra t o r p ed a l a s s em b ly ov er s t u d sprotruding from floor pan. Tighten mounting nuts to

5 Nm (46 in. lbs.) torque.

(2) Connect electrical connector.

(3) Before start ing the engine, operate the acceler-

a t or p ed a l t o ch eck f or a n y bin din g .

AIR CLEANER ELEMENT

REMOVAL(1) Remove hose clamp at Mass Air Flow Sensor.

(2) Remove hose from Mass Air Flow Sensor.

(3) L o ose n 2 cla m p s h old in g a ir clea n e r h ou sin gha lves t ogether.

(4) Remove left side of air cleaner housing.

(5) Remove element from air cleaner housing.

INSTALLATION(1) I n st a l l a n e w e le m e n t in h o u sin g .

(2) Posit ion left side of housing.

(3) Snap clamps into place.

(4) I n st a l l h ose s a n d cla m p s.

Fig. 22 Overflow Valve

Fig. 23 Bleeding HighPressure Fuel LineTypical

XJ FUEL SYSTEM 2.5L DIESEL ENGINE 14 - 13

SERVICE PROCEDURES (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

14/38

FUEL DRAIN TUBESTh e f u el d r a in t u bes (F ig . 25) a r e low p r essu r e

type.P u ll e a ch t u be f r om t h e in je ct o r f o r r e m ova l . P u sh

on for installat ion. Clamps are not required for these

tubes.

FUEL FILTER/WATER SEPARATORTh e f u el f il t e r/w a t e r se pa r a t o r is loca t e d in t h e

e n g in e co m p a r t m e n t o n t h e le f t s id e n e a r t h e sh o ck

tower. (Fig. 26).

The fuel filter/wa ter separa tor assembly conta ins

t h e f ue l f il t er, f ue l h e a t e r e le me nt , a n d f u el d r a i n

valve (Fig. 26).

DRAINING WATER FROM FILTER BOWLMoisture (wat er) collects at the bottom of the filter/

se pa r a t o r in a p la st ic bo w l. Wa t e r e n t er in g t h e f u e l

i nject i on pu m p ca n ca u s e s er iou s d a m a g e t o t h e

pump. Note that the bulb will be illuminated for

approximately 2 seconds each time the key isinitially placed in the ON position. This is donefor a bulb check.

WARNING: DO NOT ATTEMPT TO DRAIN WATER

FROM THE FILTER/SEPARATOR WITH THE ENGINEHOT.

(1) Th e b ot t om of t h e f il t er /s ep a r a t or b ow l i s

e q ui pp ed w i t h a d r a i n v a l ve (F i g. 26). Th e d r a i n

v a l v e i s e q ui pp ed w i t h a f it t i n g. A t t a ch a p ie ce of

rubber hose to this fit t ing. This hose is to be used as

a d r a in h o se .

(2) Pla ce a d r a in p a n u n d e r t h e d r a in h o se .(3) Wit h t h e e n gin e n o t r u n n in g, op en t h e d r a in

va lve (u n scr e w d r a in va lve h a s r ig h t h a n d t h r e a d s)

from the filter/separ at or bowl. To ga in access to this

fit t ing, the two filtertomounting bracket nuts (Fig.

26) m a y h a ve t o be loose n ed a f ew t u r n s.

(4) H o ld t h e d r a in o p e n u n t i l c le a n f u e l e x it s t h e

d r a in .

(5) After draining, close drain valve.

(6) Remove rubber drain hose.

(7) D isp ose o f m ixt u r e in d r a in p a n a ccor d in g t o

applicable local or federal regulations.

Fig. 24 Accelerator Pedal Mounting-Typical

Fig. 25 Fuel Injectors and Drain Tubes

Fig. 26 Fuel Filter/Water Separator Location

14 - 14 FUEL SYSTEM 2.5L DIESEL ENGINE XJ

REMOVAL AND INSTALLATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

15/38

FUEL FILTER REMOVAL(1) D rain all fuel a nd/or w at er from fuel filter/wa -

t e r se pa r a t o r a ssem bly. Re fe r t o t h e p r e viou s D r a in -

ing Wat er From Filter B owl.

(2) U n p lu g t h e e le ct r ica l con n e ct o r s a t bot t o m of

plastic bowl.

(3) Remove plastic bowl from bottom of fuel filter(unscrews).

(4) Rem ove f u el f il t e r f r om bot t o m of f il t e r ba se

(unscrews).

FUEL FILTER INSTALLATION(1) Clean bottom of fuel filter base.

(2) Apply clean diesel fuel to new fuel filter gasket.

(3) Install and t ighten filter to filter base. The bev-

e le d p a r t of t h e r u bb er g a s k et s h ou ld b e f a c in g u p

t o w a r d s t h e f i l t e r ba se .

