Eshan Dave Department of Civil Engineering University …ncaupg/Activities/2013... · Eshan V....

Transcript of Eshan Dave Department of Civil Engineering University …ncaupg/Activities/2013... · Eshan V....

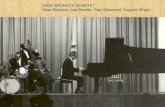

Eshan V. Dave, University of Minnesota Duluth

Eshan Dave Department of Civil Engineering University of Minnesota Duluth

NCAUPG Technical Conference, St. Louis MO

01/24/2013

Eshan V. Dave, University of Minnesota Duluth

Outline

1. Low temperature cracking and fracture energy

2. Fracture energy tests

3. Effectiveness of fracture energy as low temperature cracking performance predictor

4. Low temperature cracking mix specifications

5. Current and future research

2

Eshan V. Dave, University of Minnesota Duluth

Low Temperature Cracking (LTC) Problem LTC is a major cause of pavement deterioration in regions with

severe winter climates

3

Eshan V. Dave, University of Minnesota Duluth

Mechanism of Thermal Cracking

SUPERPAVE: Binder properties at low-temperatures are used as the main

criteria to address thermal cracking

Asphalt pavement contraction during cooling induces tensile thermal stresses

Thermal stresses are greatest at

critical low temperatures or very fast cooling rates

Thermally induced stresses well in

excess of material strength result in onset of thermal cracking

4

Eshan V. Dave, University of Minnesota Duluth

Why do we need specify LTC performance of asphalt mix?

Binder is important, but does not completely control material behavior: – Aggregate/mastic effects on mixture creep/fracture properties – Effects of RAP, RAS, WMA, and other additives – Mixture volumetrics – voids, aggregate structure – Plant/field aging – Structural effects of fracture process

Mix testing can provide:

– Improved comparisons between LTC performance of asphalt mixes – Inputs for performance prediction models – Input for maintenance decisions – Insight for policy decisions

5

Eshan V. Dave, University of Minnesota Duluth

Cracking of Asphalt Materials

6

Cracking Damage Zone

Crack formation

Onset of damage

δc

σt

Gf

Crack Mouth Opening Displacement (CMOD)

Load

Quasi-brittle fracture

Softening

Load

Load

CMOD

Eshan V. Dave, University of Minnesota Duluth

Fracture Energy, Gf

Sf

Crack Mouth Opening Displacement (CMOD), u

Load

, P

Quasi-brittle fracture

Softening (damage)

7

P

P

CMOD, u

Fracture Energy, Gf: Energy required to create unit fracture surface Fracture work: Area under Load-Displacement curve Gf = Fracture Work Fracture Area

Eshan V. Dave, University of Minnesota Duluth

Tensile Strength-Fracture Energy Comparison

102

103

104

100

101

102

Fracture Energy (J/m2)

Indi

rect

Ten

sile

Stre

ngth

(MP

a)

Data from Iowa ProjectData from Other Projects

More Ductile (Compliant)

• Fracture energy appears to disseminate between mixes better than IDT strength

• Especially prevalent with modified binders

• Data supports need for true fracture mechanics approach

8 Source: Wagoner and Buttlar, 2007

Eshan V. Dave, University of Minnesota Duluth

-40 -30 -20 -10 0 100

500

1000

1500

2000

2500

Temperature, T (oC)

Frac

ture

Ene

rgy,

Gf (J

/m2 )

PG58-28PG64-22

Gf=627.1Exp0.041*T

r2 = 0.564

Gf =1299.3Exp0.047*T

r2 = 0.564r2 = 0.507

Test Temperature and Fracture Energy

9

In terms of fracture energy the temperature spread is consistently greater than 6ºC

Eshan V. Dave, University of Minnesota Duluth

Outline

1. Low temperature cracking and fracture energy

2. Fracture energy tests

3. Effectiveness of fracture energy as low temperature cracking performance predictor

4. Low temperature cracking mix specifications

5. Current and future research

10

Eshan V. Dave, University of Minnesota Duluth

Disk-Shaped Compact Tension (DCT ) Test ASTM D7313-08 Loading Rate:

– Crack Mouth Opening Displacement – CMOD Rate = 1.0 mm/min

Measurements: – CMOD – Load

Wagoner, Buttlar and Paulino, Experimental Mechanics, 45:270, 2005. ASTM D7313: Standard Test Method for Determining Fracture Energy of Asphalt-Aggregate Mixtures Using the Disk-Shaped Compact Tension Geometry (2008)

11

P

P

CMOD, u

Eshan V. Dave, University of Minnesota Duluth

Semi-circular Bend, SC(B) Test Test Control: Constant CMOD Measurements:

– CMOD – Load

Li and Marasteanu, J. Asphalt Pav. Tech., 73:401-426, 2004.

