EVERNEW® VINYL MASTER RAILING AND DECK ......The EverNew® Railing and Deck Education and...

Transcript of EVERNEW® VINYL MASTER RAILING AND DECK ......The EverNew® Railing and Deck Education and...

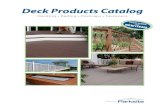

MASTER CRAFTSMANEDUCATION & DEVELOPMENT PROGRAM

EVERNEW® VINYL RAILING AND DECK SYSTEMS

The EverNew® Railing and Deck Education and Development

Workbook is a key element in CertainTeed’s Master Craftsman

education and training program. We hope that you will use it to

master the information critical to installing our vinyl railing and

deck products.

The more you know about CertainTeed railing and deck, the

better able you’ll be to recommend solutions and estimate jobs

for your customers.

After you have reviewed this workbook, you will be prepared

to take the Master Craftsman Test, which will earn you valuable

rewards. These rewards—and more importantly, the leg up

you’ll have on the competition—are not available to everyone,

just to those who have successfully passed the test.

When you pass, you will:

• Receive a personalized Certificate of Completion that you

can use to promote your professional services

• Be listed as a Master Craftsman on our website; the listing

will include your name, company name, phone number,

e-mail address, and a link to your website if you have one

Become a CertainTeed

Table of ContentsGlossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

1. The Benefits of Vinyl Railing and Deck . . . . . . . . . 1

1.1 Homeowners Turn to Vinyl . . . . . . . . . . . . . . . . . . . . 1 1.2 Quality Counts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1.3 Higher Profit Margins . . . . . . . . . . . . . . . . . . . . . . . . 2 1.4 More Referrals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Company History . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 One Man’s Dream . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2.2 CertainTeed Today. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Manufacturing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Raw Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3.2 Manufacturing Process . . . . . . . . . . . . . . . . . . . . . . . 5 3.3 Quality Counts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. Tools and Substructure . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Tools You Will Need . . . . . . . . . . . . . . . . . . . . . . . . . 7 4.2 Additional Tools Required for Specific Jobs. . . . . . . . 8 4.3 Substructure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5. EverNew® Vinyl Railing and Deck Components . . 11

5.1 Deck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 5.2 Railing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6. The EverNew® Vinyl Product Line . . . . . . . . . . . . 14

7. Installing Post Support Kits for Vinyl Railing . . . 16

7.1 Wood Post Mount Installation. . . . . . . . . . . . . . . . . 16 7.2 Concrete Post Mount Installation . . . . . . . . . . . . . . 17 7.3 Post Support Kits for Bracketed Vinyl Railing . . . . . 18

8. Installing Kingston Railing . . . . . . . . . . . . . . . . . . 20

8.1 Assembly for Flat and Column . . . . . . . . . . . . . . . . 20 8.2 Assembly for 22-1/2° and 45° . . . . . . . . . . . . . . . . . 21 8.3 Assembly for Stair . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9. Installing Oxford Railing . . . . . . . . . . . . . . . . . . . 23

9.1 Post Support Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 9.2 Multi 45° Angle – Deck Frame and Post Layout . . . . . 24 9.3 Locate and Install Post Supports . . . . . . . . . . . . . . . 25 9.4 Post Center Spacing on Diagonal. . . . . . . . . . . . . . . 25 9.5 Check the Substructure . . . . . . . . . . . . . . . . . . . . . . 25 9.6 Determine Post Height. . . . . . . . . . . . . . . . . . . . . . . 25 9.7 Install Post Supports – Wood . . . . . . . . . . . . . . . . . 26 9.8 Install Post Supports – Concrete . . . . . . . . . . . . . . . 27 9.9 Install Post Supports – In Ground. . . . . . . . . . . . . . 28 9.10 Install Railing Sections . . . . . . . . . . . . . . . . . . . . . . 29 9.11 Install EZ Set Brackets . . . . . . . . . . . . . . . . . . . . . . . 30 9.12 Install Railing Sections . . . . . . . . . . . . . . . . . . . . . . 31 9.13 Install Railing Sections at 45° Angle . . . . . . . . . . . . 32 9.14 Install Stair Railing . . . . . . . . . . . . . . . . . . . . . . . . . 32 9.15 Cut Bottom Stair Post and Post Support . . . . . . . . . 33 9.16 Cut the Rail-to-Stair Angle and Length . . . . . . . . . . 34 9.17 Assemble Stair Rail Section . . . . . . . . . . . . . . . . . . . 35 9.18 Finish Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 9.19 Corner Application . . . . . . . . . . . . . . . . . . . . . . . . . 36 9.20 Stair Application . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 9.21 Install Rail System Anchor . . . . . . . . . . . . . . . . . . . 37 9.22 Install Post Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 9.23 Bracket and Railing Installation. . . . . . . . . . . . . . . . 38

9.24 45° Bracket Installation . . . . . . . . . . . . . . . . . . . . . . . 40 9.25 22-1/2° Bracket Installation. . . . . . . . . . . . . . . . . . . . 41 9.26 Stair Bracket Installation . . . . . . . . . . . . . . . . . . . . . . 41 9.27 Column Bracket Installation . . . . . . . . . . . . . . . . . . . 42 9.28 Column Stair Bracket Installation . . . . . . . . . . . . . . . 42

10. Installing EverNew® Vinyl Decking . . . . . . . . . . . . 43

10.1 Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 10.2 Fastening to the Substructure . . . . . . . . . . . . . . . . . 44 10.3 Install Fill Pieces . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 10.4 Trim the Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 10.5 Install “C” Channel . . . . . . . . . . . . . . . . . . . . . . . . . 45 10.6 Install Fascia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

11. Installing EverNew® Structural Porch Posts and Columns . . . . . . . . . . . . . . . . . . . 47

11.1 Installing Porch Posts . . . . . . . . . . . . . . . . . . . . . . . 48 11.2 Installing Round Porch Columns . . . . . . . . . . . . . . 51 11.3 Installing Square Porch Columns . . . . . . . . . . . . . . 53 11.4 Modifying Base Trim for Porch Columns When Installing Railing System . . . . . . . . . . . . . . . 54

12. Installing Certa-Snap® Wrap 4x4 and 6x6 Post Wraps . . . . . . . . . . . . . . . . . . . . 55

12.1 Assembling Certa-Snap . . . . . . . . . . . . . . . . . . . . . . 56 12.2 Assembling Certa-Snap Trim Accessory . . . . . . . . . 56

13. Installing EverNew® Vinyl Handrail Component System . . . . . . . . . . . . . . . . . . . . . . . . 57

13.1 Stringer Layout for Handrail Transition Blends. . . . 57 13.2 Attachment to CertainTeed Vinyl Post Support System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 13.3 Attachment to CertainTeed Vinyl Sleeve-Over System . . . . . . . . . . . . . . . . . . . . 59 13.4 Attaching Handrail to Brackets . . . . . . . . . . . . . . . . 6013.5 Component Installation. . . . . . . . . . . . . . . . . . . . . . 6113.10 Suggested Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

14. Installing UnderShield® Water Diversion System. . . . . . . . . . . . . . . . . . . . . . . . . . 67

14.1 Layout Grid Bars and Clips . . . . . . . . . . . . . . . . . . . 68 14.2 Install Clips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69 14.3 Attach Grid Bars . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 14.4 Install Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 14.5 Finish Edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

15. Light/Ceiling Fan Installation. . . . . . . . . . . . . . . . 74

16. Care and Maintenance . . . . . . . . . . . . . . . . . . . . . . 75

16.1 Care and Maintenance. . . . . . . . . . . . . . . . . . . . . . . 75 16.2 Cleaning Vinyl Decking and Railing . . . . . . . . . . . . 75 16.3 Cleaning UnderShield Water Diversion System. . . . 75

17. Job Safety and Workmanship . . . . . . . . . . . . . . . . 76

17.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 17.2 Personal Protective Equipment . . . . . . . . . . . . . . . . 76 17.3 Housekeeping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

17.4 Professionalism . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

18. Taking the Master Craftsman Test . . . . . . . . . . . . 77

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

iii

ACQ Alkaline copper quaternary. The ACQ preservative

in pressure-treated wood is a copper plus quat system

that provides the same level of protection to wood as CCA

preservatives against decay, rot and termite attack (without

the use of arsenic and chromium).