(4) C le a n t h e in sid e o f bo w l w it h a so a p a n d w a t e r

mixture before installat ion. Carefully clean any resi-

d u e b et w e en t h e t w o m e t a l p rob es a t t h e t o p o f t h ew a t e r in f u el se n sor . D o n ot u se ch e m ica l cle a n e r s

a s d a m a g e t o t h e p la s t i c b ow l m a y r es u lt .

(5) P ou r d i es el f ue l i n t o t h e p la s t i c b ow l b ef or e

insta lling bowl to bottom of fuel filter. D o this to help

prevent air from entering fuel injection pump w hile

a t t e m p t in g t o st a r t in g e n g in e .

(6) Install f ilter bowl to bottom of filter .

(7) I n st a l l t h e e le ct r ica l con n e ct o r s a t bot t o m of

bowl.

(8) Tig h t en t h e f i lt e r t o m o un t in g br a cke t n u t s

(Fig. 26) to 28 Nm (250 in. lbs.) torque.

FUEL HEATERI f t h e f u e l h e a t e r e le m e n t n e e d s r e p la ce m e n t , t h e

p la st ic f i lt e r bow l a sse m bly m u st be r e p la ced . Re fe r

to Fuel Filter/Wat er Separa tor for informa tion.

FUEL HEATER RELAYTh e f u el h ea t e r r el a y i s l oca t e d i n t h e P D C . F or

t h e l oca t i on of t h e r e l a y w i t h in t h e P D C (F i g. 27),

refer to label on PDC cover.

FUEL LEVEL SENSORT h e f u e l le ve l se n so r is lo ca t e d o n t h e sid e o f t h e

fuel pump module (Fig. 28).

REMOVAL(1) Remove fuel ta nk. Refer t o Fuel Tan k R emoval/

I n st a l la t io n .

(2) Remove fuel pump module. Refer to F uel P ump

Module Removal/Ins ta llat ion.

(3) Re m ove e le ct r ica l w ir e con n e ct o r a t se n din g

u n it t e r m in a ls .

(4) P r e ss o n r e le a se t a b (F ig . 29) t o r e m ove se n d -

ing unit from pump module.

FUEL INJECTION PUMPREMOVAL

(1) Disconnect the negative battery cable.

(2) Thoroughly clean the ar ea ar ound the injection

pump and fuel lines of all dirt , grease and other con-

t a m i n a n t s . Due to the close internal tolerancesof the injection pump, this step must be per-formed before removing pump.

Fig. 27 Power Distribution Center (PDC) Location

Fig. 28 Fuel Level Sensor

XJ FUEL SYSTEM 2.5L DIESEL ENGINE 14 - 15

REMOVAL AND INSTALLATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

16/38

(3) Remove the engine accessory drive belt . Refer

to Group 7, Cooling System for procedures.

(4) Remove the generator assembly.

(5) R em ov e t h e r u bb er f u el r et u r n a n d s u pp ly

hoses from the metal lines at the pump (Fig. 30).

(6) Remove the electrical connector at engine cool-

ant temperature sensor.

(7) Disconnect the Fuel Injection P ump electrical

connector at fuel pump (Fig. 30).

(8) D is con n ect t h e m a i n e ng in e w i r in g h a r n es s

from the glow plugs.

(9) D iscon n e ct t h e f ou r h ig h p r essu r e f u el l in e s

f r om t h e f u el in je ct ion p u m p. Also d iscon n e ct f u el

l in e s a t t h e f u el in je ct o r s. F o r p r oced u r es, r e fe r t o

H ig h Pr e ssu r e F u e l L in e s in t h is g r o u p . Pla ce a r a g

beneath the fit t ings to catch excess fuel.

(10) Remove the plug from timing gear cover.

(11) The Top Dea d C ent er (TDC ) compr ession fir -in g st r o k e f o r t h e # 1 cy lin d e r ca n be d e t e r m in e d a s

follows:

(a ) U s in g a s ock et a t t a ch ed t o t h e f r on t of t h e

cr a n k sh a f t , r o t a t e t h e e n g in e clo ck w ise u n t i l sp e -

ci a l a l i gn m en t t ool VM # 1035 ca n b e i n ser t ed

t h r o ug h t h e h ole in t h e bot t o m of t h e clu t ch h o u s-

ing, st opping t he flywheel rotat ion. This posit ion is

TDC or 180 away from TDC. Engine must be atTDC #1 compression firing stroke.

(b) To ve r if y t h a t y ou a r e a t TD C . Re m ove t h e

oi l f i ll ca p f r om t h e cy l in d er h ea d cov er a n d t h e

alignment tool from the clutch housing.

