ETA-19/0438 HALFEN HM Mounting Channel and HALFEN HS ...

Transcript of ETA-19/0438 HALFEN HM Mounting Channel and HALFEN HS ...

®

ETA_HM 12/19-E

HALFEN HM MOUNTING CHANNELHALFEN HS SPECIAL BOLTSEuropean Technical Assessment ETA-19/0438

This approval only applies to original HALFEN products. The specifications in this approval are not transferable to other products. Users are fully liable for personal injuries and material damage caused by third-party products used instead of HALFEN products.

Use of third-party products

HALFEN HM MOUNTING CHANNEL, HS SPECIAL BOLTSGeneral Note

Deutsches

Institut

für

Bautechnik DIEt

Approval body for construction products and types of construction

Bautechnisches Prüfamt

An institution established by the Federal and Laender Governments

European Technical

Assessment

**

*Designated

* acco rding to *

Article 29 ol Regula-

* tion (EU) No 305/2011

* end member of EOTA (European Organi-

* sation forTechnical *Assessment)

* *

ET A-19/0438

of 27 November 2019

Member of

www.eota.eu

English translation prepared by DIBt - Originalversion in German language

General Part

Technical Assessment Body issuing the European Technical Assessment:

Trade name of the construction product

Product family to which the construction product belongs

Manufacturer

Manufacturing plant

This European Technical Assessment contains

This European Technical Assessment is issued in accordance with Regulation (EU) No 305/2011, on the basis of

Deutsches Institut für Bautechnik

Deutsches Institut für Bautechnik

HALFEN Hot-rolled mounting channel HM; Special screws HS

Hot-rolled mounting channel

Halfen GmbH Liebigstraße 14 40764 Langenfeld DEUTSCHLAND

HALFEN GmbH Liebigstraße 14 40764 Langenfeld DEUTSCHLAND

18 pages including 14 annexes which form an integral part of this assessment

EAD 330667-00-0602

Kolonnenstraße 30 B l 10829 Berlin I GERMANY I Phone: +49 3078730-01 Fax: +49 3078730-3201 Email:[email protected]

239466.19 8.06.02-81/17

European Technical Assessment

ET A-19/0438

English translation prepared by DIBI

Deutsches

Institut

für

Bautechnik DIBt

Page 2 of 18127 November 2019

The European Technical Assessment is issued by the Technical Assessment Body in its official language. Translations of this European Technical Assessment in other languages shall fully correspond to the original issued document and shall be identified as such.

Communication of this European Technical Assessment, including transmission by electronic means, shall be in full. However, partial reproduction may only be made with the written consent of the issuing Technical Assessment Body. Any partial reproduction shall be identified as such.

This European Technical Assessment may be withdrawn by the issuing Technical Assessment Body, in particular pursuant to information by the Commission in accordance with Article 25(3) of Regulation (EU) No 305/2011.

239466.19 8.06.02-81/17

Deutsches

Institut

für

Bautechnik UIBt

European Technical Assessment

ET A-19/0438 Page 3 of 18 1 27 November 2019

English translation prepared by DIBt

Specific part

1 Technical description of the product

The Halfen hot-rolled mounting channel HM is a system consisting of a C-shaped channel profile of carbon steel and stainless steel as weil as a special shaped (hooked) Halfen-channel bolts.

The mounting channel can be welded to the steel structure. Any fixture may be connected to the mounting channel by Halfen-channel bolts with appropriate nuts and washers.

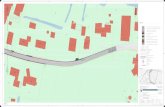

Figure 1 shows the principal setup of the construction product.

The product description is given in Annex A.

Figure 1: Principle setup of hot-rolled mounting channel

2 Specification of the intended use in accordance with the applicable European Assessment Document

239466.19

The performances given in Section 3 are only valid if the mounting channel is used in compliance with the specifications and conditions given in Annex B.

The verifications and assessment methods on which this European Technical Assessment is based lead to the assumption of a working life of the mounting channel of at least 50 years. The indications given on the working life cannot be interpreted as a guarantee given by the producer, but are to be regarded only as a means for choosing the right products in relation to the expected economically reasonable working life of the works.