Actual dimensions The exact measurements of a piece of

lumber after it has been cut, surfaced and dried.

Aluminum Channel Aluminum structural support inside

vinyl rails.

Auger A hand or machine-operated tool with a screw-like

shank for boring holes in soil.

Backfill Soil used to fill in the hole next to the post. It adds

stability to the post and keeps water away from it.

Baluster (spindle) The small vertical members of a railing

system, usually spaced at regular intervals between posts.

Beam A large horizontal framing piece, usually made of

4x or doubled 2x lumber, which usually rests on posts

and is used to support joists.

Board Any piece of lumber more than 3" wide and less than

2" wide in thickness.

Board foot The standard unit of measurement for

wood. One board foot is equal to a piece 12" x 12" x 1"

(nominal size).

Bracket cover Vinyl trim that covers rail-to-post connections

when using rail mounting brackets.

Bridging (blocking) Short pieces of lumber, usually the

same dimension as the joists, cut to fit between joists.

Blocking prevents the warping of joists and adds strength.

Building codes Community ordinances governing the

manner in which a home or other structure may be

constructed or modified. Most codes deal primarily with

fire and health concerns and have separate sections relating

to electrical, plumbing, and structural work.

Butt joint A joint formed by two pieces of material when

fastened end-to-end, end-to-face, or end-to-edge.

CCA Chromate copper arsenate. A chemical formerly used

in pressure-treated wood.

Cantilever A construction method that involves extending

the joists beyond the support beam or the support beam

beyond the posts.

Cement A powder that serves as the binding element in

concrete and mortar.

Check Lengthwise separation of wood that usually extends

across annual growth rings and commonly results from

stresses arising in wood during drying.

Composite An item manufactured out of wood and plastics.

Concrete A building and paving material made by mixing

water with sand, gravel and cement. Deck posts typically rest

on footings made of concrete.

Culling The process of selecting the best pieces of wood or

lumber for a project.

Cup Type of warp; the distortion or deviation of a board

flat-wise from a straight line across the width of the board.

Deck plank The extruded vinyl profile or composite board

that forms the base of the walking surface or stairs.

Die Tooling used for shaping or molding plastic/ PVC products.

Divider board 2" x 8" pressure treated board used to

divide a deck into two smaller areas that will accomodate

UnderShield.

Elevation drawing A view of the deck that shows the

vertical face.

End cover “C” channel vinyl profile used to finish open

ends of planks; can be cut to “L” channel for concealing ends

along walls and covering fascia ends.

End cover fastener Fastener used to attach “C” channel or

“L” channel to deck ends.

End grain The ends of wood fibers that are exposed at the

ends of boards.

Extruder Machine that converts PVC compound to molten

plastic and forces it through a die.

EZ Set bracket Aluminum bracket that fits over steel post

support to keep vinyl post in place and square on deck or

concrete pad.

Glossary

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

iv

Fascia Trim board used to finish exterior deck framing.

Fascia cover plug 3/4" vinyl plugs used in conjunction with

vinyl fascia.

Fastener Generic term for nails, screws, bolts and metal

hardware used to connect deck members.

Fill strip Vinyl strip that fits into the channels of deck

planks; covers exposed hardware.

Finish Refers to the texture and sometimes the gloss level.

Flashing Continuous galvanized or copper channel which is

used to prevent moisture from penetrating between the wall

of the house and the ledger board.

Footing A concrete pier that extends below the frost line

that bears the weight of the deck.

Frost line The maximum depth frost normally penetrates

the soil during the winter. This depth varies from area to

area depending on the climate.

Gate Framework or solid structure that swings on hinges.

Guardrail A railing placed alongside a dangerous place in

order to improve safety.

Gloss Term to describe amount of reflection or sheen

on a surface.

Grid bar 1-1/2" x 1-1/2" x 97-1/2" PVC profile which is

attached to underside of deck joist.

Handrail A rail which can be held, such as on the side

of a staircase, ramp or other walkway, and serves as a

support or guard.

Header The framing component spanning a door or window

opening in a wall. A header supports the weight above it.

HDG (hot-dipped galvanized) Twist nail, casing nail,

common nail, decking screw, etc., with thick zinc coating

and rough surface.

Joist hanger A metal connector used to join a joist to a

ledger, beam or rim joist so their top edges are flush.

Joists Structural members, usually 2x lumber, commonly

placed perpendicularly across beams to support decking boards.

Kerf The void created by the blade of a saw as it cuts

through a piece of material.

Ledger A board equal in size to the joists that anchors the

deck to the house and supports one end of the joists.

Ledger board A ledger board is a horizontal lumber beam

attached to an existing wall and used to tie in construction

elements such as porch roofs and decks. A deck ledger is

installed as part of the deck frame construction. The frame

is then attached at either end, with the deck joists butting

up to it. The last deck board against the house wall will be

attached to the ledger’s top edge in the case of a deck where

it is parallel to the joists.

Level A tool that indicates whether surfaces are horizontally

level or vertically plumb.

Linear foot A term used to refer to the length of a board or

piece of molding, in contrast to board foot.

Live load The amount of weight a deck is designed to support.

Load-bearing The carrying of loads.

Miter joint The joint formed when two members meet that

have been cut at the same angle, usually 45°.

Nominal dimension The stated size of a piece of

lumber, such as a 2x4 or a 1x12. The actual dimension

is somewhat smaller.

On center (o.c.) A point of reference for measuring from the

center of one framing member to the center of the next.

Pier A vertical piece of concrete, used as a footing to support

a post. Make your own piers by pouring concrete, or

purchase a ready-made concrete pier.

Plan drawing An overhead view of a deck, which shows

locations of footings and framing members.

Post A vertical member, usually 4x4 or 6x6, used to support

a beam or joist.

Post anchor Metal fastener designed to keep the post from

wandering and to inhibit rot by holding the post a bit above

the concrete.

Post base trim cover Trim piece used to cover post-to-

floor connection.

Post caps Vinyl cap placed on the tops of posts to provide a

finished look and prevent water penetration.

Post support kit Galvanized steel structural support post

inside vinyl post.

Posthole digger Clamshell-type tool used to dig holes for

posts.

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

v

Pressure-treating Preservatives are forced into softwood

under pressure to make the wood repel rot and decay and

withstand fungal and insect attack.

PVC Polyvinylchloride; the plastic resin used to manufacture

“vinyl” railing and deck.

Quaternary (quat) Quat acts as the co-biocide in the ACQ

preservative providing additional protection from fungi and

insect attack that copper alone would not control. Quats are

commonly used in household and industrial disinfectants

and cleaners and are biodegradable in soil.

Racking The tendency of stair balusters to come closer

together as the stairs rise.

Rail A horizontal member that is placed between posts and

used for support and as a barrier.

Rail mount bracket Aluminum brackets used to fasten rails

directly to posts or other structural surface.

Rail plate Stainless steel screw flange used to secure top rail

inside post-to-post support pipe.

Rail post A vertical structural support for the railing,

sometimes also supporting the deck itself and extending

down to a footing.

Rim joist The outside joist, to which the majority of joists

are attached at right angles.

Ring-shank nail A nail with grooves and ridges around the

shank to prevent the nail from popping out of the wood as the

wood contracts and expands because of changes in moisture

and temperatures; also called an annular grooved nail.

Rip To saw lumber or sheet goods parallel to its grain pattern.

Rise The height of a step.

Riser A board attached to the vertical cut surface of a stair

stringer to cover up the gap between treads and to provide

additional tread support.