(c) Rotate the crankshaft one-quarter turn clock-w ise a n d cou n t e r -clock w ise w h ile obser vin g t h e

r ock er a r m t h r ou gh t h e oi l f il l ca p h ol e. I f t h e

r o ck e r a r m m o ve s y o u a r e n o t a t T D C .

(d ) I f T D C w a s f o u n d co n t in u e , i f n o t r o t a t e t h e

cra n k sh a f t on e r e volu t ion u n t i l t h e a l ig n m en t t o ol

can be re-installed in the flywheel. You are now at

TDC for the #1 cylinder compression fir ing stroke.

Mark the damper and t iming cover for reference to

TD C . Re m ove t h e a l ig n m en t t o ol f r om t h e clu t ch

housing.

(12) Re m o ve a cce ss p lu g a n d p lu g w a sh e r a t r e a r

of pump (Fig. 31). Thread special dial indicator and

a d a p t er t o ol VM.1011 (F ig . 32) in t o t h is op en in g .H a n d t ig h t e n o n ly.

(13) Slightly rotat e t he engine in a counter-clock-

w i s e d ir ect i on u n t il t h e d i a l g a u g e i n di ca t o r s t op s

moving (20 -25 before TDC ).

(14) Re m ove in je ct ion p u m p d r ive g e a r n u t (F ig .

33).

(15) A s peci a l 3 pi ece g ea r r em ov a l t ool s et

VM.1003 (Fig. 34) must be used to remove the injec-

t io n p u m p d r ive g e a r f r o m t h e p u m p sh a f t .

(a ) T h r e a d t h e a d a p t e r (F ig . 35) in t o t h e t im in g

cover.

(b ) Th r ea d t h e g ea r p ul le r i n t o t h e i n je ct i on

pump drive gear (Fig. 35). This tool is also used to

h ol d t h e g ea r i n s y nch r on iz a t ion d ur in g pu m p

removal.

(c) Re m ove t h e t h r e e in je ct ion p u m p t o g ea r

cove r m ou n t in g n u t s (F ig . 36). CAUTION: Thisstep must be done to prevent injection pumpdamage.

(d ) I ns t a l l t h e d r iv e b ol t i n t o t h e g ea r p ul ler

(Fig. 35). Tighten the drive bolt to press (remove)

t h e d r iv e g ea r f r om i n je ct i on p um p s h a f t w h i le

Fig. 29 Fuel Level Sensor Release Tab

Fig. 30 Fuel Injection Pump

14 - 16 FUEL SYSTEM 2.5L DIESEL ENGINE XJ

REMOVAL AND INSTALLATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

17/38

d r ivin g in je ct ion p u m p r e a r w a r d f r om t im in g g e a r

cover mounting studs.

(16) Remove pump from engine. Do not rotateengine while gear puller is installed. Enginedamage will occur.

INSTALLATION/ADJUSTING PUMP TIMING(1) C lea n t h e m a t in g su r f a ce s of in je ct ion p u m p

and t iming gear cover.

(2) I n st a l l a n e w in je ct ion p u m p t o t im in g g ea r

cover gasket.

(3) R em ov e t h e g ea r r em ov in g b ol t (d r iv e b ol t )

from gear puller. CAUTI ON: Do not remove the

special gear puller or timing cover adaptertools from timing cover at this time. Gear mis-alignment will result.

(4) Pla ce t h e k e y w a y o n t h e p u m p sh a f t t o t h e 11

oclock p osit ion a s view e d f r om t h e f r on t of p u m p.

I n s t a l l t h e p u m p i n t o t h e r e a r o f t i m i n g g e a r c o v e r

w h il e a l i gn in g k ey w a y on p um p s h a ft i nt o p u m p

gear.

(5) I n st a l l a n d sn u g t h e 3 in je ct io n p u m p m o u n t -

ing nuts. This is not the final t ightening sequence.

(6) R em ov e t h e s pe ci a l g ea r p ul ler a n d a d a p t er

tools from timing gear cover.

Fig. 31 Access Plug at Rear of Pump

Fig. 32 Installing Dial Indicator and Special AdapterTools

Fig. 33 Removing Pump Drive Gear Nut

Fig. 34 Pump Gear Tools

XJ FUEL SYSTEM 2.5L DIESEL ENGINE 14 - 17

REMOVAL AND INSTALLATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

18/38

(7) I n st a l l t h e i nject i on pu m p d r iv e g ea r n u t .

Tighten nut to 88 Nm (65 ft . lbs.) torque.

(8) R em ov e t h e a c ce ss p lu g a n d p lu g w a s h er a t

rear of pump (Fig. 37). Thread special dial indicator

a d a p t er t o ol V M.1011 (F ig . 38) in t o t h is op en in g .Hand t ighten only.

(9) Attach special dial indicator tool VM.1013 into

the adapter tool (Fig. 38).