8.06.02-81/17

Deutsches

Institut

für

Bautechnik DIBt European Technical Assessment

ET A-19/0438 Page 4 of 18127 November 2019

English translation prepared by DIBI

3

3.1

3.2

Performance of the product and references to the methods used for its assessment

Mechanical resistance and stability (BWR 1)

Essential characteristic Performance

Characteristic resistance for tension under static See Annex C1 to C2 and quasi-static loading

Characteristic resistance for shear under static and See Annex C3 to C4 quasi-static loading

Installation parameters See Annex B1 to BS

Geometrie values See Annex A 1, A3 and A4

Durability See AnnexA2

Characteristic resistance for fatigue tensile loading NPD

Safety in case of fire (BWR 2)

Essential characteristic Performance

Reaction to fire Class A1 according to EN 13501-1

4 Assessment and verification of constancy of performance (AVCP) system applied, with reference to its legal base

In accordance with EAD No. 330667-00-0602, the applicable European legal act is: 1998/214/EC

The system to be applied is: 2+

5 Technical details necessary for the implementation of the AVCP system, as provlded for in the applicable EAD

Technical details necessary for the implementation of the AVCP system are laid down in the control plan deposited with Deutsches Institut für Bautechnik.

lssued in Berlin on 27 November 2019 by Deutsches Institut für Bautechnik

BD Dipl.-Ing. Andreas Kummerow

Head of Department

239466.19

beglaubigt:

8.06.02-81/17

Page 5 of European Technical Assessment ETA-19/0438 of 27 November 2019

English translation prepared by O/Bt

// �[ V" II

L.:,_J

1

1

1 1

1

1

-;-

bch

1

'

1�

Deutsches Institut

für Bautechnik DIBt

VHot-rolled mounting channel,e.g., HM 40/22

� HALFEN channel --- e.g., HS 40/22 M12 x 40

1

/washer

[UIJ _,,.,.,,.,.- hexagonal nut

HALFEN hot-rolled mounting channels

HALFEN hot-rolled bch mountlng channel [mm]

HM 40/22 39,50

HM 50/30 49,00

HM 52/34 52,50

HM 55/42 54,50

HM 72/48 72,00

Material of channels:

Steel

1.0038/1.0044

Stainless steel

A2

A4

L4, DX

F4,FA

HCR

1.4301 /1.4307 /1.4541

1.4401 /1.4404/1.4571

1.4362

1.4462

1 .4529/1 .454 7

hch [mm] 23,00

30,00

33,50

42,00

48,50

HALFEN Hot-Rolled Mounting Channels HM

Product description Marking and materials

263684.19

Marking of the HALFEN channel bolts e.g.: HALFEN A4-70

�

H or HALFEN ldentifying mark of the producer

A4 Material

70 Strength grade

Material of channel bolts:

Steel

No marking

Stainless steel

A2

A4

L4

F4,FA

HCR

1.4301 /1.4307/1.4567/1.4541

1.4401 /1.4404/1 .4571 /1 .4578

1.4362

1.4462

1.4529/1.4547

Strength grade of the channel bolts:

Steel

4.6, 8.8 Strength grade 4.6, 8.8

Stainless steel

50, 70 Strength grade 50, 70

Annex A1

8.06.02-81/17

Page 6 of European Technical Assessment ETA-19/0438 of 27 November 2019

English translation prepared by O/Bt

Deutsches Institut

für Bautechnik

Table A2: Materialsand intended use

lntended use

1 2 3

Dry Interna! condltlons Interna! condltions wlth usual Medium corroslon exposure humldlty

Hot-Rolled Mounling Channels Hot-Rolled Mounting Channels Hot-Rolled Mounting Channels may only be used in struclures may also be used in structures may also be used in structures subject 10 dry intemal conditions. subject to inlemal condilions wilh subjecl to extemal atmospheric

usual humidity. exposure (incl. induslrial and C marine en,,ironment) o, exposure

d 0

in permanenlly damp inlemal � conditions, if no particular

E � aggressile condillons exist. � e.g. accomodations, bureaus, e.g. kitchen, bath and laundry in e.g. structures subject to external schools, hospitals, shops, residential buldings, exceptional atmospheric exposure if no exceplional inlemal conditions permanent damp conditions and particular aggressiw conditions with usual humidity acc. column 2 application under wate< exisl acc. column 4

Materials

Steel Steel Stalnless steel 4>

HALFEN 1.0038 (A), 1.0044 (A) 1.0038 (A), 1.0044 (A) 1.4401 (B), 1.4404 (B),

(i) Hot-Rolled hol-dip galv. � 55 µm acc. to (J) hot-dip galv. � 55 im acc. to (J) 1.4571 (B), 1.4362 (B)

Mounting Stainless Steel 4>

Channel 1.4301 (B), 1.4307 (B),

1.4541 (B)

Steel Steel Stalnless steel 4> strength grade 4.6 / 8.8 (C) strength grade 4.6 / 8.8 (C) slrength grade 50, 70 (D)

