Electrical Machine Design Chapter.1 PRINCIPLES OF …fmcet.in/EEE/EE2355_uw.pdf · Electrical...

-

Upload

dinhnguyet -

Category

Documents

-

view

224 -

download

1

Transcript of Electrical Machine Design Chapter.1 PRINCIPLES OF …fmcet.in/EEE/EE2355_uw.pdf · Electrical...

Electrical Machine Design

Chapter.1 PRINCIPLES OF ELECTRICAL MACHINE DESIGN

Introduction

The magnetic flux in all electrical machines (generators, motors and transformers) plays an

important role in converting or transferring the energy. Field or magnetizing winding of rotating

machines produces the flux while armature winding supplies either electrical power or mechanical

power. In case of transformers primary wing supplies the power demand of the secondary.

The basic design of an electrical machine involves the dimensioning of the magnetic circuit,

electrical circuit, insulation system etc., and is carried out by applying analytical equations.

A designer is generally confronted with a number of problems for which there may not be one

solution, but many solutions. A design should ensure that the products perform in accordance

with the requirements at higher efficiency, lower weight of material for the desired output, lower

temperature rise and lower cost. Also they are to be reliable and durable.

A practical designer must effect the design so that the stock (standard frames, punching etc.,) is

adaptable to the requirements of the specification. The designer must also affect some sort of

compromise between the ideal design and a design which comply with manufacturing conditions.

A electrical designer must be familiar with the, a. National and international standards

Indian Standard (IS), Bureau of Indian Standard (BIS), India

British Standard (BS), England

International Electrotechnical Commission (IEC)

NEMA (The National Electrical Manufacturers Association).

b. Specifications (that deals with machine ratings, performance requirements etc., of the

consumer) c. Cost of material and labour

d. Manufacturing constraints etc.

A designer can refer to Design Data Handbook (Electrical Machine Design Data Book, authored

by A Shanmugasundaram and others , New Age International Publishers, Reprint 2007, or any

other such handbooks) which is a source of design procedure, properties of materials, ranges of

design parameters etc., and manufacturer’s brochure.

As the design involves a number of assumptions and constraints, final design values can be

obtained only by iterative methods. Computer plays a vital role in arriving at the final values. By

Finite Element Method (FEM), the effect of a single parameter on the dynamical performance of

the machine can be studied. Furthermore, some tests, which are not even feasible in laboratory

setup, can be virtually performed by Finite Element Method.

The design problems, that have been considered to solve in the latter chapters, are of different

nature from the design worked out in detail in respect of any machine. However, these test

1

problems provide adequate elementary skills in design, which is an indication that a student has a

fair knowledge to deal with the entire design.

Factors for consideration in electrical machine design

The basic components of all electromagnetic apparatus are the field and armature windings

supported by dielectric or insulation, cooling system and mechanical parts. Therefore, the

factors for consideration in the design are,

1. Magnetic circuit or the flux path: Should establish required amount of flux using

minimum mmf. The core losses should be less.

2. Electric circuit or windings: Should ensure required emf is induced with no

complexity in winding arrangement. The copper losses should be less.

3. Insulation: Should ensure trouble free separation of machine parts operating at

different potential and confine the current in the prescribed paths.

4. Cooling system or ventilation: Should ensure that the machine operates at the

specified temperature.

5. Machine parts: Should be robust.

The art of successful design lies not only in resolving the conflict for space between iron, copper, insulation and coolant but also in optimization of cost of manufacturing, and operating

and maintenance charges.

The factors, apart from the above, that requires consideration are

a. Limitation in design ( saturation, current density, insulation, temperature rise etc.,)

b. Customer’s needs

c. National and international standards

d. Convenience in production line and transportation

e. Maintenance and repairs

f. Environmental conditions etc.

Limitations in design

The materials used for the machine and others such as cooling etc., imposes a limitation

in

design. The limitations stem from saturation of iron, current density in conductors, temperature, insulation, mechanical properties, efficiency, power factor etc.

a. Saturation: Higher flux density reduces the volume of iron but drives the iron to

operate beyond knee of the magnetization curve or in the region of saturation.

Saturation of iron poses a limitation on account of increased core loss and

excessive

excitation required to establish a desired value of flux. It also introduces harmonics.

b. Current density: Higher current density reduces the volume of copper but

increases the losses and temperature.

c. Temperature: poses a limitation on account of possible damage to insulation and other

materials. d. Insulation (which is both mechanically and electrically weak): poses a limitation on

account of breakdown by excessive voltage gradient, mechanical forces or heat.

e. Mechanical strength of the materials poses a limitation particularly in case of large and

high speed machines. f. High efficiency and high power factor poses a limitation on account of higher capital

cost. (A low value of efficiency and power factor on the other hand results in a high

maintenance cost). g. Mechanical Commutation in dc motors or generators leads to poor commutation.

Apart from the above factors Consumer, manufacturer or standard specifications may pose a

limitation.

Materials for Electrical Machines

The main material characteristics of relevance to electrical machines are those associated with

conductors for electric circuit, the insulation system necessary to isolate the circuits, and with

the specialized steels and permanent magnets used for the magnetic circuit.

Conducting materials

Commonly used conducting materials are copper and aluminum. Some of the desirable

properties a good conductor should possess are listed below. 1. Low value of resistivity or high conductivity

2. Low value of temperature coefficient of resistance

3. High tensile strength

4. High melting point 5. High resistance to corrosion

6. Allow brazing, soldering or welding so that the joints are reliable

7. Highly malleable and ductile 8. Durable and cheap by cost

Some of the properties of copper and aluminum are shown in the table-2.

Table-2

Sl. Particulars Copper Aluminum

No 1 Resistivity at 20

0C

2 Conductivity at 200C

3 Density at 200C

4

0.0172 ohm / m/ mm2

58.14 x 106S/m

8933kg/m3

0.393 % per 0C

0.0269 ohm / m/ mm2

37.2 x 106S/m

2689.9m3

0.4 % per 0C

Temperature coefficient

(0-100oC)

Explanation: If the temperature increases by 1oC, the

resistance increases by 0.4% in case of aluminum

5 Coefficient of linear

expansion (0-100oC)

6 Tensile strength

7 Mechanical property

8 Melting point

9 Thermal conductivity

(0-100oC)

10 Jointing

16.8x10-6 per

oC

25 to 40 kg / mm2

highly malleable and ductile

10830C

599 W/m 0C

can be easily soldered

23.5 x10-6 per

oC

10 to 18 kg / mm2

not highly malleable and ductile

6600C

238 W/m 0C

cannot be soldered easily

3

For the same resistance and length, cross-sectional area of aluminum is 61% larger than that of

the copper conductor and almost 50% lighter than copper. Though the aluminum reduces the cost of small capacity transformers, it increases the size and

cost of large capacity transformers. Aluminum is being much used now a days only because

copper is expensive and not easily available. Aluminum is almost 50% cheaper than Copper

and not much superior to copper.

Magnetic materials

The magnetic properties of a magnetic material depend on the orientation of the crystals of the

material and decide the size of the machine or equipment for a given rating, excitation

required, efficiency of operation etc. .

The some of the properties that a good magnetic material should possess are listed below.

1. Low reluctance or should be highly permeable or should have a high value of relative

permeability r.

2. High saturation induction (to minimize weight and volume of iron parts)

3. High electrical resistivity so that the eddy emf and the hence eddy current loss is less

4. Narrow hysteresis loop or low Coercivity so that hysteresis loss is less and efficiency of

operation is high

5. A high curie point. (Above Curie point or temperature the material loses the magnetic

property or becomes paramagnetic, that is effectively non-magnetic)

6. Should have a high value of energy product (expressed in joules / m3).

Magnetic materials can broadly be classified as Diamagnetic, Paramagnetic, Ferromagnetic,

Antiferromagnetic and Ferrimagnetic materials. Only ferromagnetic materials have properties

that are well suitable for electrical machines. Ferromagnetic properties are confined almost

entirely to iron, nickel and cobalt and their alloys. The only exceptions are some alloys of

manganese and some of the rare earth elements.

The relative permeability r of ferromagnetic material is far greater than 1.0. When

ferromagnetic materials are subjected to the magnetic field, the dipoles align themselves in the

direction of the applied field and get strongly magnetized.

Further the Ferromagnetic materials can be classified as Hard or Permanent Magnetic materials

and Soft Magnetic materials.

a) Hard or permanent magnetic materials have large size hysteresis loop (obviously

hysteresis loss is more) and gradually rising magnetization curve.

Ex: carbon steel, tungsten steal, cobalt steel, alnico, hard ferrite etc.

b) Soft magnetic materials have small size hysteresis loop and a steep magnetization

curve. Ex: i) cast iron, cast steel, rolled steel, forged steel etc., (in the solid form).

-Generally used for yokes poles of dc machines, rotors of turbo alternator etc., where

steady or dc flux is involved.

