Executive Director (Petrochemicals) Indian Oil Corporation Ltd

Transcript of Executive Director (Petrochemicals) Indian Oil Corporation Ltd

Mr. Siddhartha Mitra

Executive Director (Petrochemicals) Business DevelopmentIndian Oil Corporation Ltd.New Delhi

Currently heading the Petrochemical group of Indian Oil, Mr. Mitra, hasbeen with Indian Oil for more than three decades now and has richexperience in Process & Refinery Operations.

A Chemical Engineer from Jadavpur University, Calcutta and Post Graduatein Polymer Engineering, Mr. Mitra has been associated with the BusinessDevelopment group for the past 18 years now and is one of the chiefarchitects in spreading the vast business of Indian Oil in to Petrochemicals.

His responsibilities include Conceptualization of new projects, Feasibility /Detailed feasibility study for prioritized projects, Technology selection,M&A opportunities in brownfield projects and Marketing of petrochemicalproducts.

Building on Strengths Building on Strengths --

Advantage IndianOilAdvantage IndianOil

Building on Strengths Building on Strengths --

Advantage IndianOilAdvantage IndianOil

Petrochemical Conclave - 2013

Hotel Leela Kempinski, Gurgaon

March 2013

1

Agenda

About IndianOil

IndianOil’s Vision for Petrochemicals

IndianOil in Petrochemicals

Business Scenario

Future Plans

Summary & Conclusion

2

Agenda

About IndianOil

IndianOil’s Vision for Petrochemicals

IndianOil in Petrochemicals

Business Scenario

Future Plans

Summary & Conclusion

IndianOil at a Glance

34,233

Employees

21 Companies

Group

Companies

Rs 99,183 Cr

US$ 19.49 Bn

Total

Assets

» India’s largest commercial enterprise

» Highest-ranked Indian Company in Global Fortune 500 ranking : 83rd Rank

Net Worth

Rs 4,09,957 Cr

US$ 85.56 Bn

Rs 3,955 Cr

US$ 825 Mn

Net Sales

Net Profit

1.4.2012

Rs 57,877 Cr

US $ 11.38 Bn

3

Vision

Strategic Vision & Long term Planning behind sound base and strong growth

Visionary Progress

2009

New Shared

Vision

Formulated

1999

Vision

Formulated

A integrated

energy a

strong a

national

A major, diversified, transnational, integrated

energy company, with national leadership and a

strong environment conscience, playing a

national role in oil security & public distribution

Navratna status granted in 1997

Reconstituted Board started

functioning in 1999

Maharatna status granted in May 2010Maharatna status granted in May 2010

1st Maharatna Board Meeting held in

March, 20124

•10 out of 22 refineries in the country

•65.7 MMTPA capacity ( 31%)

Group Refining

•37,000 Touch Points (52%)

•66.8 million LPG customers

Marketing

•Over 10,909 Km length

•79 MMTPA capacity

Pipelines

•Lube formulations

•Technology dev.

•Patents (215)

•Catalyst dev.

•Petchem/nano-tech initiatives

R&D

• Operates world scale Naphtha Cracker unit

• Major player in petrochemicals in India

• Export to 45 countries

Petrochemicals

• Domestic:13 Blocks NELP(11),CBM(2)

• Over Seas:9 blocks Libya (3), Iran (1), Yemen (2), Nigeria (1), Gabon (1), & Venezuela (1)

Exploration & Production

• Co-promoter in M/s PLL

• LNG at Doorstep

• CGD

• Gas infrastructure (Storage / Transportation)

Gas

•Biofuel : Captive plantation

•Wind : 37.8 MW capacity

•Nuclear : Equity partnership

• Solar: Grid-connected 5 MW PV solar power plant , Solarization of Ros (103)

Renewable

Business Space

Downstream Major foray into …. Petrochemicals, Gas, E&P Wind, Solar, Nuclear Power and

Bio-fuels 5

IndianOil in Every Part in Every Heart

6

Only oil company

operating in every

part of India

Along, Passighat, Ziro

Leh, Kargil, Lahaul Spiti

North East

Islands Andaman, Nicobar, Lakshadweep

Himalayas

Retail Outlet at Boat house Kisan Seva Kendra outlets for extending rural reach

Modern XTRAcare ROs

Serving the Nation- Kashmir to Kanyakumari - Kohima to Kutch

7

Agenda

About IndianOil

IndianOil’s Vision for Petrochemicals

IndianOil in Petrochemicals

Business Scenario

Future Plans

Summary & Conclusion

Vision Statement: Petrochemicals Business

To be a dominant petrochemical player in India withfootprints in international markets, consolidation ofexisting business and diversification into niche, specialtychemicals & elastomer product segments.