(10) U s i n g a s ock et a t t a ch ed t o t h e f r on t of t h e

cranksha ft , r ota te t he engine in a counter-clockwise

d ir e ct io n u n t i l t h e d ia l g a g e in d ica t o r st o p s m o vin g

(2025 before TDC).

(11) S e t t h e d ia l in d ica t or t o 0m m . B e su r e t h e t ip

of t h e d i a l i n d i ca t o r i s t ou ch i ng t h e t i p i n s id e t h e

adapter tool.

(12) The Top Dea d C ent er (TDC ) compression fir-

ing stroke can be determined as follows:

(a ) R ot a t e t h e e ng in e cl ock w i se u n t il s pe ci a l

alignment tool VM# 1035 can be inserted through

the hole in the bottom of the clutch housing, stop-

ping the flywheel rotat ion. This posit ion is TDC or

180 away from TDC. Engine must be at TDC #1compression firing stroke.

Fig. 35 Installing Pump Drive Gear Removal Tools

Fig. 36 Injection Pump Mounting Nuts

Fig. 37 Access Plug at Rear of Pump

Fig. 38 Installing Dial Indicator and Special AdapterTools

14 - 18 FUEL SYSTEM 2.5L DIESEL ENGINE XJ

REMOVAL AND INSTALLATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

19/38

(b) To ve r if y t h a t y ou a r e a t TD C . Re m ove t h e

oil f ill cap from t he rocker cover a nd the alignment

tool from the clutch housing.

(c) Rotate the crankshaft one-quarter turn clock-

w ise a n d cou n t e r-clock w ise w h ile obser vin g t h e

r ock er a r m t h r ou gh t h e oi l f il l ca p h ol e. I f t h e

r o ck e r a r m m o ve s y o u a r e n o t a t T D C .(d ) I f T D C w a s f o u n d co n t in u e , i f n o t r o t a t e t h e

cr a n k sh a f t on e r e volu t ion u n t i l t h e a l ig n m en t t o ol

can be re-installed in the flywheel. You are now at

TDC.

(13) Th e g a u g e r e a d in g sh ou ld be a t 0 .60 m m . I f

n o t , t h e p u m p m u st be r o t a t e d f o r a d ju st m e n t :

(a ) L o osen t h e t h r e e in je ct ion p u m p m ou n t in g

n u t s a t t h e m ou n t in g f la n g es . Th es e f la n g es a r e

equipped with slotted holes. The slotted holes are

used to rotate and posit ion the injection pump for

f u e l t im in g . L o o se n t h e t h r e e n u t s ju st e n o u g h t o

r o t a t e t h e p u m p .

(b) Ro t a t e t h e p u m p u n t i l 0 .60 m m is in d ica t e do n t h e d i a l i n d i c a t o r g a u g e . I f w h i l e r o t a t i n g t h e

p u m p t h e 0.60m m sp ecif ica t ion is p a ssed d o n o t

a t t e m p t t o r o t a t e t h e p u m p in t h e o p p o sit e d ir e c-

t i on . You m u s t r ot a t e t h e p um p b a ck b el ow t h e

0.60mm specification and start the procedure over

from the sta rt of the TDC procedure. This w ill pre-

ve n t a f a lse r e a d in g d u e t o g e a r ba ck la sh .

(c) Tighten t he thr ee pump mounting nuts to 30

Nm (22 ft . lbs.) torque.

(d ) Rech eck t h e d ia l in d ica t or a f t e r t ig h t e n in g

t h e p um p m ou n t in g n u t s . G a u g e s h ou ld s t i ll b e

reading 0.60 mm.

(14) Remove dial indicator and adapter tools.(15) I n st a l l a c ces s pl ug a n d w a s h er t o r ea r of

injection pump.

(16) Install plug at t iming gear cover.

(17) I n s t a l l a n d con n ect t h e f ou r h i gh pr es s ur e

f u el l in e s t o t h e f u el in je ct ion p u m p. Also con n e ct

fuel lines at the fuel injectors. For procedures, refer

t o H ig h P r e ssu r e F u e l L in e s in t h is g r ou p .

(18) Inst all electrical connector at engine coolan t

temperature sensor.

(19) Connect electrical connector at fuel shutdown

solenoid.

(20) C o nn ect t h e m a i n e ng in e w i r in g h a r n es s t o

the glow plugs.

(21) C o n n ect t h e f u el t im in g solen oid p ig t a i l h a r -

n e ss t o t h e e n g in e w ir in g h a r n e ss.

(22) C onnect th e overflow va lve/ban jo fittin g (fuel

return line assembly). Replace copper gaskets before

installing.