Routing template Guide for field routing that requires hole

positions other than standard.

Run The length of a step.

Sister joist A new joist which is placed next to and attached

to a damaged floor joist.

Site plan A map showing the location of a new building

project on a piece of property.

Slope The degree of angle of an incline; measured in inches

of rise per horizontal foot.

Span The distance covered by a beam, joist or decking

board between supporting structures.

Stringer A diagonal board used to support treads and risers

on a stairway. Stringers usually are made of 2x12s.

Substructure Unexposed framing of deck structure.

Toenail To drive a nail at an angle to hold together two

pieces of material.

Tread In a staircase, the horizontal platform you step on.

Treated lumber Lumber that has been pressure-treated with

an approved preservative under appropriate standards of the

American Wood Preservers’ Association (AWPA) or American

Society for Testing and Materials (ASTM).

UnderShield® clip PVC clip attached to grid bar. Clips

are used for the installation of UnderShield panels and to

achieve pitch.

UnderShield® clip pitch gauge Notched side of the

grid clip.

UnderShield® starter/end clip When clip is installed with

slotted end of clip facing down.

Weathering The breakdown of a surface caused by the

effects of sunlight (UV radiation), water and abrasion.

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

vi

1. The Benefits of Vinyl Railing and Deck

The variety of wood and wood composites used for railing

and deck is wider than it’s ever been. So why should you

consider adding yet another type of railing and deck to

your already wide product offering? Because homeowners

demand it. Busy, over-scheduled homeowners and their

children want a place to kick back and relax, a place to

spend time together. So adding railing and deck is more

than a building project — it’s a lifestyle decision.

Right now, decking is a $6 billion industry, and today’s

homeowners seem determined to keep it growing. Although

25 percent of all the homes in the United States have decks,

more than 3 million additional decks are built, replaced or

repaired every year. In fact, building a deck is one of the

most popular remodeling projects homeowners undertake.

1.1 Homeowners Turn to Vinyl

Though relatively new, vinyl railing and deck are becoming

the preferred alternative to wood for six main reasons:

1. Homeowners are questioning the safety of

pressure-treated lumber. Their children play on treated

decks, and parents worry about the toxicity of possible

by-products as treated wood ages. Also, there is

concern about the safety of the sealants and stains used

to maintain wood building products.

2. Decreasing supply and increased transportation costs

have dramatically increased the prices for natural

lumbers like cedar and redwood. Prices for exotic

woods like mahogany have become astronomical.

3. Homeowners are making purchase decisions that

reflect their concerns about the environment and the

ecological cost of harvesting trees for wood railing

and decks. Vinyl offers an alternative to the dwindling

supply of quality wood.

4. Vinyl railing and decks are virtually maintenance

free. Homeowners don’t want to sand and stain or

paint wood decks annually. They continue to choose

modern, maintenance-free building products over more

traditional materials. Thus, they turn to vinyl because

it never needs sealing, staining or painting. It is safe for

their children and pets because it doesn’t splinter, and

there is no exposed hardware.

5. Vinyl railing and deck increases the value of their

property and maintains the added value over time.

6. Vinyl railing and deck complements vinyl siding.

1.2 Quality Counts

Homeowners are willing to pay more for quality,

and CertainTeed building products are known for their high

quality. Our 25 years of experience extruding vinyl siding

and fence have made CertainTeed a leader in vinyl building

products and services. We produce a competitively priced

vinyl railing and deck system while maintaining customer

service and dealer support that are recognized by builders,

remodelers and homeowners as the best in the industry.

While wood decks are not warranted and typically need

to be replaced every 10 to 15 years or sooner, CertainTeed

vinyl railing and deck systems are protected by a lifetime

limited transferable warranty and our exclusive 5-year

SureStart™ material and labor warranty.

Finally, over the life of the deck, vinyl is less expensive

than wood (see table on page 2).

Can you sell a product that, on the surface, looks pricier

than wood? Certainly — once you demonstrate the

significantly less maintenance and longer life of CertainTeed

vinyl railing and deck.

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

1

1.3 Higher Profit Margins

For you, recommending vinyl railing and deck makes good

business sense. First, vinyl is recognized as a premium

building material. You won’t be competing on price with the

low-end weekend remodelers, and you can position your

business as the modern, professional alternative to builders

and remodelers who offer only wood railing and decks.

Second, in markets where severe weather — extreme heat

and cold, salt air, high humidity, mold, mildew and termites

— significantly reduces the life of wood products, home

builders and owners are looking for a long-lasting, low-

maintenance alternative to wood. Vinyl railing and decking

is that durable alternative.

Finally, CertainTeed vinyl railing and deck let you spend

less time on installation. Profits will improve because

you won’t:

• Spend time or money picking through warped,

split and knotted wood.

• Invest time or money in staining and sealing

or painting.

• Be called back to replace checked, cracked or warped

rails or boards.

1.4 More Referrals

CertainTeed vinyl railing and deck is an attention-getter,

even after years of use. It resists mildew better than wood.

Most important, it keeps its like-new appearance for years.

You can be assured of continued referrals, especially when

homeowners experience the joys of a product that:

• Does not splinter

• Stays cool to the touch

• Requires only occasional cleaning with water

and mild detergent

• Will not rot or decay

• Is impervious to termites and other

wood-boring insects

• Is backed by CertainTeed’s exclusive 5-year

SureStart™ labor and material warranty.

Total Installed Cost* of Wood Deck vs. Vinyl Deck

PRESSURE-TREATED YELLOW PINE CERTAINTEED VINYL

INSTALLATION:

Deck surface, substructure and labor $ 3,500 $ 4,600

Stain/sealant $ 200 N/A

Maintenance x 10 years: $ 2,000 N/A

Staining/sealant $ 250 N/A

Material replacement $ 500 N/A

Labor

TOTAL COST OF OWNERSHIP $ 6,450 $ 4,600

*Prices will vary by geography and market conditions

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

2

2. Company History

Quality Made Certain … Satisfaction Guaranteed. More

than just a slogan, it’s our name. And since 1904, when

the General Roofing Manufacturing Company began

producing asphalt roofing materials, quality products

and satisfied customers have been the hallmark of

CertainTeed Corporation.

2.1 One Man’s Dream

First established in 1904 by George M. Brown, the

General Roofing and Manufacturing Company was

created to produce a fire-resistant and less expensive

alternative to wood shingles. In 1917, the company

changed its name to CertainTeed to reflect its expanding

product line and Brown’s business philosophy. In 1923,

it began manufacturing gypsum wallboard for new home

construction.

During World War II, CertainTeed lent its extensive

management and production expertise to the war effort,

but in 1946 began investigating the potential of a new

product—fiber glass insulation. Within 10 years, CertainTeed

was supplying roofing materials, gypsum, and fiber glass

insulation to the booming construction industry and had

established itself as a leader in the country’s effort to supply

affordable housing for former GIs and their families.

In 1965, CertainTeed took its first step into PVC. Its later

acquisition of Plains Plastic made CertainTeed a major

manufacturer of plastic pipe. In 1969, the company began

offering solid vinyl (PVC) siding to builders and contractors.

The development of decking and railing began in 1996 with

the acquisition of Bufftech® vinyl fence and the development

of EverNew® vinyl railing and deck. In 2006, CertainTeed

added Panorama® Composite Railing to its product portfolio.

Today, CertainTeed is North America’s leading brand of

exterior and interior building products, including roofing,

siding, fence, decking, railing, trim, insulation, gypsum

and ceilings.

2.2 CertainTeed Today

CertainTeed is part of the worldwide Saint-Gobain

organization. Saint-Gobain is a global manufacturer and

distributor of flat glass, building products and high-

performance materials. With more than 1,000 subsidiaries

in 67 countries, it is the world’s largest building materials

company and a leading distributor of building products.

