Environmental Guidelines for Controlling Emissions of Volatile ...

Transcript of Environmental Guidelines for Controlling Emissions of Volatile ...

/ft

CCMECanadian Council Le Consell canadlen

of Ministers des mlnlstresof the Environment de I'envlronnement

ENVIRONMENTAL GUIDEUNESFOR CONTROLLING EMISSIONS OFVOLATILEORGANIC COMPOUNDS

FROM ABOVE GROUNDSTORAGE TANKS

PN 1180

Preface

Theseguidelineshavebeendevelopedas part of theManagementPlanfor NitrogenOxides(NO)andVolatileOrganicCompounds(VOC):PhaseI (CCME-EPC/TRE-31E) publishedNovember1990by the CanadianCouncilof Ministersof the Environment.The purposeof these guidelinesis toreduceVOCemissionsfrom tanks storing volatile organic liquids (VOLs).Theyare intendedtopromoteconsistency,uniformity,andcompatibilityin the implementationof VOCcontrolsfor tanks.Over20 000 storagetanks (excludingtanks at service stations)are presentlyin VOLservice inCanada.EnvironmentCanadaestimatesthat thesetanks are responsiblefor emittingmorethan37000tonnesof VOCsintotheatmosphereeachyear (over1.5 percentof the nationaltotal). Thereductionsobtainedbytheimplementationof theseguidelinescould ultimatelyaccountfor overfivepercentof all the reductionsoutlinedin the ManagementPlan.

VOCandNOxreactin thepresenceof sunlighton a warmdayto form ground-levelozone,aprincipalcomponentof urbansmog. Ozoneis knowntodecreaselungfunction,causeprematureagingof thelung,anddamagecropsandvegetation.At manylocationsin Canadaduringthesummer,ground-levelozoneconcentrationsoftenexceedthemaximumone-houracceptablenationalambientairqualityobjectiveof 82 partsperbillion*(ppb).Amongthemonitoredareas,theLowerFraserValleyofBritishColumbia,theWindsor-QuebecCityCorridor,andtheSaintJohn,NewBrunswickareaoftheSouthernAtlanticRegionexperiencetheworstandmostfrequentozoneepisodes.

Theseguidelinesweredevelopedby representativesfrom industry,environmentalgroups,andmunicipal,regional,provincial,andfederalgovernments.Thecontributionsof all taskforceparticipantsaregratefullyacknowledged.Themembersof thistaskforcearelistedinAppendixA.

Otherrecentfederalguidelinesthat applyto abovegroundstoragetanksareEnvironmentalCodeof Practicefor VapourRecoveryin GasolineDistributionNetworks(PN 1057) forcontrollingemissionsof vapours,and EnvironmentalCodeof Practicefor AbovegroundStorageTanksSystemsContainingPetroleumProducts(PN1148)for controllingliquidleaks.

Inquiriesandcommentsontheseguidelinesarewelcomeandmaybesentto:

ChiefOil,GasandEnergyDivision

IndustrialSectorsBranchEnvironmentCanada

Ottawa,OntarioK1A OH3"

Tel:(819)953-1120Fax:(819)953-8903

· 1billion= 1 x 10'

-. I

Table of Contents

Preface. .. . .. .. .. iGlossary vAbbreviations .. .. . . viiiConversionFactors . viii

I

Part1 Introduction,

,IPart2 Applicability

Section2.1Section2.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . " 1

2

General. . . 2~~M 2

Part3 Timing 3I

Section3.1Section3.2Section3.3

NewTanks 3ExistingTanks 3Inspections and Record Keeping . . . . . . . . . . . . . . . . . . . . . . . . . .. 4I

II Part4 Requirements 5I

Section4.1Section4.2Section4.3

VerticalTanks.. . . 5Non-verticalTanks . 5AllTanks . . 6

Part5 Specifications 7

Section5.1Section5.2Section5.3Section5.4Section5.5Section5.6

SubmergedFillPipe 7InternalFloatingRoof 7ExternalFloatingRoof. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 8VapourControlSystem.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 8VapourBalancingSystem.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 9Pressure-vacuumVent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 9

I Part6 Inspections 10

---

Section6.1Section6.2Section6.3Section6.4Section6.5

.

InternalFloatingRoof 10ExternalFloatingRoof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 10Vapour Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 10

VapourBalancingSystem.. . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 10Pressure-vacuumVent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 10

IIIII

Part7 RecordKeeping , '..., ,.." ,..., 11

Section7,1Section7.2

Tankswith a FloatingRoof or a Pressure-vacuumVent " . . . . ... 11Tankswith a VapourControlSystemor a VapourBalancingSystem, . . . . . , , . . . . , . , . . , . . . . . . . . . . . . . . , , , '. 11

Summary . . . . . . . . . . , . . . , , . , . . . . . . . . . . . . . . . . . .Bibliography. . . . . . . . . . . . . . . . . . . , . , . . , , . . . , . . . . . , . . . .

List of Appendices

AppendixA

AppendixB

AppendixC

Appendix0

AppendixE

AppendixF

Iv

Listof TaskForceMembers.. , , . . . . . . . . . . . . . . . . . . . . . . . . . . . , . , . .

VapourPressureofSelectedLiquidsat21.1OC(70°F) ................

Procedurefor MeasuringCumulativeGapArea '.......

AlternativeInspectionProcedurefor InternalFloatingRoofTanks . . . . . . . .

IllustrationsofVariousSealTypes , , ,.':'., ,..".,.,

AuthorityHavingJurisdictionoverStorageTanks. . . . . . . . . . . . . . . . . . .. 31

I12 I15

II

17\I

21123

251.

271

Glossary

Themeaningof certainterms, within the contextof theseguidelines,is describedin the following.

Aboveground-Notcompletelyburiedbeneaththegroundsurface.

· Authorityhavingjurisdiction- Thegovernmentdepartmentor agencythatis responsiblefortheenforcementofanyactorregulationthatpertainstotheemissionsfromtanks.AppendixFprovides

I alistofcontactsfor theappropriateauthorityhavingjurisdiction.

, Bulkplant-Asecondarydistributionfacilitythatnormallyreceivesvolatileorganicliquidsbycargotanktrucksandstorestheliquidsintanksforsubsequenttransportationordistributionbycargotank

I trucks.

I Capacity-Themaximumliquidvolumethatatankhasbeendesignedto store.

Cumulativegaparea- Thesumof thesurfaceareasof eachgap. Theprocedureto measurethecumulativegapareaisdescribedinAppendixC.

Degassing-Theprocessof removingall thevapoursfrom a tank in orderto safelypreparethe tankfor entry,as describedin API-2015.

Diameter-Theinteriordiameterof atank.

Emissioncontrol efficiency- Theefficiencyis equalto 1 minustheratioof theatmosphericemissionsfromatankwithavapourcontrolsystemorvapourbalancingsystemto theatmosphericemissions(inthesameunits)fromthesametankwithnofloatingroof,vapourcontrolsystem.orvapourbalancingsysteminplace.

Existingtank- A tankthatcommencedoperationbeforethe one-yearanniversaryof the publicationof theseguidelinesby the CCME.

Externalfloatingroof- Afloatingroofthatformstheroofofatank.

Floatingroof- A structurethatfloatsuponandis supportedby thesurfaceof a liquidfor thepurposeof limitingvapourlossto theatmosphere.

Gap width- Thedistancebetweenthewallofatankandtheseal..

I

Internal floating roof- Afloatingroofinsideatankcoveredbya permanentfixedroof.

Liquid-mountedseal- A sealthatis fully incontactwiththeliquidbetweenthefloatingroofandthewallof atank.

....--

. v

I

Lowerflammable limit- Theconcentrationof flammablegasesor vapoursin the air abovewhichthe mixtureis flammable. Theterm "lowerexplosivitylimit' is also used.

Mechanical-shoeseal- Acurvedmetalsheet,orshoe,thatis heldverticallyagainstthewallofatankbysprings,weightedleversor othermechanismsandis attachedto the floatingroof by braces I

or othermeans.Thesealhasanenvelopeattachedto thefloatingroof that is imperviousto volatile Irorganiccompounds.

Newtank-Atankthatcommencedoperationanytimeonor aftertheone-yearanniversaryofthe

Ipublicationof theseguidelinesby the CCME.

Non-pressurizedtank- Any tankthat meetsthe scopingrequirementsof API-650,namelya tank Ihavinginternalpressuresapproximatingatmosphericpressure(Le.,internalpressurenot exceedingthe weightof the roof plates).

Non-verticaltank- Anyabovegroundtankthatisnotaverticaltank.Thesetanksinclude,butarenotlimitedto, horizontaltanks,sphericalvessels,andnon-cylindricalcontainers.

Owner- Theindividual,company,corporateentity,institution,or governmentdepartmentor agencythat has legalownershiprightsto the tankor hasbeenassignedthe custodyto control, carefor,manage,or disposeof thetank. Forthepurposeof theseguidelines,the ownerof the landonwhich

the tank is locatedshallbedeemedto betheownerof thetank,un'lesstheownerof thelandIsatisfiestheauthorityhavingjurisdictionto thecontrary.