HALFEN Channel electroplated � 5 µm acc. to (G) hot-dip galv. � 50 im acc. to (H) 1 > 1.4401 (B), 1.4404 (B),

a> Bolls Stalnfess Steel 4> 1.4571 (B), 1.4362 (B), s1rength grade 50, 70 (D) 1.4578 (B) 1.4301 (B), 1.4307 (B), 1.4567 (B), 1.4541 (B)

Washer'> Steel Steel Stalnless steef 4> (1) and (K) EN 10025 EN 10025 s1eel grade A4, A5 (D)

� produc1ion class electroplaled � 5 µm acc. 10 (G) hot-dip galv. � 50 im acc. to (H) 1> A, Stalnless Steel 4J

200HV steel grade A2, A3 (0)

Steel Steel Stafnless steel 4' strength grade 518 (E) strength grade 518 (E) strength grade 70, 80 (F)

© Hexagonal nuts electroplaled � 5 µm acc. to (G) hot-dip galv. � 50 im acc. to (H) 1> steel grade A4, A5 (F)

(L) Stalnless steel 41 strength grade 70, 80 (F) sleel grade A2, A3 (F)

A • EN 10025-2:2004 E - EN ISO 898-2:2012 1 • EN ISO 7089:2000 B - EN 10088-3:2014 F - EN ISO 3506-2:2009 J • EN ISO 1461:2009 C - EN ISO 898-1:2013 G - EN ISO 4042: 1999 K • EN ISO 7093-1 :2000 D • EN ISO 3506-1 :200 H • EN ISO 10684:2004 L • EN ISO 4032:2012

'1 or eleelropiated with special coaling � 12 µm '1 1.4462 not applicable for indoor swimming pools 31 not included in scope ol deliwry 4> stainless steel channel f)(Ofiles only In combination with slainless steel channel bolls, washers and nuts

HALFEN Hot-Rolled Mounting Channels HM

Product description Materials and intended use

263684.19

OIBt

4

High corroslon exposure

Hot-Rolled Mounting Channels may also be used in structures subjecl to exposure inparticular aggressiw conditions.

e.g. pe<manenl, alle<nating immersion in seawater or the

splash zone ol seawater, chloride atmosphere of indoor swimming pools or atmosphere wilh chemical pollullon (e.g. In desulphurizalion plants o, road tunnels where de-lcing materials are used)

Stalnless steel 41 1.44622> (B), 1.4529 (B), 1.4547 (B)

Stalnlesssteel 4> strength grade 50, 70 (D) 1.44622> (B), 1.4529 (B), 1.4547 (B)

Stafnless steel 4> 1.4462'> (B), 1.4529 (B), 1.4547 (B)

Stalnfess steel 41 strength grade 70, 80 (F) 1.446221 (B), 1 .4529 (B), 1.4547 (B)

Annex A2

8.06.02-81/17

Page 7 of European Technical Assessment ETA-19/0438 of 27 November 2019

English translation prepared by D/Bt

Deutsches Institut

für Bautechnik

i4=1 bch

1z 1

1 1 1

.t::

��-� -r-�" J ��

Table A3-1: Profile dimensions (steel and stainless steel)

Hot-rolled-

mountlng

channel

40/22 50/30 52/34 55/42 72/48

40/22 50/30 52/34 72/48

Material

ä3 2 (J)

(J) (J)

-

� gi·- .....

ro w

U)

bch

[mm]

39,50 49,00 52,50 54,50 72,00

39,50 49,00 52,50 72,00

Dimensions

hch 4:h b 4:h 1

[mm] [mm] [mm]

23,00 2,60 2,30 30,00 3,20 2,65 33,50 4,10 4,00 42,00 5,00 5,00 48,50 4,50 5,00

23,00 2,60 2,30 30,00 3,20 2,65 33,50 4,10 4,00 48,50 4,50 5,00

DIBt

b1 f

[mm) [mm]

18,00 6,00 22,50 7,85 22,50 10,50 26,00 12,90 33,00 15,50

18,00 6,00 22,50 7,85 22,50 10,50 33,00 15,50

Table A3-2: Cross-section values of profiles (steel and stainless steel)

Hot-rolled- Cross-sectlon values

mountlng Material e lv lz Wer.v Weiz Wol.v Wrl,z

channel [mm] [mm� fmm4] fmm3] [mm3] [mm3) [mm3l

40/22 12,46 19859 57718 1594 2922 2169 3681 50/30 ä3 16,29 52575 137809 3228 5625 4383 7051 52/34 2 17,42 93336 237412 5357 9044 7186 11502 55/42 22,10 187482 362909 8485 13318 11727 16687 72/48 24,01 349723 833480 14279 23152 18283 28943