Founded in 1665 and headquartered in Paris, France,

Saint-Gobain had worldwide sales of $43.3 billion in 2016

and employs 170,000 people worldwide.

www.saint-gobain.com

CertainTeed is part of the Construction Products division of

Saint-Gobain. This division enjoys a leading position in the

United States’ home construction market. All across the U.S.

and Canada, CertainTeed also offers a full line of outdoor

living product solutions for individual homes including

roofing shingles, vinyl siding, PVC trim, fence, decking,

railing and housewrap. CertainTeed also offers top-of-the-

line interior products, including insulation, gypsum and

ceilings. All of these products are renowned for their ease of

use, nearly maintenance-free materials, weather resistance

and smart appearance.

The Outdoor Living division, which supplies EverNew

vinyl railing and deck, is just one of a number of operating

groups that make up CertainTeed Corporation. CertainTeed

roofing and vinyl building products are consistently rated at

the top for quality and performance by consumer and trade

publications alike.

From its humble beginnings in East St. Louis, through

two World Wars and the Great Depression, CertainTeed

has become one of the nation’s largest and most respected

manufacturers of building products.

Today, CertainTeed celebrates more than 100 years of

leading the building industry with creative advancements,

insightful solutions and unparalleled dedication to service.

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

3

3.1 Raw Materials

The quality you’ve come to expect from CertainTeed is

built in at the factory. From the time raw materials are

manufactured until finished product is shipped to our

customers, we control, inspect and test throughout every

step of the manufacturing process. As part of ongoing

quality assurance, we work with all our suppliers to develop

tight specifications and test for their consistency. The result

is a line of vinyl building products you can count on for

superb appearance, durability and ease of installation —

every time. Though our railing, deck and accessories are

referred to simply as “vinyl,” vinyl railing and deck are

actually a precise blend of carefully tested and controlled

materials, all of which contribute to their performance,

durability and appearance.

Polyvinyl Chloride Resin

Polyvinyl chloride resin gives vinyl its name. PVC, which

starts as a powder, is a thermoplastic, which means

that when it is exposed to high temperatures in the

manufacturing process, the compound can be shaped,

embossed and formed. Eighty percent of the weight of

vinyl railing, deck and accessories is PVC resin. The

remaining 20 percent is the critical micro-ingredients that

impart the distinctive color, opacity, gloss, texture, impact

resistance, flexibility and durability to the railing and deck

and accessories.

Color Technology

Color is carefully manufactured to meet our precise

specifications. We select and test the pigment to

verify that it is stable and has excellent weathering

properties. To verify consistency, spectrophotometers

carefully measure the color.

TiO2

Titanium dioxide is a critical additive in vinyl because it

protects PVC from potentially harmful UV rays. It acts to

prevent the sun from degrading the resin. A manufacturer

of low-cost vinyl products may attempt to use less

TiO2 because this additive is expensive. Without TiO

2,

vinyl products could become cracked and brittle due to

weathering. Unsuspecting customers will not notice the

weathering for a few years.

ASA

Acrylic-Styrene-Acylonitrile is specially engineered to

retain its color and mechanical properties under long-

term exposure to ultraviolet light, moisture and heat.

This is particularly important with darker shades, which

tend to weather more quickly than lighter tones. The ASA

formulation delivers a rich, long-lasting color that will resist

fading for years to come.

Calcium Stearate

CertainTeed uses only fused granular calcium stearate.

It helps the various ingredients in the PVC compound

blend into a uniform, stable dispersion and aids in the

manufacturing process. Its use particularly improves the

fusion of the PVC compound and produces a uniform finish

that resists cracking.

Waxes

Waxes prevent the PVC compound from sticking to the

metal surfaces in the extrusion process. Wax also affects

the gloss on the finished product, and it is always used in

precise amounts to ensure a consistent, reproducible finish

from batch to batch.

Impact Modifiers

Impact modifiers do just that. They make vinyl railing and

deck more resistant to the dings and dents that routinely

occur during installation and use. Carefully selected and

blended impact modifiers help vinyl railing, deck and

accessories withstand normal installation and use.

Stabilizers

Stabilizers are used to protect the PVC compound from

degrading as it is heated and subjected to pressure. This

keeps the plastic flexible. Also, additional UV

stabilizers protect the color from oxidizing and fading.

3. Manufacturing

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

4

3.2 Manufacturing Processes

Technical excellence, processing expertise, and an

unwavering commitment to quality characterize the

equipment, processes, and personnel at our vinyl

railing and deck manufacturing plants. Since the 1960s,

CertainTeed has been developing innovative products

and processes to improve the look and durability of our

polyvinyl chloride.

At the same time, tried and true manufacturing

methods are tested and re-tested to ensure that you

consistently receive the highest quality product.

Blending

The manufacturing process begins as resin is unloaded

from railroad cars through an air-conveying system

into huge silos, then is conveyed to a state-of-the-art

computerized blending system where TiO2 and other

micro-ingredients are added to create the processing

compound. This precise measuring of ingredients and

uniform blending under proper heat conditions are critical

for the production of uniform, high-quality products. After

blending, the compound is conveyed to the extrusion line

where it is carefully metered so a consistent amount enters

the extruder.

Extrusion

Basically, extrusion is a process in which a thermoplastic

resin (one that softens when heated and hardens when

cooled) is pushed through a heated barrel and die by two

large, precisely tooled screws. As they turn, the screws

knead and thoroughly mix the PVC compound. Both

the screws and the barrel of the extruder are heated,

which melts the resin and makes it easier to mix and

push. The heat (300°F to 400°F) also accelerates the

physical reaction (fusion) between the PVC and the micro-

ingredients in the compound.

All vinyl railing and deck products are extruded,

but CertainTeed was the first to extrude all its products

with twin screw extruders. Twin-screw extrusion is

preferable to single-screw extrusion because it heats and

distributes material more evenly, resulting in a product with

better physical properties. As the PVC compound is forced

ahead of the rotating screws, the very tight tolerances in the

double barrel promote complete fusion of the ingredients.

Color concentrate is added at the extruder, a technique that

produces rich, durable, color in every piece of

railing and deck.

Co-extrusion

Co-extrusion is the joining of two flows of molten PVC

compound from two extruders in a single die to produce a

single profile made of two layers of material: substrate and

capstock. Co-extrusion allows us to concentrate the most

important, expensive micro-ingredients in the capstock,

which acts as a shield protecting the extrusion from the

dangers of UV light.

Water Tank

The vinyl profile enters a water tank immediately after

vacuum sizing. Once the hot profile is in the cooling

tank, the temperature quickly drops and the final shape

thermally sets.

3.3 Quality Control

Before, during and after they are manufactured, CertainTeed

vinyl railing and deck products are tested against a set of

manufacturing and product specifications. These specs

define the minimums, maximums and tolerances that a

raw material or sample of a finished product must meet to

satisfy either our standards, ASTM requirements, or local

and national building codes. While some of these tests don’t

appear to directly relate to the conditions the railing and

deck are exposed to during installation and use, they all

contribute to the quality and durability of the final product.

Raw Material Testing

Each lot of raw material that comes into our facilities must

include a certificate of analysis from the vendor as part of

an ongoing quality assurance plan. CertainTeed quality

assurance verifies that our suppliers maintain consistently

high standards and that minor variations in materials do

not affect the appearance or quality of our products. While

the raw data that these tests generate are of little value

to you or your customers, we mention them because it’s

worth noting that top-quality vinyl building products can

be produced only from the highest quality raw materials.

Following is just a sampling of the raw material properties

that are certified on a regular basis.

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

5

Raw Material Properties

color specific gravity

porosity oil absorption

trace elements refractive index

Izod impact percent stearic acid

particle size flow time

pH grit

contaminants melt viscosity

percent ash percent moisture

density viscosity

weight resistance (ohms)

hardness congealing point

Y-brightness percent insolubles

Product Testing

Finished products are also subjected to a series of tests to

evaluate how well they meet specifications. The first tests

occur during the manufacturing process. The materials

that go into each product are continually scrutinized;

operators monitor mixes, line speeds and other process

variables to ensue optimal finished quality. Resin and all

micro-ingredients are checked for weight even as they draw

samples for quality assurance testing.