IPressure-vacuumvent-AventdesignedtoallowrelativelysmallpressureincreasesordecreasesIwithinatank,withoutallowingvapourto beemittedto theatmosphereor airto bedrawnintothe

~ IPrimaryseal- Thesealmountedclosestto thesurfaceof theliquidcontainedinatank. I

Reidvapourpressure- Thevapourpressureof a volatileorganicliquidmeasuredat a temperatureIof 37.8 CC(100oF)accordingto the test methodASTM-D323.

I

Relief tank- A tankthat hasthe sole purposeof providingshort-termstorageof volatileorganicIliquidsinemergencysituations,suchas over-pressuringon the main line. Relieftanksareprimarilyfound in pipelineservice.

Rim-mountedseal- A sealthatis mountedontherimof afloatingroof.

Seal-Aperipheralstructurethatcoversthespacebetweenafloatingroofandthewallof atanktolimitvapourlossto theatmosphere.VarioussealsandsealconfigurationsareillustratedinAppendixE.

Secondary seal- A sealmountedabovethe primaryseal.

vi

Shoe-mountedseal- A secondarysealthat is mountedon the metalplateof the mechanical-shoeseal.

Standinglosses- Theexpulsionof vapoursfrom a tank,dueto changesin temperatureandI pressure,withoutanyappreciablechangeintheliquidlevelofthetank.

Tank-Anyabovegroundnon-pressurizedstoragecontainer,vessel,or reservoirthat storesa liquid.

I Throughput-Thevolumeof a liquidthatis movedthroughatankina unitof time.

Vapourbalancingsystem- Asystemthatis intendedto controlworkinglossesof volatileorganiccompoundsfromatank.[Note:anexampleof sucha systemis describedinEnvironmentalCodeofPracticefor VapourRecoveryin GasolineDistributionNetworks(CCME-EPC/TRE-30E).]

Vapourcontrolsystem- A systemthatcontrolsstandingandworkinglossesofvolatileorganiccompoundsfromatank. [Note:thisdefinitiondiffersfromthatdefinedinEnvironmentalCodeofPracticefor VapourRecoveryin GasolineDistributionNetworks(CCME-EPC/TRE-30E)inwhichonlyworkinglosseswereconsidered.]

Vapour-mountedseal- A sealmountedabovetheliquidbetweenthefloatingroofandthewallofatank.

Vapourpressure- Thepressureexertedwhena liquidis inequilibriumwithitsownvapouratagiventemperature.Forthepurposeoftheseguidelines,thetemperatureshallbeequalto (i) 21.1OC(lO°F)if the liquidis storedatambienttemperature,or (ii) themaximummonthlyaverageliquidstoragetemperatureif theliquidis artificiallyheatedorcooled.

Vapourspace-Thespaceenclosedbythewallof thetank,theverticalsurfaceattheperipheryofthefloatingroof,thesurfaceof theliquid,andtheundersideof theof thefloatingroofseal(ortheundersideof theenvelopeinthecaseofa mechanical-shoeseal).

Verticaltank- Acylindricaltankthathasitsaxisperpendicularto thegroundsurface.

Volatile organic compound- Any organic compound that participates in atmosphericphotochemicalreactions,but excluding,becauseof negligiblephotochemicalreactivity,methane,ethane,1,1,1-trichlorethane,methylenechloride,fluorocarbons(FCs),chlorofluorocarbons(CFCs),andhydrochlorofluorocarbons(HCFCs).

, Volatileorganicliquid- Anyliquidthatcontainsanyvolatileorganiccompound.I

Weathershield- A peripheralstructurethatcoversa primaryorsecondarysealfor theprimarypurposeofprovidingshelterfromrain,snowandultravioletradiation.

Workinglosses- Thedisplacementofvapoursfromatankduringtheemptyingandfillingof thetank.

vii

Abbreviations

API

ASTM

CCMEcmcm2CCOF

kgkm/hkPa

. LFLmm3RVPVOCVOL

AmericanPetroleumInstituteAmericanSocietyfor TestingandMaterialsCanadianCouncilof Ministersof the EnvironmentcentimetresquarecentimetredegreesCelsiusdegreesFahrenheitkilogramkilometresperhourkilopascallowerflammablelimitmetrecubic metre

Reidvapourpressurevolatileorganiccompoundvolatileorganicliquid

ConversionFactors

Thefollowingapproximateconversionfactorsarelistedfortheconvenienceof thereader.

viii

1 kPa = 0.145poundsper square inch= 0.750cm of mercury

1 m = 100cm= 3.281 feet

1 m3 = 1000 litres

= 264.17 U.S. gallons= 219.97 Imperial gallons= 6.29 barrels (petroleum)

I

1 tonne = 1000 kg= 1.102 Imperialtons

l

1 km/h = 0.62 miles per hour1

Temperature (CC) = [Temperature eF) - 32] x 5/9I

,....

-------

Part 1

Introduction

Thepurposeof theseguidelinesis to adviseenvironmentalregulatingauthoritiesandownersofstoragetanksof meansto reduceVOCemissionsfromtanksstoringVOLs.Theseguidelinescategorizetanksbydiameteror capacityandbythevapourpressureof thestoredliquidat21.1OC(70'f),andthendescribetheequipmentrequiredtoreduceVOCemissions.Thetaskforcebelievesthattheseguidelinesshouldbethenormfor newtanksbuiltanywhereinCanadaandfor existingtankslocatedintheLowerFraserValleyofBritishColumbia,theWindsor-QuebecCityCorridor.andtheSaintJohn,NewBrunswickareaof theSouthernAtlanticRegion.

Inadditionto reducingVOCemissionsto theatmosphere.ownersof storagetankswill realizeanumberof benefitsbyimplementingtheseguidelines.Theseincludea reductioninthelossesoftheliquid,andthereforeafinancialgain.anda reductionintheexposureof theemployeesandthelocalcommunityto VOLvapours.Thecostof theseguidelines,in dollarspertonneof VOCsreduced,is lowerthanmostotherVOCreductionmeasures.

Becauseof thedifficultyof measuringemissionsfromtanksstoringVOLs,amaximumallowableemissionratecannotbeassigned(althoughestimatesof emissionsfromatankcanbecomputedusingtheUnitedStatesEnvironmentalProtectionAgency'sstoragetankemissionestimationsoftware:TANKS).Theseguidelines,therefore,usuallyspecifytechnologystandardsinsteadofperformancestandards.

TheseguidelinesaddressVOCemissionsfrom storagetanksanddo notsupersedeexistingregulations.Additionalconsiderations,suchastheidentificationof a vapourfromastoragetankasahazardouspollutant,anairtoxic,agreenhousegas,a stratosphericozone-depletinggas,oranodour-causingvapour,maymaketherequirementsdescribedintheseguidelinesinsufficientforcertainVOLs.

.--......-

-.

- -

1

III

I

Part 2

Applicability

Section2.1 GeneralI

Theseguidelinesapplyto all newtanksbuilt anywherein Canada,andto existingtanks locatedintheLowerFraserValleyof BritishColumbia,theWindsor-QuebecCityCorridor,andthe SaintJohn,1NewBrunswickareaof theSouthernAtlanticRegion.Althoughthe approximateboundariesin theselthree regions are defined in the ManagementPlan for Nitrogen Oxidesand Volatile Organic.Compounds:PhaseI (CCME-EPC/TRE-31E),theexactboundariesareto bedefinedby the authorityhaving jurisdiction. Otherregionsof Canadamay applytheseguidelinesto existingtanksat the~discretionof the authorityhavingjurisdiction.

Section2.2 Exemptions

Theseguidelinesexclude:

. tankswith capacitiesof lessthanor equalto 4 m3,

· tanksstoringliquidswithavapourpressure(asdefinedintheGlossaryofTerms)of lessthan10kPa,

· tanksthatarecompletelyburiedbeneaththegroundsurface,

· tanksthatareportable,and

· relieftanks,providedthattheliquidlevelis lessthan15percentof theheightof thetankwall95percentofthetime,anda recordof therelieftank'suseandliquidlevelis kept(thisrecordshall bemadeavailableto theauthorityhavingjurisdictionuponrequest).

..

2

Part 3

Timing

Section3.1 NewTanks

Newtanksshallconformwith Part4 (Requirements)andPart5 (Specifications)oneyearafterthe

publicationof theseguidelinesby the CCME.

Section3.2 ExistingTanks

3.2.1 Existingtanksthatdo nothavea floatingroof,a vapourcontrolsystem,or a vapourbalancingsystemoneyearafterthepublicationof theseguidelinesby theCCMEshallconformwithPart4 (Requirements)andPart5 (Specifications)whenthetankis degassedfor scheduledmaintenanceorbyDecember31,2004,whicheverisearlier.