4

ii) Silicon steel (Iron + 0.3 to 4.5% silicon) in the laminated form. Addition of silicon in

proper percentage eliminates ageing & reduce core loss. Low silicon content steel or

dynamo grade steel is used in rotating electrical machines and are operated at high flux

density. High content silicon steel (4 to 5% silicon) or transformer grade steel (or high

resistance steel) is used in transformers. Further sheet steel may be hot or cold rolled. Cold

rolled grain oriented steel (CRGOS) is costlier and superior to hot rolled. CRGO steel is

generally used in transformers.

c) Special purpose Alloys:

Nickel iron alloys have high permeability and addition of molybdenum or chromium

leads to improved magnetic material. Nickel with iron in different proportion leads to (i) High nickel permalloy (iron +molybdenum +copper or chromium), used in

current transformers, magnetic amplifiers etc.,

(ii) Low nickel Permalloy (iron +silicon +chromium or manganese), used in transformers, induction coils, chokes etc.

(iii) Perminvor (iron +nickel +cobalt)

(iv) Pemendur (iron +cobalt +vanadium), used for microphones, oscilloscopes, etc.

(v) Mumetal (Copper + iron)

d) Amorphous alloys (often called metallic glasses):

Amorphous alloys are produced by rapid solidification of the alloy at cooling rates of about a million degrees centigrade per second. The alloys solidify with a glass-like atomic structure

which is non-crystalline frozen liquid. The rapid cooling is achieved by causing the molten

alloy to flow through an orifice onto a rapidly rotating water cooled drum. This can produce

sheets as thin as 10µm and a metre or more wide. These alloys can be classified as iron rich based group and cobalt based group.

Material

3% Si grain oriented

Maximum permeability

µ x 10-3

90

Saturation magnetization

in tesla

2.0

Coercivity A/m

6-7

Curie temperature

oC

745

Resistivity

Ωm x 108

48

2.5% Si grain non -oriented 8 2.0 40 745 44

<0.5% Si grain non oriented 8

2.1

50-100 770

12

Low carbon iron 3-10 2.1 50-120 770 12

78% Ni and iron

50% Ni and iron

250-400

100

0.8

1.5-1.6

1.0

10

350

530

40

60

Iron based Amorphous 35-600 1.3-1.8 1.0-1.6 310-415 120-140

5

Insulating materials

To avoid any electrical activity between parts at different potentials, insulation is used. An

ideal insulating material should possess the following properties.

1) Should have high dielectric strength.

2) Should with stand high temperature.

3) Should have good thermal conductivity

4) Should not undergo thermal oxidation

5) Should not deteriorate due to higher temperature and repeated heat cycle

6) Should have high value of resistivity ( like 1018

cm)

7) Should not consume any power or should have a low dielectric loss angle 8) Should withstand stresses due to centrifugal forces ( as in rotating machines), electro

dynamic or mechanical forces ( as in transformers)

9) Should withstand vibration, abrasion, bending 10) Should not absorb moisture

11) Should be flexible and cheap

12) Liquid insulators should not evaporate or volatilize

Insulating materials can be classified as Solid, Liquid and Gas, and vacuum. The term insulting

material is sometimes used in a broader sense to designate also insulating liquids, gas and

vacuum.

Solid: Used with field, armature, transformer windings etc. The examples are:

1) Fibrous or inorganic animal or plant origin, natural or synthetic

paper, wood, card board, cotton, jute, silk etc.,

rayon, nylon, terelane, asbestos, fiber glass etc.,

2) Plastic or resins. Natural resins-lac, amber, shellac etc., Synthetic resins-phenol formaldehyde, melamine, polyesters, epoxy, silicon resins,

bakelite, Teflon, PVC etc

3) Rubber : natural rubber, synthetic rubber-butadiene, silicone rubber, hypalon, etc., 4) Mineral : mica, marble, slate, talc chloride etc.,

5) Ceramic : porcelain, steatite, alumina etc.,

6) Glass : soda lime glass, silica glass, lead glass, borosilicate glass 7) Non-resinous : mineral waxes, asphalt, bitumen, chlorinated naphthalene, enamel etc.,

Liquid: Used in transformers, circuit breakers, reactors, rheostats, cables, capacitors etc., & for

impregnation. The examples are: 1) Mineral oil (petroleum by product)

2) Synthetic oil askarels, pyranols etc.,

3) Varnish, French polish, lacquer epoxy resin etc.,

6

Gaseous: The examples are:

1) Air used in switches, air condensers, transmission and distribution lines etc., 2) Nitrogen use in capacitors, HV gas pressure cables etc.,

3) Hydrogen though not used as a dielectric, generally used as a coolant

4) Inert gases neon, argon, mercury and sodium vapors generally used for neon sign lamps. 5) Halogens like fluorine, used under high pressure in cables

No insulating material in practice satisfies all the desirable properties. Therefore a material

which satisfies most of the desirable properties must be selected.

Classification of insulating materials based on thermal consideration

The insulation system (also called insulation class) for wires used in generators, motors

transformers and other wire-wound electrical components is divided into different classes

according the temperature that they can safely withstand. As per Indian Standard ( Thermal evaluation and classification of Electrical

Insulation,IS.No.1271,1985,first revision) and other international standard insulation is

classified by letter grades A,E,B,F,H (previous Y,A,E,B,F,H,C).

Insulation class

Previous Present

Y

Maximum

operating temperature

in

90

Typical materials

Cotton, silk, paper, wood, cellulose, fiber etc., without

impregnation or oil immersed

The material of class Y impregnated with natural resins, A

E

B

F

H

C

A

E

B

F

H

C

105

120

130

155

180

>180

cellulose esters, insulating oils etc., and also laminated wood,

varnished paper etc. Synthetic resin enamels of vinyl acetate or nylon tapes, cotton and paper laminates with formaldehyde bonding etc.,

Mica, glass fiber, asbestos etc., with suitable bonding substances, built up mica, glass fiber and asbestos laminates.

The materials of Class B with more thermal resistance bonding materials Glass fiber and asbestos materials and built up mica with

appropriate silicone resins Mica, ceramics, glass, quartz and asbestos with binders or

resins of super thermal stability.

The maximum operating temperature is the temperature the insulation can reach during

operation and is the sum of standardized ambient temperature i.e. 40 degree centigrade, permissible temperature rise and allowance tolerance for hot spot in winding. For example, the

maximum temperature of class B insulation is (ambient temperature 40 + allowable

temperature rise 80 + hot spot tolerance 10) = 130oC.

Insulation is the weakest element against heat and is a critical factor in deciding the life of

electrical equipment. The maximum operating temperatures prescribed for different class of

7

insulation are for a healthy lifetime of 20,000 hours. The height temperature permitted for the machine parts is usually about 200

0C at the maximum. Exceeding the maximum operating

temperature will affect the life of the insulation. As a rule of thumb, the lifetime of the winding

insulation will be reduced by half for every 10 ºC rise in temperature. The present day trend is to design the machine using class F insulation for class B temperature rise.

8

Chapter.3 Design of Commutator and Brushes

The Commutator is an assembly of Commutator segments or bars tapered in section. The

segments made of hard drawn copper are insulated from each other by mica or micanite, the

usual thickness of which is about 0.8 mm. The number of commutator segments is equal to the

number of active armature coils.

The diameter of the commutator will generally be about (60 to 80)% of the armature diameter.

Lesser values are used for high capacity machines and higher values for low capacity

machines.

Higher values of commutator peripheral velocity are to be avoided as it leads to lesser

di commutation time dt, increased reactance voltage RV = L

dt and sparking commutation.

The commutator peripheral velocity vc = DC N / 60 should not as for as possible be

more

than about 15 m/s. (Peripheral velocity of 30 m/s is also being used in practice but should be

avoided whenever possible.)

The commutator segment pitch C = (outside width of one segment + mica insulation between

segments) = DC / Number of segments should not be less than 4 mm. (This minimum

segment pitch is due to 3.2 mm of copper + 0.8 mm of mica insulation between segments.) The

outer surface width of commutator segment lies between 4 and 20 mm in practice.

The axial length of the commutator depends on the space required

1

1) by the brushes with brush boxes

2) for the staggering of brushes 3) for the margin between the end of commutator and brush and

4) for the margin between the brush and riser and width of riser.

If there are nb brushes / brush arm or spindle or holder, placed one beside the other

on the

commutator surface, then the length of the commutator LC = (width of the brush wb + brush

box thickness 0.5 cm) number of brushes / spindle + end clearance 2 to 4 cm + clearance for

risers 2 to 4 cm + clearance for staggering of brushes 2 to 4 cm.

If the length of the commutator (as calculated from the above expression) leads to small

dissipating surface DC LC, then the commutator length must be increased so that the

temperature rise of the commutator does not exceed a permissible value say 550C.

