Empowering Gearbox Product Development with Simulation...

Transcript of Empowering Gearbox Product Development with Simulation...

Empowering Gearbox Product Development with Simulation Apps

March 22, 2016 Starts at 12:00pm ET

• All attendees are muted

• The event is being recorded

• A recording of the event and presentation will be made available to attendees following the conclusion of the event

• If you have a question during the presentation, you can ask it using the Questions panel on the GoToWebinar Control Panel to the right of your screen. Questions will be answered on a one-on-one basis after the conclusion of the event.

Housekeeping Items

• Introduction

• Gearbox System Product Development – Where is it today?

– Brian Wilson, CEO of Advanced Drivetrain Engineering & Technology (ADET)

• Gearbox Product Design Automation - Integrating common Gearbox tools with Comet Solutions

– Malcolm Panthaki, Founder & CTO of Comet Solutions, Inc.

• Comet Demonstration

– Tim Keer, VP Technical Services

• Conclusion

Agenda

Virtual Development in Gearbox Industry

Issues with Current Product Dev Process Tool Silos Everywhere

American Axle NVH Whitepaper

Glen Steyer, American Axle’s Executive Director of Product Engineering, reports major benefits from the new tool:

• Average 75% time reduction for each analysis iteration. • Approximately $130,000 in annual cost savings at a single engineering site. • Improved quality through globally enforced modeling and NVH standards/practices which minimizes opportunity

for human error. • Ability to run many more NVH analysis iterations, leading to more design decisions, earlier. • Ability to redeploy resources as less experienced engineers are now able to safely run simulations.

Comet Solutions: Our Mission

Comet Solutions helps product development organizations automate design engineering process rapidly, using a software platform that allows easy integration of many popular Math, CAD and CAE tools.

• Make CAE activities more efficient

– Automation that works

– Elimination of rework & repetition

• Make CAE more impactful to business

– Useful to more people

– Results obtained in time to support decisions

• Simplify the complex process of engineering product “systems”

– Build system dependencies into models

– Create transparency across disciplines

• More Detailed Discussions

• Technology Validation Pilot

Conclusion – Next Steps

The Drivetrain CAE Engineer’s Dilemma

March 2016

Principal

Brian K. Wilson, Founder, President, & CEO of ADET, has 25+ years of experience in the design, test and analysis of rotating machinery. His experience includes Romax Technology, Inc. where he served as Chief Technology Officer, Ford Motor Company where he held the position of NVH Technical Specialist and work as a consultant for SDRC (Now Siemens PLM). Wilson’s expertise is in rotating machinery dynamics, helping major OEMs worldwide to solve an assortment of drivetrain dynamics problems over the years. He currently serves as Vice-Chair on the AGMA Sound & Vibration Committee and sits on ASME’s Power and Transmission Gearing Committee. Wilson holds a BSME from Michigan State University.

What We Do

• Drivetrain consulting

• CAE and custom software

• Test systems

• Training and seminars

• R&D

• Other advanced technology

Model T Differential

Drivetrain Design – PRESENT STATE

Product Development Timeline: 24-36 months

Definition of Basic Requirements: Speed, Torque, Ratios

CONCEPT DESIGN: gear sizing, bearing sizing, bearing forces for housing design

CAE DETAILED DESIGN: gears, bearings, shafts, housings

Order Tooling – Protos and Production

Proto-1 Proto-2 Production

CAE REFINEMENT: troubleshooting gears, bearings, shaft, housings, lubrication, cooling

CONCEPT DESIGN: only

slight deviations from known

successful designs

Scramble to support

production and launch

!

Exp

erie

nce

b

ase

d

Hardware development is faster than CAE analysis – resources don’t align

Too few CAE resources

Too few experts

Experts spend time checking others work, not doing the difficult tasks

Compromise on model quality to save time

I need multiple software tools to do my analysis – I pass data manually between them. Prone to errors and slow results

CAD models are difficult and time consuming to mesh

Global CAE methods and processes not aligned

Optimization? I stop when I have a right answer (not the right answer) due to time constraints

We need more qualified engineers. The level of inexperience is causing delays

Monte Carlo? Variation? I can barely complete nominal analyses

Drivetrain CAE Engineer’s Dilemma

0D/1D/2D/3D

CAE tools,

Optimization,

Automation,

Standardization

Real Estate

Powerflow (Advanced)

Assembly&

Variation

Fuel Economy

& Controls

Efficiency

Manuf

Durability

NVH

Weight

Overall cost

CFD, lube, thermal

Basic Req’s (speed, tq,

ratio)

Drivetrain Design – IDEAL STATE (FUTURE?)

