Elizabeth Towle Batch Distillation of Ethanol Design

-

Upload

elizabeth-towle -

Category

Documents

-

view

105 -

download

3

Transcript of Elizabeth Towle Batch Distillation of Ethanol Design

Batch Distillation Project

A Project Report for CHE 2014

Submitted to the Faculty of the

Department of Chemical Engineering

Worcester Polytechnic Institute

Worcester, MA 01609

April 14, 2016

Coal Rocks!

“What’s that rock? It’s coal!”

Benjamin Drury

Weiran Gao

Natalie Thompson

Elizabeth Towle

Introduction:

Batch distillation has fulfilled many requirements in human life and throughout our history. Whether it be

making alcoholic beverages or producing a few hundred kilomoles with a varying molar concentration,

batch distillation has thoroughly incorporated itself as a necessity for human productivity. This project

required us to utilize batch distillation to separate ethanol from water as a model for a palm oil purification

process to create ethanol fuel in Cameroon. While both batch distillation and continuous distillation have

both advantages and disadvantages, batch distillation was selected for this report as continuous distillation

was already shown to be impractical in previous reports. Furthermore, batch distillation will be useful if

the palm oil has varying ethanol composition or if the process is to be run sporadically. This report

endeavors to analyze the batch distillation as conducted in a test pilot column, using both theoretical and

experimental data.

Methods:

To conduct theoretical analysis, the Rayleigh Equation was first used to analyze the validity of the

experimental data. Several top stage vapor temperatures and their corresponding reboiler temperatures

from the experimental data were chosen as data points for the analysis. These data points were then

converted to compositions in the still pot (xw) and their corresponding distillate compositions (xD) using a

T-x,y graph for an ethanol/water binary system found from a VLE database (Appendix, Figure 1). This

was followed by calculations of the final pot volume (Wfinal) using the Rayleigh Equation:

.nl FWfinal = − ∫

xF

xw, f inal

dxWxD−xW

Total distillate volume (Dtot) and average distillate composition, xD, avg were then calculated using

equations:

Dtotal = F - WF

xD, avg= F−WfinalF xF−Wfinal xw, f inal * *

respectively. These calculated data were then compared to the data collected from the column.

The second part of theoretical analysis was conducted using the software Aspen Batch Distillation Version

7.2. This allowed for the analysis of ideal enthalpic condition. This data was run on the basis of an initial

charge and composition and a final still pot composition matching the experimental data. The IDEAL

model was used to create an ideal set of data from Aspen, though this is highly unrealistics. Two other

models, the Polymer Soave-Redlich-Kwong Equation-of-State Property Method (POLYSRK) and the

non-random two-liquid (NRTL) model were used to calculate this data. This is a possible source of error,

as neither method will fit the data perfectly. However, this report worked upon the premise that POLYSRK

and NRTL would be more accurate models than the ideal, and the most accurate models available. Varied

reflex ratios were tested to analyze their impact upon the data collected, within the NRTL model. Varied

distillation column diameters were tested within the POLYSRK model. The data calculated was compared

with the experimental data and the data calculated using the Rayleigh equation.

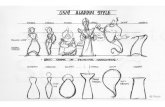

Figure 1: Professional Drawing of Pilot Distillation Column

The figure above represents a multistage batch distillation column. An initial amount of material is fed

into the pot at the bottom and then heated up such that some of the material escapes the pot as a vapor.

The vapor then rises up the column through the stages until it exits through the top of the column in the V

line. From there, the vapor enters a total condenser which converts it to a liquid. The liquid gets divided

into two pipes; some goes back into the column to increase the quality of the product and some gets

extracted as the final product.

Results and Discussion: Calculated and Experimental Data Table 1: Comparisons of Data Methods

Value Exp. Data Aspen Ideal (D= 1.64 ft) Aspen Nonideal (D= 1.64 ft) Rayleigh

F (kmoles) 2.62988 2.62988 2.62988 2.62988

Wfinal (kmoles) 2.54322 2.55486 2.54875 2.6068

Dtotal (kmoles) 0.04072 0.021017 0.018134 0.023

xD, avg 0.4862 0.523 0.607 0.4744

xF 0.0063 0.0063 0.0063 0.0063

xw,final 0.002183 0.002183 0.002183 0.0022

Time (hrs) 5.55 4.866 5.2

In the above data, the experimental data is compared to the various methods of calculating it, including the

Rayleigh equation, Aspen IDEAL and Aspen POLYSRK. Rayleigh seems to be the closest in both xDavg

and Dtotal. Aspen Ideal is closer in xDavg,but POLYSRK is more accurate in time. NRTL was not included

here as the times calculated were significantly different. However, it will be used later.