(23) C on n ect t h e r u bb er f ue l r et u r n a n d s u pp ly

hoses t o metal lines a t pump. Tighten hose clam ps to

2 Nm (20 in. lbs.) torque.

(24) Install generator assembly.

(25) I n st a l l e n g in e a cce ssor y d r ive be lt . Re fe r t o

Group 7, Cooling System for procedures.

(26) I n st a l l n e ga t ive ba t t e r y ca ble t o ba t t e r y.

(27) S t a r t t h e e n g in e a n d br in g t o n o r m a l o p e r a t -

ing temperature.

(28) Check for fuel leaks.

FUEL INJECTORSF ou r f ue l i n je ct or s a r e u s ed on e a ch e ng in e. O f

t h e se f ou r, t w o d i ff er en t t y pe s a r e u s ed . Th e f u el

in je ct o r u sed on cylin de r n u m ber on e is e q u ip pe d

with a fuel injector sensor (Fig. 39). The other three

fuel injectors are identical. Do not place the fuelinjector equipped with the fuel injector sensorinto any other location except the cylindernumber one position.

REMOVAL(1) Disconnect negative battery cable at battery.

(2) Thoroughly clean the ar ea around the injector

with compressed air .

(3) Re m ove t h e f u el d r a in h ose s (t u bes) a t e a ch

injector (Fig. 40) being serviced. Each of these hoses

is slipfit to the fit t ing on injector.

(4) Remove the highpressure fuel line at injector

being removed. Refer to HighPressure Fuel Lines in

this group for procedures.

(5) Remove the injector using special socket tool

number VM.1012A. When removing cylinder number

o n e in je ct o r , t h r e a d t h e w ir in g h a r n e ss t h r o u g h t h e

access hole on the special socket (Fig. 41).

(6) Remove and discar d t he copper w ash er (seal) at

bottom of injector (Fig. 39).

Fig. 39 Fuel Injector Sensor #1 Cylinder

XJ FUEL SYSTEM 2.5L DIESEL ENGINE 14 - 19

REMOVAL AND INSTALLATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

20/38

INSTALLATION(1) Clean the injector threads in cylinder head.

(2) Inst all new copper w ash er (seal) t o injector.

(3) I n st a l l in je ct o r t o e n gin e. Tig h t en t o 70 N m

(52 ft. lbs.) torque.

(4) Install highpressure fuel lines. Refer to High

Pressure Fuel Lines in this group for procedures.

(5) Inst all fuel dra in hoses (tubes) to each injector.

D o n o t u se cla m p s a t f u e l d r a in h o se s.

(6) Connect negative battery cable to battery.

(7) B l ee d t h e a i r f r om t h e h i gh pr es s ur e l in es .

R ef er t o t h e Ai r B l e ed P r o ce du r e s ect i on of t h i s

group.

FUEL TANK

REMOVAL(1) Disconnect negative cable from battery.

(2) Insert fuel siphon hose into fuel filler neck and

p us h i t i n t o t h e t a n k .

(3) D r a in f uel t a n k d r y i nt o h ol di ng t a n k or a

properly labeled diesel safety container.(4) Raise vehicle on hoist .

(5) Disconnect both the fuel fill and fuel vent rub-

be r h o se s a t t h e f u e l t a n k .

(6) D iscon n e ct f u el su pp ly a n d r e t u r n l in es f r om

the steel supply line (Fig. 42).

The fuel reservoir module electrical connec-tor has a retainer that locks it in place.

(7) Slide electrical connector lock to unlock.

(8) Push down on connector retainer (Fig. 44) and

pull connector off module.

(9) U se a t r a n sm ission ja ck t o su p por t f u el t a n k .

Re m ove bo lt s f r om f u el t a n k st r a p s.

Fig. 40 Fuel InjectorTypical

Fig. 41 Wiring Harness Through Socket

Fig. 42 Fuel Tank Connections at Front of Tank

Fig. 43 Fuel Fill/Vent Hose Index Marks

14 - 20 FUEL SYSTEM 2.5L DIESEL ENGINE XJ

REMOVAL AND INSTALLATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

21/38

(10) L o w er t a n k sl ig h t ly. C a r e f u lly r e m ove f i ller

h ose f r om t a n k .

(11) L ow e r t h e f uel t a n k . R em ov e cl a m p a n d

r e m ove f u e l f i ller t u be ve n t h ose . Re m ove f u e l t a n k

from vehicle.

INSTALLATION(1) Po sit ion f u el t a n k on t r a n sm ission ja ck . C on -

nect fuel filler tube vent hose and replace clamp.

(2) R a i s e t a n k i n t o p os it i on a n d ca r e fu ll y w o rk

f i l le r t u be in t o t a n k . A l ig h t co a t in g o f cle a n e n g in e

o il o n t h e t u be e n d m a y be u se d t o a id a sse m bly .

