Euro VI - International Council on Clean Transportation Mexico Euro VI... · Euro VI technologies...

Transcript of Euro VI - International Council on Clean Transportation Mexico Euro VI... · Euro VI technologies...

mscoCDMX Workshop September 2016

msco GmbH CH-9320 Arbon 1

Euro VI

• Regulation• Emissions in real driving conditions• Euro VI engine system technologies• Maintenance

Meinrad SignerConsultant, Switzerland

Swiss government contractor

mscoEuro VI test procedures

msco GmbH CH-9320 Arbon 4

Cold test soak

Weighting factor

14% 86%

1. Test1. Test 2. Test2. Test

10 min

Cold test soak

Weighting factor

14% 86%

1. Test1. Test 2. Test2. Test

10 min

WNTE - C13 560 PS

0

250

500

750

1000

1250

1500

1750

2000

2250

2500

2750

500 1000 1500 2000 2500

n [rpm]

M [

Nm

]

1/3

1/3

1/3 1

2

3

4

5

6

Grid-cells

70% rated power

30% max torque30% max power

30% cumulated frequency

in WHTC

7

8

9

1/3

WNTE - C13 560 PS

0

250

500

750

1000

1250

1500

1750

2000

2250

2500

2750

500 1000 1500 2000 2500

n [rpm]

M [

Nm

]

1/3

1/3

1/3 1

2

3

4

5

6

Grid-cells

70% rated power

30% max torque30% max power

30% cumulated frequency

in WHTC

7

8

9

1/3

Test:

5 random points

Cell A

5 random points

Cell B

5 random points

Cell C

Average NOx Average NOx Average NOx

Average PM

Cell A, B and C random selected

Stepped cycle

5 random points

Cell A

5 random points

Cell B

5 random points

Cell C

Average NOx Average NOx Average NOx

Average PM

Cell A, B and C random selected

Stepped cycle

Emissions are integrated (measurement of concentration and exhaust flow g emissions

Emissions are integrated (measurement of concentration and exhaust flow g emissions

Emissions are integrated (measurement of concentration and exhaust flow g emissions

Drive the vehicle until a certain work is accumulated, for example same work as in WHTC work wondow (kWh)

Drive the vehicle until a certain work is accumulated, for example same work as in WHTC work wondow (kWh)

Drive the vehicle until a certain work is accumulated, for example same work as in ETC work wondow (kWh)

Drive the vehicle until a certain work is accumulated, for example same work as in WHTC work window (kWh)

Moving window

Emissions are integrated (measurement of concentration and exhaust flow g emissions

Sp

ec

ific

em

iss

ion

s i

n g

/kW

h

CF

= m

ea

sure

d e

mis

sio

ns

/ l

imit

CF

Every sample (second by second) is checked for power and integrated over the work-window, work-windows where the average power is <20% of max power will be discarded

90% of measured values must be within limits

WHTC NTE

ISC-PEMS

mscoSCR tampering

msco GmbH CH-9320 Arbon 66

• AdBlue consumption is monitored

• AdBlue quality is constantly monitored

• SCR functionality is monitored and controlled(incl. AdBlue/DEF)

– If AdBlue is frozen and SCR not operational after certain time the vehicle speed reduces to 20km/h

Misuse/tampering of SCR-AdBlue/DEF system

• Optical and acoustical warning with increased intensity

– First warning when AdBlue/DEF level is lower than 10%

• First degree of restriction

– Empty tank (at 2.5% quantity left), quality out of limits

20% torque reduction in complete speed range

• Second degree of restriction

– Empty tank, water in the tank, SCR not functioning

– Max speed of vehicle reduced to 20km/h, beginning after a new start after parking (not during driving).

mscoSwiss television 2013

msco GmbH CH-9320 Arbon 8

Ambient near truck12100

Exhaust Euro VI truck1860

Particle number count

mscoVTT Finland Euro VI Buses (7) in Braunschweig cycle

msco GmbH CH-9320 Arbon 11

EEV: lowestprevious standard

7 Euro VI buses

mscoRicardo study: Euro V hybrid bus – Euro VI truck

msco GmbH CH-9320 Arbon 14

Euro V BusEuro V Hybrid Bus

Euro VI truck fully loaded

Euro VI truck empty

mscoEuro VI technology options

msco GmbH CH-9320 Arbon 17

5.03.52.0

0.02

NOx (g/kWh)