In this table WF and F are estimates based on the densities of ethanol and water and the assumption that

they form an ideal mixture. In addition, xF and xw,final used for Aspen analysis were estimated to be equal to

those given by the experimental data. For the Rayleigh calculations, several assumptions were necessary.

First, the pressure was approximated at 1 atm. Values for xF and xw, final were found using T-xy graph with

the initial and final temperatures given in the experimental data. To calculate the integral of the Rayleigh

equation, it was necessary to use the trapezoidal method, an imprecise method. Another source of error

may be the estimated initial charge, as the increased operational temperatures may mean that the densities

used were imperfect. Another point of difference between the Raleigh calculated values and the Aspen DT

values is due to the fact that Aspen accounts for holdup in the column while the Rayleigh equation

assumes that the amount of distillate received is equal to the amount of initial charge lost in the distillation

process. Finally the T-x-y graph is read by hand, which is an imprecise method.

Table 2: Comparisons of Experimental and POLYSRK Aspen Model

Temperature Value Aspen Calculated (oC) Experimental (oC)

Top Stage Initial 81 79

Top Stage Final 94.6 93

Still Pot Initial 102.3 98

Still Pot Final 102.55 99.7

It was interesting, though not unexpected, to see that the theoretical and experimental temperatures varied

for each section. Primarily, Aspen is showing higher temperatures, most likely because it does not account

for heat loss to the environment, as the pilot plant is not likely to be perfectly adiabatic. Other contributing

factors include assuming no interaction occurred between the water and ethanol molecules, measuring

inaccurate height and diameter of the column, and assuming an inaccurate reflux ratio. The Aspen data also

represents a total change in temperature of 0.002ºC which is not accurate as the temperature should change

drastically as the process goes on. This could be because our chosen property method, POLYSRK, was

not accurate for our system, because there was pressure buildup in the column, or that any other

assumptions we made are not accurate. However, it was the most accurate calculator of time. Therefore,

the model POLYSRK was used for non ideal Aspen calculations. Below, diameter was varied to

demonstrate the effects of adjusting this variable on other variables, especially xDavg and time.

Table 3: Variations in Diameter in the Non-ideal POLYSRK Aspen Model

Value D = 1.64 ft D = 4 ft D = 6 ft

F (kmoles) 2.62988 2.62988 2.62988

Wfinal (kmoles) 2.54875 2.53332 2.52471

Dtotal (kmoles) 0.018134 0.042563 0.05117

xD, avg 0.607 0.259 0.216

Time (hrs) 5.2 4.7 3.5

Table 4: Variations in Reflux Ration in the Non-ideal NRTL Aspen Model

Reflux Ratio Time (hrs) xDavg Still Pot Final (oC)

1 0.291 0.524 102.673

2 0.459 0.501 102.674

3 0.610 0.493 102.674

The data above were taken from another attempt of Aspen analysis using the NRTL model. Using the

NRTL Method, a similar temperature compared to both the IDEAL and POLYSRK models, though no

closer to the experimental data. The xDavg was slightly closer to the xDavg found experimentally, however the

time obtained was significantly different. However, in a further attempt to approximate the xDavg obtained

experimentally, the reflux ratio was modified. As is visible in the table above, increasing the reflux ratio

from the given value of 2 did bring the xDavg to nearly the experimental value. However, this only extended

the time to 0.610 hours, still an order of magnitude away from the experimental time.

Conclusions and Recommendations:

The analysis provided in this report suggests that the process can be modeled successfully. It was found

that the data from Aspen, the experimental data, and the Rayleigh Equations were all within an order of

magnitude. The POLYSRK Aspen Model was the closest to the experimental data in some regards, and the

calculated Rayleigh values were more accurate in other respects. Based on this similarity in values and

considering the fact that these methods of calculating the required data each used different assumptions,

this process is recommended as a basis for the final column design.

Appendix:

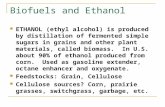

Figure I: T-x,y graph for ethanol/ water binary system.

Liquid/vapor mole fraction EtOH

Composition Calculations

VF= 48 L

Vfinal= 46 L

VD=1.57 L

Molar volume of water Vm, water= 0.018 L/mole

Molar volume of ethanol Vm, EtOH= 0.058 L/mole

Initial volume fraction of ethanol ϕF= 0.02

Final volume fraction of ethanol ϕfinal =0.007

Volume fraction of ethanol in total distillate ϕD =0.773

Initial moles of ethanol nF, EtOH= (VF*ϕF)/Vm, EtOH= (48*0.02)/0.058= 16.55 moles

Initial moles of water nF, water= [VF*(1-ϕF)]/Vm, water= [48*(1-0.02]/0.018= 2613.33 moles

F = nF, EtOH + nF, water= 16.55 + 2613.33= 2.62988 kmoles

xF = nF, EtOH/ F = 16.55/2629.88 = 0.0063

Final moles of ethanol nfinal, EtOH= (Vfinal*ϕfinal)/Vm, EtOH= (46*0.007)/0.058= 5.552 moles