40/22 (J) 12,46 19859 57718 1594 2922 2169 3681 50/30 :ß ä3 16,29 52575 137809 3228 5625 4383 7051 52/34 :S2 17,42 93336 237412 5357 9044 7186 11502 ro w

72/48 U) 24,01 349723 833480 14279 23152 18283 28943

HALFEN Hot-Rolled Mounting Channels HM

Product description Annex A3

Profile dimensions

263684.19 8.06.02-81/17

Page 8 of European Technical AssessmentETA-19/0438 of 27 November 2019

English translation prepared by O/Bt

HALFEN channel bolt, Hook-head geometry

Deutsches

Institut

für

Bautechnik DIEt

Notch for marking the position l

1-!T

-?fl [11��-�ll 1 rGi

:j

king acc Annex A1

. 1° 1.alternative Hook-head geometry

Notch for marking th� /-:: J position Jfft /. I • � -, _ "j

Marking acc Annex A 1

Table A4: Dimensions of HALFEN channel bolts

Thread Channel bolts - wing shape Channel bolts - alternative shape

(1j HS (IJ 0 :r: Width Length Thickness Width Length Thickness

b1 [mm] b2 [mm] k [mm) b1 [mm] b2 [mm] k [mm] M10 15 30,8 7,2 - - -

40/22 M12 15 30,8 7,2 - - -

M16 17,4 30,8 8,2 (9,8) - - -

M10 16,3 40,2 10 15 41,5 10

M12 16,3 40,2 10 15 41,5 10 (1j 50/30 M16 19,4 40,2 11 20 41,5 11 0 M20 21 39,5 12,5 21 41,5 12 0

M24 - - - 24,5 41 18

M20 - - - 23 58 14

M24 - - - 25 58 16 72/48

M27 - - - 28 58 18

M30 - - - 31 58 20

( ) value applies for strength grade 8.8

HALFEN Hot-Rolled Mounting Channels HM

Hot-rolled

mounting channel

40/22

50/30

52/34

55/42

55/42

72/48

Product description Annex A4

HALFEN channel bolts, dimensions

263684.19 8.06.02-81/17

Page 9 of European Technical Assessment ETA-19/0438 of 27 November 2019

English translation prepared by D/Bt

Deutsches Institut

für Bautechnik DIBt

Table A5: Strength grade of HALFEN channel bolts

Strength grade 4.6

fuk [N/mm2] 400

fyk [N/mm2] 240

Steel 1 l

8.8

800

640

Finish electroplated, hot-dip galv. 1l materials according Annex A1 and Annex A2, Tab. A2

HALFEN Hot-Rolled Mounting Channels HM

Product description HALFEN channel bolts, strength grade

263684.19

Stainless steel 1 l

50 70

500 700

210 450

Annex AS

8.06.02-81/17

Page 10 of European Technical Assessment ET A-19/0438 of 27 November 2019

Deutsches Institut

für Bautechnik DIBt English translation prepared by D/Bf

Specifications for intended use

HALFEN hot-rolled mountlng channels and channel bolts subject to:

• Static and quasi-static loads in tension and shear perpendicular to the longitudinal axis of thechannel and combinations of these loads.

• Shear loads with or without lever arm.

z

y

tension load: z-direction

shear load: y-direction

• HALFEN hot-rolled mounting channels can be connected to the structure by direct welding or by lugswelded to the channel walls.

Use conditions (Environmental conditions):

• Structures subject to dry internal conditions (e.g. accommodations, bureaus, schools, hospitals,shops, exceptional internal conditions with usual humidity)(hot-rolled mounting channels and channel bolts according to Annex A2, Table A2, column 1 - 4)

• Structures subject to internal conditions with usual humidity (e.g. kitchen, bath and laundry inresidential buildings, exceptional permanent damp conditions and application under water)(hot-rolled mounting channels and channel bolts according to Annex A2, Table A2, column 2 - 4)

• Structures subject to external atmospheric exposure (incl. industrial and marine environment) orexposure to permanently damp internal conditions, if no particular aggressive conditions (e.g.permanent, alternating immersion in seawater etc.) exist.(hot-rolled mounting channels and channel bolts according to Annex A2, Table A2, column 3 - 4)

• Structures subject to exposure in particular aggressive conditions (e.g. permanent, alternatingimmersion in seawater or the splash zone of seawater, chloride atmosphere of indoor swimmingpools or atmosphere with chemical pollution (e.g. in desulphurization plants or road tunnels wherede-icing materials are used))(hot-rolled mounting channels and channel bolts according to Annex A2, Table A2, column 4)

Design:

• HALFEN hot-rolled mounting channels are designed under the responsibility of an engineerexperienced in framing systems and bolted connections.