3.2.2 Existingtanksthathaveaninternalfloatingroofoneyearafterthepublicationof theseguidelinesby the CCMEshall conformwith Part 4 (Requirements)and Part 5(Specifications)whentheexistingsealsonthefloatingroofneedto bereplacedbecausetheyarewornpastthepointof goodworkingorderorbyDecember31,2004,whicheveris later.Sealsshallbeconsideredwornpastthepointofgoodworkingorderwhen:

. it is determinedduringaninspectionthattheprimaryseal'scumulativegapareaforgapwidthsgreaterthan0.3cmexceeds200cm2permetreof tankdiameter,andthatthesealcannotberepairedto meetthislimit;or

. therearetearsorholesinthesealsthatcannotberepairedinasatisfactorymanner.

It is recommendedthatanysealreplacedbeforeDecember31, 2004,conformwith Part5(Specifications).

3.2.3 Existingtanksthathaveanexternalfloatingroofoneyearafterthepublicationof these{luide1inesby the CCMEshall conformwith Part 4 (Requirements)and Part 5(Specifications)whentheexistingsealsonthefloatingroofneedto bereplacedbecausetheyarewornpastthepointof goodworkingorderorbyDecember31,2004,whicheveris later.Sealsshallbeconsideredwornpastthepointof goodworkingorderwhen:

. it is determinedduringaninspectionthattheprimaryseal'scumulativegapareaforgapwidthsgreaterthan0.3cm exceeds200 cm2permetreof tankdiameter,andthatthe sealcannotbe repairedto meet1hislimit;

. I(

. it is determinedduringaninspectionthatthe secondaryseal'scumulativegapareaforgapwidthsgreaterthan0.3 cm exceeds20 cm2permetreof tankdiameter,andthatthe sealcannotbe repairedto meetthis limit; or

3

. therearetearsor holesinthesealsthatcannotberepairedinasatisfactorymanner.J

IIt is recommendedthatanysealreplacedbeforeDecember31,2004,conformwithPart5i(Specifications). I

I

3.2.4 Existingtanksthat havea vapourcontrol systemor a vapourbalancingsystem oneyearlafter the publication of these guidelines by the CCME shall conform with Part 41(Requirements)and Part5 (Specifications)by December31,2004. I

Section3.3 Inspectionsand RecordKeeping INewandexistingtanksshallconformwithPart6 (Inspections)andPart7 (RecordKeeping)on~yearafterthepublicationof theseguidelinesbytheCCME.[Note:Part6 (Inspections)andPart~(RecordKeeping)haverequirementsonlyfor tanksthathaveor installa floatingroof,a vapou

1

controlsystem,avapourbalancingsystem,or apressure-vacuumvent.]

...

4

Part 4

Requirements

Section4.1 VerticalTanks

4.1.1 Verticaltankswithacapacitygreaterthan4 m3butwithdiameterslessthan4.0mstoringa VOLwith a vapourpressuregreaterthanor equalto 10 kPashallhavea pressure-vacuumvent,asdescribedinPart5 (Specifications).Tanksequippedwithafloatingroof,avapourcontrolsystem,oravapourbalancingsystemareexemptfromthisrequirement.If, intheopinionof theauthorityhavingjurisdiction,theconditionof anexistingtankissuchthattheinstallationof a pressure-vacuumventwouldresultina safetyhazard,thetankis exemptfromthisrequirement.

4.1.2 Verticaltankswithdiametersgreaterthanorequalto4.0mbutlessthan9.0mstoringaVOLwithavapourpressuregreaterthanorequalto 10kPabutlessthan76kPashallhaveoneof: an internalfloatingroof,anexternalfloatingroof,a vapourcontrolsystem,or avapourbalancingsystem.ThesedevicesaredescribedinPart5 (Specifications).

4.1.3 Verticaltankswithdiametersgreaterthanor equalto9.0mstoringaVOLwithavapourpressuregreaterthanorequalto 10kPabutlessthan76kPashallhaveoneof:aninternalfloatingroof,anexternalfloatingroof,or a vapourcontrolsystem.Thesedevicesaredescribedin Part5 (Specifications).

Exception:Existingverticaltankswithdiametersgreaterthanorequalto 9.0mbutlessthan15.0mstoringaVOLwithavapourpressuregreaterthanorequalto 10kPabutlessthan76 kPaandlocatedin a bulkplantshallhaveoneof: an internalfloatingroof,anexternalfloatingroof,a vapourcontrolsystem,or a vapourbalancingsystem.ThesedevicesaredescribedinPart5 (Specifications).

Section4.2 Non-verticalTanks

4.2.1 Non-verticaltankswithcapacitiesgreaterthan4 m3butlessthan75m3storingaVOLwithavapourpressuregreaterthanor equalto 10kPashallhavea pressure-vacuumvent,asdescribedinPart5 (Specifications).Tanksequippedwithavapourcontrolsystemoravapourbalancingsystemareexemptfrom this requirement.If, in theopinionof theauthorityhavingjurisdiction,theconditionof anexistingtankissuchthattheinstallationof a pressure-vacuumventwouldresultina safetyhazard,thetankis exemptfromthisrequirement.

4.2.2 Non-verticaltankswithcapacitiesgreaterthanor equalto 75 m3butlessthan500m3storingaVOLwithavapourpressuregreaterthanor equalto 10kPabutlessthan76kPashallhaveeitheravapourcontrolsystemoravapourbalancingsystem.ThesedevicesaredescribedinPart5 (Specifications).

5

4.2.3 Non-verticaltankswithcapacitiesgreaterthanor equalto 500m3storingaVOLwitha Part 5vapourpressuregreaterthanorequalto 10kPabutlessthan76kPashallhaveavapourcontrolsystem,asdescribedinPart5 (Specifications). Specification

Section4.3 All Tanks

4.3.1 All tankswith capacitiesgreaterthanor equalto 75 m3storinga VOLwith a vapourpressuregreaterthanorequalto76kPashallhaveavapourcontrolsystem,asdescribedinPart5 (Specifications).

4.3.2 In additionto anyotherrequiredequipment,all tankswithcapacitiesgreaterthan4 m3storinga VOLwith a vapourpressuregreaterthanor equalto 10 kPashallhaveasubmergedfill pipe,asdescribedinPart5 (Specifications).

4.3.3 Duringdegassingof thetank,theownershallminimizetheemissionsof VOCsto theatmosphere.TheownershallusegoodoperatingpracticesasdescribedinAPI-2015.

4.3.4 Inspectionsshallconformwith Part6 (Inspections),andrecordsshall bekeptas describedin Part7 (RecordKeeping).

4.3.5 Anypieceof equipmentthatis partof apressure-vacuumvent,afloatingroof,a vapourcontrolsystem,or a vapourbalancingsystemandthatis foundnotto meettheabovespecificationsor to beotherwisedefectiveduringaninspection,mustberepairedinasatisfactorymannerwithin45daysof theinspectionor replacedwithin180daysof theinspection,unlesstheauthorityhavingjurisdictionhasacceptedanalternativerepairorreplacementplanandschedulesubmittedbytheownerof thetank.

4.3.6 Atthediscretionof theauthorityhavingjurisdiction,theauthoritymayrequiretheownerof anexistingtankto providea retrofitplanandschedule.

4.3.7 It is recommended,asa minimum,thatexistingtankslocatedoutsideof thethreeareaslistedinPart2 (Applicability)shouldconformwithPart6 (Inspections)andPart7 (RecordKeeping).

6

Section5.1 Sub

Thefill pipeshallthe tankduringm

I Section5.2 Inte

i Tanksthathavear5.2.1 Equipme

ingoodmechanilsealshefloating~shallCOl

Forthesealonl)wallforandatleithesegu

Forthedesignedemissioequivale

5.2.2 Gapspe

Primary:forgapv

Secondamaximurgreatert

storingaVOLwitha Part 5I shallhaveavapour

t VOLwith a vapouriystem,as described

es greaterthan4 m310 kPa shall havea

,ionsof VOCsto thecribedinAPI-2015.

bekeptas described

loatingroof, a vapourlot to meetthe above

mustbe repairedin avithin180daysof theinalternativerepairor..

nayrequiretheowner

Specifications

Section5.1 SubmergedFillPipe

Thefill pipeshallbecompletelyandcontinuouslysubmergedbeneaththesurfaceof theliquidinthetankduringnormalfillingor partialfillingof thetank.

Section5.2 InternalFloatingRoof

Tanksthathaveaninternalfloatingroof shall meetthe following equipmentandgapspecifications.

5.2.1 Equipmentspecifications.Theroofshallhavegasketedorotherwisecontrolledopeningsin goodworkingorder. Inaddition,theroofshallhaveoneof:a liquid-mountedseal,amechanical-shoeseal,oravapour-mountedsealwitharim-mountedsecondaryseal.Thesealshallforma continuousvapour-tightenclosurearoundtheentireperimeterof thefloatingroof,exceptwherethesealis incontactwiththetankwall,inwhichcasethesealshallconformwiththefollowinggapspecifications.