The temperature rise of the commutator can be calculated by using the following empirical

formula.

2

o

θ C = 120 watt loss / cm of dissipating surface D L

C C

1 0.1 vC

The different losses that are responsible for the temperature rise of the commutator are (a) brush contact loss and (b) brush frictional loss.

Brush contact loss = voltage drop / brush set Ia

The voltage drop / brush set depend on the brush material – Carbon, graphite, electro graphite

or metalized graphite. The voltage drop / brush set can be taken as 2.0 V for carbon brushes.

Brush frictional loss (due to all the brush arms)

= frictional torque in Nm angular velocity

2

= frictional force in Newton x distance in

metre

= 9.81 PbAball DC

2N = 9.81 PbAball

vC

2 60

2 N

60

where = coefficient of friction and depends on the brush material. Lies between 0.22 and 0.27

for carbon brushes

Pb = Brush pressure in kg / m2 and lies between 1000 and 1500

Aball = Area of the brushes of all the brush arms in m2

= Ab number of brush arms

= Ab number of poles in case of lap winding

= Ab 2 or P in case of wave winding Ab = Cross-sectional area of the brush / brush arm

Brush Details

Since the brushes of each brush arm collets the current from two parallel paths, current

collected by each brush arm is 2 Ia and the cross-sectional area of the brush or brush arm or A

holder or spindle Ab = 2 I

a cm2. The current density b depends on the brush material and

A b

can be assumed between 5.5 and 6.5 A / cm2 for carbon.

In order to ensure a continuous supply of power and cost of replacement of damaged or worn

out brushes is cheaper, a number of subdivided brushes are used instead of one single brush.

Thus if

i)

ii) iii)

tb is the thickness of the brush

wb is the width of the brush and

nbis the number of sub divided brushes

thenAb = tbwbnb

As the number of adjacent coils of the same or different slots that are simultaneously

under

going commutation increases, the brush width and time of commutation also increases at the

same rate and therefore the reactance voltage (the basic cause of sparking commutation)

becomes independent of brush width.

With only one coil under going commutation and width of the brush equal to one segment

width, the reactance voltage and hence the sparking increases as the slot width decreases.

Hence the brush width is made to cover more than one segment. If the brush is too wide, then

those coils which are away from the commutating pole zone or coils not coming under the

influence of inter pole flux and under going commutation leads to sparking commutation.

Hence brush width greater than the commutating zone width is not advisable under any

circumstances. Since the commutating pole zone lies between (9 and 15)% of the pole pitch,

15% of the commutator circumference can be considered as the maximum width of the brush.

It has been found that the brush width should not be more than 5 segments in machines less

than 50 kW and 4 segments in machines more than 50 kW.

The number of brushes / spindle can be found out by assuming a standard brush width or a

maximum current / sub divided brush.

Standard brush width can be 1.6, 2.2 or 3.2 cm

Current/subdivided brush should not be more than 70A

A Thus with the brush width assumed, nb= b . With the current / sub divided brush assumed

t w

nb = 2 Iaand wb =

A x 70

Ab

t n b b

b b

Note :

A) Staggering of Brushes :

Because of the current flowing from commutator segments to the brush, copper is

eaten away leading to formation of ridges between the subdivided brushes of the same brush

arm. Since it is not possible to avoid eating away copper by the arc, eating away of copper

must be made to take place over the entire axial length of the commutator to ensure

uniform commutator surface. This is achieved by displacing all the positive brushes in one

direction and all the negative brushes in the other direction or by staggering of brushes in

pairs as shown below.

4

B) Brush materials and their properties

Peripheral

Current

Voltage drop

Coefficient of Material

Normal carbon

Soft graphite Metalized graphite (copper carbon mixture)

Electro graphite

(Graphitized by heating)

velocity m/s

5 to 15

10 to 25

5 to 15

5 to 15

density in A/cm2

5.5 to 6.5

9.0 to 9.5

15 to 16

8.5 to 9.0

per brush set in volts

2.0

1.6

0.24 to 0.35

1.7 to 1.8

friction

0.22 to 0.27

0.12

0.16

0.22

C) Step by step design procedure of commutator and brushes

1) Diameter of the commutator DC = (0.6 to 0.8) D and must be such that the

peripheral

velocity of the commutator vC = DC N / 60 is not more than 15 m/s as far as possible.

2) The commutator segment pitch C = DC / Number of segments should not be less than 4

mm from the mechanical strength point of view.

3) The number of commutator segments is equal to number of active armature coils.

4) Length of the commutator LC = (width of the brush + brush box thickness 0.5 cm)

number of brushes / spindle nb + end clearance 2 to 4 cm + clearance for risers 2 to 4 cm + clearance for staggering of brushes 2 to 4 cm.

2 Ia 5) Cross-sectional area of the brush / spindle or arm or holder Ab = A

b

cm2. The current

density in the brushes b lies between 5.5 and 6.5 A / cm2 for carbon brushes.

6) Maximum thickness of the brush tb max = 4 C for machines greater than 50 kW

= 5 C for machines less than 50 kW

7) With standard brush width Wb assumed, the number of brushes / spindle nb

= A b

t W b b

8) Total commutator losses = Brush contact loss + Brush frictional loss

= voltage drop / brush set Ia + 9.81 PbAballv

C

where voltage drop / set = 2.0 V for carbon brushes

= coefficient of friction and lies between 0.22 to 0.27 for carbon brushes

Pb = Brush pressure and lies between 1000 and 1500 kg / m2

9) Temperature rise of the commutator 0C = Cooling coefficient x watt loss / dissipating surface

120 = 1 0.1

vC

watt loss / cm2 of dissipating surface DC LC

10) Temperature rise should be less than about 550C.

*******

6

Example.1

DESIGN OF COMMUTATOR AND BRUSHES

A 500kW, 500V, 375 rpm, 8 pole dc generator has an armature diameter of 110 cm

and the

number of armature conductor is 896. Calculate the diameter of the commutator, length of the

commutator, number of brushes per spindle, commutator losses and temperature rise of the

commutator. Assume single turn coils.

Diameter of the commutator DC = (0.6 to 0.8) D = 0.7 x 110 = 77cm

Length of the commutator LC = (width of the brush Wb + brush box thickness 0.5 cm) number

of brushes / spindle nb + end clearance 2 to 4 cm + clearance for risers 2 to 4 cm + clearance

for staggering of brushes 2 to 4 cm.

Armature current Ia =

kW x 103 =

V

500 x 103= 1000A

500

Note : An armature current of 1000 A obviously calls for a lap winding.

Cross-sectional area of the brush per spindle or brush arm or holder Ab =

2 I

a since the current density lies between 5.5 and 6.5 A/cm2 for carbon brushes,

A b

let it be 6 A/mm2

Ab = 2 x 1000 = 41.66 cm2

8 x 6

maximum thickness of the brush = 4 C

Commutator segment pitch C = DC / Number of segments or coils

Number of coils = Z / 2 x number of turns per coil = 896 / 2 x 1 = 448

Therefore C

=

x 77 = 0.54 cm 448

Maximum thickness of the brush = 4 x 0.54 = 2.16 cm

Let the thickness of the brush tb= 2.0 cm

If a brush width of 2.2 cm (a standard value) is assumed then Wb = 2.2 cm

Therefore, number of brushes / spindle

nb= A b

= 41.66

= 9.46 and is not possible t W b b

2 x 2.2

Let the number of brushes / spindle be = 10

Therefore LC = (2.2 + 0.5) 10 + 2 + 2 + 2 = 33 cm

Brush contact loss = voltage drop / brush set x Ia = 2 x 1000 = 2000 W

Brush frictional loss = 9.81 PbAball vC

Let the coefficient of friction = 0.25 as it lies between 0.22 to 0.27 for carbon brushes.

Let the brush pressure Pb= 1215 kg/m2 as it lies between 1000 to 1500 kg/m

2

Aball = Area of the brushes of all the brush arms

= tbwbnb x number of brush arms or number of poles as the number of brush arms number of poles for a lap winding

= 2 x 2.2 x 10 x 8 x 10-4 = 0.0352 m

2

Brush frictional loss = 9.81 x 0.25 x 1215 x 0.352 x 15.1 = 1583.8 W

Therefore commutator losses (total) = 2000 + 1583.8 = 3583.8 W

Temperature rise in degree centigrade 2

=

=

Example.2

120 x watt loss / cm of the commutator dissipating surface

1 0.1 vC

120 x 3583.8 / x 77 x 33 = 21.46

1 0.1 x 15.1

L DCC

A 20 Hp, 4 pole, 250V, 1000 rpm wave wound D.C. machine has the following

design

data. Diameter of the armature = 25 cm, number of slots = 41, number of coil sides / slot =

4, turns / coil = 2. Calculate the number of segments, outside width of one segment and

mica, brush thickness, length of the commutator and brush contact loss.