• For static and quasi-static loading the hot-rolled mounting channels are designed according toAnnexes C1 - C4 and EN 1993-1-1.

• The welding seams are calculated in accordance to EN 1993-1-8. The spacing of the welding seamsmust not exceed the minimum spacing of the channel bolts given in Annex C 1, Table C 1-1 resp.Annex C3, Table C3-1 (max. ew :5 Smin,s,N),

HALFEN Hot-Rolled Mounting Channels HM

lntended use Specifications

263684.19

Annex 81

8.06.02-81/17

Page 11 of European Technical Assessment ETA-19/0438 of 27 November 2019

Deutsches Institut

für Bautechnik DIBt English translation prepared by O/Bt

lnstal lation:

• The installation of hot-rolled mounting channels is carried out by appropriately qualified personnelunder the supervision of the person responsible for the technical matters on site.

• Use of HALFEN hot-rolled mounting channels only as supplied by the manufacturer without anyalterations. Hot-rolled mounting channels and channel bolts are a complete system and must alwaysbe used as a set.

• For hot-rolled mounting channels made of stainless steel there are no restrictions regardingcorrosion resistance when using cut channel pieces, if cutting is done professionally andcontamination of cutting edges with corroding material is avoided.

• Installation in accordance with the installation instruction given in Annexes 84 and 85.• Washers may be chosen according to Annex A2 and provided separately by the user.• Orientating the channel bolt (groove mark according to Annex 84) rectangular to the channel axis.• The required installation torque given in Annex 83 must be applied and must not be exceeded.

Transport and storage of hot-rolled mounting channels made of stainless steel:

• Hot-rolled mounting channels made of stainless steel must be stored separately from carbon steeland other metallic materials to avoid surface contamination.

• Store in a dry place.

HALFEN Hot-Rolled Mounting Channels HM

lntended use Specifications

263684.19

Annex 82

8.06.02-81/17

Page 12 of European Technical Assessment ET A-19/0438 of 27 November 2019

English translation prepared by Dlßt

Deutsches Institut

für Bautechnik UIBt

Table B3: Installation torque of HALFEN channel bolts

Min. Installation torque T1nst 2)

HALFEN HALFEN spaclng Steel - steel contact 1 l hot-rolled channel Smtn,cbo Of Stainless mountlng bolts 0 channel Steel 4.6 Steel 8.8

steel 50 channel bolts [mm] [mm] [Nm]

10 50 15 40 15

40/22 12 60 25 70 25

16 80 65 180 60

10 50 15 40 15

50/30 12 60 25 70 25

16 80 65 180 60

20 100 130 360 120

10 50 15 40 15

52/34 12 60 25 70 25

16 80 65 180 60

20 100 130 360 120

10 50 15 40 15

12 60 25 70 25

55/42 16 80 65 180 60

20 100 130 360 120

24 120 230 620 200

20 100 130 360 120

72/48 24 120 230 620 200

27 135 340 900 300

30 150 460 1200 400 1 l materials according to Annex A1 and Annex A2, Tab. A22J T;nst must not be exceeded

HALFEN Hot-Rolled Mounting Channels HM

l ntended useInstal lation parameters

263684,19

Stalnless steel 70

30

50

130

30

50

130

250

30

50

130

250

30

50

130

250

440

250

440

650

850

Annex B3

8.06.02-81/17

Page 13 of European Technical Assessment ETA-19/0438 of 27 November 2019

English translation prepared by D/Bt

Installation of hot-rolled mounting channels

Deutsches

Institut

für

Bautechnik OIEt

• Hot-rolled mounting channel is cut to length and positioned. lt can be advisable to set some weidspots for pre-fixation. Hot-rolled mounting channels made of carbon steel have to be welded beforecorrosion protection e.g. hot-dip galvanising.

• Weiding may only be carried out by qualified personnel with suitable welding procedures.• Steel components to which the hot-rolled mounting channels are welded must have sufficient

weldability.• lf necessary, the quality of the weid seam shall be tested by suitable non-destructive testing.• The welding seams are calculated in accordance to EN 1993-1-8. The spacing of the welding seams

must not exceed the minimum spacing of the channel bolts given in Annex C1, Table C1-1 resp.Annex C3, Table C3-1 (max. ew :s Smln,s,N),

• After the welding residues have been removed the entire structure (carbon steel) is protected againstcorrosion, e. g. by hot-dip galvanizing.