8

Emergence of Emergence of National Oil CompaniesNational Oil Companies

Growing significance of National Oil and Petrochemical Growing significance of National Oil and Petrochemical companies. companies.

−− 10 years back, they were 11% of global total in petrochemicals. 10 years back, they were 11% of global total in petrochemicals. Today they have Today they have 22% share22% share

−− Located in resource rich regions or in high demand Located in resource rich regions or in high demand countriescountries

−− Integrated, access to Integrated, access to feedstocksfeedstocks

−− Aligned to the National Vision for development of the countryAligned to the National Vision for development of the country

9

Approach: Petrochemical Business

10

Refinery Synergy and Augment

Petchem capacity

To achieve economies of scale

Pooling of feed stock from refineries

Integration with refinery for Capex/ Opex optimization

Product Expansion and Consolidation

Consolidation in commodity products

Exploit potential in niche products

Exploit potential in Specialty Products

Technology Adoption

Adoption of the state of the art

technologies

Guarded Petchemtechnology

collaboration through JV

Drivers for IndianOil’s Petrochemicals

11

Utilization of surplus naphtha and stranded propylene from refineries

+

Utilization of other potential molecules from refineries such as n-paraffins, pet coke etc

+

No specialty chemicals producers in the country. Opportunity for offering full chain of petrochemicals

+

Opportunity for import substitution

+

Petrochemicals - Competitiveness Criteria

PARAMETER KEY OBJECTIVES

Size

Location

Technology

Integration

Capture economies of scale

Access to low cost feed stocks/ deficit markets

Cost advantage/ product differentiation

Synergies with adjacent facilities

IndianOil is ideally positioned for success in Petrochemicals Market

12

13

Petrochemicals – IndianOil’s Strengths

Best in Class Technology

Technology Selected for Each Plantprovides unique strengths in productquality & envelope

Marketing Strengths

# Trained Manpower

# Nationwide Presence

# User friendly Business Processes

Technical Services Backup

#Trained TS Engineers posted Nation wide

# Immediate Attention to Customer Issues

# Onsite Trials and New Grade Development

Application Development Center

#Latest Equipment#Trained, Quality Manpower#Extensive Application Devpt Work

Infrastructure Developed

Nationwide Network of web enabled:

#Channel Partners

#Warehouses

#Consignment Stockists

IT Enabled

Online Business Environment

Transparency & Ease of Doing Business

Transportation Infrastructure#Location Specific Transportation Contracts# Service Level Agreements for Delivery#Multimodal Transport for Overseas Exports#Robust Supply Chain for Regional Exports#Third party quality control

Fully Integrated - Access to feedstocks from IndianOil’s own Refineries

Front Runner Among PSU’s in Petrochemicals – Aspirations to be a dominant Player

14

Agenda

About IndianOil

IndianOil’s Vision for Petrochemicals

IndianOil in Petrochemicals

Business Scenario

Future Plans

Summary & Conclusion

Forward Integration: Petrochemicals

Already India’s second largest petrochemical player

Value addition to downstream business through sizeable investment of over Rs 20,000 crore

•Polyethylene

•Poly-propylenePolyolefins

•PTA

•LABAromatics

Surfactant F/s

•MEG

•DEG

•TEGGlycols

Pro

du

cts

pro

file

LAB at Gujarat

(Rs. 1,112 crore)

• 120 TMTPA capacity

plant commissioned

in 2004

• 24% capacity of the

Indian industry

Px/PTA at Panipat

(Rs. 4,081 crore)

• 553 TMTPA PTA

capacity plant

commissioned in

2006

• 14.3% capacity of

the industry

Polymer/Glycol

(Naphtha Cracker at Panipat)

(Rs. 15,508 crore)