Number of segments = number of active coils for a wave winding

i)

ii)

Number of coil sides (total) = 41 x 4 = 164

Number of coils = 164 / 2 = 82 as each coil will have 2 coil sides OR

Since the coil is of 2 turns, each coil side will have 2 conductors and therefore the

number of conductors per slot = 4 x 2 = 8.

Total number of conductors = 41 x 8 = 328

Number of coils = total number of

conductors

2 x number of

turns / coil

328

2 x

2

82 OR

iii)

Number of coils = number of slots x number of coil sides / layer

= 41 x 2 = 82

For a wave winding YC =

82 1

C 1

p

must be an integer. With the number of coils calculated, YC

= 2 is a fraction. Therefore a wave winding is not possible. However a wave winding can

be made possible by considering one of the coils as dummy. Therefore number of active coils =

81 and number of commutator segments = 81.

Outside width of one segment and mica = Commutator segment pitch

=

=

DC

number of

segments

x 0.7 x 25

81

with the assumption that

= 0.68 cm DC = 0.7 D

Maximum thickness of the brush = 5 times the commutator segment pitch

= 5 x 0.68 = 3.4 cm

Let the thickness of the brush tb = 2.5 cm

Armature current Ia =

Hp x

746 /

V

250

20 x

746 /

0.9

66.3 A

Cross-sectional area of the brush / spindle Ab = 2 I

a = 2 x 66.3 = 11.65 cm2

Let the standard brush width Wb = 1.6 cm A b 2 x 6

Number of brushes / spindle nb = A b =

11.65 = 2.76 and is not possible

t W b b

2.5 x 1.6 = 3 (say)

Length of the commutator LC = (1.6 + 0.5) 3 + 2 + 2 + 2 = 12.3 cm

Brush contact loss = Voltage drop / brush set x Ia = 2.0 x 66.3 = 132.6W

Example.3

A 600 kW, 6 pole lap connected D.C. generator with commutating poles running at 1200 rpm

develops 230V on open circuit and 250V on full load. Find the diameter of the commutator,

average volt / conductor, the number of commutator segments, length of commutator and brush

contact loss. Take Armature diameter = 56 cm, number of armature conductors = 300, number

of slots = 75, brush contact drop = 2.3 V, number of carbon brushes = 8 each 3.2 cm x 2.5 cm.

The voltage between commutator segments should not exceed 15V.

[ Note :

1. The D.C. generator is a cumulative compound one, with 230V on open circuit and 250V on

full load. Therefore while calculating the load current, 250V is to be considered.

2. The number of commutator segments or coils and hence the number of turns / coil must be

so selected that the voltage per segment is not greater than 15V.

3. For a given voltage between segments, the volt / conductor goes on reducing as the number

of turns / coil goes on increasing. Thus the volt / conductor is maximum when the turns / coil is

minimum or turns / coil is one.

4. Volt / conductor = (voltage between segments) / (conductors /coil) or (2 x number of turns

per coil)

5. There are 8 brushes / spindle of width 3.2 cm or 2.5 cm. ]

********

10

Department of Electrical and Electronics Engineering

Notes on Lessons

Class : VI semester B.E. Sub. EE2355 Design of Electrical Machines

UNIT -1

INTRODUCTION

Flux (Φ) = (MMF/ Reluctance) , Wb ; Reluctance(S) = (l/aµ) , A/Wb ;

Permeance = ( 1/S) , Wb/A ; where l = length of the flux path, m ;

A = area of cross section for the flux path, m2 ; µ = permeability = µo µ

r ;

µo = absolute permeability = 4π x 10-7 H/m and µr = relative permeability.

H = Ampere turns / m = MMF/ l = S Φ/ l = S Ba /l = (l/aµ) Ba/l = B/µ . or B = µH

Series magnetic circuit : S = S1 + S2+… Parallel magnetic circuit: Per= Per1+ Per2+...

Leakage Coeff. = total flux/useful flux; total flux = useful flux + leakage flux

Expressions for reluctance: Sg = lg/ µ

ol y

s

1. Various configurations of slotting

i) Smooth iron surface on both sides of the air gap : ys l = ys

ii) slotted armature : ys l = ys

- Ws = Wt (no fringing)

iii) slotted armature : ys l = ys – Kcs

Ws ; Ws = slot width , Wt = tooth width

Kcs = Carter’s Coefficient for slots depends on the ratio of slot opening /airgap length or the empirical relation is 1/ 1+ (5lg

/Ws

)

If radial ventilating ducts are provided: Ll = L – Kcd n

d W

d

where Kcd = Carter’s Coefficient for ducts, nd = No.of ducts, Wd= width of each duct

1

If ducts are provided on the stator and on the rotor, then Kcdshould be based on half the air gap.

Considering the effect of both slotting and ducts, Kg( gap contraction factor) = Kgs Kgd where Kgs = ys

/ ys

l and Kgd =L /Ll

If slots are provided on both sides of the airgap, Kgs = Kgss K

gsr (ss and sr denoting stator and rotor slots respectively).

MMF for airgap = H Kg lg = B/ µoKg lg = 8,00,000 B Kg lg.

Effect of Saliency : K f =Field form factor = Bave / Bg

= ψ = pole arc/pole pitch ;

pole pitch = πD/P ; Bave= Φ /( πDL/P) _______________________________

2. MMF calculation for teeth

The calculation of MMF for producing flux in the Teeth of the machine is difficult because :

i) the teeth are tapered when parallel sided slots are used and this results in variation in the flux density over the depth of the tooth. ii) the slots provide another parallel path for the flux flow, the teeth are normally worked in saturation and hence µr becomes low.

Following methods are usually employed for the calculation of MMF required for the tapered teeth:-

i) Graphical method :ATt = Mean ord. x lt Mean ord. is the mean ord. of “at” variation with tooth depth.

ii) Simpson’s rule :at mean = (at1 +4 at2 + at3)/6 A/m

iii) Bt1/3 method : ATt = at1/3 x lt ,

where at1/3 = MMF for corresponding to B at 1/3rd height from the narrow end.

3. Real and Apparent flux densities

Breal = Bapp - 4π x 10 -7 at (Ks –1) ;where Ks = A

total / A

iron = Lys / Li Wt

Specific Permeance : λ = Permeance per unit length or depth of the field.

Parallel sided slot :

2

λ=µo[(h1/3ws) + (h2/ws )+ 2h3/ws+wo) + (h4/wo) ]

4. Leakage reactance of transformers

Concentric winding

Total leakage reactance of the transformer referred to the primary = Xp = 2πf µoTp

2(Lmt/Lc) a+ (bp + bs)/3 The per unit reactance can also be calculated as εx = Ip

Xp /V

p ; where Ip , and Vp are rated phase current and voltage respectively.

Sandwich winding:

Xp = πf µo(Tp2/n)(Lmt/w) a+ (bp + bs)/6

5. Temperature rise calculations

Q = Power loss(heat produced ), J/s or W G = weight of the active material of the Machine, kg h = specific heat, J/kg-C

S = cooling surface area, m2

λ = specific heat dissipation, W/ m2-C

c = 1/ λ = cooling coefficient, m2-C / W θm = final steady temperature rise, C

The temperature of the machine rises when it is supplying load. As the temperature rises, the heat is dissipated partly by conduction, partly by radiation and in most cases largely by air cooling. The temperature rise curve is exponential in nature. Assuming the theory of heating of homogeneous bodies ,

Heat developed = heat stored + heat dissipated

Q dt = Gh dθ + Sλθ dt ; solving → θ = θm ( 1- e –t/Th ) + θi e –t/Th

If the machine starts from cold, θi = 0 →θ = θm ( 1- e –t/Th )

Th=heating time constant (time taken by the machine to attain 0.632 times θm) = Gh/Sλ

Tc= cooling time constant (time taken by the machine to fall to 0.368 times θi)

Cooling curve is an exponentially falling curve.

6. Rating of machines

IS: 4722-1968: specification for Rotating Electrical machinery: 1. continuous duty 2. short time duty (T‹‹ Th) 3. intermittent periodic duty 4. intermittent periodic duty with starting 5. intermittent periodic duty with starting and braking 6. continuous duty with intermittent periodic loading 7. continuous duty with starting and braking 8. continuous duty with periodic speed changes

7. Determination of motor rating

From the point of calculation of motor rating, the various duty cycles listed earlier, can be broadly classified as i) Continuous duty ii) Fluctuating duty and iii) Short time and intermittent duty.

Continuously duty motors work These motors work with the same load through out the duty cycle.

Fluctuating loads The motor is switched on for a period T1 and kept off for a period T2.

To calculate the power rating of motors to be used with fluctuating loads, the commonly used methods are :

i) Method of average losses ii) Equivalent current method iii) Equivalent torque method.