HALFEN Hot-Rolled Mounting Channels HM

lntended use Annex B4

Installation instruction - HALFEN hot-rolled mounting channels

263684.19 8.06.02-81/17

Page 14 of European Technical Assessment ETA-19/0438 of 27 November 2019

English translation prepared by D/Bt

Installation of HALFEN channel bolts

Selection of Insert the

the HALFEN HALFEN

channel bolts channel bolts

in accordance into the channel

with the slot. After a 90°

planning turn clockwise

document. the HALFEN

screw locks into

position (check

whether the

groove mark is

perpendicular to

the channel

longitudinal

axis).

et

�����

O[-f_jo . □ 1

Positioning of

the HALFEN

channel bolts:

The bolts must

not be mounted

outside the

welding seams

at the channel

ends.

Deutsches

Institut

für

Bautechnik

Tighten the hexagonal

nut to the installation

torque (T1ns1.) acc. table

stated below. T1ns1 must

not be exceeded. 4.1:

general application, 4.2:

installation with lever arm

Table B5: Installation torque of HALFEN channel bolts

Hot-T1nst [Nm] 1> Materlal/strength rolled

grade mounting M10 M12 M16 M20 channel 4.6 15 25 65 130

Steel 8.8 All 40 70 180 360

Stainless 50 profiles 15 25 60 120

steel 70 30 50 130 250 lJ Tinst must not be exceeded

HALFEN Hot-Rolled Mounting Channels HM

lntended use Installation instruction - HALFEN channel bolts

263684.19

DIBt

®✓

Alter tightening the nut check

if the groove mark on the

HALFEN channel bolt is

perpendicular to the channel

longitudinal axis. lt it is not

perpendicular the screw

must be clompletely

loosened, re-inserted and

tightened again.

M24 M27 M30

230 340 460

620 900 1200

200 300 400

440 650 850

Annex 85

8.06.02-81/17

Page 15 of European Technical Assessment ETA-19/0438 of 27 November 2019

English translation prepared by O/Bt

Deutsches Institut

für Bautechnik OIBt

Table C1-1: Characteristic resistance for tension under static and quasi-static loading

Mountlng channel 1 > HM 40/22 HM 50/30 HM 52/34 HM 55/42 HM 72/48

Resistance for tension, local failure of channel llps

Minimum spacing of bolts Smin,s, N [mm] 150 200 200 250 300

Characteristic resistance NRk,s,I [kN] 26 38 68 100 120

Partial safety factor YMs,I 2)

1,8

'1 for steel and stainless steel 2> in absence of other national regulations

NRk,s,l NRk,s,l

Ss ::: Smin s N

- - - - - - - --

i - ;__ - - -i- ---

1 1 1

Table C1-2: Displacements under tension service load

Mountlng channel 1 > HM 40/22 HM 50/30 HM 52/34 HM 55/42 HM 72/48

Displacement due to tenslle loadlng

Service load N [kN] 10,4 15,2 27,2 40,0 48,0

Displacement ◊N [mm] 0,5 0,5 0,6 0,6 0,6

'1 for steel and stainless steel

HALFEN Hot-Rolled Mounting Channels HM

Performances Annex C1

Characteristic resistances under tension load - steel failure of channel and displacements

263684.19 8.06.02-81/17

N

l:l"'a,

t (0

a, 0Cl)� �...,

07J ::, (1) ll> ::::i, ... 0 ll> ...

$l 3 (1) ll> ::::!. :::J Cl) C) � CO C) Cl)

in Cl)

1n·

s-:J C) (1) Cl)

C: :J Q.

...

CD :J Cl)

o·:J

0 ll> Q.

1 Cl)

CD � � c ... (1)

g_ C) ::, ll> :J :J

� C" Q. cn

)> :J :J (l) X 0 1\)

::c )> r

""Tl m

z ::c 0

7 ::0 0

CD Cl.

s::: 0 C:::J e:::!".::J

(0

0 ::rDl ::J ::J CD cn

::c s:::

Table C2: Characteristic resistances under tension load - steel failure of HALFEN channel bolts

HALFEN channel bolts 0 M10 M12 M16 M20 M24 M27

Steel failure

4.6 23,2 33,7 62,8 98,0 141,2 183,6

8.8 46,4 67,4 125,6 196,0 282,4 367,2

Charakt. resistance NRk,s [kN] 50 l

)29,0 42,2 78,5 122,5 176,5 229,5

70 l)

40,6 59,0 109,9 171,5 247,1 321,3

4.6 2,00

8.8 1,50

Partial safety factor YMs 2)

50 l)

2,86

70 l)

1,87

1) materials according Annex A1and A22) in absence of other national regulations

M30

224,4

448,8

280,5

392,7

g,

iii" ::i c,,

g "t:,

eil "t:, Cl

eil Q.