Forthepurposeof theseguidelines,a sealshallbeconsideredto bea mechanical-shoesealonlyif themetalsheetis designedto extendandbeinverticalcontactwiththetankwallfor at least10cm belowtheliquidsurface,at least10cmabovetheliquidsurface,andatleast30cmintotal.If thesealdoesnotmeetthesesizecriteria,forthepurposeoftheseguidelines,thesealshallbeconsideredto beavapour-mountedseal.

Forthe purposeof theseguidelines,a sealthatdoesnotmeetthesecriteriaor thatisdesigneddifferentlymaybeacceptedbytheauthorityhavingjurisdiction,providedthattheemissionreductionperformanceof thesealis proventhroughappropriatetestingto beequivalentor betterthanthespecifiedequipment.

)ideof thethreeareas

s) andPart7 (Record 5.2.2 Gapspecifications.

Primaryseal: Themaximumgapwidthshallnotexceed4 cm, andthe cumulativegapareafor gapwidths greaterthan0.3 cm shall not exceed200 cm2permetreof tankdiameter.

Secondaryseal: If asecondarysealis requiredbythe aboveequipmentspecifications,themaximumgapwidthshallnot exceed1.3 cm, andthe cumulativegapareafor gapwidthsgreaterthan 0.3 cm shall not exceed20 cm2per metreof tankdiameter.

7

Section5.3 ExternalFloatingRoof

Tanksthathaveanexternalfloatingroofshallmeetthe followingequipmentandgapspecifications.

5.3.1 Equipmentspecifications.Theroofshallhavegasketedor otherwisecontrolledopeningsandtwosealsthatareingoodworkingorder.Theprimarysealshallbea liquid-mountedsealoramechanical-shoeseal,andthesecondarysealshallbea rim-mountedseal.Thesealshallforma continuousvapour-tightenclosu(earoundtheentireperimeterof thefloatingroof,exceptwherethesealis incontactwiththetankwall,inwhichcasethesealshallconformwiththefollowinggapspecifications.Aweathershieldis notconsideredto beaseal.

Forthe purposeof theseguidelines,a sealshallbeconsideredto be a mechanical-shoesealonly if the metalsheetis designedto extendandbe in verticalcontactwith the tankwallfor at least10cm belowtheliquidsurfaceandat least60 cm abovethe liquidsurface.If the sealdoesnot meetthesesizecriteria,for the purposeof theseguidelines,the sealshall beconsideredto bea vapour-mountedseal.

Avapour-mountedprimarysealwitha rim-mountedsecondarysealmaybeusedonlyifthe ownerof the tankcan demonstrateto the satisfactionof the authorityhavingjurisdictionthat,becauseof thenatureof thestoredliquid,thesealsspecifiedbytheseguidelineswill notperforminasatisfactorymanner.

Forthe purposeof theseguidelines,a sealthatdoesnotmeetthesecriteriaor thatisdesigneddiflerentlymaybeacceptedbytheauthorityhavingjurisdiction,providedthattheemissionreductionperformanceof thesealis notproventhroughappropriatetestingtobeequivalentor betterthanthespecifiedequipment.

5.3.2 Gapspecifications.

Primaryseal: Themaximumgapwidthshallnotexceed4 cm, andthe cumulativegapareafor gapwidthsgreaterthan0.3 cm shall not exceed200 cm2permetreof tank diameter.

Secondaryseal:Themaximumgapwidthshallnotexceed1.3cm,andthecumulativegapareafor gapwidthsgreaterthan0.3cm shallnotexceed20 cm2permetreof tankdiameter.

Section5.4 VapourControlSystem

Thevapourcontrolsystemshallrecoverthevapours,destroythevapoursbythermaloxidationorothermeans,orrecyclethevapoursforotherusesinthefacility.Thesystemshallpreventvapoursfrombeingemittedto theatmospherewithanefficiencyof atleast95percentbyweight.

.

Section5.5

Duringfillingvapourstoanbyweightinpnetworkbein

Section5.6

Thepressure-exceptwhenEventtobecor

ifications.

openings-mountedseal.Theterof theetheseal)nsidered

ical-shoeI thetankI surface..theseal

!donlyifI havingbythese

Irthatisthatthe!stingto

lapareaameter.

tivegapof tank

itionorapours

Section5.5 VapourBalancingSystem

Duringfillingorpartialfillingof thetank,thevapourbalancingsystemshalltransferthedisplacedvapoursto anotherpartof thesystem.Thesystemshallhaveanefficiencyof at least90percentbyweightinpreventingworkinglossesfrombeingemittedto theatmospherefromthedistributionnetworkbeingbalanced.

Section5.6 Pressure-vacuumVent

Thepressure-vacuumventshallbeincontinuousoperationduringthe normaloperationof thetank,exceptwhensuchoperationcausessafetyconcernsdueto the potentialfor the pressure-vacuumventto becomepluggedif the VOLor its vapoursfreeze.

9

Part 6

Inspections

Section6.1 InternalFloatingRoof

InspectionsshallfollowproceduresoutlinedineitherMethod1 orMethod2. Method2 hascertainsafetyadvantagesoverMethod1;however,it hashadlimiteduseinassessingtheperformanceofinternalfloatingroofs. Theacceptanceof this methodwas basedon limiteddatafromtankscontaininggasoline.Method2 will befurthertestedtoevaluateitsfutureapplicability.Method2may also be usedfor tanksthatcontainVOLsotherthangasoline,providedthatdataexisttodemonstratetheeffectivenessof Method2 inassessingtheperformanceof internalfloatingroofsintanksstoringthatparticularVOL.

6.1.1 Method1. Allequipmentshallbeinspectedandthesealgapsmeasured,asdescribedinAppendixC,everytimethetankis degassedfor entryandat leastonceevery10years.Thefloatingroofandtheprimaryseal(orthesecondarysealif oneis present)shallbevisuallyinspectedatleastonceayear.Avisualinspectionis definedtobeaninspectionfromtheopeningsinthefixedroofof thetank.

6.1.2 Method2. Thelowerflammablelimit(LFL)shallbemeasuredannually,asdescribedinAppendixD.

Section6.2 ExternalFloatingRoof

AllequipmentandsealsshallbevisuallyInspectedat leastonceayear.Theprimarysealshallbevisuallyinspectedat leastatevery45°aroundthecircumferenceof thetank.

Theprimarysealgapshallbemeasuredat leastonceeveryfiveyears,andthesecondarysealgapshallbemeasuredat leastonceayear,asdescribedinAppendixC.

Section6.3 VapourControlSystem

Vapourcontrolsystemsshallbe inspectedat leastoncea yearto ensurethesystemhasanefficiencyof atleast95percentbyweightinpreventingvapoursemissionsto theatmosphere.

Section6.4 VapourBalancingSystem

Vapourbalancingsystemsshallbe inspectedat leastoncea yearto ensurethesystemhasanefficiencyofat least90percentbyweightinpreventingworkinglossesfrombeingemittedto theatmospherefromthedistributionnetworkbeingbalanced.

Section6.5 Pressure-vacuumVent

Thepressure-vacuumventshallbeinspectedannuallyto ensurethatit is ingoodworkingorder.

10

Part 7

Record

Section 7.1

Theownerc. tankCOl. inspecticonditioroofseaofcontl. tankthrl

Therecords

Section7.2

Theownerc. tank COl. system. inspecti,conditiceffectivl. tankthr

Theownerownershall. thephy:. theproc

oftheti. theprocbetakel. anyotilneceSSi

Therecords

. Method2 hascertain

;ingthe performanceofimiteddatafrom tanksapplicability.Method2videdthat data exist to

)f internalfloatingroofs

asured,as describedin;t onceevery10 years.Jneis present)shall benedto bean inspection

lnually,as describedin

le primarysealshall benk.

thesecondarysealgap

urethesystemhasanIStotheatmosphere.

mrethe systemhasanJmbeingemittedto the

in goodworkingorder.

Part 7

Record Keeping

Section7.1 Tankswitha FloatingRoofor a Pressure-vacuumVent

Theownerof thetankshallkeeprecordsof:

· tankconstructionandmodificationdataforthelifeof thetank;

· inspectiondatafor thelast10years(consistingof, asa minimum,dateof inspection,visualconditionofequipment.gapmeasurementsandcumulativegapareacalculationsforfloatingroofseals,LFLreadingsif measured,andanyotherinformationpertainingto theeffectivenessof controllingemissions);and

· tankthroughputbyliquidtypeandvapourpressurefor thelastthreeyears.

Therecordsshallbemadeavailableto theauthorityhavingjurisdictionuponrequest.

Section7.2 Tankswitha VapourControlSystemor a VapourBalancingSystem

Theownerof thetankshallkeeprecordsof:

· tankconstructionandmodificationdataforthelifeof thetank;

· systemconstructionandmodificationdataforthelifeof thesystem;

· inspectiondataforthelast10years(consistingof,asa minimum,dateof inspection,visualconditionof equipment,efficiencycalculations,andanyotherinformationpertainingto theeffectivenessofcontrollingemissions);and

· tankthroughputbyliquidtypeandvapourpressureforthelastthreeyears.