(3) Feed filler vent line thorough frame rail. Care-

ful not to cross lines.

(4) Ti gh t e n s t r a p b ol t s t o 9 N m (80 i n . l bs .).Remove transmission jack.

CAUTION: Ensure straps are not twisted or bentbefore or after tightening strap nuts.

(5) C o n n ect m od u le e le ct r ica l con n e ct o r. P la ce

retainer in locked position.

(6) Lubricate the fuel supply and return lines with

clean 30 weight engine oil, install the quick connect

fuel fit t ing. Refer to Tube/Fitt ing Assembly in the

Fuel Delivery section of this Group.

(7) Attach filler line to filler tube. Pull on connec-

tor to make sure of connection.

(8) Fill fuel tank, replace cap, and connect battery

negative cable.

FUEL RESERVOIR MODULE

REMOVAL

WARNING: THE FUEL RESERVOIR OF THE FUELMODULE DOES NOT EMPTY OUT WHEN THE TANKIS DRAINED. THE FUEL IN THE RESERVOIR WILL

SPILL OUT WHEN THE MODULE IS REMOVED.

(1) Disconnect negative cable from battery.

(2) D r a in f uel t a n k d r y i nt o h ol di ng t a n k or a

properly labeled diesel safety container.(3) Raise vehicle on hoist .

(4) U s e a t r a n s m is s ion ja c k t o s u pp or t t h e f u el

t a n k . R em ov e b ol t s f r om f ue l t a n k s t r a p s. L ow e r

tank slightly.(5) C le a n a r e a a r o u n d f u el r e se r voir m o du le a n d

t a n k t o k e e p d ir t a n d f o r e ig n m a t e r ia l o u t o f t a n k .

(6) D i s con n ect f ue l l in es f r om f u el m od u le b y

d ep r essin g q u ick con n e ct r e t a in er s w it h t h u m b a n d

fore fing er.

(7) S l id e m od u le e le ct r i ca l con n ect or l ock t o

unlock.

(8) Push down on connector retainer and pull con-

nector off module.

(9) U sing Special Tool 6856, r emove plast ic locknut

counterclockwise to release pump module (Fig. 45).

(10) C a r ef ul ly r em ov e m od u le a n d o-r i ng f r om

t a n k .

(11) Discard old o-ring.

INSTALLATION(1) Th or ou g h ly clea n lock n u t t h r e a d s a n d m a t in g

fule tank threa ds. U se a soap/wa ter solution. Do notuse carburetor cleaner to clean threads.

(2) Ap ply cle a n w a t e r t o t h e o -r in g se a l a n d p la ce

on t h e m a t i n g f u el t a n k t h r e a d s .(3) Wipe se a l a r e a of t a n k clea n a n d p la ce a n e w

o-ring seal in posit ion on pump.

(4) P o s it i on f ue l r es er v oi r m od u le i n t a n k w i t h

locknut.

(5) Tighten locknut to 75 Nm (55 ft. lbs.).

(6) Connect fuel lines.

(7) P lu g in e le ct r ica l con n e ct o r. S l id e con n e ct o r

lock into position.

(8) R a i se f uel t a n k , i ns t a ll b ol ts i nt o f uel t a n k

s t r a p s a n d t i gh t e n.

(9) Lower vehicle on hoist.

Fig. 44 Module Connector Retainer and Lock

Fig. 45 Fuel Reservoir Module Lock Nut Removal

XJ FUEL SYSTEM 2.5L DIESEL ENGINE 14 - 21

REMOVAL AND INSTALLATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

22/38

(10) Connect negative cable from battery.

(11) Fill fuel tank. Check for leaks.

(12) Install fuel f iller cap.

HIGH-PRESSURE LINESAll highpressure fuel lines are of the same length

and inside diameter. Correct highpressure fuel lineu s a g e a n d i n st a l l a t i on i s cr i t ica l t o s m oot h e ng in e

operation.

CAUTION: The highpressure fuel lines must beclamped securely in place in the holders. The linescannot contact each other or other components. Donot attempt to weld highpressure fuel lines or torepair lines that are damaged. Only use the recom-

mended lines when replacement of highpressurefuel line is necessary.

REMOVAL(1) Disconnect negative battery cable from battery.(2) Remove the necessary clamps holding the lines

to the engine.

(3) C lea n t h e a r e a a r o u n d e a ch f u el l in e con n e c-

t i on . D i s con n ect e a ch l in e a t t h e t op of e a ch f ue l

injector (Fig. 46).

(4) D iscon n e ct e a ch h ig h p r essu r e l in e f it t in g a t

each fuel injection pump delivery valve.

(5) Ver y ca r ef ul ly r em ov e ea c h l in e f rom t h e

engine. Note the posit ion (fir ing order) of each line

w h ile r e m ovin g. Do not bend the line whileremoving.