� c:i §

m-c--1 Dl )>IC .!,. (1) <0 ....0 Q) .c:,.O c..> -ex> m 0 c; -aIS) 'O "'4 (1)

Z Dl

0 ::l < --1 (1) (D 30 c- ::r Cl) ::l ... -· N O

0� .... )><0"' "' Cl) "' "' 3 Cl) ::l -

g1 C C C1> ... -c (D ::l ... n "'"' ::r ... n =..._�-:r --c;, C CD A-. .+U,

Page 17 of European Technical Assessment ETA-19/0438 of 27 November 2019

English translation prepared by D/Bt

Deutsches

Institut

für

Bautechnik OIBt

Table C3-1: Characteristic resistance for shear un.der static and quasi-static loading

Mounting channel 1> HM 40/22 HM 50/30 HM 52/34 HM 55/42 HM 72/48

Reslstance for shear, local fallure of channel llps

Minimum spacing of bolts Smin,s, V [mm] 150 200 200 250 300

Characteristic resistance VRk,s,I (kN] 14 27 38 45 50

Partial safety factor VMs,I 1,8 ,i for steel and stainless steel

VRk,s,1 VRk,s,1

Ss � Smin,s,V

i i !

1

! 1 1 1

Table C3-2: Displacements under shear service load

Mountlng channel 1 > HM 40/22 HM 50/30 HM 52/34 HM 55/42 HM 72/48

Dlsplacement due to shear loading

Service load V [kN] 5,6 10,8 15,2 18,0 20,0

Displacement ov [mm] 0,3 0,8 0,6 0,6 0,9 •i for steel and stainless steel

HALFEN Hot-Rolled Mounting Channels HM

Performances Annex C3

Characteristic resistances under shear load - steel failure of channel and displacements

263684.19 8.06.02-81/17

N (1) "' (1) Q) ="'"

tD

Q) 0 (1) 0

i....

0-0 �CD Pl ::i, ..... 0 Pl ..., Q.3 CD Pl�-:::::, (JJ 0 �(l) 0 (JJ

cii (JJ

cn· s-::, 0 CD (JJ

C: ::, a. CD .....(JJ � CD� 0 Pl a. 1

(JJ

<ii � fil: E..... CD 8. 0 � Pl::,::, � CT 0

�

)> ::, ::, CD X

0 .i:,.

I )> r "Tl m z I

� :0 Q. cö Cl.

� 0 C a s·

CO

() ::, Dl :::1 :::1 CO cn

I

�

Table C4: Characteristic resistances under shear load - steel failure of HALFEN channel bolts

HALFEN channel bolts 0 M10 M12 M16 M20 M24 M27

Steel failure

4.6 13,9 20,2 37,7 58,8 84,7 110,2

8.8 23,2 33,7 62,8 98,0 141,2 183,6 Characteristic

VRk,s [kN] resistance

50 l) 17,4 25,3 47,1 73,5 105,9 137,7

70 l)24,4 35,4 65,9 102,9 148,3 192,8

4.6 29,9 52,4 133,2 259,6 449,0 665,8

Characteristic 8.8 59,8 104,8 266,4 519,3 898,0 1331,5

flexure M0

Rk,s [Nm]

resistance 50 l)

37,4 65,5 166,5 324,5 561,3 832,2

70 l)52,3 91,7 233,1 454,4 785,8 1165, 1

4.6 1,67

Partial safety 8.8 1,25

YMs 2)

factor 50

l) 2,38

70 l) 1,56

l) materials according Annex A1 and A22) in absence of other national regulations

M30

134,6

224,4

168,3

235,6

899,6

1799,2

1124,5

1574,3

gi (Q

� � :::, "'1ii"

g "t:,

eil "t:, Ql

eil Q. � 0

§

m-c -III>;r:,cc ' (1) ....

(0 .... -eo 0

0 �-com

0 C: _ ... N

O

.._. --g z11> 0 ::::i < --1 (1) (1) 3 (") C"::;(1) :!..., (") NIi> o-

.... l> (0"' "' (1)"'

"' 3 (1)

a

a:, II> 0 C CD ... -c (1) ::::i ... .., "'"' ::; ,...., :::, �::.� --c,c (1) :,.� .,.cn

For more information on the products featured here, please contact Leviat:

Notes regarding this catalogue

© Protected by copyright. The construction applications and details provided in this publication are indicative only. In every case, project working details should be entrusted to appropriately qualified and experienced persons. Whilst every care has been exercised in the preparation of this publication to ensure that any advice, recommendations or information is accurate, no liability or responsibility of any kind is accepted by Leviat for inaccuracies or printing errors. Technical and design changes are reserved. With a policy of continuous product development, Leviat reserves the right to modify product design and specification at any time.