Proto-1: Additive Manufacturing direct from design – quick, inexpensive functional verification – no “tooling”

Manuf process and tooling defined by design process – direct order production tooling

Production runs using production tooling only; minor refinement to process – not design

Lighter, Cheaper, Faster-to-Market, Higher performance

New Design

0D/1D/2D/3D CAE tools,

Optimization, Automation,

Standardization

Thank you for your attention

Gearbox Product Design Automation Integrating common Gearbox tools using Comet’s Intelligent Templates

Malcolm Panthaki, Founder & CTO

Comet Solutions Company Overview

Pioneer in Simulation Automation for Model-Based Engineering using unique Abstract Modeling Technology

• Formed in 2001 in Albuquerque, New Mexico, with technology developed at UNM

• 100-150 man-years development of proprietary Abstract Engineering Model® (AEM)

• Initial commercial product release in 2008 in the Satellite Optical Systems market

• Experienced leadership team: >100 years combined PLM industry

• One of the fastest growing companies in the PLM industry

2

FE Structural Solvers

Acoustics Solvers

GD&T Tolerance Stack-Up Analysis

CAD

Gearbox Product Design: Common Silos & Tools

3

FE Meshing

Gear/Bearing/Shaft System Simulation

Simulation Team

Status Quo: Simulation only for Experts

Simulation has been in the hands of too few, for too long How can we get complex simulation safely and effectively to “Everyone Who Needs It”?

CAECode 1

CAECode 2

CAECode 25

CAECode 13

CAECode 32

CAECode 35

CAECode 40

CAECode 38

Excel

Matlab

Optimization

Product Managers Product Development Engineers Systems Engineers Test Engineers Salespeople …everyone needs simulation!

Product Development Team Simulation Data: in silos, inconsistent, non-integrated Simulation Processes: manual, error-prone, highly inefficient inconsistent

Multiple Global Engineering Centers

5 days to “clean up” geometry and create a “perfect” mesh?? 4-6 weeks to complete a single analysis?

How can simulation be a driving force in design?

Simulation Experts: become the bottleneck

4

Gear

Clutch

Bearing

Shaft

The Problem With Engineering Models

• Product Descriptions Are Functional and Descriptive

– Common language understood by all your designers, engineers, customers, and suppliers

• But, Engineering Models Are Tool-Specific And Unique

– C-Bush, P-Bush, Spider Joint, MNF, M-File, Modal Model, FRF, Beam with rotational DOF

– Every tool has its own language

• Each Product Variation Drives Many Model Changes – FEA, CAD, MBD, Excel, In-House Tools, and more…

• Every Model Change introduces rework, translation errors, cost, and huge amounts of time for re-analysis

5

What Engineers Really Need

Gear

Clutch

Bearing

Shaft

Structural FEA & Life In-house

tools

FE Mesher CAD

Gear/Bearing System Analysis

Acoustics Analysis

• Functional representation of product systems – System & product Intent

– Functional requirements

– Design variables

– System constraints

– Operating conditions

– Performance metrics

• Tool-agnostic engineering automation – CAD, FEA, MBD, Gearbox, math tools

• Automation that is robust across design changes and Product Families

• Automated mixed-fidelity modeling

6

Comet Template

Comet’s Intelligent Templates Product Evaluation Using Simple “Engineering Calculators” (SimApps)

• Embed expert knowledge – In robust, reliable, easy-to-create templates – Minimal or no scripting – Experts Tools – Your CAD, Your CAE

• Automate repetitive modeling & analysis work – Using Abstract Modeling, they work

across the entire Family of Products that share a basic architecture

• Deploy Anywhere! – Web-based, cloud-enabled

• Run by Anyone! – Easily, Rapidly & Automatically analyze

and optimize design variants – Within a discipline or across multiple

disciplines

CAD in

Report out

7

Template

True Virtual Test Rigs

Comet Workspace Parametric, Multi-Fidelity, Multi-Source, Multi-Discipline

Abstract Engineering Model™

Adaptors to External Tools

Mesh Models

Systems Models

CAD Models

Product Representations

Analysis Models (Auto-Generated)