CAUTION: Be sure that the highpressure fuel linesare installed in the same order that they wereremoved. Prevent the injection pump delivery valve

holders from turning when removing or installinghighpressure lines from injection pump.

INSTALLATION(1) Carefully posit ion each highpressure fuel line

to the fuel injector and fuel injection pump delivery

valve holder in the correct f ir ing order. Also posit ion

each line in the correct line holder.

(2) L oosely ins ta ll t he line clamp/holder bolts.

(3) Tig h t en e a ch l ine a t t h e d e liver y va lve t o 30

Nm (22 ft . lbs.) torque.(4) Tighten ea ch line a t the fuel injector t o 30 Nm

(22 ft . lbs.) torque.

Be sure the lines are not contacting eachother or any other component.

(5) Tighten t he clamp bracket bolts to 24 Nm (18

ft . lbs.) torque.

(6) B leed a ir from t he fuel system. Refer to t he Air

Bleed Procedure section of this group.

SPECIFICATIONS

FUEL TANK CAPACITY75 Liters (20.0 Gals.)N om i na l r ef il l ca p a ci t ie s a r e s h ow n . A v a r i a t ion

may be observed from vehicle to vehicle due to man-

u f a ct u r in g t ol er a n c es , a m b i en t t e m pe ra t u r e s a n d

refill procedures.

IDLE SPEED900 rpm 25 rpm w it h e n g in e a t n o r m a l o p e r a t -

ing temperature.

FUEL INJECTOR FIRING SEQUENCE1342

FUEL SYSTEM PRESSUREPeak Injection Pressure/Fuel Injection Pump

Operating Pressure: 40,00045,000 kP a (58016526 psi).

Opening Pressure of Fuel Injector:15,00015,800 kP a (21752291 psi).

Fig. 46 Fuel Lines at Fuel Injectors

14 - 22 FUEL SYSTEM 2.5L DIESEL ENGINE XJ

REMOVAL AND INSTALLATION (Continued)

-

7/29/2019 EXJ_14A99 jeep xj service manual

23/38

FUEL INJECTION SYSTEM2.5L DIESEL ENGINE

INDEX

page page

GENERAL INFORMATIONINTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 23

DESCRIPTION AND OPERATION

AIR CONDITIONING (A/C) CONTROLSECM INPUTS . . . . . . . . . . . . . . . . . . . . . . . . . 27

AIR CONDITIONING RELAYECM OUTPUT . . . 28ASD RELAYECM INPUT . . . . . . . . . . . . . . . . . 28

BATTERY VOLTAGEPCM INPUT . . . . . . . . . . . 25BOOST / PRESSURE SENSOR . . . . . . . . . . . . . 25BRAKE SWITCHECM INPUT . . . . . . . . . . . . . . 27DATA LINK CONNECTORPCM AND ECM

INPUT AND OUTPUT . . . . . . . . . . . . . . . . . . . 27ELECTRIC VACUUM MODULATOR (EVM)

ECM OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . 30ENGINE COOLANT GAUGEPCM OUTPUT . . . 28

ENGINE COOLANT TEMPERATURE SENSORECM/PCM INPUT . . . . . . . . . . . . . . . . . . . . . . 26

ENGINE OIL PRESSURE GAUGEPCM OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . 28

ENGINE SPEED/CRANK POSITION SENSORECM INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

FIVE VOLT POWERECM/PCM OUTPUT . . . . . 28FUEL INJECTOR SENSORGROUND . . . . . . . . 26GLOW PLUG LAMPPCM OUTPUT . . . . . . . . . 28

GLOW PLUG RELAYECM OUTPUT . . . . . . . . 29GLOW PLUGS . . . . . . . . . . . . . . . . . . . . . . . . . . 30IGNITION CIRCUIT SENSEMSA/PCM INPUT . 25IGNITION CIRCUIT SENSEPCM INPUT . . . . . 26

NEEDLE MOVEMENT OR INSTRUMENTEDFIRST INJECTORECM INPUT . . . . . . . . . . . 26

POWER GROUND . . . . . . . . . . . . . . . . . . . . . . . 26POWERTRAIN CONTROL MODULE (PCM) . . . . 24

SENSOR RETURNECM/PCM INPUT(ANALOG GROUND) . . . . . . . . . . . . . . . . . . . . 25

SPEED CONTROLECM INPUT . . . . . . . . . . . . 28SPEED CONTROLPCM OUTPUTS . . . . . . . . . 28TACHOMETERPCM OUTPUT . . . . . . . . . . . . . 29TIMING SOLENOIDECM OUTPUT . . . . . . . . . . 29VEHICLE SPEED SENSORECM INPUT . . . . . 27