At the extruder, there are more quality assurance checks. In

addition to equipment checks, operators verify:

size (H, W, Radii) wall thickness

bow squareness

weight gloss color

length routing cut outs

The final product check includes:

factory codes

labels

packs per pallet

quality assurance acceptance stamp

decks, rails, posts and accessories per pack

Physical Property Testing

• Length, width, and radii:

Posts, rails, balusters and planks that are not uniformly

sized cannot be installed properly, even by the best

of remodelers. For this reason, all vinyl posts, rails,

balusters and planks are held to close tolerances.

• Expansion and contraction:

As outside temperatures change, all vinyl rails expand

and contract. In the laboratory, vinyl rails are tested for

expansion and contraction by alternatively exposing a rail

to hot and cold environments and measuring the changes

in length throughout the test.

• Impact:

The ability of the planks and rails to resist impact is

measured in an Izod Impact test (ASTM D256). From a

specified height, a test instrument dropsa weight onto an

area of the product. When the vinyl fails, it will either

crack, split or shatter. Our vinyl planks, rails and posts

are manufactured to withstand 5.0 ft-lbs/in. notch at 23°

and 2.0 ft-lbs/in. notch at 0°. Profile products containing

internal webs are tested per ASTM D4226, which requires

a minimum brittle impact failure of 1.5 in-lb/mil.

Impact resistance also affects compliance with

international code requirements for guardrails. When

properly installed, CertainTeed post supports, posts and

rails meet ICC guardrail requirements.

• Tensile (ductile) strength:

Tensile strength is the measure of a material’s ability to

“stretch.” It’s vinyl’s ability to “bounce back” when it is hit

with something or put under tension. CertainTeed vinyl

posts, rails, balusters and planks will withstand 6500 psi

before they fail to “bounce back” when tested according

to ASTM D638.

• Slip resistance:

Slip resistance for deck plank is measured according

to two tests, the English Tester and the Brungraber

Tester. Dry planks measure 0.86 (English) and 0.64

(Brungraber). A 0.50 rating, which is significantly less

than the CertainTeed test results, is considered slip

resistant according to the standard in the Americans with

Disabilities Act (ADA).

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

6

4. Tools and Substructure

Installing vinyl railing and deck is predictable and easy if

you have the right tools and install the railing and deck on

a properly constructed substructure.

Helpful Hints

Read these instructions thoroughly before beginning

the assembly.

• Use carbide-tipped multi-purpose blade for cutting.

• Do not lay vinyl components on abrasive surfaces.

• If any components are missing or defective, please call

us at 800-233-8990.

Tips

• Make sure you have all the pieces you need to complete

the job.

• It is the responsibility of the owner to meet or exceed all

code and safety requirements and to obtain all required

building permits. These instructions are only a guide

and may not address every circumstance. The railing

and deck installer should determine and implement

appropriate installation techniques for each situation.

Fire Information

Rigid vinyl railing and deck are made from organic

materials that will not burn on their own but melt or

burn when exposed to a significant source of flame or

heat. Consequently, owners and installers should take a

few simple steps to protect vinyl building materials from

fire. Building owners, occupants and outside maintenance

personnel should always take normal precaution to keep

sources of fire, such as barbecues, and combustible

materials, like dry leaves, mulch and trash, away from

vinyl railing and deck.

Important

Always wear safety glasses when cutting or routing

vinyl products.

4.1 Tools Required for All Installations

• Chop/mitre saw (with carbide-tipped, multi-purpose

blade or non-ferrous blade)

• Power drill and bits

• Tape measure

• Pencil

• Level

• Safety glasses and equipment (as identified by tool

manufacturers)

• #2 square drive

• Phillips screwdriver or bit

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

7

4.2 Additional Tools Required for Specific Jobs

Certa-Snap® Post Wrap

• Hammer

• Siding snips

Gates

• 1/8" drill bit

• 3/16" drill bit

• 1/4" drill bit

• 5/32" drill bit

• 11/64" drill bit

• 7/16" wrench

• #3 square drive bit

Handrail Component System

• 3/8" masonry drill bit (for concrete installation)

• 3/4" drill bit

• Angle finder

• Quick-clamps

• Adhesive

• Recommended adhesives:

Aluminum bonding-

Loctite® Metal/Concrete Epoxy™

Gorilla™ Epoxy–Impact Tough®

J-B Weld®-2-Part Epoxy

Loctite® Extra Time Epoxy

Mount Post Support Wood Surface

• 2" x 6" or 2" x 8" blocking

• Wood screws to attach blocking to deck

• 3/8" drill bit

• 1/8" drill bit

• 1/2" wrench or socket

Porch Columns

• Saber saw with a fine-tooth blade

• Hammer drill with 1/4" and 1/2" drill bits

• T-square

UnderShield® Water Diversion

• Gloves

• Step ladder

• Snips

• Utility knife

• Chalk line

• 12" speed square

• Vinyl snap lock punch

• Cordless drill/driver

• 1-inch “J” channel

• Flashing

• Gutter and Downspout

• Fascia boards

Vinyl Decking and Oxford T-Rail

• 2" hole saw

• Circular saw

• Drop cloth

• Screwdrivers (Phillips and flat-bladed)

• Wood clamps

• Wrenches (sockets)

3/4" (post support)

7/16" (EZ Set bracket)

3/8" (rail plate)

• Bevel guide (optional)

• Chalk line (optional)

• File (optional)

• Jigsaw/hacksaw (optional)

• Rotary hammer drill (optional)

• Utility knife (optional).

TIP: Stainless steel fasteners are recommended to prevent future rust streaking.

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

8

4.3 Substructure

The substructure required for CertainTeed vinyl railing

and deck is the same as for a wood deck. It should be solid

and, except as where noted below, built on 16" centers.

Avoid triple joisting the outer rim whenever possible. The

substructure should be substantial and built with high-

quality lumber. Always check applicable building codes

before you begin.

If the vinyl deck is a replacement for a previously installed

deck, examine the existing substructure closely. Check that

the deck is level and square, and inspect the lumber for

rotting and water damage. Replace rotted or suspect lumber

as needed.

CertainTeed vinyl deck planks have the strength and ability to

span 24" joists, but we recommend that joists be spaced 16"

o.c. for optimal performance. Posts must be installed 120" on

center maximum, so once the deck is laid out, you may have

to bridge some joists. Bridging will provide a secure surface for

mounting post supports.

If you are planning to install planks diagonally, joists

must be spaced on 12" centers maximum. Plan your

substructure accordingly.

Cantilever the deck substructure off the wood posts or

beams because wood posts at the corners of the deck will

interfere with the placement of the railing posts. Wood

post supports used in the railing system are designed with

an “L”-shaped bracket that attaches to the substructure in

two directions. Substructure posts along the perimeter of

the deck may interfere with the placement of that bracket.

When planning stairs, ensure that the top step is lower than

the deck surface.

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

9

Stringer

120" or less

between center points

of post supports.

Joist

Finished

Riser

Rimboard

Bridging

To determine maximum stair

post support spacing,

lay a rail on

the stringer.

CertainTeed

Wood PostSupport System

CertainTeed railing and deck must be installed according to our

written instructions. We strongly recommend that before starting

a job, you review our installation instructions, as PVC is different

from wood or other building materials. Consult our Installation

Support Department for applications not covered in this manual.

Helpful Hints

Tips

Read these instructions thoroughly before beginning

the assembly.

• Use carbide-tipped multi-purpose blade for cutting.

• Do not lay vinyl components on abrasive surfaces.

• If any components are missing or defective, please

call us at 800-233-8990.

• Make sure you have all the pieces you need to

complete the job.