For information on certified management systems and standards, see www.halfen.com

Leviat.com Halfen.com

AustraliaLeviat

98 Kurrajong Avenue,

Mount Druitt Sydney, NSW 2770

Tel: +61 - 2 8808 3100

Email: [email protected]

AustriaLeviat

Leonard-Bernstein-Str. 10

Saturn Tower, 1220 Wien

Tel: +43 - 1 - 259 6770

Email: [email protected]

BelgiumLeviat

Borkelstraat 131

2900 Schoten

Tel: +32 - 3 - 658 07 20

Email: [email protected]

China Leviat

Room 601 Tower D, Vantone Centre

No. A6 Chao Yang Men Wai Street

Chaoyang District

Beijing · P.R. China 100020

Tel: +86 - 10 5907 3200

Email: [email protected]

Czech Republic Leviat

Business Center Šafránkova

Šafránkova 1238/1

155 00 Praha 5

Tel: +420 - 311 - 690 060

Email: [email protected]

FinlandLeviat

Vädursgatan 5

412 50 Göteborg / Sweden

Tel: +358 (0)10 6338781

Email: [email protected]

France Leviat

18, rue Goubet

75019 Paris

Tel: +33 - 1 - 44 52 31 00

Email: [email protected]

Germany Leviat

Liebigstrasse 14

40764 Langenfeld

Tel: +49 - 2173 - 970 - 0

Email: [email protected]

IndiaLeviat

309, 3rd Floor, Orion Business Park

Ghodbunder Road, Kapurbawdi,

Thane West, Thane,

Maharashtra 400607

Tel: +91 - 22 2589 2032

Email: [email protected]

Italy Leviat

Via F.lli Bronzetti 28

24124 Bergamo

Tel: +39 - 035 - 0760711

Email: [email protected]

MalaysiaLeviat

28 Jalan Anggerik Mokara 31/59

Kota Kemuning, 40460 Shah Alam

Selangor

Tel: +603 - 5122 4182

Email: [email protected]

Netherlands Leviat

Oostermaat 3

7623 CS Borne

Tel: +31 - 74 - 267 14 49

Email: [email protected]

New ZealandLeviat

2/19 Nuttall Drive, Hillsborough,

Christchurch 8022

Tel: +64 - 3 376 5205

Email: [email protected]

Norway Leviat

Vestre Svanholmen 5

4313 Sandnes

Tel: +47 - 51 82 34 00

Email: [email protected]

Philippines Leviat

2933 Regus, Joy Nostalg,

ADB Avenue

Ortigas Center

Pasig City

Tel: +63 - 2 7957 6381

Email: [email protected]

Poland Leviat

Ul. Obornicka 287

60-691 Poznan

Tel: +48 - 61 - 622 14 14

Email: [email protected]

SingaporeLeviat

14 Benoi Crescent

Singapore 629977

Tel: +65 - 6266 6802

Email: [email protected]

Spain Leviat

Polígono Industrial Santa Ana

c/ Ignacio Zuloaga, 20

28522 Rivas-Vaciamadrid

Tel: +34 - 91 632 18 40

Email: [email protected]

Sweden Leviat

Vädursgatan 5

412 50 Göteborg

Tel: +46 - 31 - 98 58 00

Email: [email protected]

Switzerland Leviat

Hertistrasse 25

8304 Wallisellen

Tel: +41 - 44 - 849 78 78

Email: [email protected]

United Kingdom Leviat

A1/A2 Portland Close

Houghton Regis LU5 5AW

Tel: +44 - 1582 - 470 300

Email: [email protected]

United States of America Leviat

6467 S Falkenburg Rd.

Riverview, FL 33578

Tel: (800) 423-9140

Email: [email protected]

For countries not listedEmail: [email protected]

Imagine. Model. Make. Leviat.com

© 2

02

0

M-0

14-E

– 0

1/2

0

PD

F 10

/20

![HALFEN FLEXIBLE FRAMING CONNECTIONSdownloads.halfen.com/catalogues/de/media/catalogues/framingsystem… · 6 HM 52/34 Material Order no. 0280. Length [mm] wb 190-00002 fv 190-00003](https://static.fdocuments.net/doc/165x107/5afa06a67f8b9ae92b8d2ff8/halfen-flexible-framing-6-hm-5234-material-order-no-0280-length-mm-wb-190-00002.jpg)