Theownerof thetankshallkeepa writteninspection,maintenanceandoperationplan,andtheownershalladhereto theplan.Asa minimum,theplanshalldescribe:

· thephysicalcharacteristicsof thesystem;

· theprocedurestobefollowedduringtheoperation(filling,emptying,degassing,andcleaning)of thetank;

· theproceduresto befollowedduringinspectionof thetank,includingthecorrectiveactiontobetakenif a problemis identified;and

· anyotherprocedureor physicalcharacteristicthattheauthorityhavingjurisdictiondeemsnecessary.

Therecordsandthe planshall bemadeavailableto the authorityhavingjurisdictionuponrequest.

1 1

Clu3

12

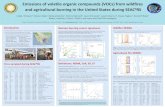

GUIDELINESSUMMARY(use as a guide only -seetext for details) .Areas of Application Theseguidelinesareapplicableto newtankseverywherein Canada,andto existing

tanksin theLowerFraserValley,theWindsor-QuebecCityCorridor,andtheSaintJohn,NewBrunswickareaof the SouthernAtlantic Region.

Effective Date . Newtanks:1 yearafterthe publicationof theseguidelinesby the CCME.. Existingfixed roof tanks: when degassedfor scheduledmaintenanceor byDecember31, 2004,whicheveris earlier.. Existingfloatingrooftanks:whensealsarewornorbyDecember31, 2004,whicheveris later. .

. Existingvapourcontrolandbalancingsystems:byDecember31 , 2004.

. Tankssubjectedto theseguidelinesshallcomplywiththeInspectionsandRecordKeepingsections:oneyearafterthe publicationof theseguidelinesby theCCME.

SubmergedFillPipe All tankswith capacities> 4 m3storinga liquidwith vapourpressure:.:10 kPashall havea submergedfill pipe.

Pressure-vacuumVent . Verticaltankswithcapacities> 4 m3 but diameters < 4 m storing a liquid with

vapourpressure:.:10 kPashall havea pressure-vacuumvent.. Non-vertical tankswith capacities> 4 m3but < 75 m3storinga liquidwithvapourpressure:.:10 kPashallhavea pressure-vacuumvent.

Technology InternalFloating or External or Vapour or VapourRoof FloatingRoof ControlSystem BalancingSystem

Requirements

Vertical Tanks Yes Yes Yes YesDiameter 4.0 but < 9.0 mVapourPressure:;,10 but < 76 kPaVertical Tanks Yes Yes Yes NoDiameter:e9.0 mVapourPressure;, 10 but < 76 kPaNon-verticalTanks nla nla Yes Yes

Capacity 75 but < 500 m3VapourPressure 10 but < 76 kPaNon-verticalTanks nla nla Yes No

Capacity 500 m3VapourPressure:;,10 but < 76 kPaAll Tanks No No Yes No

Capacity 75 m3VapourPressure:.:76 kPa

Specifications Primaryseal. Primaryseal (liquid Vapourcontrol VapourbalancingSecondaryseal or shoe). efficiency:.: 95% efficiency:.: 90%(only with vapour Secondaryseal. by weight. by weight for theprimaryseal). Gaps.Covers. workinglosses.Gaps.Covers.

Inspections Onceevery10 Visual annually. Annually. Annually.yearsandvisual Primarysealonceannually,or LFL everyfiveyears,measurements. and secondary

seal annually.

RecordKeeping . Tank/systemconstructionandmodificationdatafor the life of thetank/system.. Inspectiondataforthelast10 years.

. Tankthroughputby liquid type andvapourpressurefor the last threeyears.

.. w

u o 5; "0 ;;: '" '" 5; CD

.....

o ....

:r CD

i» ~ :r ;;: CD

'< CD e: '"

a s' :I "'" a ... ~ :r CD ~ 2- :r CD

I

5" :I I: !!!.

~

am<

'<~.

..:E

2:-g

CD

CD

I:

c§5;

;-'<

0.

ta

<00

tn-

'*» :I :I I: !!

!. ~

:EeT

CD

<o

'<~.

g~

~~.

0~

cC":

:1~

O":

:t~~

~0'

f",'

i»(0

-'<0:

:1C

h:r

0"!

:!.

.C

D*c

E

'-

-< CD

'"-< C

D'"

-< CD

'"-< C

D'"

-< CD

'"

C"J

o :I0 -"'" e.

~en

"0'<

0'"

I:C

D...

.3

W.p

.(J)

"-+

-'"

'""'

"'"

3'"

_.~

~~3

Ic:

.CD~--:iCD

g/I

gC

iI1:

1:/\

3tn3

,j:>

.n3

3",

n33

acn::!.cn

.0"

'8"

::s.

::s.

::s::s

<c

<c

......

.c'

.0'

I:I:

cs:

cs:

~.~.

~:T

... .0' I: c: ~. :r < ... "0 o 5; '" ;;: Cl)

Cl)

I: (iJ

I....

~ o "'"

"U '"

SUM

MA

RY

FIG

UR

E:

CC

ME

GU

IDE

LIN

ES

NE

WA

ND

EX

IST

ING

TA

NK

SST

OR

ING

VO

LA

TIL

EO

RG

AN

ICL

IQU

IDS

100

and

up

u o .....

76

(;j 1;j

Iii'

a. :!!. I!!

::s III

III I!!

a. ~ ::s o c. ~

50 25 10

o

Dia

met

er(m

)0

Cap

acity

(m3)

4

Pres

sure

-V

acuu

mV

ent"

z oz o

-< CD

'"-< C

DC

l)

(Use

asa

guid

eon

ly-s

eete

xtfo

rdet

ails

)

CD

... i» ::s0

(")

"'"

S'<

<c

'"~g '"

....

CD 3

Not

es:

Ver

tical

tank

requ

irem

ents

are

defi

ned

inle

""s

ofta

nkdi

amet

er.

Nor

wer

tical

tank

requ

irem

ents

are

defi

ned

inle

nns

ofla

nkca

paci

ty.

exis

ting

lixed

root

tank

sm

ust

mee

tth

ere

quire

men

tsw

hen

dega

ssed

orby

Dec

embe

r31

,20

04,

whi

chev

eris

earl

iest

.

All

tank

sw

ithca

paci

ties>

4m

3re

quire

asu

bmer

ged

fill

pipe

.

Futu

reta

xaco

nsid

erat

ions

may

mak

ere

quire

men

tsm

ore

stri

ngen

t.

.exem

ptio

n:If

tank

has

af~

ing

roof

,a

vapo

urco

ntro

lsy

stem

,or

vapo

urba

lanc

ing

syst

em.

z o

Inte

mal

orE

xtem

alFl

oatin

gR

oof

or

Vap

ourC

ontr

olSy

stem

Opt

iona

l

49

7550

0

at::;

-..c

:"'

''''''

---

--

CD

g.8i

J!...

3..

et.~

ero

_'<

:1'<

02.

~.~

~~3

"'::T

eTC

DC

DC

D<

c_.

...I:::SW

_.en

~"'