Short time duty The motor carries a load much higher than the rated continuous load for a short time. The time for which the motor may be allowed to carry the short time higher load is th = Th log ph/

(ph – 1) l

where ph = θml / θm ; θm = final steady temperature that would be attained if the machine

is allowed to run indefinitely at its short time rating.

8. Cooling of rotating electrical machines

In most cases, the cooling electrical machines is carried out by air flow and this cooling is called ventilation. In high speed machines such as turbo alternators, hydrogen is used for cooling.

Advantages of hydrogen cooling: Compared with air, hydrogen has the following properties:-

4

i) (1/14) th density thereby the windage losses and noise reduced ii) 14 times specific heat and 1.5 times heat transfer leading to improved cooling iii) 7 times thermal conductivity resulting in reduced temperature gradient iv) reduced corona effect v) will not support combustion so long as the hyd /air mixture exceeds 3/1.

In operation, the fans mounted on the rotor circulate hydrogen through the ventilating ducts and internally mounted gas coolers. The required gas pressure is maintained by a regulator. The precaution to be observed is the stator frame must be gas tight and explosion proof and oil film gas seals at the rotor shaft ends are essential.

Induced and Forced ventilation: In induced ventilation, the fan produces decreased air pressure inside of the machine, causing air to be sucked into the machine under the external atmospheric pressure ; and in the forced ventilation, the air is forced into the fan by the fans mounted internally or externally.

The ventilation can also be classified as i) Radial, ii) axial and iii) combined radial and axial.

9. Quantity of the cooling medium employed

Volume of air required = Va = (Q/cp θ) 103 x (760/H) x ( θi + 273)/273 V, m3 /s

cp = 995 and V = 0.775 m3 assumed; then

Va = 0.78 (Q/ θ) x (760/H) x ( θi + 273)/273 , m3

The capacity of the fan required = Pfan = P Va /ηfan, W

Similar calculations can be made for the volume of hydrogen or air or oil used for cooling the machine.

5

UNIT II

DC MACHINES

D = stator bore or armature diameter, m L = stator core length, m p = number of poles Z = Total numbers of armature conductors Iz = current in each conductor(Ia/A) , A E = induced EMF, V P = machine rating (power output),kW Pa = power developed by the armature, kW Q = kVA rating of the machine Φ = flux per pole, Wb τ = pole pitch (π D/p), m

Total Electric loading = pΦ ; Total Magnetic loading = IzZ

Specific Electric loading = ac = IzZ

(amp.conductor/m) π D

Specific magnetic loading = Bave = pΦ (Wb/m2) π DL

1. Output equation

Pa = E Ia x 10 -3 = (p/A)(ΦZN/60) Iz A 10 -3

= π2 Bave ac x10-3D2 L n = CoD2 L n where Co = output coefficient ___________________________________

Generator: Pa = (P/η) – (FW & Iron losses) ; Motor : Pa = P + (FW & Iron losses)

For large machines : FW & Iron losses are neglected i.e.,

Pa = P/ η (Generator) = P (Motor)

For small machines : FW & Iron losses can be taken as 1/3 rd of the total losses. So,

Pa = (P/η) – (1/3) P (1-η)/ η = P(2+ η)/(3 η) …generator

= P + (1/3) P (1-η)/ η = P(1+2η)/(3 η) …motor

2. Choice of specific magnetic loading (Bave)

6

i) B max in the iron part of the magnetic circuit: B max ≤ maximum allowable density

i.e., Bt = B

aveY

s /w

t (non-salient pole machines); Ys = slot-pitch and wt = tooth width.

&Bt = (Bave /ψ)Ys /w

t (salient pole machines) where ψ = pole arc /pole-pitch ratio. If Ys =2 wt and ψ = 0.667 , then Bt = 3 Bave : For example,if Bt is to be limited to 2.2 Wb/m2, Baveshould excced 2.2/3 = 0.73 Wb/m2.

ii) Magnetizing current: large Bave→ high magnetizing current → large core loss

3. Choice of specific electric loading (ac)

i)Temperature rise(θ) θ depends on Q (losses),which in turn depends on ac. Allowable θ depends on insulating material used.

ii) Cooling coefficient (C) θ is also proportional to the cooling coefficient; a machine with a better ventilation has a lower C and then higher ac can be used.

iii)Operating voltage (V) In high voltage machines, the slot space factor, Sf is less and so only smaller ac can be used. It also depends on the shape of the conductors, circular or rectangular in cross section.

iv) Current Density (δ) choice of δ depends on cooling; higher C → higher value in the choice of ac.

4. Constraints in the design of DC machines

i) Peripheral speed,v ≤ 45 m/s ii) Frequency of flux reversal, f ≤ 50 Hz iii) Current per brush arm ≤ 400 A

iv) Armature MMF per pole ≤ 7000 A

The MMF required for the airgap = 50% of the armature MMF and gap contraction factor = 1.1.

The current per brush arm (Ib) = 2Ia/p , A For square poles: L = ψ π D/p

In the design process, choose p based on f& Ib and then calculate D and L

7

5. Armature Design

Considerations in choice of number of armature slots :

i) mechanical difficulties ii) cooling of armature iii) pulsation of flux iv) cost v)commutation (Slots/pole ≥ 9 ) vi) slot pitch (ys

=25 to 35 mm) vii) slot loading (Iz Z

s ≤ 1500 Amp-cond) viii) suitability of the winding – doublelayer Lap or wave )

Slot dimensions:

i) the slot area should accommodate the armature conductors and the required insulation depending on the operating voltage ii) Bt1/3 ≤ 2.1 Wb/m2 iii) deep slots cause eddy current losses iv) slot opening should be narrow to reduce the flux pulsation and hence to reduce eddy current losses.

Armature voltage drop = Ia r

a ;

ra = (Z/2) ρLmt /(a2 az) ;

where Lmt = length of mean turn, m = 2L + 2.3τ +5ds ; a = no.of parallel paths and az = area of each conductor, m2.

6. Design of the Field system

Area of each pole (Ap) = Flux in the pole body / Flux density = cl φ / Bp

where cl = leakage coefficient

Width of the pole = Ap /Li ; where Li = net iron length = 0.9 L

Height of the pole(hf) chosen based on the MMF to be provided by the pole at full-load.

( ATf at full-load) /(ATArm. at full-load) =1.0 to 1.25 (to overcome armature reaction)

7. Tentative design of Field winding

Copper loss in the field winding = If2 Rf

= (δfa

f)2 ρLmt

Tf/af = δf

2ρLmt T

f a

f

= δf2ρLmt

Sf h

fd

f ; ………………….(1) where df = depth of the pole winding. Tf = no.of turns in each field coil. Permissible loss = S qf = 2Lmt

hf q

f ..(2) _______ Equating (1) and (2) ; δf

=104 √ qf

/ Sf d

f

8

MMF per metre of the field winding = ATf/ hf = If Tf /hf = δf (af Tf )/ hf = δf

Sf h

fd

f/h

f = δf S

f d

f = Sqrt 2 qf S

f d

f /ρ

8. Design of commutator and brushes

i) The number of commutator segments is equal to the number of coils.

ii)The commutator diameter Dc = 60 – 70 % of the armature diameter (D)

iii)Peripheral speed of commutator = π DcN/60 ≤ 20 m/s

iv) Pitch of the commutator segment = βc = π Dc/C ≥ 4.0 mm (3.2 mm for the conducting portion and 0.8 mm for mica separator)

v) Distance between brush spindles = π Dc/p (25 – 30 cm)

vi) Length of the commutator = Lc= n

b (w

b + cb) + c1+ c

2

where nb = number of brushes per brush arm, wb = width of the brush, cb = clearance between brushes ,

c1 = clearance for staggering (10–30 mm), c2 = clearance for end

ply (10-25 mm).

vii) Current carried by each brush spindle

= Ib= 2Ia/p = Ab δb ; where Ab= nbwbtb

= total brush contact area ; δb = current density in the brushes (≈0.1 A/mm2).

nb is selected such that each brush does not carry more than about 70 A . viii) The thickness of brush = (2-3) βc

ix) Com. surface area = Sc= π DcLc m2

x) Commutator surface losses: 1.brush contact loss = Wbc = VbIa ; Vb= brush contact drop ≈ 1.0 V/brush

2.brush friction loss =Wbf = μ ρbpA

bV

c

μ = coefficient of friction (0.1 - 0.3) ; ρb= brush pressure (10 – 15 kN/ m2)

3. Cooling coefficient = c =k/(1+0.1Vc) ; k = 0.015 – 0.025

4. Temperature rise θc = Qcc /Sc 9. Losses and efficiency in DC machines

1. I2R losses : copper loss in i) armature ii) Field iii) Inter pole winding

9

2. Rotational losses :i) Friction &windage

ii)Iron loss a) Hysterises =Kh B

m1.6 f b) Eddy current loss =Ke Bm

2 f2t2

For the calculation of copper losses , the total length and area cross section of each of the windings should be first calculated.