PM (g/kWh)Euro IIIEuro III

Euro IVEuro IVEuro VEuro V

EGR

Fuel consumption

2-st. TL

1-st. TL

Euro VI0.46

SCR

Combustion

0.1

0

100 10%

0

SC

R e

ffic

ien

cy

Ad

Blu

e c

on

su

mp

tio

n

0

40 50%

0

EG

R R

ate

ad

d.c

oo

lin

g p

ow

er

SCR EGR

DPF

6*E11

mscoEuro VI technology options

msco GmbH CH-9320 Arbon 18

5.03.52.0

0.02

NOx (g/kWh)

PM (g/kWh)Euro IIIEuro III

Euro IVEuro IVEuro VEuro V

Fuel consumption

2-st. TL

1-st. TL

0.46

SCR

Combustion

0.1

0

100 10%

0

SC

R e

ffic

ien

cy

Ad

Blu

e c

on

su

mp

tio

n

0

40 50%

0

EG

R R

ate

Ad

d.

Co

olin

g p

ow

er

SCR EGR

DPF

EGR

Euro VI

6*E11

mscoEuro VI technology options

msco GmbH CH-9320 Arbon 19

5.03.52.0

0.02

NOx (g/kWh)

PM (g/kWh)Euro IIIEuro III

Euro IVEuro IVEuro VEuro V

EGR

Fuel consumption

2-st. TL

1-st. TL

0.46

Combustion

0.1

0

100 10%

0

SC

R e

ffic

ien

cy

Ad

Blu

e c

on

su

mp

tio

n

0

40 50%

0

EG

R R

ate

ad

d.

Co

olin

g p

ow

er

SCR EGR

DPF

SCR

Euro VI

6*E11

mscoEuro VI technology options

msco GmbH CH-9320 Arbon 20

5.03.52.0

0.02

NOx (g/kWh)

PM (g/kWh)Euro IIIEuro III

Euro IVEuro IVEuro VEuro V

Fuel consumption

2-st. TL

1-st. TL

DPF

0.46

SCR

Combustion

0.1

0

100 10%

0

SC

R e

ffic

ien

cy

Ad

Blu

e c

on

su

mp

tio

n

0

40 50%

0

EG

R R

ate

ad

d.

Co

olin

g p

ow

er

SCR EGR

Euro VI

6*E11

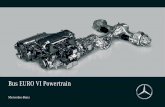

mscoEuro VI technologies Diesel

msco GmbH CH-9320 Arbon 21

Euro VI

• SCR only for Iveco/FPT and partly Scania, all others combination of SCR/EGR

• All Euro VI have DPF

• Electronic control of engine and aftertreatment system, NOx sensor

• Fuel mandatory <10 (15)ppm

• Maintenance: typical engine maintenance as for all electronic controlled

• Diesel engines, DPF regular maintenance (at 300-400’000km)

• LowSAPS lubricants, maintenance of sensors as specified

• OBD

mscoEuro VI technologies CNG

msco GmbH CH-9320 Arbon 22

Euro VI

• stoichiometric combustion, spark ignition

• Some with EGR

• Multipoint port injection, direct injection

• 3-way catalyst system

• Electronic control of engine and aftertreatment system, NOx sensor

• Best fuel methane content >90%

• Maintenance: typical engine maintenance as for spark ingnition engines

• OBD

mscoMaintenance requirements

msco GmbH CH-9320 Arbon 23

Euro IV Euro V Euro VI Euro V / VI CNG

EGR or SCR EGR / SCR EGR / SCR / DPF (EGR) / 3way Cat

Lubricating oil E9, APT CJ-4 (low SAPS)