"",-

~~~

<0-

.0

",o,

j:>.

::S.

eT",

'< -'" ::T:I

CD

"'"

U> e: CD :E o 3 ~ eT '< o CD

(")

CD

3 eT ~ ~ . '" o o ,j:>

.

Vap

our

pres

sure

ofse

lede

dliq

uids

at21

.18C

:

.Pe

ace

Riv

erC

onde

nsat

e

-lsop

enta

ne

-Rai

nbow

Lig

htC

rude

-n-P

enta

ne-

Gas

olin

eR

VP

=90

kPa

-Lig

htS

ourB

lend

Cru

de

-Gas

olin

eR

VP

=S

9kP

a

-Pea

ceR

iver

Hea

vyC

rude

-Car

olin

eC

onde

nsat

e

-Gas

olin

eR

VP

:48

kPa

.Ben

zene

-Tol

uene

-o-X

ylen

e

20an

dup

4000

and

up

U>

0C

D...

.."'

"- ::T

CD

o'"

"'"

CD

"'<

cg.

5.C

D"'

""'

"CD

C=

:-:

::JC

DC

D"'

"Cl)

3eT

",'<

:j'E

rC

DC

D:I

(")

'"C

"J~

s:C

D!T

'~ eT '<

~(:

)C

D

~6C

igc

~::::~::T

(")

CD

CD

:nn@

cZ~

:j'

s''<

C"J

::sC

"J...

.o:

:s3.

~"'

"...

o-

-"'"

'"...

::s::s

"'"

"'"- o

:rC

Dco

~.en

!!:,

e!.

:r~<

c

... - CD

)C - 0' .. a. CD

- !!.

.E

Bibliography

Codes of Practice for Storage Tanks

AmericanPetroleumInstitute,WeldedSteelTanksfor Oil Storage,API-650,ninthedition,Washington,D.C.(1993).

\

I

AmericanPetroleumInstitute,SafeEntryandCleaningof PetroleumStorageTanks,API-2015,fifthedition,Washington,D.C.(1994).

AmericanSocietyfor TestingandMaterials,StandardTestMethodfor VaporPressureof PetroleumProducts(Reidmethod),ASTM-D323-90,Philadelphia,Pennsylvania(1990).

. CanadianCouncilof Ministersof theEnvironment,EnvironmentalCodeofPracticeforVapourRecoveryin GasolineDistributionNetworks,CCME-EPCITRE-30E,Winnipeg,Manitoba(March,1991).

CanadianCouncilof Ministersof theEnvironment,EnvironmentalCodeof Practicefor AbovegroundStorageTankSystemsContainingPetroleumProducts, CCME-EPC/LST-71E,Winnipeg,Manitoba(August,1994).

CanadianGeneralStandardsBoard,Standardsfor VapourControlSystemsin GasolineDistributionNetworks, CAN/CGSB-3.1000-M91,Ottawa,Ontario(May, 1991).

U.S.Government.StandardsofPerformancefor VolatileOrganicUquidStorageVesselsfor whichConstruction,Reconstruction,or ModificationCommencedafter July 23, 1984,Codeof (U.S.)FederalRegulations,Title40, Part60, SubpartKb,Washington,D.C.(April, 1987).

Control Technologies

CanadianAssociationof PetroleumProducers,TechnicalandCostEvaluation:Optionsfor ReducingMethaneandVOCEmissionsfromUpstreamOiland GasOperations,Calgary,Alberta(December,1993).

I

U.S.EnvironmentalProtectionAgency,VOCEmissionsfromVolatileOrganicUquidStorageTanks- BackgroundInformationforProposedStandards,EPA-450/3-81-003a,Washington,D.C.(July,1984).

U.S.EnvironmentalProtectionAgency,VOCEmissionsfrom VolatileOrganicUquidStorageTanks- BackgroundInformationfor PromulgatedStandards,EPA-450/3-81-003b,Washington,D.C.(January,1987).

U.S.EnvironmentalProtectionAgency,ControlCostManual,Officeof AirQualityPlanningandStandards,EPA-450/3-90-006,Washington,D.C.(January,1990).

15

U.S.EnvironmentalProtectionAgency,Controlof VolatileOrganicCompoundEmissionsfromVolatileOrganicliquidStorageinFloatingandFixedRoofTanks,EmissionStandardsDivision,draft,Washington,D.G.(July,1992).

U.S.EnvironmentalProtectionAgency,HazardousAirPollutantEmissionsfromProcessUnitsintheSyntheticOrganicChemicalManufacturingIndustry- BackgroundInformationfor ProposedStandards:Volume18:ControlTechnologies,EPA-453/D-92-016b,Washington,D.G.(November,1992).

Emission Calculations

AmericanPetroleumInstitute,EvaporativeLossesfromInternalFloatingRoofTanks,API-2519,thirdedition,Washington,D.G.(1990- addendum1993).

AmericanPetroleumInstitute,EvaporativeLossesfromExternalFloatingRoofTanks,API-2517,thirdedition,Washington,D.G.(1989- addendum1994).

AmericanPetroleumInstitute,EvaporativeLossesfromFixedRoofTanks,Manualof PetroleumMeasurementStandards,Chapter19.1(replacingAPI-2518),Washington,D.C.(1994).

U.S.EnvironmentalProtectionAgency,CompilationofAir PollutantEmissionFactors,reportAP-42(supplementE,chapter12),Washington,D.G. (1993).

U.S.EnvironmentalProtectionAgency,TANKS:StorageTankEmissionsCalculationSoftware,Version2.0,ResearchTrianglePark,NorthCarolina(September,1993).

Inventoriesof vac Emissions

CanadianPetroleumAssociation,A DetailedInventoryof CH4andVOCEmissionsfrom UpstreamOiland GasOperationsin Alberta,threevolumes,Galgary,Alberta(March,1992).

CanadianPetroleumProductsInstitute,AtmosphericEmissionsfrom CanadianPetroleumRefineriesandtheAssociatedGasolineDistributionSystemfor 1988,Report91-7,Ottawa,Ontario(February,1991).

EnvironmentCanada,CanadianEmissionsInventoryof CommonAir Contaminants(1985), EPS-5/AP/3, Ottawa,Ontario(March,1990).

General

GanadianCouncilof Ministersof theEnvironment,ManagementPlanfor NitrogenOxides(NOx)andVolatile Organic Compounds (VOCs): Phase I, GCME-EPCITRE-31E,Winnipeg, Manitoba(November,1990).

16

Working GroupMel

ConradAnctilYvesBourassaEdwardGocchiarell:GordonFergGiorgioGrappoliniBarbaraGreenDavidHallShairoleHenchallJimHomerKellyKarrFran~oisLalondeJimLeBlancChow-SengLiuStanLiuIdreesMahmudGaryMillerNorbertOilgumuelllDanO'RourkeRogerQuanTimShopikPatSiskArtStelzigMarkTushinghamBruceWalkerLynnWarner

CorrespondingMI

EdAntonioJohnBaguzisPatrickBallanceDaveBlairBillBlumquistEstherBobetGregBrownPaulineBrownTomBrownDanielCarriePeterGousineau

CompoundEmissionsfrom;ionStandardsDivision,draft,

~sionsfromProcessUnitsin

'ndInformationfor ProposedVashington,D.C.(November,

!tingRoofTanks,API-2519,

atingRoofTanks,API-2517,

Tanks,Manualof PetroleumIgton,D.C.(1994).

fssionFactors,reportAP-42

sionsCalculationSoftware,13).

~Emissionsfrom Upstreamlarch,1992).

from CanadianPetroleumteport91-7,Ottawa,Ontario

Contaminants(1985), EPS-

NitrogenOxides(NOx)and.31E, Winnipeg, Manitoba

WorkingGroup Members

ConradAnctilYvesBourassaEdwardCocchiarella

GordonFergGiorgioGrappoliniBarbaraGreenDavidHallShairoleHenchallJimHomerKellyKarrFrangoisLalondeJimLeBlancChow-SengLiuStanLiuIdreesMahmudGaryMillerNorbertOilgumuellerDanO'RourkeRogerQuanTimShopikPatSiskArtStelzigMarkTushinghamBruceWalkerLynnWarner

CorrespondingMembers

EdAntonioJohnBaguzisPatrickBallanceDaveBlairBillBlumquistEstherBobetGregBrownPaulineBrownTomBrownDanielCarriePeterCousineau

Appendix AList of Task Force Members

Ministerede l'Environnementet de la Faunedu QuebecCommunauteurbainede MontrealCanadianSteelEnvironmentalAssociationandDofascoInc.CanadianPetroleumProductsInstituteandShellCanadaLtd.CanadianPetroleumProductsInstituteandPetro-CanadaLtd.EnvironmentCanada

OntarioMinistryof EnvironmentandEnergyHMTCanadaLtd.

TransMountainPipeLineCo. Ltd.EnvironmentCanada

EnvironmentCanada(Chairperson)IrvingOilLtd.AlbertaEnvironmentalProtectionEnvironmentCanadaCanadianChemicalProducersAssociationand EssoChemicalsLtd.

TransMountainPipeLineCo. Ltd.StelcoInc.

TransMountainPipeLineCo. Ltd.GreaterVancouverRegionalDistrictInterprovincialPipeLine Inc.EnvironmentCanadaEnvironmentCanada

EnvironmentCanada(Coordinator)STOP

TransportCanada

ShraderCanadaInc.

FordMotorCompany(USA)PacificCoastTerminalsCo.Ltd.

NovaScotiaDepartmentof the EnvironmentPetrexInc. (USA)EnvironmentCanadaStanchemInc.EnvironmentCanadaSunocoInc.TerminalNorcanInc.SOSEnvironment

17

Andy DaySatiananDebidinBill Dibden