10

UNIT III

TRANSFORMERS

1. Single-Phase Transformers

Voltage per turn = E/T = 4.44fΦm = Et

The window in a single-phase transformer contains one primary and one secondary winding. The total copper area in the window:

Ac = Tpap + Tsas = ( TpIp + TsIs )/δ since ap = Ip/ δ and as = Is/ δ

= 2AT/ δ ; since TpIp = Ts

Is neglecting magnetizing current

Aw = total window area ; Kw = window space factor = Ac/ Aw

Ac = K

w A

w = 2AT/ δ → AT = Kw A

w δ/2

Rating in kVA = Q = Vp I

p x 10 -3 = Ep I

p x 10 -3 = Et ( Tp I

p )x 10 -3

= 4.44 fΦm ( Kw Aw δ/2 ) 10 -3 ; where Φm = Bm Ai

= 2.22 fΦm (Kw

Aw δ ) 10-3

2. Three-phase transformers

Each window contains two primary and two secondary windings

Ac =2 (Tpa

p + Tsa

s ) = 4 AT / δ → AT = Kw A

w δ/4

Rating in kVA = Q = 3Vp I

p x 10 -3 = 3Ep I

p x 10 -3 =3 Et ( Tp I

p )x 10 -3

= 3 x 4.44 fΦm ( Kw Aw δ/4 ) 10 -3 where Φm = Bm Ai

= 3.33 fΦm (Kw

Aw δ ) 10-3

Using the output equation it can also be shown that _____ __________ E t = K √ kVA where K =√ 4.44 f r 103 ; r = Φm / AT

r is a constant for transformer of a given type ,service and method of connection, since Φm determines the core section and AT fixes the total copper area.

3. Ratio of Iron loss to copper loss

11

Copper loss/m3 = (ρl/a) (current)2 /(la) = (ρl/a) (aδ)2/la

= ρδ2 W/m3 = ρδ2/density W/Kg

Taking ρ =0.021 x 10-6and density = 8.9 x 103 Kg/m3 Copper loss/Kg = specific copper loss = pc = 2.36 x 10 12 δ2 W/Kg . Then total copper loss = Wc = pc

Gc where Gc weight of copper , Kg

In addition to the above , we must add stray losses which may be 5 to 25 % of copper loss.

The total iron loss / Kg = specific iron loss (pi) can be found from the iron loss curves. Then the total iron loss = Wi = pi

Gi

Where Gi = weight of iron . Ratio of Iron loss / copper loss = pi G

i / pc

Gc

4. Design of the core

The core section of the core type transformer may be rectangular , square or stepped. Shell type transformers use cores with rectangular cross section. For the rectangular core the ratio of depth to width 1.4 to 2.0.

Square or stepped coreWhen circular coils are required for high voltage transformers , square and stepped cores are used . Circular coils are preferred because of their superior mechanical characteristics.

As the size of the transformer increases, it becomes wasteful to use rectangular cores. Square cores are used and the surrounding circle, representing the inner surface of the tubular form carrying the windings, is called the circumscribing circle. Even now a lot of useful space is wasted and the length of the mean turn increases causing higher I2R

losses.

With larger transformers, cruciform cores, with better utilization of the space, are used. It should be born in mind that two different types of laminations are used in cruciform cores. With still larger transformers, further step sizes are introduced to utilize the core even more effectively. However, larger step sizes → larger number of lamination sizes → higher labor cost.

Assuming a stacking factor for iron = 0.9 , Net core area / area of circumscribing circle = 0.637 for square core and = 0.710 for stepped core with a= 0.851d , b= 0.526 d ; where d = diameter of the circumscribing circle.

5. Choice Flux density and Current density( Bm and δ)

12

Bm determines the core area.

Higher Bm → smaller area → smaller Lmt → saving in the cost of iron and copper. But higher Bm increases the iron loss and temp rise. For Distribution transformer Bm = 1.1 to 1.35 Wb/m2. For Power transformer Bm = 1.25 to 1.45 Wb/m2 .

The area of conductors for the primary and secondary windings determined after choosing a suitable value for δ which depends on the method of cooling.

6. Types of Windings

i) Cylindrical winding with circular conductors ii) Crossover winding with circular or rectangular conductors iii) Continuous disc type winding with rectangular conductors iv) Helical winding

7. Design of insulation

i) Electrical insulation: depends on the operating voltage ii) Eddy current loss in the conductors and tank walls iii) Mechanical considerations: high mechanical forces during fault iv) Thermal considerations: depends on cooling

Major insulation : between windings and core (grounded) Minor insulation ; between turns and layers Materials : cotton thread, cotton tape, leatheriod paper, millinax paper etc.

8. Window dimensions

a = width of the largest samping ; d = dia of the circumscribing circle D = distance between centres of adjacent limbs Ww , Hw = width and height of the window ( length of the window) Hy = height of the yoke

For core type: D = d + Ww ; W = D+a ; H = Hw + 2Hy

For core type, the yoke section may be either rectangular or stepped. In rectangular yoke sections, depth of the yoke = depth of the core; when stepped cores are used the core depth = width of the largest stamping; area rectangular yokes = Ay

= Dy H

y = a Hy

For three phase transformers : W = 2d + a

Window space factor, Kw = Ac/A

w = 10 /(30+kV) Area of the window = Aw = Hw Ww ; Aw = 2ap

Tp/ Kw (single-phase) = 2ap

Tp/ Kw ( three-phase)

13

For shell type : Dy = b ; Hy = a ; W = 2Ww+4a ; H = Hw + 2a

9. No-load current calculations

The phasor sum of the magnetizing current (Im) and the loss component of current (Il) ; Im is calculated using the MMF/m required for the core and yoke and their respective length of flux path. Il is determined using the iron loss curve of the material used for the core and yoke and the flux density employed and their weight.

10. Temperature rise of transformers

Losses dissipated in transformers in the core and windings get converted into thermal energy and cause heating of the corresponding transformer parts.The heat dissipation occurs as follows: i) from the internal heated parts to the outer surface in contact with oil by conduction ii) from oil to the tank walls by convection and iii) from the walls of the tank to the atmosphere by radiation and convection.

11. Transformer oil as a cooling medium

The specific heat dissipation due to convection of oil = λconv = 40.3 (θ /H) ¼ W/m2

- oC ; = temp difference of the surface relative to the oil and

H = height of the dissipating surface.

Experimentally found that a plain tank surface dissipates 6.0 W/m2-oC by radiation and 6.5 W/m2-oc by convection (.for a temp rise of 40 oC above an ambient temp of 20 oc). Thus a total of 12.5 W/m2-oC is taken. The temp rise θ = total loss/ (λ St) = (Pi + Pc) / (λ St

)

Where St = heat dissipating surface area of the tank.

For small transformers , plain walled tank is enough to dissipate the losses. As the rating of the transformer increases, the volume increases as he cube of the linier dimensions but the heat dissipating surface area increases only as square of the linier dimensions. So above certain rating, plain tank becomes inadequate to dissipate losses and the area is increased by providing tubes. For larger ratings forced air cooling is used.

If tubing is provided, the oil circulation is improved due to the head of the oil, and this causes an additional dissipation by convection of about 35 % .

Let x St be the area of the cooling tubes. Then Loss dissipated by the tank surface 12.5 St W/0C

Loss dissipated by the tubes (1.35 x 6.5) x St W/

0 C = 8.8 x St W/

0C

Total loss dissipated by the tank and oil tubes

14

= (12.5 St + 8.8 x St ) W/0C

Hence θ = ( Pi + Pc)/ (12.5 St + 8.8 x St ) →Total tube area x St

= (1/8.8) [ (Pi + Pc)/ θ – 12.5 St ]

The number of tubes = nt = Total tube area /(π dt lt )

The arrangement of the tubes on tank side walls should be made uniformly with a spacing of usually 75 mm. Examples of calculation of nt and the arrangement of the tubes should be studied.

1. Output Equation

Q(kVA) = m EphIph

10-3

= m (4.44f Φm TphKw ) (ac πD)/( m 2Tph)

= 4.44 (pNs/120) (Bave π DL/p) Kw (ac πD/ 2) x 10-3

= 1.11 π2 Bave ac Kw x 10-3D2L ns

= 11 Bave ac Kw x 10-3 D2L ns = C

oD

2L ns

Co = output coefficient , Q is calculated as ( hp x 0.746 )/(η cosΦ)

2. Choice of Bave

i) Low Bave → large size machine for a given hp

ii) high Bave → large magnetizing current → low power factor iii) high Bave→ high iron loss iv) high Bave → high Φm→ less Tph→ low leakage reactance → larger diameter for the circle diagram→ larger over load capacity For 50 Hz motors Bave: 0.3 to 0.6 Wb/m2

3. Choice ac (ampere conductor /m)

Low ac → large size machine for a given hp

High ac → higher copper loss and temp rise

High ac → large Tph→ large leakage reactance → lower diameter for the circle diagram→ lower over load capacity

For 50 Hz motors ac : 10,000 to 45,000 amp.cond/m The value ac chosen depends on the ventilation and cooling

It should be remembered that the Power factor (PF) and efficiency(η) of the motor at full load increases with the rating of the machine. Again η and Pf are higher for high speed motors compared to low speed motors.