• Commissioned in 2010

• Polymer• 1250 TMTPA Capacity

• 19.2% Capacity of the Industry

• Glycol• 325 TMTPA Capacity

• 25 % Capacity of the Industry

Export: LAB to 20 countries, Polymer to 31 countries & Glycols to 9

countries 15

Indian Oil Projects: Technology Excellence

LAB at Gujarat Improved product quality due to:

- High 2-phenyl alkanes

- Lower benzene content

- Better color performance

Adoption of fixed bed catalyst based Detal Process resulting in higher product yield

PX/PTA at Panipat High PX yield due to:

- Adoption of upgraded adsorbent /catalyst

- Adoption of optimized secondary & tertiary processes

Upgraded PTA technology resulting in reduced energy consumption

Naphtha Cracker Complex at Panipat Cracker Unit

- Increased olefins yield

- Reduced specific energy consumption

Polymer Units based on solution/slurry processes resulting in:

- Lower transition time between grades

- Better stability of products

- Better stereo regularity of products

Polymer Technologies adopted targets production of all grades

16

IndianOil Petrochemicals – Promoting Investment

RefineryRefinery NCU/PX C2/C3 d/s,

PTA units

WarehouseWarehouseProcessing Processing

unitFinished Goods

End to End Infrastructure

17

PADC is the interface between Plant, Marketing & Customers

State of Art Technology Centre with sophisticated Plastic Processing & Characterisation equipments

Product Application & Development Centre - PADC

PADC

Technical Support to Customer

New ApplicationDevelopment

New GradeDevelopment

Developed and Introduced 2 High Performance Grades 1110MAS, 2120MC

+

Developed HD Grade for Tarpaulin Application produced from Swing Plant

+

USFDA Approval obtained for 19 PE/PP Grades for Food Applications and 7 for RoHE (Reduction of Heavy Substance)

+

Developed recipes for sourcing cost effective additives from domestic market for TQPP and LLDPE

+

Stringent Quality monitoring done to deliver high quality grades

+

18

Petrochemicals - Applications

15 OEM approvals obtained for Propel brand of PE and PP

19 CFTRI approval obtained for Propel brand of PE and PP

grades for general food contact application

(conforms to USFDA and BIS standards)

19

Propel– Global Presence

Exports - Petrochemicals

Angola Indonesia Mexico Peru UAE

Australia Israel Netherlands Phillipines USA

Bangladesh Italy Nigeria Portugal Vietnam

Belgium Japan Norway Qatar Yemen

China Kenya Oman Saudi Arabia Thailand

Ghana Malaysia Pakistan South Africa Turkey

South Korea Spain Sri Lanka Syria Nepal

20

21

Agenda

About IndianOil

IndianOil’s Vision for Petrochemicals

IndianOil in Petrochemicals

Business Scenario

Future Plans

Summary & Conclusion

Markets in North and East India have a lot of unfulfilled potential

Target Pan India Presence with special focus on North & East Markets

Develop Neighbouring markets – Pakistan, Nepal, Bangladesh

22

IndianOil’s Vision

23

Presence of a proximate Polymer Plant

Market Growth – Proximate to a Major Plant

IndianOil Plant will

promote growth in

Northern Region

23

31%

22%

26%

21%

Population Vs Petrochem Demand

24Source: IOCL Analysis

21%

11%47%

21% Demand

Popln

•Regional Imbalance

•Increase Manufacturing

Capacity in North & East

50% 50%

Development of Eastern India

8%

22%

32%

1980 2000 2010 2020 2040

West of the

Kanpur-

Chennai line

East of the

Kanpur-

Chennai line

Chennai

Kanpur-

IndianOil’s Paradip Refinery will be a major driver of growth in Eastern India

25

Focus – The North Indian Trading Zone

•Outlined Tear Drop Shape is home to

800 million people in 3 countries!

