Escalator 2D Fine Screen - Longwood...

Transcript of Escalator 2D Fine Screen - Longwood...

Escalator2D Fine Screen

Industry-leading specialists in automated screens and screenings handling equipment

• WIMES 5.03 Compliant 2D screens

• Aperture size 6mm or 3mm for sewage and storm water channel flow from 50l/s to 4500l/s

• Construction in mild steel or stainless steel (304 or 316)

• Proven history since 1993, with continual industry lead development

• Bespoke design to your requirements

• High performance - low operating costs

• Self adjusting rotating brush

Escalator 2D Fine Screen

Features and Benefits Specifications

• The Longwood Escalator provides continuous fine screening.

• Standard 6mm or optional 3mm perforations.

• Either channel or stainless steel tank mounting.

• WIMES 5.03 Fine (2D) screens compliant.

• Performance testing by NSEF proved an average screenings capture ratio of 79% on all solids

• Tines - Optional to help prevent rag rolling and to help pickup larger matter

• Over 1300 screens sold in the UK

• Single/dual speed options available

• Hygienically encapsulated above coping level

• ATEX compliant for Hazardous Areas.

• Coarse protection is not required.

• Stainless steel elements carried on specially designed mild steel or stainless steel chains.

• Self cleaning, patented, deluge system to provide wash water where site source is unavailable.

• Screen installation angle 60° or 45° to optimise screenings area.

• Screen is sized to suit customer requirements.

• Excellent for retrofitting into existing channels.

• Low operating costs/low maintenance costs/low whole life costs

Min channel width 450mm

Max channel width 3250mm

Min channel depth 500mm

Max channel depth 10000mm

Min flow per screen 50l/s

Max flow per screen 4000l/s

Perforations diameter 3mm or 6mm

Screen Angle 45° - 60°

Washwater Req. 1-2l/sec @ 4 Bar

Noise Level <80dB

Design Life >20 Years

The Longwood Engineering Company LimitedSilver Street, Huddersfield

HD5 9BS, England

T +44 (0) 1484 424545

F +44 (0) 1484 437379

E [email protected] www.longwoodengineering.co.uk

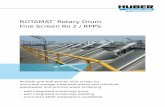

Inspection Door

Discharge Point

Self adjusting brush system

Screen drive

Wash water spray system termination

Maintenance Panel

Direction of travel

Channel Invert ( optional )

Channel

Coping Level

WaTEr FLoW

![3D SCREEN PRINTING MASS PRODUCTION OF ... - · PDF file3D SCREEN PRINTING MASS PRODUCTION OF ... [HB] 3D Metal Printing - Binder Jetting approach ... 2D screen printing is an established](https://static.fdocuments.net/doc/165x107/5aa545cf7f8b9ab4788cecdc/3d-screen-printing-mass-production-of-screen-printing-mass-production.jpg)