Isight Optimization Tools

MBD Tools Systems Tools FEA Tools

ANSA Mesher

CODE V Optics

Automating Product Development Processes Integrating Tools & Data Across All Design Phases

8

Simulation Apps: Simulation for Everyone

Product Managers Systems Engineers

Designers Salespeople

… (use the Sim Apps)

Targeted Applications: answer particular questions, on a particular product family, at a particular level of fidelity

Simple GUI’s that drive Templates that capture/enforce expertise Must work across significant design changes and across a Product Family

Must speak the language of the user, not “Simulation”

Optionally, Web-deployed on Intranets & “The Cloud” Provide all the computing required for rapid throughput

Product Development & Sales Teams Simulation Team

Simulation Apps (SimApps™)

(author the Apps

+ use the apps)

CAE Code 1

CAE Code 2

Math Tool Systems Tool

CAD Tool Optimization

Simulation Experts

PLM

Expert Certified! Safe and robust for all users

9

Robust across a Product Family

Target End Users of Comet SimApps

Simulation Experts: Multi-Disciplinary Processes Create and validate best-practice analysis processes Run the most complex simulations

Design Engineers: Standard, Repetitive Processes Run well-defined standard analyses safely & consistently Use web-deployable, role-based Vertical Applications that

drive Comet Templates (built and updated by the experts)

Chief Engineers/Program Managers/Systems Engineers Run multi-fidelity systems analyses from the dashboard Conduct design reviews effectively, without needing

presentations

Ultimately, “Anyone asking Performance Questions” Run actual simulations through a simple web interface to

quickly ascertain the performance and cost of customized engineered products

750K engineers

worldwide of this type today already using

CAE

8M engineers who aren’t benefiting

from the use of simulation tools today

10

Wide Scope of SimApps™

Automotive subsystems Off-Road vehicles

Plastics & containers Consumer appliances

Aerospace subsystems Optical Imaging systems

Laser systems Electronics PCBs

Plastic Bottle Design Automotive Driveline Design

Automotive Spring Design

Vehicle Suspension Design Engine Connecting Rod Design

Electronics Board Reliability Laser Systems Design

Heavy Equipment Design

Washing Machine Design

Automotive Bumper Design

Aircraft Metallic Seal Design

Space-Borne Optical Systems with Thermal Controls

11

Business Benefits of Comet Automation

• Enable Engineers and Teams of Engineers to perform Rapid & Robust Design Space Exploration early & often

• Significantly reduce the cycle time of each design iteration (>80-90%)

• Explore the design space more accurately and automatically

• Evaluate more concepts

• Better utilize limited resources: human experts & non-experts, time/schedule, program cost

• Capture knowledge of scarce and dwindling number of experts in an executable/reusable form using Comet’s Templates

• Facilitate the spread of “Systems Thinking” across the multi-disciplinary team of product development engineers

Significantly increase the ROI of your simulation investments

over the entire product development lifecycle 12

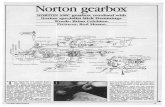

Planetary Gearbox Template: Summary

• Full automation: – Rebuilt the CAD with new CAD Parameters

– Created a Finite Element Mesh

– Ran an ANSYS Modal Analysis

– Ran a RomaxDESIGNER static analysis

– Post-processed

… in 10 minutes

• Comet template includes the embedded experience of various experts

• Not restricted to a single topology – this template will accept any combination of CAD / RomaxDesigner models which are consistent and tagged appropriately

• Can be used for design space exploration – Design of Experiments

– Parameter Study

– Optimization

• Comet Automation Templates – Capture CAD/CAE expertise & company best Practice/IP for

safe reuse

– Are intelligent and work across a wide range of design changes and product families

– Are easy to use and enterprise accessible allowing the safe creation of complex designs by experts and non-experts

• Benefits – Increased efficiency (>80%)

– Increased product design quality

– Global process consistency and repeatability

– Enterprise wide impact of your best engineering expertise

Conclusion – Key Take Aways