•Youngest Population – Av Age 25 yrs

•Low per capita consumption of

Petrochemicals – scope for growth

•Adequate supply – new plants

•Borders and Trade Opening up via

Road and Rail routes

•Future growth hotbed

27

Agenda

About IndianOil

IndianOil’s Vision for Petrochemicals

IndianOil in Petrochemicals

Business Scenario

Future Plans

Summary & Conclusion

Petrochemicals – Upcoming Projects

Indian Synthetic Rubber Ltd (ISRL)

JV PARTNERS:

IOC;

M/s Taiwan Synthetic Rubber Corp (TSRC);

M/s Marubeni, Japan

JV PARTNERS:

IOC;

M/s Taiwan Synthetic Rubber Corp (TSRC);

M/s Marubeni, Japan

Feedstock:

Styrene and Butadiene

Capacity :

120TMTPA

Expected Completion:

Q3 2013

Cap Ex:

Rs 890 Crs.

Feedstock:

Styrene and Butadiene

Capacity :

120TMTPA

Expected Completion:

Q3 2013

Cap Ex:

Rs 890 Crs.

28

Petrochemicals – Upcoming Projects

Acetic Acid Project at Baroda

JV PARTNERS:

IOC;

M/s BP Chemicals, UK

JV PARTNERS:

IOC;

M/s BP Chemicals, UK

Feedstock:

Carbon Mono-oxide ( produced from petcoke gasification) & Methanol

Capacity :

1000 TMTPA

Expected Completion:

2016-2017

Cap Ex:

Rs 7900 Crs.

Feedstock:

Carbon Mono-oxide ( produced from petcoke gasification) & Methanol

Capacity :

1000 TMTPA

Expected Completion:

2016-2017

Cap Ex:

Rs 7900 Crs.

29

Ongoing projects and Investments

30

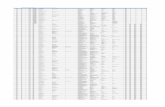

PLANT LOCATION CAPACITY EXPECTED COMPLETION

New Plants

PP Plant Paradip 680 TMT 2015-16

Acrylic Acid/Acrylates

Oxo Alcohols

Gujarat

Gujarat/Barauni

130 TMT

110 TMT

2016-17

Cumene/Phenol Haldia/Barauni 280 TMT 2016-17

Revamps

LAB Gujarat 42 TMT* 2015-16

PX/PTA Panipat 100 TMT* 2016-17

Naphtha Cracker Panipat 250 TMT* 2017-18

20701

3729135397

In C

rs

2012-13 2015-16 2012-13 2015-16

Investment (Crs)

Turnover (Crs)

*Incremental Capacities

15158**

**Apr’12-Feb’13

31

Alternate Feedstock Options for Petrochemicals

Raw C4/C5 streams from Naphtha Cracker – significant potential to reduce

cash cost of production of ethylene from Naphtha cracker by adding value to C4/C5

streams that are traditionally hydrogenated and recycled back to supplement cracker

feed

Upgradation of Pyrolysis Gasoline from Naphtha Cracker – potential to

recover styrene, mixed xylenes, toluene, naphthalenes which are petrochemical building

blocks

Petcoke/Coal/Residue Gasification & downstream based on syn gas

production

Deep Catalytic Cracking (DCC) - Selective cracking of feed stocks to maximizelight olefins, recovery of ethylene from dry gas & propylene from LPG. e.g IOCL’s

INDMAX technology

Utilization of surplus Coker naphtha – olefins production while maximizing

propylene. e.g. IOCL’s INDALIN technology

Ethane recovery Unit (for CDU, COKER Off gases) for feed to steam cracker

Propane Dehydrogenation Unit (PDH) for on-purpose propylene production

32

Agenda

About IndianOil

IndianOil’s Vision for Petrochemicals

IndianOil in Petrochemicals

Business Scenario

Future Plans

Summary & Conclusion

Summary & Conclusion

• Significant opportunity in domestic and neighboring market

• Petrochemical Projects would aim to achieve competitiveness by:

• Leveraging existing strengths in refining, marketing & supply chain

• Employing state of art technologies

• Locating plants close to low cost feedstock/ demand centres

• Building world scale capacities

• Low cost revamps/Creation of grassroots integrated complexes

• Exploiting synergies available by integration with refineries

• Emphasis on C4/C5 feed streams available from cracker

• Enter into Niche segments in polymers/specialty chemical/elastomers

• Development of Alternate sources of petrochemical feedstock like Coal/Residue

gasification, MTO/MTP, Deep Catalytic Cracking etc.

• Explore opportunities for participation in international projects with competitive

feedstock pricing and bringing the end product to India

• Sustaining leadership in petrochemical business amongst PSUs33

34