• It is the responsibility of the owner to meet or

exceed all code and safety requirements and

to obtain all required building permits. These

instructions are only a guide and may not address

every circumstance. The railing and deck installer

should determine and implement appropriate

installation techniques for each situation.

Fire Information

Rigid vinyl railing and deck are made from organic

materials that will not burn on their own but melt or

burn when exposed to a significant source of flame or

heat. Consequently, owners and installers should take

a few simple steps to protect vinyl building materials

from fire. Building owners, occupants and outside

maintenance personnel should always take normal

precaution to keep sources of fire, such as barbecues,

and combustible materials, like dry leaves, mulch and

trash, away from vinyl railing and deck.

Important

Always wear safety glasses when cutting or routing vinyl

products.

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

10

5. EverNew® Vinyl Railing and Deck Components

Before you order materials, determine what you will need.

5.1 Deck

Deck Planks

Decking: The vinyl deck is available

in three colors (white, almond and gray)

and three lengths (actual length

is approximately 1" over stated

measurement).

1-1/2" x 5-1/2" x 12'

1-1/2" x 5-1/2" x 16'

1-1/2" x 5-1/2" x 20'

Fill Piece

Fill Pieces: Snap-in fill pieces hide

fasteners and are available in 12',

16' and 20' lengths, in matching

colors. Use two pieces per deck

plank length.

Fascia Board with Cover Plug

Fascia: Fascia board is used to finish

stairs and framing. It is available in

matching colors and in three sizes.

7/8" x 6" x 96"

7/8" x 3" x 96"

7/8" x 1-1/2" x 96"

Matching 3/4" vinyl plugs cover exposed hardware.

End Cover with Fasteners

End Cover: “C” channel vinyl end covers

are used to finish deck edges. Along

walls or to cover corners of fascia, end

cover is cut to “L” channel. End cover

is available in matching colors; it is

1-3/4" x 1-1/2" x 12'.

5.2 Railing

2.1 Railing Systems

Rails: There are two top rail styles to choose from: Oxford

(“T” rail top/2x4 bottom) and Kingston (Classic Top Round

top and bottom). All rails are reinforced with aluminum

channels and are available in 6', 8' and 10' lengths. Rails

are pre-routed for either flat, stair, or in some styles, steep

stair. On stair and steep stair rails, the spacing and holes for

balusters are wider to account for racking.

The Oxford and Kingston systems are available

in white, almond, clay, black, rustic rose and

warm spice.

Balusters: Balusters for the Oxford system

are available in two styles, Square and

Colonial (white and almond only), measuring

1-1/4" x 1-1/4".

Balusters for the Kingston systemare offered in

two styles, Square and Traditional (white and

almond only), measuring 1-1/2" x 1-1/2". To

account for racking, the balusters for stair rails

are typically shorter than flat railing balusters.

BALUSTER LENGTHS FLAT STAIR

1-1/4" x 1-1/4" x 3' Square or Colonial 33-1/4" 31-3/4"

1-1/4" x 1-1/4" x 3-1/2' Square or Colonial 39-1/4" 37-3/4"

1-1/2" x 1-1/2" x 3' Traditional 33-1/4" 33-1/4"

1-1/2" x 1-1/2" x 3' Square 33-1/4" 32-1/2"

1-1/2" x 1-1/2" x 3-1/2' Square 39-1/4" 39-1/2"

You can cut flat railing balusters down to make stair railing balusters. Colonial

balusters must be cut equally from measuring ends. Traditional balusters

do not require modification.

Oxford Rail

Kingston Rail

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

11

2.2 Posts

Posts: CertainTeed vinyl

posts are available in two styles,

Square and Newel, and two

heights, 38" and 44", as well

as stair lengths. Square posts

are available in white, almond, clay,

black, rustic rose and warm spice.

Newel posts, which look like a

traditional turned newel

post, are available in white.

After you choose a style, it is important that you decide

in advance if the railing will be bracket mounted or a

routed post system (Oxford only), how many steps you

will be building, and the number of railing sections that

will be needed.

If you will be installing the railing to a porch post,

existing post, column or wall, you should plan to use

rail mounting brackets.

2.3 Mounting Options

Rail Mounting Brackets: There are a variety of rail mounting

brackets available from CertainTeed. These aluminum brackets

should not be attached directly to ACQ treated wood.

For Oxford: Aluminum brackets mount directly to the post

and are then fastened to the rail’s aluminum channel with

screws to provide a secure metal-to-metal rail-to-post

connection. The aluminum bracket is concealed by a vinyl

cover designed for the specific application — flat, stair,

column or 45°. Steep stair rail should not be installed with

rail mounting brackets.

For Kingston: Aluminum brackets mount directly to the

post and are then fastened to the rail’s aluminum channel

with screws to provide a secure metal-to-metal rail-to-post

connection. The aluminum bracket is concealed by a vinyl

cover designed for the specific application — flat, stair,

column, 45° and 22-1/2°.

Blank Posts: Blank posts are available in two styles, Newel

(38" and 44") and Square (38", 44", 48" and 51-1/2").

Square blank posts can be used to sleeve over wood posts

to create a complete maintenance-free system where the

rails are installed using rail mounting brackets.

Routed Post Systems: The routed system is only available

for the Oxford railing style — in both 3' and 3-1/2' — flat

and stair applications. The routed post system provides a

secure, internal metal-to-metalrail-to-post connection using

a CertainTeed post support kit system.

NewelSquare

Use “I” post and router template.

B

C

D

F

G

H

I

E

A

End Post Line Post Corner Post

Flat to Stair Corner Left Flat to Stair Corner Right Line Post Stair

45° Line Post Flat to Stair Line Post End Post Stair

(also available for

“inground” installation)

HG

D E F

CBA

I

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

12

There are nine routed post types to choose from, so we

suggest you sketch the deck you are planning to install

before you order materials. Note that stair posts are routed

to accept rails at a standard 32° angle (i.e., openings are

taller than for flat posts). If using steep stair rails, you

will need to field route your posts to accommodate

additional rack.

Post Support Kits: CertainTeed offers a variety of post support

kits for most applications. Refer to product catalog for

complete offering.

2.4 Finishing Accessories

Post Caps: Post caps are placed on top of posts to provide a

finished look. There are five post cap styles to choose from

for the Square posts and two for the Newel posts. All can be

secured using PVC glue or clear silicone adhesive.

Post Trim: CertainTeed supplies vinyl trim pieces for

posts and rails. These pieces give the deck and railing a

finished look.

Decorative Post Covers: A non-

structural porch post cover can

be fitted over conventional load-

bearing porch supports to provide

an all-vinyl system. Porch post covers are available for 4x4

and 5x5 posts up to 107" and 6x6 posts up to 120".

Structural Porch Posts: CertainTeed offers two styles of

structural porch posts: Colonial and Square. Reinforced

with an aluminum load-bearing support system, the vinyl

structural porch posts can be used alone or with any

CertainTeed railing system. Tie-down kits and post trims

are included.

Structural Porch Columns: CertainTeed’s structural porch

columns are available in Round tapered, Round non-

tapered and Square styles. Load bearing up to 18,000 lbs.,

the vinyl porch columns include mounting plates for easy

installation. Cap and base trim is sold separately.