DougDicksonDuncanFergusonTony FlemingNeilFranklinKimGraceFredGrimmettJackieHamiltonNadineHarrisHeleneHenning-HiIITomHewittMarkJonesDavidKoehlerMarinaKovrigWaiterKrausSteveLauridsenLarryLechnerMartinlecoursDorisleeEA leinerAngeloLigoriG.L.MajuryVinodMarwahaBobMillerBillMooresH.ClareMosterSingOwTonyPannicciaPierrePelletierJacquesPerreaultDavePicardRachelPollardRobertPowerJohnRichFredRodriguesMaryRoyFarhadSeifBlakeSmithLomaSquiresDavidStudholmeDougTaylorR.TaylorJohnThordarson

18

CelaneseCanadaInc.TransportCanadaThorcoEquipmentInc.ShellCanadaChemicalCo.Ltd.

BritishColumbiaMinistryof Environment,LandsandParksConsultantAlconsultInc.

TransportCanadaCloverdalePaintInc.

BritishColumbiaMinistryof Environment,LandsandParksGoodfellowConsultantsInc.

ConsumersCooperativeRefineriesLtd.ImperialOilLtd.NewBrunswickDepartmentof the EnvironmentSandbornRoofsInc.RecochemInc.WesternFoodsLtd.DuPontCanadaInc.

SaskatchewanEnvironmentandResourceManagementMinisterede l'Environnementetde la Faunedu Quebeclever IndustrialLtd.HelmitinCanadaInc.BASFCanadaInc.StelcoInc.EnvironmentCanadaElfAtochemCanadaInc.EnvironmentCanada

ManitobaEnergyandMinesVanWaters& RogersLtd.Hondaof CanadaManufacturingCo.Ltd.UltramarCanadaInc.

CanadianPaintandCoatingsAssociationClearstoneEngineeringLtd.VancouverInternationalAirportAuthorityNationalEnergyBoardConcordEnvironmentalLtd.EnvironmentCanadaCCl IndustriesInc.Petro-CanadaLtd.

FordMotorCompanyof CanadaLtd.CMCSInc.RielloCanadaInc.NovacorChemicalsLtd.

BaycoatInc.ThorcoEquipmentInc.

BillTrusMariannBobWaRaeWaMichaelGaryWRossVIFrancis

Non-ml

TomDcMarcDSteve~Robin,RandyRaymoMarkR

)arks

BillTrusslerMariannUtrosaBobWaddenRaeWaltonMichaelWaxGaryWebsterRossWhiteFrancisYuen

ShellCanadaLtd.CanadEERInc.NationalDefenceStoneandWebsterCanadaLtd.

Instituteof CleanAir Companies(USA)CanadianAssociationof PetroleumProducersEnvironmentCanadaGreaterVancouverRegionalDistrict

Non-members(providedtechnicalexpertise)larks

TomDannMarcDeslauriersSteveHaigleRobinJonesRandyMcDonaldRaymondPerrasMarkRaizenne

,t

EnvironmentCanadaEnvironmentCanadaTexasNaturalResourceConservationCommission(USA)MidwestResearchInstitute(USA)EnvironmentalProtectionAgency(USA)EnvironmentCanadaHealthCanada

19

Appendix BVapour Pressure of Selected Liquids at 21.1°C (70°F)

Thistableis providedfor thereader'sconvenienceandshouldbe usedfor illustrativepurposesonly.Crudeoils andcondensatesareparticularlyvariable,so the pipelinecarrieror the suppliershouldbeconsultedfor the appropriatevapourpressure.

VolatileOrganicliquids VapourPressureat21.1°C (kPa)

Gasolines RVP= 90kPaRVP= 69kPaRVP= 48kPa

57.543.329.3

JetFuels JetNaphthaJetKerosene

10.80.1

CrudeOils RainbowLightLightSourBlendManitobaSweet

PeaceRiverHeavySyncrudeSaskatchewanSweet

Lloydminster-Wainwright

69.051.745.440.732.427.614.5

Condensates PeaceRiverFortSaskatchewanRainbowGibsonCaroline

93.186.266.257.931.0

Chemicals Isopentanen-PentaneAcetonen-HexaneBenzeneToluenem-Xyleneo-XyleneStyrene

86.458.126.016.810.63.11.20.70.7

21

Step1.

Step2.

Step3.

Step4.

Step5.

Step6.

Step7.

Appendix CProcedure for Measuring Cumulative Gap Area

Findeachlocationon thecircumferenceof thetankwherea probeof a uniformdiameterof 0.3cm passesfreelybetweenthesealandthewallof thetank(withoutforcingor bindingagainsttheseal).

Foreachgap.measurethe gapwidth (incentimetres)alongthe perimeterof the tankbetweenthetwo extremeoppositelocationsof the gapthat acceptthe O.3-cmprobe.

Thetotalsurfaceareaof eachgapidentifiedinStep1 shallbedeterminedbyusingprobesof variousdiametersto measureaccuratelythe actualgap width (incentimetres)betweenthesealandthewallof thetank(interpolatethegapwidthbetweenprobediameters),andthenmultiplyingeachsuchgapwidthby itsrespectivecircumferentialdistance(incentimetres).Referto FigureC.1foranexample.

Recordthelargestgapwidth(incentimetres)foundin thetank.

SumtheindividualsurfaceareasasdeterminedinStep3 for allgapsidentifiedinStep1.

Dividethe cumulativegapareaas determinedin Step5 by the insidediameterof thetank (in metres).

ComparetheresultsofStep4 andStep6 to thelimitsstatedintheseguidelines.

23

24

1

O.3-cmProbe

FIGURE C. 1 Alte

MEASURINGTHE GAPAREA Section [

EarlydetEMonitorin!lowerliqurepair.

Circumferential Gap Distance

ThisappetheroofSIMeasurerusedto imaintenarmeasurerneedto rE

Tank Wall TheproceTheauthosatisfactcroofsors

Section[

0.2.1

Probe MaximumGap Width 0.2.2

InterpolateGap Width

0.2.3

0.2.4

The curvature of the tank is exaggerated.

Except for the O.3-cm probe, probe widths are illustrative. 0.2.5

Appendix DAlternative Inspection Procedure for Internal Floating Roof Tanks

SectionD.1 Overview

Earlydetectionof floatingroofefficiencyproblemscanleadto reducedevaporativeemissions.Monitoringroofemissionscanalsobeofeconomicbenefitto theownerof thetankbecauseof thelowerliquidlossresultingfromearlydetectionoffloatingrooforsealfailureandtheirsubsequentrepair.

Thisappendixdescribesthe procedureto determinethe conditionof the internalfloatingroof andtheroofseals.The proceduretests the vapourspacebetweenthefloating roof andthefixedroof.Measurementsof the vapourspace'sLFLat a consistentelevationabovethe floating roof canbeusedto indicatethe conditionsof the floating roof and seals. This in turn will allow plannedmaintenanceof theroofandsealswhentheirefficiencyfalls to unacceptablelevels. Theuseof LFLmeasurementsto determinethe relativeconditionof the floatingroof andits sealswill reducetheneedto regularlydegassthe tankandinternallyinspectthe floatingroof andseals.

Wall Theproceduredescribedinthisappendixhasonly beendemonstratedfor tanksthat storegasoline.Theauthorityhavingjurisdictionmayextendits useto otherVOLsif the authorityis providedwithsatisfactoryevidenceof accuracy,reliabilityand repeatabilityto detectdefectiveinternalfloatingroofsor seals.

SectionD.2 Procedure

D.2.1 Thefloatingroofshallbeatorabovehalfof itsmaximumoperatingheight.Thefloatingroof shallbestablefor at leastfourhoursto avoidtheinfluencesof wettedwallsandvapourproductionfromthefillingoremptyingprocess.

D.2.2 Vapour-spacetestingshallonlybeconductedwhenthewindspeedis lessthan10km/handtheambienttemperatureis between5 and15OC.Producttemperatureshouldbeasclosetoambientaspossible.

D.2.3 Thetestshallconsistof takinghydrocarbonreadingsof thevapourspacebetweenthefloatingroofandthefixedroofatalevelbetweentwoandfourmetresbelowthefixedroof.

D.2.4 Readingsshallbetakenusingeithera testinginstrumentequippedwith a sensorextensionora testinginstrumentthat is ratedfor usein a potentiallyexplosiveatmosphereandcanbe loweredinto the vapourspace.

D.2.5 Readingsshallbemeasuredby anexplosimeteror anothersimilarinstrumentthatcanmeasurethehydrocarbonmixinairandconvertit to a percentageof LFL.Thecalibrationgasfortheinstrumentshallbesuitablefor detectingtheVOLcontainedinthetank.

25

Section0.3 Interpretationof results

0.3.1 Normalreadingsshouldrangebetween0 and15percentof LFL.Generally,highervaluesareto beexpectedcloserto thefloatingroofandfromtankswitholderseals.

0.3.2 Anyreadingthatexceeds20percentofLFLshallrequirefurtherinvestigation,asdescribedinSection0.4.