4. Separation of D and L and air gap length

i) ii) iii)

L/τ can be assumed for best power factor τ = Sqrt( 0.18 L) or D= 0.135p√ L D can be chosen based on peripheral speed = πDN/60

The stator winding can be connected in star or delta. The motors meant for starting with star- delta starter should be designed with delta connected stator winding.

16

Stator slot –pitch = yss = π D/Ss where Ss =number of stator slots Stator outer diameter Do = D + 2 dss + 2dcs

Where dss = stator slot depth and dcs = stator core depth

Air gap length = 0.2 + 2 sqrt(DL) where Dand L are in metre.

After designing the main dimensions, the following calculations can be made:

i)

ii)

iii)

iv)

v)

vi)

The flux per pole, Φm = B

ave π DL/p

Turns in series per phase, Tph = V/ (4.44f ΦmK

w )

Number of slots per pole per phase can be suitably assumed

Slot pitch should not exceed about 24 mm

Number of conductors per slot should be rounded off

Tph recalculated

vii) Iph = [Q x 103/(√3 400)] for star

and [Q x 103 /(√3 400)] /√3 for delta connection

viii) Assuming suitable current density (δs) , conductor area required is calculated (as

= Iph / δs )

ix)

x)

Total copper area in the slot = (conductors /slot) as

Total area of the slot = copper area /slot space factor Slot space factor is to account for the space for insulation

xi) A suitable tooth flux density is assumed and tooth width is calculated

xii) slot width = slot pitch- tooth width (at different diameters)

xiii) The core flux(Φm/2) , core area and core depth are calculated assuming a core flux density. Core depth = core area/ Li

xiv) The rotor bar and end rings are designed (sq.cage rotor)

xv) The rotor winding is designed similar to stator winding (wound rotor)

5. Losses in the Induction motor

17

i) stator copper loss ii) rotor copper loss iii) iron loss in the stator teeth and core iv) friction and windage loss (1- 1.5 % of output)

The rotor resistance in stator terms can be obtained as rotor copper loss/ I2’ ; where I2’ = 0.85 I1

6. No-load current

Iron loss component = Il =(Iron loss/phase) /Vph

Magnetizing component = Im =(0.427 p ATtotal )/( Kws Tph)

ATtotal = sum of the ampere turns for airgap ,stator tooth and core and rotor tooth and core. No-load current = In = Il

2+ Im 2 1/2

The leakage reactance calculations are made to find x1 , x2 and x01.

UNIT V

SYNCHRONOUS MACHINES

1. Construction

Stationary armature, rotating field type of construction is preferred. High speed alternators have non-salient pole rotor (Turbo alternators) and they have

either 2-pole or 4-pole. Slow speed alternators have salient pole rotor (water wheel alternators) and they have more than 4 poles.

2. Output Equation

Q = m EphIph

10-3

= 11 Bave ac Kw x 10-3 D2L ns = C

oD

2L ns

Where Co= output coefficient (see Unit -4 for derivation)

D and L are separated using L/τ ratio or maximum specified peripheral speed of the rotor.

Damper winding is used for starting and damping rotor oscillations that occur during sudden load changes.

3. Choice of specific magnetic loading (Bave)

i) High Bave→ high flux density in the teeth and core → high iron loss → higher temperature rise.

ii) high Bave → low Tph → low leakage reactance (Xl )

→ high short circuit current

iii) In high voltage machines slot width required is more to accommodate thicker insulation →smaller tooth width → small allowable Bave

iv) stability : Pmax =VE/Xs . Since high Bave gives low Tph and hence low Xl

Pmaxincreases and improves stability.

v) Parallel operation : Ps = (VE sinδ)/Xs ; where δ is the torque angle. So low Xs gives higher value for the synchronizing power leading stable parallel operation of synchronous generators.

Guide lines : Non-salient pole alternator : 0.54 – 0.65 Wb/m2 Salient – pole alternator : 0.52 – 0.65 Wb/m2

4. Choice of specific Electric loading (ac)

i) Copper loss and temperature rise: High value of ac → higher copper loss leading high temperature rise. So choice of depends on the cooling method used.

ii) Operating voltage : High voltage machines require large insulation and so the slot space available for conductors is reduced. So a lower value for ac has to be chosen.

iii) Synchronous reactance (Xs) : High value of ac results in high value of Xs , and this leads to a) poor voltage regulation b) low steady state stability limit.

iv) Stray load losses increase with increase in ac.

Guide lines : Non-salient pole alternators : 50, 000 – 75,000 A/m Salient pole alternators : 20,000 – 40,000 A/m

5. Short Circuit Ratio (SCR)

SCR = Field current required to produce rated voltage on opencircuit Field current required to produce rated current on short circuit

= 1/ direct axis synchronous reactance = 1/Xd

Thus SCR is the reciprocal of Xd , if Xd is defined in p.u.value for rated voltage and rated current. But Xd for a given load is affected by saturation conditions that then exists, while SCR is specific and univalued for a given machine.

Non-salient pole alternators : 1- 1.5 ; Salient pole alternators : 0.5 – 0.7

Effect of SCR on machine performance

i) Voltage regulation : A low SCR → high Xd → large voltage drop → poor voltage regulation..

ii) Parallel operation : A low SCR → high Xd → low synchronizing power → parallel operation becomes difficult.

iii) Short circuit current : A low SCR → high Xd →low short circuit current. But short circuit current can be limited by other means not necessarily by keeping a low value of SCR.

iv) self excitation : Alternators feeding long transmission lines should not be designed with small SCR as this would lead to large terminal voltage on open circuit due to large capacitance currents.

Summarizing ,high value of SCR leads to i) high stability limit ii) low voltage regulation iii) high short circuit current iv)large air gap

The present trend is to design machines with low value of SCR, this is due to the recent development in fast acting control and excitation systems.

6. Length of airgap

The length of air gap very much influences the performance of a synchronous machine. A large airgap offers a large reluctance to the path of the flux produced by the armature MMF and thus reduces the effct of armature reaction. Thus a machine with large airgap has a small Xd and so has i)small regulation ii) high stability limit iii) high synchronizing power which makes the machine less sensitive to load variations iv) better cooling at the gap surface v) low magnetic noise and smaller unbalanced magnetic pull.

But as the airgap length increases, a large value of Field MMF is required resulting in increased cost of the machine.

7. Number of stator slots

Factors to be considered in the selection of number of slots : 1. Balanced 3-phase winding to be obtained 2. With large number of slots i)→large number of coils → increased labor cost ii) cooling is improved iii) tooth ripples are less iv) Flux density in the iron increases due to decreased tooth width.

Guide lines : Slot pitch (ys )≤ 25 mm for low voltage machines; ≤ 40 mm for machines upto 6 kV ; ≤ 60 mm for machines upto 15 kV.

8. Methods of Eliminating Harmonics

By using i)distributed windings ii) fractional coil pitch iii) fractional slot windings iv) skewing v) large airgap

Further calculations needed after determining D and L :

i) Flux per pole = Φ = Bave (π DL/p ) ii) Tph is calculated from the EMF equation taking Eph

= Vph

iii) Iph = (Qx 103 ) / √ 3 VL iv) Armature MMF/pole = Ata = 2.7 Iph

Tph

Kw

/p

v) Effective area per pole = 0.6 – 0.65 times actual area

9. Field Design (Salient poles)

Data needed for the design of the Field winding :

i) Flux density in the pole core ii)Winding depth (df)iii) Leakage factor (pole flux/gap flux) iv) Field winding space factor (Sf) v) Power dissipation (qf

)in W/m2 v) The ratio

21

of field MMF to armature MMF vi) Allow about 30 mm for insulation , flanges and height of the pole shoe. MMF per unit height of the winding = 104 Sqrt (Sf

df q

f )

Computer Aided Design of Electrical Machines

The process of design any electrical may be broadly divided into three major aspects: i) Electrical design ii) Mechanical design iii) Thermal design. Even though, these problems can be solved separately, there are many inter- related features.

The advantages of computer aided design are : i) The computer can handle large volume of data to make a number of trial designs. And speed and accuracy of calculations are very high. iii) It can be programmed to satisfying take logical decisions iv) An optimized design with least cost and the required performance can be easily obtained.

Generally any design method can be i) analysis method ii) Synthesis method iii) Hybrid method

In the analysis method of design , a preliminary design is made by the designer regarding the machine dimensions, materials and other constructional features and these are given as input data to the computer and the performance quantities are calculated. The designer examines the performance and accordingly alters the input data and then feed them to the computer again. The computer calculates the new performance with the revised data. This process is repeated till the required performance is achieved.