Gas engine oil

Fuel Low sulfur diesel

AdBlue DEF Standard2-4%

Standard3-5%

Standard4-7%

DPF Maintenanceafter 300’000-500’000 km

SCR dosing unit Filter replacement

Filter replacement

Filter replacement

Breather filter Replacement Replacement Replacement Replacement

Engine general standard standard standard Standard

Sensors NOx sensor NOx sensor NOx/NH3 sensor Oxigen sensor

mscoSummary

msco GmbH CH-9320 Arbon 24

• Euro VI regulation provides low emissions under all conditions of use, from sea level to altitude and from low tohigh temperatures

• Euro VI regulation is strongly based on in-use emissioncontrol and checked with PEMS for each engine family overthe useful life

• In-use emission emission measurement has confirmed theexcellent emission performance of Euro VI

• Euro VI is the way forward

mscoSelective Catalytic Reduction

msco GmbH CH-9320 Arbon 27

NONO

AdBlue

Urea + Water

NH3 = AmmoniaNH3 = Ammonia

NO2NO2

NH3NH3 SCR CatalystSCR Catalyst

NH3NH3NH3NH3NH3NH3

NO2NO2 NONO

N2N2

NONO

H2OH2O

SCR CatalystSCR Catalyst

N2N2

H2OH2O

NONO

NO2NO2

Injection of AdBlue …(Urea – Water solution / 32.5 wt.-% Urea)with / w.o. compressed air (dosing system)

Control system connected to engine ECU

mscoEuro IV – V technologies Diesel

msco GmbH CH-9320 Arbon 28

Euro IV

• either SCR (using AdBlue) or EGR

• Electronic controls of engine and aftertreatment system, NOx sensor

• DPF sometimes used for buses, then in combination with Oxidation cat

• Fuel sulfur best is <10ppm, 50 ppm is still ok , 500ppm detrimental for oxi-cat and EGR

• Maintenance: typical engine maintenance as for all electronic controlled

• Diesel engines, in case of DPF regular filter maintenance (at 300-400’000km)

• LowSAPS lubricants, maintenance of sensors as specified

Euro V

• either SCR (using AdBlue) or EGR with DPF or the combination of both

• Electronic controls of engine and aftertreatment system, NOx sensor

• DPF used for the version with EGR only, of for bus application

• Fuel sulfur best is <10ppm, when DPF is installed also <10ppm, otherwise 50ppm could work

• Maintenance: typical engine maintenance as for all electronic controlled

• Diesel engines, in case of DPF regular filter maintenance (at 300-400’000km)

• LowSAPS lubricants, maintenance of sensors as specified

mscoEuro VI Maintenance requirements Diesel

msco GmbH CH-9320 Arbon 29

Lubricating OilACEA classification E9, APT CJ-4 (low SAPS)

FuelUltra low sulphur diesel fuel (<10 ppm sulphur)

AdBlue / DEFRefill with strandard fluid meeting specifications

DPFClean following the maintenance guidelines (usually between 300-500’000km)

Dosing unit filterReplacement in-line with maintenance guidelinesPreventing blockage of AdBlue / DEF flow in injector

Breather filterAs it is a closed system, filters must be replaced according to guidelines

mscoCNG engines layout

msco GmbH CH-9320 Arbon 30

• Stoichiometric NG applications offer 5 – 8% lower CO2 emissions than On Road Diesel which corresponds to a operating cost saving of 25 – 30%.

• A lean burn combustion concept or the application of EGR may allow for a further reduction. Exhaust emissions, however, would not be as low as with the stoichiometric version.

Brake Thermal Efficiency

Stoichiometric Lean Burn

msco

msco GmbH CH-9320 Arbon 3131

No additional fluid on board the vehicle

Increased fuel consumption 2-stage turbocharging

Deposit formation possible, negative influence on lubricant performance

Increased cooling power installation constrains increased consumption

High EGR rates even under full load conditions

SCR

Second fluid on board, AdBlue-consumption depending on conversion rate

Engine optimised for low fuel consumption

Fuel quality sensitive (in particular sulfur)

Fuel quality sensitive at high conversion rate conditions

No negative effects on lubricant

Big volume to be installed

Limits with respect to conversion rate (temperature)

EGR

DPFFuel quality sensitive (passive regeneration)

LowSAP lubricants are required