PORCH POST AND COLUMN STYLES SIZE

Colonial Porch Posts 4" x 4" x 108", 5" x 5" x 108"

Square Porch Post 5" x 5" x 108"

Round Tapered Columns 8" – 108" length

10" – 108" and 120" lengths

Round Non-tapered Column 8" – 108" length

Square Column 8" – 108" length

Gothic CapFlat Cap External

Flat Cap Internal

Ball CapNew England King Newel Cap

Queen Newel Cap

Two Piece One Piece

Col

onia

l Pos

t 4

" x

4"

x 1

08

"

Col

onia

l Pos

t 5

" x

5"

x 1

08

"

Squ

are

Pos

t 5

" x

5"

x 1

08

"

Rou

nd T

aper

ed C

olum

n 8

" &

10

"

Rou

nd N

on-t

aper

ed C

olum

n 8

"

Squ

are

Col

umn

8"

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

13

6. The EverNew® Vinyl Product Line

Oxford Railing

• Popular T-rail top rail and 2x4 bottom rail system

• Durable, heavy-duty design

• Safe and secure metal-to-wood (bracketed) and metal-to-metal (routed) rail-to-post connection

• Corrosion-resistant stainless steel screws included

• Decorative glass balusters also available (42" height only)

• Available in two heights and three lengths

• Independent tested as designated in report CCRR-0187 (white, almond, clay, warm spice and rustic rose)

Decking

• Virtually maintenance free

• Easy to clean, non-porous surface

• UV protected for long-term durability and superior color retention

• Cuts, fastens and handles easier than wood

• Safe, slip-resistant tread — ideal for docks

• Available in 12', 16' and 20' lengths

• Independent tested as designated in report CCRR-0219

UnderShield® Water Diversion System

• Low-maintenance water diversion system for new or existing decks

• Easy-to-install adjustable grid system

• High-quality 6" x 16' vinyl panels

• Concealed clip system

• Stainless steel hardware provides security and lasting performance

• Choice of two panel styles and three colors

Kingston Railing

• Classic bread-loaf rail design for top and bottom rails

• Premium features at an affordable price

• Aluminum rail mount brackets provide a safe and secure metal-to-metal rail-to-post connection

• Unique molded vinyl bracket cover designed for flat, stair, column, 45° and 22-1/2° applications

• Brackets come complete with corrosion-resistant stainless steel screws for long-lasting security

• Available in two heights and three lengths

• Independent tested as designated in report CCRR-0211 (white, almond, clay, warm spice and rustic rose)

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

14

Porch Posts

• Pivoting mounting plate provides safe and easy installation

• Aluminum reinforced for rigidity and strength

• Load bearing up to 5,000 lbs.

• Colonial and square styles

• 108" length

• Standard tie-down connection eliminates the need for separate hurricane tie-down kit

Porch Columns

• Aluminum insert provides outstanding support

• Load bearing up to 18,000 lbs.

• Round tapered, round non-tapered and square styles

• 108" and 120" lengths

• Includes mounting plate and hardware

• Cap and base trim sold separately

Handrail System

• Complies with ADA (Americans with Disabilities Act)

• 1-1/2" diameter gripping area

• Continuous handrail runs

• Safe for stair and ramp applications

• Aluminum construction provides enduring strength

• Functional finishing touches: post and wall returns, end caps and loops

• Unique adjustable internal and external joiner accommodates any transition – 0˚ to 90˚ bends

Certa-Snap® Wrap

• Specifically designed for existing wood posts

• 8-piece system — 4 vinyl post sections plus 4 corner trim pieces

• Components snap together for easy installation

• Available in 4" x 4" or 6" x 6" in 10' lengths — can be field cut to any length

• 4-piece post trim for top and bottom sold separately

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

15

7.1 Wood Post Mount Installation 1.1 Lay out the location of the post.

- Install at least 3" of blocking under the mounting

location. Securely attach the blocking using

reinforcement screws.

1.2 Using the leveling plate as a template, mark the

location of the four mounting holes to be drilled.

- Drill four holes through the decking and blocking

using a 3/8" diameter drill bit.

1.3 Install the four leveling bolts into the post

mount member.

- Place the leveling plate on the decking surface and

align over the four drilled holes.

- Place the post mount member on top of the leveling

plate and align the four holes.

- Adjust the leveling screws to ensure the post mount

member is level.

1.4 Install the four mounting bolts with washers

as shown.

- On the underside, place the back plate over the

exposed mounting bolts. (Use the centered holes for

in-line applications and the offset holes for corner

applications.)

- Secure the back plate by using the supplied

mounting nuts and washers.

1.5 Install the two guide blocks onto the post mount

member. They should be positioned so that the

screws from the railing brackets will screw into

the guide blocks.

- Once the proper heights are established, drill

a 1/8" diameter hole through both the guide block

and the post mount member. Install the supplied

guide block screws to hold the guide blocks in place.

1.6 Install the post profile and rail brackets according to

manufacturer specifications.

Made in USA of U.S. and imported parts.U.S. Patent # 7,530,550

Guide Block

Post Mount Member

Guide Block Screw

Mounting Bolts

Leveling Bolt

Leveling Plate

Decking

Blocking

Back Plate

Mounting Nut

Framing

Washer

Washer

Reinforcement Screws

1

2

3

4

5

7. Installing Post Support Kits for Vinyl Railing

Important

Installer must consult local code officials for compliance to building code requirements.

1.1

1.3

1.2

1.4

1.5

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

16

7.2 Concrete Post Mount Installation 2.1 Lay out the location of the post.

2.2 Using the leveling plate as a template, mark the

location of the four mounting holes to be drilled.

- Drill four holes into the concrete using a 1/4"

diameter masonry drill bit. The hole must be drilled

to a minimum depth of 3-1/2".

- Clean out the holes of all dust and debris.

2.3 Install the four leveling bolts into the post

mount member.

- Place the leveling plate on the concrete surface and

align over the four drilled holes.

- Place the post mount member on top of the leveling

plate and align the four holes.

- Adjust the leveling screws to ensure the post mount

member is level.

2.4 Install the four concrete bolts with washers as shown

by applying downward pressure while turning in a

clockwise direction.

- Continue to tighten the bolts until the heads are

firmly seated. (Do not over-tighten.)

2.5 Install the two guide blocks onto the post mount

member. They should be positioned so that the

screws from the railing brackets will screw into the

guide blocks.

- Once the proper heights are established, drill

a 1/8" diameter hole through both the guide block

and the post mount member. Install the supplied

guide block screws to hold the guide blocks in place.

2.6 Install the post profile and rail brackets according to

manufacturer specifications.

Guide Block Screw

Concrete Bolt

Washer

Leveling Bolt

Leveling Plate

Concrete

Guide Block

Post Mount Member

1

2

3

4

5

Made in USA of U.S. and imported parts.U.S. Patent # 7,530,550

2.1

2.3

2.2

2.4

2.5

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

17

Steel Post Support

Nylon Blocks

7.3 Post Support Kits for Bracketed Vinyl Railing

EZ Set Bracketed Post Support Kit (Concrete):

Vinyl posts alone do not provide adequate fastener

retention. The EZ Set kit provides easy bracketed system

installation on concrete surfaces. This post support is

designed to install with all CertainTeed bracketed vinyl

railing systems and is compatible with CertainTeed’s

Self-Leveling Kit.

NOTE: Install railing brackets by driving screws as

perpendicular to the post as possible.

3.1 To install the posts on concrete, use the concrete

mounting plate as a guide to mark holes.

3.2 Drill four 1/2" holes, 3-1/4" deep.

3.2

3.1

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

18

3.3 Attach a nut to the top of the anchor to protect the

threads and hammer it into the concrete. Leave

approximately 3/4" of the thread above the ground.

3.4 After all anchors are in place, replace the post support

and tighten the nuts. Recheck that the post is level. If

not, shim the base.

3.5 Insert two pairs of blocks with nut and bolt into

predrilled holes on post support and tighten.

3.6 Sleeve over vinyl post.

3.3

3.4

3.5

3.6

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

19

1.1 Check for equal baluster spacing at posts. For flat and

columns, mark rail where it meets the post. Measure

back 1/4" from mark.

1.2 Square rails and cut. Install crush block to bottom rail.

1.3 Slide vinyl covers over ends of rails. Insert aluminum

brackets into both ends of rails.

NOTE: Vinyl cover can be field cut to avoid baluster

interference.

1.4 Position bottom rail between posts.

1.5 To secure aluminum bracket to posts with screws

provided (two screws per aluminum bracket)

on the TOP rail, place screws in the bottom holes of the

bracket. On the BOTTOM rail, place screws in the top

holes of the bracket. Slide vinyl covers to posts.