VEHICLE THEFT ALARM . . . . . . . . . . . . . . . . . . 25DIAGNOSIS AND TESTING

ASD RELAY TEST . . . . . . . . . . . . . . . . . . . . . . . 30BOOST / PRESSURE SENSOR . . . . . . . . . . . . . 33

DIAGNOSTIC TROUBLE CODES . . . . . . . . . . . . 34DIESEL DIAGNOSTICS . . . . . . . . . . . . . . . . . . . 30ENGINE COOLANT TEMPERATURE

SENSOR TEST . . . . . . . . . . . . . . . . . . . . . . . . 30

ENGINE SPEED SENSOR TEST . . . . . . . . . . . . 30GLOW PLUG RELAY TEST . . . . . . . . . . . . . . . . 32GLOW PLUG TEST . . . . . . . . . . . . . . . . . . . . . . 31RELAYSOPERATION/TESTING . . . . . . . . . . . . 32

VEHICLE SPEED SENSOR TEST . . . . . . . . . . . . 34REMOVAL AND INSTALLATION

A/C CLUTCH RELAY . . . . . . . . . . . . . . . . . . . . . 34ASD RELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34ENGINE COOLANT TEMPERATURE SENSOR . . 34

ENGINE SPEED SENSOR . . . . . . . . . . . . . . . . . 34GLOW PLUG RELAY . . . . . . . . . . . . . . . . . . . . . 35GLOW PLUGS . . . . . . . . . . . . . . . . . . . . . . . . . . 34POWERTRAIN CONTROL MODULE (PCM) . . . . 35

VEHICLE SPEED SENSOR . . . . . . . . . . . . . . . . 36SPECIFICATIONS

GLOW PLUG CURRENT DRAW . . . . . . . . . . . . . 37TORQUE CHART2.5L DIESEL . . . . . . . . . . . . 37

GENERAL INFORMATION

INTRODUCTIONThis section will cover components either regulated

o r co n t r o lle d by t h e EC M co n t r o lle r a n d t h e Po w e r -

t r a in C o n t r ol Mod u le (P C M). Th e f u el h e a t e r r e la y

and fuel heater are not operated by the ECM control-

ler or the PCM. These components are controlled by

the ignit ion (key) switch. All other fuel system elec-

t r ica l com p on e n t s n e ce ssa r y t o op er a t e t h e e n g in e

a r e con t r o lled or r e gu la t e d by t h e EC M con t r o ller,

w h ich in t e r f a ce s w it h t h e PC M. Re f e r t o t h e f o l lo w -

ing description for more information.

C e r t a in f u el sy st e m com p on e n t f a i lur e s m a y ca u se

a n o st a r t , o r p r e ve n t t h e e n g in e f r o m r u n n in g . I t is

im por ta n t t o kn ow t ha t t he E C M h a s a fea t ur e

where, if possible, it will ignore the failed sensor, set

a co d e r e la t e d t o t h e se n so r , a n d o p e r a t e t h e e n g in e

in a Limp Home mode. When the ECM is operating

in a L im p H om e m o d e, t h e C h e ck E n g in e L a m p o nt h e in st r u m e n t p a n e l m a y be con st a n t ly i l lum in a t e d ,

and the engine will most likely have a noticeable loss

of p er f or m a n ce . An e xa m p le of t h i s w o ul d b e a n

Accelerator Pedal Posit ion Sensor failure, and in that

s it u a t i on , t h e e ng in e w ou ld r u n a t a con s t a n t 1100

RPM, r e g a r d le ss o f t h e a ct u a l p o sit io n o f t h e p e d a l .

T h is is t h e m o st e x t r e m e o f t h e t h r e e L im p H o m e

modes.

W h e n t h e C h e ck En g in e L a m p is i l lu m in a t e d co n -

s t a n t l y w i t h t h e k e y o n a n d t h e e n g i n e r u n n i n g , i t

usually indicates a problem has been detected some-

XJ FUEL SYSTEM 2.5L DIESEL ENGINE 14 - 23

-

7/29/2019 EXJ_14A99 jeep xj service manual

24/38

w h e r e w it h in t h e f u e l sy st e m . T h e D RB I I I sca n t o o l

is t h e be st m e t h o d f o r co m m u n ica t in g w it h t h e EC M

a n d P C M t o d i a g n os e f a u l t s w i t h i n t h e s y st e m .

DESCRIPTION AND OPERATION

POWERTRAIN CONTROL MODULE (PCM)O n L H D ve h icle s, t h e EC M is m o u n t e d be h in d t h e

lo w e r I n st r u m e n t Pa n e l t o t h e r ig h t o f t h e a cce le r a -

t or ped a l (F ig . 1). O n R H D v eh icl es , t h e E C M i s