In the synthesis method, the required performance values are also given to the computer as input. The computer through an iterative process alters the dimensions till the required performance is obtained.

In the hybrid method, by some human intervention, a combination of analysis and synthesis methods are adopted.

The method of design optimization using computers :

i) ii) iii)

Choice of independent variables Variable transformation Forming the constraint functions for the performance

22

iv)

Forming the objective function (OBJ)

v) Applying the minimization technique till the OBJ becomes with in the chosen tolerance.

Example of Design of optimization of Induction Motors

The independent variables which has a significant effect on the performance are

stator core diameter, stator core length , stator core depth, stator slot depth, stator slot width, rotor slot depth, rotor slot width, end ring depth, end ring width, . airgap length and airgap flux density.

The other variables in the design are either taken as constants dased on the voltage and power rating of the machine or they are in some way related to the above 11 variables.

During the course of optimization when the variables undergo incrementing or decrementing, they should also be constrained to be with in practical ranges. This is obtained by variable transformation. For example for airgap Xact = X tran + Lg min

;

where they respectively denote actual and transformed values and Lg min = minimum airgap required.

Performance Specifications:

1. Starting torque 2. maximum torque 3. Full- load power factor 4. full -load efficiency 5. full load slip 6.tooth and core flux densities 7. starting current 8. temperature rise 9. cost of the machine.

Objective function

The objective function is formed by comparing the specified and calculated values of the performance quantities at each iteration. Objective function minimization can be carried out either using conventional methods such as Powel’s algorithm or Rosenbrock method or the recent techniques such as Genetic algorithm.

It should be noted that the independent variables or the performance specifications vary with the type of machine and its application.

23

Chapter.2 DESIGN OF DC MACHINES

Details to be specified while ordering a DC machine or consumer’s specification

1. Output : kW (for generators), kW or Hp (for motors)

2. Voltage : V volt

3. Speed : N rpm 4. Rating : Continuous or Short time

5. Temperature rise: 0C for an ambient temperature of 40

0C

6. Cooling : Natural or forced cooling

7. Type: Generator or motor, separately excited or self-excited-shunt, series, or compound, if compound type of connection – long or short shunt, type of

compounding – cumulative or differential, degree of compounding – over, under or

level. With or without inter poles, with or without compensating windings,with or

without equalizer rings in case of lap winding. 8. Voltage regulation ( in case of generators) : Range and method

9. Speed control ( in case of motors ) : range and method of control

10. Efficiency: must be as for as possible high (As the efficiency increases, cost of the

machine also increases).

11. Type of enclosure: based on the field of application – totally enclosed, screen protected,

drip proof, flame proof, etc., 12. Size of the machine etc.,

Size of the DC machine

The size of the DC machine depends on the main or leading dimensions of the machine viz.,

diameter of the armature D and armature core length L. As the output increases, the main

dimensions of the machine D and L also increases.

L

D

1

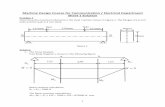

Figure.1.Armature of a dc machine Figure.2. Yoke and pole arrangement of a

dc machine

OUTPUT EQUATION

Note: Output equation relates the output and main dimensions of the machine. Actually it

relates the power developed in the armature and main dimensions.

Derivation:

Nomenclature: E : emf induced or back emf

Ia : armature current

: Average value of flux / pole

Z : Total number of armature conductors

N : Speed in rpm

P : Number of poles

A : number of armature paths or circuits D : Diameter of the armature

L : Length of the armature core

Power developed in the armature in kW = E Ia x 10-3

Z N P I 10 -3 60 A

I Z

a -3

N x 10

(P )

a

A 60 ....... (1)

The term P represents the total flux and is called the magnetic loading. Magnetic loading/unit

area of the armature surface is called the specific magnetic loading or average value of the flux

density in the air gap Bav. That is,

2

Bav

P Wb/m2or tesle denoted by T

DL Therefore P

B DL

................ (2)

av

The term (Ia Z/A) represents the total ampere-conductors on the armature and is called

the

electric loading. Electric loading/unit length of armature periphery is called the specific electric

loading q. That is,

I Z q a

A D

ampere - conductors / m

Therefore I Z/A q D ............ (3) a

Substitution of equations 2 and 3 in 1, leads to -3

kW B DL q D

N 10

av -4

2

60

1.64 10 B q D L N 2

C D L N

av

0

where C is called the output coefficeint of the DC machine and is 0

-4

equal to 1.64 x 10 B q. 2

Therefore D L

av

kW -4

3

m 1.64 10 B q N

av

The above equation is called the output equation. The D2L product represents the size

of the

machine or volume of iron used. In order that the maximum output is obtained/kg of iron used,

D2L product must be as less as possible. For this, the values of q and Bav must be high.

Effect of higher value of q

Note: Since armature current Ia and number of parallel paths A are constants and armature

diameter D must be as less as possible or D must be a fixed minimum value, the number of

armature conductors increases as q Ia Z / A D

increases.

a. As q increases, number of conductors increases, resistance increases, I2R loss increases

and therefore the temperature of the machine increases. Temperature is a limiting factor

of any equipment or machine.

b. As q increases, number of conductors increases,conductors/slot increases, quantity of

insulation in the slot increases, heat dissipation reduces, temperature increases, losses

increases and efficiency of the machine reduces. c. As q increases, number of conductors increases, armature ampere-turns per pole

AT / pole = (I Z / 2 A P)aa increases, flux produced by the armature increases, and

therefore the effect of armature reaction increases. In order to overcome the effect

of

3

armature reaction, field mmf has to be increased. This calls for additional copper

and

increases the cost and size of the machine. d. As q increases, number of conductors and turns increases, reactance voltage

proportional to (turns)2 increases. This leads to sparking commutation.

Effect of higher value of Bav

a. AsBav increases, core loss increases, efficiency reduces.

b. AsBav increases, degree of saturation increases, mmf required for the magnetic circuit increases. This calls for additional copper and increases the cost of the

machine.

It is clear that there is no advantage gained by selecting higher values of q and Bav. If the

values selected are less, then D2L will be large or the size of the machine will unnecessarily be

high. Hence optimum value of q and Bav must be selected.

In general q lies between 15000 and 50000 ampere-conductors/m.

Lesser values are used in low capacity, low speed and high voltage machines.

In general Bav lies between 0.45 and 0.75 T.

SEPARATION OF D2L PRODUCT

Knowing the values of kW and N and assuming the values of q and Bav, a value for

2

D L = kW -4

can be calculated.

1.64 10 B q N 3

Let it be 0.1 m .

av

Since the above expression has two unknowns namely D and L, another expression relating D and L must be known to find out the values of D and L.

Usually a value for the ratio armature core length L to pole pitch is assumed to separate D2L

product. The pole pitch refers to the circumferential distance corresponding one pole at

diameter D. In practice L / lies between 0.55 and 1.1.

Therefore L = (0.55 to 1.1)

= (0.55 to 1.1) D / P

If L/ = 1.0 and P = 4, then L = 1.0 D / P = 1.0 D / 4 = 0.785D.

Therefore D2

0.785 D = 0.1 or D = 0.5m. Thus L = 0.785 0.5 = 0.395 m.

Note: The D2 L product can also be separated by assuming a value for the peripheral velocity

of the armature.

LIMITATIONS OFD AND L

As the diameter of the armature increases, the peripheral velocity of the armature

v = π DN / 60 m / s , centrifugal force and its effects increases. Therefore the machine must be

mechanically made robust to withstand the effect of centrifugal force. This increases the cost of

the machine. In general for normal construction, peripheral velocity should not be greater than

30 m/s as for as possible.

To prevent arcing between commutator segments, voltage between the commutator segments

should not be greater than about 20V on open circuit. If a single turn coil is used

then the

voltage/conductor e = Bav L v should not be more than 10V.

(Bav – Average value of flux density in the air gap in tesla, L – Length of the

conductor or gross armature core length in metre and v – Peripheral velocity of armature in m/s).

e Therefore, armature core length L = B v should not be greater than 10 / (0.75 30) = 0.44m

for normal design. av

Ventilating ducts and net iron length of armature core

To keep down the temperature rise of the machine parts, the core is provided with both radial

and axial ventilating ducts. Radical ducts are created by providing vent or duct spacers in

between core packets of width 5-7 cm. Width of the radial duct lies between 0.8 and 1.0 cm in

practice.

It is clear from the figure that the net core length = (L – nvbv) wherenv – number of ventilating ducts and bv – width of the ventilating duct.

Since the core is laminated to reduce the eddy current loss and flux takes the least reluctance

path, flux confines to the iron only. Therefore the length over which the flux passes is not L or

(L -nvbv) but less than that. Generally the thickness of insulation on the laminated core will be

5