NOTE: When installing dark-colored product (black,

clay, warm spice, rustic rose), keep product in a

shady/cooler area and out of direct sunlight prior

to installation.

1.6 Fasten cover and rail to aluminum bracket

with 1" screws (provided) through flat sides

of vinyl covers.

NOTE: Pre-drilling rail and bracket will enhance

application. Use a 9/64" drill bit.

Alternative flat installation: Secure rail to aluminum

bracket first and then slide vinyl cover to post.

Secure cover in place with vinyl adhesive.

1.7 Insert balusters into bottom rail.

1.8 Install top rail and repeat steps 1.5-1.6.

1.9 For 10' railing, insert provided screws through flat side

of top and bottom rails into middle baluster to secure

midpoint of railing.

NOTE: Aluminum brackets can be inserted into top rail

after balusters are installed.

Important

Before installing posts, note rail lengths are nominal. Actual rail lengths are: 6' Rail = 68-1/2" 8' Rail = 92-1/2" 10' Rail = 116-1/2"To ensure meeting code requirements, be sure that the space between the last baluster and the wall or post is not more than 4".

8. Installing Kingston Railing Flat, Column, 45°, 22-1/2°, Stair

1.6

1.5

1.3

2-7/16"1.1

1.7

1.9

1.2

1.8

1.4

NOTE: Two brackets are required per section end.

8.1 Assembly for Flat and Column

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

20

2.1 Check for equal baluster spacing at posts. For

22-1⁄2° and 45°, mark rail where it meets post.

Do not measure back.

2.2 Square rails and cut. Install crush block to

bottom rail.

2.3 Slide vinyl covers over ends of rails. Insert aluminum

brackets into both ends of rails.

NOTE: Vinyl cover can be field cut to avoid baluster

interference.

2.4 Position bottom rail between posts. For 22-1⁄2°

and 45°, slide rail down inside corner of post.

2.5 To secure aluminum bracket to posts with screws

provided (two screws per aluminum bracket) on the

TOP rail, place screws in the bottom holes of the

bracket. On the BOTTOM rail, place screws in the

top holes of the bracket. Slide vinyl covers to posts.

2.6 Fasten cover and rail to aluminum bracket with 1"

screws (provided) through flat sides of vinyl covers.

NOTE: Pre-drilling rail and bracket will enhance

application. Use a 9⁄64" drill bit.

2.7 Insert balusters into bottom rail.

2.8 Install top rail and repeat steps 2.5-2.6.

2.9 For 10' railing, insert provided screws through flat

side of top and bottom rails into middle baluster to

secure midpoint of railing.

2.6

2.5

2.3

2-7/16"2.1

2.7

2.9

2.2

2.8

2.4

NOTE: Two brackets are required per section end.

8.2 Assembly for 22-1⁄2˚ and 45˚

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

21

3.1 Check for equal baluster spacing at posts.

3.2 Mark rail where it meets the post. Square top rail to

bottom rail, measure back 1/4" from the mark and

cut rails.

3.3 Transfer stair angles to covers and cut. Place covers over

a scrap piece of rail when cutting to required angle. To

hold rail level, place cover on both ends. Attach covers

to scrap rail with tape or plastic wrap to hold in place

while cutting. Do not attempt to cut covers without

placing on a rail. Slide vinyl covers over ends of bottom

rail. Insert aluminum brackets into both ends of rail.

3.4 Position bottom rail between posts.

3.5 To secure aluminum bracket to posts with screws

provided (two screws per aluminum bracket), on the

TOP rail, place screws in the bottom holes of the

bracket. On the BOTTOM rail, place screws in the

top holes of the bracket. Slide vinyl covers to posts.

3.6 Secure rail to aluminum brackets with 1" screw

(provided) through flat side of rail.

NOTE: Pre-drilling rail and bracket will enhance

application. Use a 9/64" drill bit.

3.7 Slide vinyl cover to post and fasten to rail with

vinyl adhesive.

3.8 Insert baluster into bottom rail.

3.9 Install top rail and repeat steps 3.5-3.7.

NOTE: Aluminum brackets can be inserted into top

rail after balusters are installed.

3.4

3.8

3.9

NOTE: The 1-1/2" x 1-1/2" Kingston square baluster must

measure 32-1/2" for stair applications. You can field

cut a 1-1/2" x 1-1/2" x 33-1/4" square baluster to

32-1/2" (cut 3/4" from end) for this use. The 1-1/2"

x 1-1/2" x 33-1/4" Kingston traditional baluster

works for both flat and stair applications.

3.1

3.7

3.2

3.6

3.3

3.5

8.3 Assembly for Stair

Refer to Railing and Decking Installation Instructions Guide, FRD411, for stair angle chart.

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

22

Your post support kit should include:

9. Installing Oxford Railing Flat, 8" Column, 45°, 22-1/2°, Stair

9.1 Post Support Kits

Support Pipe

Fasteners forWood orConcrete

2 EZ Set Brackets

Rail Connector Plate (Screws Included)

CONCRETE

Screw

Railing Plate

Support Plate

EZ Set Bracket

EZ Set BracketConcrete Anchors

Concrete Surface

WOOD

DeckSubstructure

ScrewRailing Plate

Support Plate

EZ Set Bracket

EZ Set Bracket

NOTE: Wood support kit shown.

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

23

9.2 Multi 45° Angle – Deck Frame and Post Layout

Proper deck frame and post layout is critical for proper railing

installation. When using 45° line posts, the useof a pressure-

treated 1" x 6" x 6" shim at different post locations will be

required. This will keep the railing parallel to the outside

rim joist. Location of the joist at the angle will determine

the amount of shimming necessary. Each layout may vary.

Additional shims typically are not required for standard flat

and stair applications.

If your installation requires solutions different from those in

this guide, please contact our Installation Support team at

800-233-8990.

Wood Shim

Wood Support Post

CertainTeed Vinyl Railing and Deck Master Craftsman Education & Development Program

24

Stringer

Max 72", 96" or 120"

between center points

of post supports.

Joist

Finished

Riser

Rimboard

Bridging

Standard 25° min – 37° maxSteep Stair 37° min – 42° max

9.5 Check the Substructure

Once you have laid out the location of the posts, check

the substructure to make sure there are two surfaces

available to mount the post support. For example, if you

run along the length of a 12' deck and put a post in the

middle, attach a bridgeboard in the middle of that run

from the rim joist to the inner joist. Attach one side of

the post support L-shaped bracket to the outside face;

attach the other to the bridge.

9.6 Determine Post Height

Posts are supplied in two standard heights, 38" (3' railing)

and 44" (3-1/2' railing). Stair post supports are purposely

supplied longer than needed to accommodate various

post positions.

9.3 Locate and Install Post Supports

3.1 Locate and mark the post centers. For flat sections,

posts should be installed no more than 72", 96"

or 120" on center. For stair sections, determine

if the rail will reach the bottom of the steps (or

the landing).

3.2 Place a rail on the stringer (make sure the rail

extends beyond the top post support). If the rail

does not reach the end of the stairs, you will need

to use an intermediate post (see illustrations at

right). Center the top stair post within 3-1/4" of

the edge of the deck.

Railings can also be mounted to walls or structural

columns with wall mount brackets.

9.4 Post Center Spacing On Diagonal

6' Section Covers 68" at 32°

8' Section Covers 90" at 32°

10' Section Covers 117" at 32°

6' Section Covers 71" at 42°

8' Section Covers 96" at 42°

Post support kit (wood)

Post support kit (wood)

Single 2x8 riser at end post

Single 2x8 Rim Joist Single Rim Joist Attachment

Standard 7/11" Rise and Run Installation

NOTE: When cutting metal

post supports for stair

sections, cut away

from vinyl decking to

avoid metal particles

from embedding into

deck surface.