0.3.3 Abaselinelevelforeachtankshallbecomputedbytakingtheaverageofthereadingsforfour years.A newbaselinelevelshallbecomputedaftera newinternalfloatingroofornewsealshavebeeninstalled.Generally,tankswill havedifferentbaselinelevels.

0.3.4 Fora baselinelevelgreaterthanorequaltofivepercentof LFL,anyreadingthatis morethan50percentabovethebaselinelevelshallrequirefurtherinvestigation,asdescribedinSection0.4.

0.3.5 Fora baselinelevellessthan5 percentof LFL.anyreadingthatis morethan7.5percentof LFLshallrequirefurtherinvestigation,asdescribedinSection0.4.

Section0.4 Requiredfurtheraction

0.4.1 TheLFLmeasurementshallberepeatedwithin14daysof thefirstmeasurement.

0.4.2 Ifthesecondreading(i) exceeds20percentof LFL,or (ii) is morethan50percentabovethebaselinelevelifthebaselinelevelis greaterthanorequalto5 percentof LFL.or (iii) isabove7.5percentof LFLif thebaselinelevelis lessthan5 percentof LFL,thetankshallbedegassedfor entryandtheninspected.Thisinspectionshallbeconductedwithin45daysof thesecondreading,unlesstheauthorityhavingjurisdictionhasacceptedanalternativeinspectionplanandschedulesubmittedbytheownerof thetank.

0.4.3 AnypieceofequipmentthatdoesnotconformwithPart5 (Specifications)or is otherwisedefectivemust be repairedor replacedwithinthe time periodstatedin Section4.3(Paragraph4.3.5).

2&

-- --

Thefollowconfiguratitheallowalthetextof

* ExceptI

Note:Rglfloatingreexternalfl

FiguNuml

E.1

E.1

E.1

E.1

E.2

E.2

E.2

E.2

E.3

E.3

E.3

3enerally,highervaluesI olderseals.

~stigation,as described

rageof thereadingsforinternalfloatingroof orIt baselinelevels.

ny readingthat is more!stigation,as described

morethan7.5 percentD.4.

;tmeasurement.

than50percentaboveercentof LFL,or (iii) isIt of LFl, thetankshallleconductedwithin45~tionhas acceptedan)f thetank.

ations)or is otherwisestatedill Section4.3

Appendix EIllustrationsof Various Seal Types

Thefollowingfiguresshowexamplesof a varietyof sealsandsealconfigurations.Notall thesealconfigurationsshowninthefiguresareallowedby theseguidelines(referto the followingtablefortheallowableconfigurations).Thetableandthefiguresshouldbe usedas a guideonly; pleaseseethetextof theseguidelinesfor details.

* Exceptunderspecialcircumstances(referto Section5.3).

Note: FiguresE.1a andE.1b showfloatingroofs andsealsdrawnas theymayappearon internalfloatingroofs;the remainingfiguresshowfloating roofs andsealsdrawnasthey mayappearonexternalfloatingroofs.

27

AllowedbytheseGuidelinesFigure Primary Secondary Internal External

Number Seal SealFloatingRoof FloatingRoof

E.1a Vapour-mounted Present Yes No*

E.1b Vapour-mounted Present Yes No*

E.1c Vapour-mounted Present Yes No*

E.1d Vapour-mounted Absent No No

E.2a Liquid-mounted Absent Yes No

E.2b Liquid-mounted Present Yes Yes

E.2c Liquid-mounted Absent Yes No

E.2d Liquid-mounted Present Yes Yes

E.3a Mechanicalshoe Absent Yes No

E.3b Mechanicalshoe Rim-mounted Yes Yes

E.3c Mechanicalshoe Shoe-mounted Yes No

28

FIGURE E. 1. VAPOUR-MOUNTED PRIMARY SEALS

~ TankWall\,-

\

1a

~a1b

Secondary Foam Seal

Wiper

Vapour SpaceBrace

,/ Floating Roof\"

Liquid

VAPOUR-MOUNTED PRIMARY SEALWITH A SECONDARY SEAL

VAPOUR-MOUNTED PRIMARY SEALWITH A SECONDARY SEAL

~Tank Wall

1'( ~ Rim-Mounted

.111 / Secondary Seal

1c Tank Wall 1d TI

\" FloatingRoof \" Aoating Roof

Resilient Foam Resilient Foam

VapourSpace Vapour Space

VAPOUR.MOUNTED PRIMARY SEALWITH A SECONDARY SEAL

VAPOUR.MOUNTED PRIMARY SEALWITH A SECONDARY SEAL

, SEALS FIGURE E. 2. LIQUID-MOUNTED PRIMARY SEALS

1b 2aTank Wall

3econdary Foam Seal

Primary Foam Seal

Vapour Space

/' ~ FloatingRoof\ Floating Roof

~

RinAllachment

Seal Fabric

Resilient Foam

~I.

Iliquid

'EO PRIMARY SEAL

ONDARY SEALLIQUID-MOUNTED PRIMARY SEAL

WITHOUT A SECONDARY SEAL

1d 2cTankWall

\ FloatingRooft Floating Roof

~ Fabric

Resiient FoamLiquid-Fdled Tube

Vapour Space

Uquld

) PRIMARY SEAL

IDARY SEAL

LIQUID-MOUNTED PRIMARY SEAL

WITHOUT A SECONDARY SEAL

2b

/~im-Mountedecondary Seal

\ FloatingRoof

Seal Fabric

Resilient Foam

Uquid

LIQUID-MOUNTED PRIMARY SEAL

WITH A SECONDARY SEAL

2d

Floating Roof

Uquid-Rlled Tube

Liquid

LIQUID.MOUNTED PRIMARY SEAL

WITH A SECONDARY SEAL

29

FIGURE E. 3. MECHANICAL-SHOE PRIMARY SEALS

Rosting Roof

MECHANICAL-SHOE PRIMARY SEAL

WITHOUT A SECONDARY SEAL

3a

Provincia

3b

This listprovjurisdiction.

Rim-Mounted

/Secondary Seal

... ~ ShoeEnvelope Federal

Roating Roof For federal laI

Vapour Space

Uquid

Alberta

MECHANICAL-SHOEPRIMARYSEAL

WITHA RIM-MOUNTEDSECONDARYSEAL

3cShoe-Mounted

/ Secondary Seal

/ __ ShoeBritishColu~

Rosting Roof

ManitobaVapour Space

New BrunsV4

liquid

MECHANICAL-SHOEPRIMARYSEALWITHA SHOE-MOUNTEDSECONDARYSEAL

30

- - ---

- - -

Appendix FAuthority Having Jurisdiction over Storage Tanks

3b

Thislistprovidesinfonnationto assistthereaderin contactingtheappropriateauthorityhavingjurisdiction.

Federal

For federallands,federalfacilities, andfederallyregulatedindustries

Chief

Oil,Gasand EnergyDivisionIndustrialProgramsBranchEnvironmentCanadaOttawa,Ontario K1AOH3(819) 953-1120

Provincial

Alberta AirandWaterApprovalsDivisionDepartmentof EnvironmentalProtection9820- 106thStreetEdmonton,AlbertaT5K2J6(403)427-5872

AL

BritishColumbia AirResourcesBranchMinistryof Environment,LandsandParks777BroughtonStreetVictoria,BritishColumbiaV8V1X5(604)387-9932

Manitoba EnvironmentalOperationsDepartmentof the Environment139 TuxedoAve.,Building2Winnipeg,Manitoba R3NOH6(204) 945-7100

NewBrunswick ManagerIndustrialProgramsSectionDepartmentof theEnvironmentP.O.Box6000364ArgyleStreetFredericton,NewBrunswickE3B5H1(506)457-4848

31

32

-- - --

Newfoundland Director Saskat:andLabrador IndustrialEnvironmentalEngineeringDivision

Departmentof EnvironmentandLandsConfederationBuilding,4th floorP.O.Box8700St.John's,NewfoundlandA1B 4J6(709) 729-2555

NorthwestTerritories EnvironmentalProtectionDivisionDepartmentof RenewableResources Yukon600, 5102-5OthAvenueYellowknife,NW.T. X1A3S8(403) 873-7654

NovaScotia Air QualityBranchDepartmentof the Environment5151TerminalRoad,5thfloor RegieP.O.Box2107Halifax,NovaScotiaB3J3B7 Greate(902)424-5300 Region

Ontario DavidHallProgramDevelopmentBranchMinistryof EnvironmentandEnergy135St.ClairAve.W..suite100Toronto,Ontario'M4V1L5 MontrE(416)314-4163 Comml

PrinceEdwardIsland MarkVictorHead,AirQualityandHazardousMaterialsDepartmentof EnvironmentalResourcesP.O.Box2000Charlottetown,P.E.I.C1A7N8(902)368-5037

Quebec JeanLavergne/ MartinLecoursLadirectiondespolitiquesdusecteurindustrielMinisteredel'EnvironnementetdelaFaune2360,cheminSte-FoySte-Foy(Quebec)G1V4H2(418)644-3630/3606

Saskatachewan

Yukon

Regional

GreaterVancouver

RegionalDistrict

MontrealUrban

Community

EarlCraigManager,Air QualitySectionCommercialBranch

Departmentof EnvironmentandResourceManagement3085 AlbertStreet

Regina,SaskatchewanS4SOB1(306) 787-6197

DirectorPublicSafetyBranchDepartmentof EnvironmentBox2703Whitehorse,YukonY1A2C6(403)667-5824

Air QualityandSourceControlDepartmentGreaterVancouverRegionalDistrict4330 KingswayBurnaby,BritishColumbia V5H4G8(604) 436-6700

FernandCadieuxDirecteurAssainissementdeI'airetdeI'eauCommunauteurbainedeMontreal827,boul.CremazieestMontreal(Quebec)H2M2T8(514)280-4321

33