12

Eshan V. Dave, University of Minnesota Duluth

Outline

1. Low temperature cracking and fracture energy

2. Fracture energy tests

3. Effectiveness of fracture energy as low temperature cracking performance predictor

4. Low temperature cracking mix specifications

5. Current and future research

13

Eshan V. Dave, University of Minnesota Duluth

Low Temperature Cracking Pooled Fund Study

Investigation of Low Temperature Cracking in Asphalt Pavements – TPF-5(132) – Phase II

Participating States: – Minnesota (Lead State) – Connecticut – Iowa – New York – North Dakota – Wisconsin

LTC performance specifications for asphalt mixes Final Report:

http://www.pooledfund.org/Document/Download/3690

14

Eshan V. Dave, University of Minnesota Duluth

Results from Phase-I of Pooled Fund Study

15

Eshan V. Dave, University of Minnesota Duluth

Results for Phase-II of Pooled Fund Study

Results for validation sections:

16

Eshan V. Dave, University of Minnesota Duluth

Results from other Minnesota Mixes

Field Cores (TH371) – RP6: Good performing section (2005 construction) – RP17/21.5: Poor performing section (2004 construction)

Plant Produced Mixes (TH9 and TH70)

17

TH9 TH70 Gradation coarse fine Design Traffic Level 1 – 3 Million ESALs Design Gyrations 60 Binder PG58-34 RAP [%] 20 20 Total AC [%] 4.0 5.2 New AC Ratio [%] 73 76

Eshan V. Dave, University of Minnesota Duluth

Results for TH371 Sections

18

RP North Bound Crack Count

South Bound Crack Count

Fracture Energy [J/m2]

Wear 6 3 4 453.44

17 12 8 356.18 21.5 10 57 330.59

050

100150200250300350400450500

RP 6 RP 17 RP 21.5

Frac

ture

Ene

rgy

[J/m

2 ]

Eshan V. Dave, University of Minnesota Duluth

TH371 Recovered Binder Grade and Fracture Energy

19

250

300

350

400

450

500

-40-35-30-25-20

DC

T Fr

actu

re E

nerg

y (J

/m2)

Low Temperature Grade of Recovered Binder (ºC)

Eshan V. Dave, University of Minnesota Duluth

DCT Testing: TH9 & TH70 Samples

• TH9 Coarse Gradation – Total AC = 4.0%

• TH70 Fine Gradation • Total AC = 5.2%

0

100

200

300

400

500

600

700

800

TH9 TH70

Frac

ture

Ener

gy [J

/m2 ]

Tested at -24CTested at -18C

Eshan V. Dave, University of Minnesota Duluth

Outline

1. Low temperature cracking and fracture energy

2. Fracture energy tests

3. Effectiveness of fracture energy as low temperature cracking performance predictor

4. Low temperature cracking mix specifications

5. Current and future research

21

Eshan V. Dave, University of Minnesota Duluth

LTC Performance Specifications

Based on traffic levels Limits based on:

– Fracture energy test @ 10ºC above 98% reliability Superpave Low Temperature PG (PGLT)

– Low temperature cracking performance model (IlliTC)

22

Limits

Project Criticality / Traffic Level High

(> 30M ESALs) Medium

(10 – 30M ESALs) Low

(< 10M ESALs) DCT Fracture Energy

(J/m2) 690 460 400

IlliTC Cracking Prediction (m/km) < 4 < 64 Not required

Eshan V. Dave, University of Minnesota Duluth

IlliTC: Low Temperature Cracking Model

Self contained user-friendly software for conducting low temperature cracking simulations

Simulations are based on the fracture mechanics principles

Accounts for pavement structure, non uniform temperature profiles, and mix viscoelastic and fracture properties

Has intuitive graphical user interface

23

Eshan V. Dave, University of Minnesota Duluth

Overview

1. Low temperature cracking and mix tests

2. Fracture energy tests

3. Effectiveness of fracture energy as low temperature cracking performance predictor

4. Low temperature cracking mix specifications

5. Current and future research

28

Eshan V. Dave, University of Minnesota Duluth

MnDOT DCT Low Temperature Fracture Testing Pilot Project

Develop DCT specimen fabrication and testing capabilities at MnDOT

Between 3 – 5 pavement projects will be used for pilot implementation/trial of LTC mix specifications

Lab testing will be conducted during mix design and production

Testing will be conducted during 2013 construction season

29

Eshan V. Dave, University of Minnesota Duluth

MnDOT Study on Asphalt Performance Test

Phase-I: Synthesis of Asphalt Performance Tests – Several cracking tests are available

Two most promising tests:

– Disk Shaped Compact Tension Fracture Test (DCT)

– Dry Indirect Tensile Strength (ITS) from TSR

Phase-II: Currently Underway – Task-1: Analysis of Laboratory Test and Field Performance Data – Task-2: Laboratory Testing and Field Performance Evaluation of

Field Sections DCT versus Field Performance

– Task-3: Analysis of Lab Testing and Field Performance Data Preliminary Performance Specification

30

Eshan V. Dave, University of Minnesota Duluth

Summary

Low temperature cracking performance of pavements show very good correlation to mix fracture energies

Fracture energy based low temperature cracking mix specifications have been developed through Pooled Fund Study

The fracture energy based specifications are supplemented with thermal cracking prediction model (IlliTC) for high traffic roadways

Currently studies are underway to: – Conduct pilot implementation of fracture energy based

specifications – Further validate the fracture energy recommendations and

develop performance based specifications

31

Eshan V. Dave, University of Minnesota Duluth

Thank you for your attention

Questions? Contributors:

– Bill Buttlar – Tim Clyne – Mihai Marasteanu – Luke Johanneck

32

Acknowledgements: US Department of Transportation (FHWA) Minnesota Department of Transportation Connecticut Department of Transportation Iowa Department of Transportation North Dakota Department of Transportation New York State Department of Transportation Wisconsin Department of Transportation Nextrans Research Center

Contact: Eshan V. Dave [email protected]