Final moles of water nfinal, water= [Vfinal*(1-ϕfinal)]/Vm, water= [46*(1-0.007]/0.018= 2537.667 moles

Wfinal= nF, EtOH + nF, water= 5.552 + 2537.667= 2.54322 kmoles

xw, final=nF, EtOH/ F =5.552/2543.22=0.002183

Moles of ethanol in total distillate nD, EtOH= (VD*ϕD)/Vm, EtOH= (1.57*0.773)/0.058= 20.924 moles

Moles of water in total distillate nD, water= [VD*(1-ϕD)]/Vm, water= [1.57*0.227]/0.018= 19.799 moles

Dtotal= nD, EtOH + nD, water= 20.924 + 19.799= 0.04072 kmoles

xD, avg=nD, EtOH/ Dtotal =19.799/40.72 = 0.4862

Rayleigh Calculations

Table 5 : Data points selected and their corresponding compositions converted using T-x,y graph

Top Stage Vapor Temperature (℃) xD Reboiler Temperature (℃) xW

79 0.7167 98 0.0063

79.5 0.6933 98.5 0.0060

81 0.6167 98.9 0.0050

87 0.4367 99.3 0.0033

93 0.2667 99.7 0.0022

Table 6: Calculations for Rayleigh Equation

ΔxW xW xD 1

xD− xW ( )avg1

xD− xW

0.0063 0.7167 1.4077

0.0003 0.0060 0.6933 1.4550 1.4313

0.0010 0.0050 0.6167 1.6348 1.5449

0.0017 0.0033 0.4367 2.3075 1.9711

0.0011 0.0022 0.2667 3.7805 3.0440

Use Trapezoid Rule:

=∑[Δxw*( )avg]∫xF

xW , f inal

dxWxD−xW

1xD− xW

=0.0003*1.4313+0.0010*1.5449+0.0017*1.9711+0.0011*3.0440

= 0.0088

Wfinal=F*exp(- ) =2.62988*exp(-0.0088) = 2.6068 kmoles∫xF

xW , f inal

dxWxD−xW

Dtotal = F-Wfinal=2.62988- 2.6068 = 0.023 kmoles

xD, avg = (F*xF - Wfinal * xw)/Dtotal = (2.62988*0.0063-2.6068*0.0022)/0.023 = 0.474

Aspen Calculations The following data is from the POLYSRK (R=2, D=1.64ft) Model as this was deemed the most accurate. Input Values Set up: Configuration Number of stages : 11 Valid phases : Vapor-Liquid Pot Geometry Orientation : Vertical Top head type : Hemispherical Bottom head type : Hemispherical Diameter : 1.64 ft Height : 8 ft Volume : 0.544 m3 Pot Heat Transfer Jacket heating Jacket covers bottom: True Jacket bottom height : 0.0 ft Jacket top height : 0.05 ft Jacket Heating Heating option : Steam Heating Steam Specification: Pressure Heat Transfer Coefficient: 0.5152 kW/m/K Steam Pressure: 7.5 psig Limiting Method: Latent Heat Steam Mass Flow Rate: 0.0028 kg/s Condenser Condenser type : Total Reflux Reflux specification : Reflux ratio Reflux ratio : 2 Reflux drum present : False Pressure Holdups: Pressure Pressure profile and holdups : Fixed Condenser pressure : 1.01325 bar Column pressure drop : 0.1 bar

Holdups Start stage: 2 End stage: 10 Holdup: 0.006 kmol Receivers: Distillate Number of distillate receivers : 1 Receiver taking liquid distillate : 1 Receiver taking vapor distillate : 1 Initial Conditions: Main Initial condition : Total reflux Initial Charge Composition basis : Mole-frac Total initial charge : 2.62988 kmol Component Fresh Charge Composition ETHANOL: 0.0063 WATER: 0.9937 Operating Steps: Operating Step distil Status : Complete Active : True Changed Parameters Location: Reflux splitter; Reflux ratio Reflux splitter; Reflux ratio; 2 Jacket Heating; Steam Pressure; 7.5 psig End Condition Step end condition : Trigger value Variable location: Pot Variable: Liquid mole fraction Component: Ethanol Approach from: Approach from below Value: 0.002 kmol/kmol

Table 7: Temperature Profile History

Table 8: Distillate Composition (Ethanol) History

Refrences:

VLE-Calc. "Vapor-liquid Equilibrium Database, Calculations and Phase Diagram Drawing." Vapor-liquid

Equilibrium Database, Calculations and Phase Diagram Drawing . VLE-Calc, 19 Sept. 2015. Web. 13

Apr. 2016. <http://vle-calc.com/phase_diagram.html?numOfC=2>.