EFFECTS OF FOOTING CONNECTION ON THE …docs.trb.org/prp/17-01256.pdf · 1 EFFECTS OF FOOTING...

Transcript of EFFECTS OF FOOTING CONNECTION ON THE …docs.trb.org/prp/17-01256.pdf · 1 EFFECTS OF FOOTING...

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

1

EFFECTS OF FOOTING CONNECTION ON THE PERFORMANCE OF 1 PRECAST HOLLOW-CORE FIBER REINFORCED POLYMER-2 CONCRETE-STEEL COLUMNS 3 4 5 Mohanad M. Abdulazeez 6 Graduate Research Assistant 7 Dept. of Civil, Architectural and Environmental Engineering 8 Missouri University of Science and Technology 9 1401 N. Pine Street, 212 Butler-Carlton Hall, Rolla, MO 65409 10 Tel: 573-202-9988; Email: [email protected] 11 12 Ahmed Gheni 13 PhD Candidate 14 Dept. of Civil, Architectural, and Environmental Engineering 15 Missouri University of Science and Technology 16 1401 N. Pine Street, 218 Butler-Carlton Hall, Rolla, MO 65409 17 Tel: 573-612-8756; Email: [email protected] 18 19 Omar I. Abdelkarim 20 Postdoctoral Fellow 21 Department of Civil, Architectural & Environmental Engineering 22 Missouri University of Science and Technology 23 1401 N. Pine Street, 218 Butler-Carlton Hall, Rolla, MO 65409 24 Email: [email protected] 25 26 Mohamed A. ElGawady, Corresponding Author 27 Benavides Associate Professor 28 Department of Civil, Architectural & Environmental Engineering 29 Missouri University of Science and Technology 30 1401 N. Pine Street, 324 Butler-Carlton Hall, Rolla, MO 65409 31 Tel: 573-341-6947; Fax: 573-341-4729; Email: [email protected] 32 33 Gregory Sanders, P.E. 34 Structural Development and Support Engineer 35 Missouri Dept. of Transportation 36 Bridge Division 37 105 W. Capital Ave., Jefferson City, MO 65102 38 Tele: 573-526-0245; Fax: 573-526-5488; Email: [email protected] 39 40

Word count: 4,582 words text + 11 tables/figures x 250 words (each) = 7,162 words 41 42 43 Submission Date: November 14th, 2016 44

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

2

ABSTRACT 45 This paper presents the seismic behavior of two large-scale hollow-core fiber-reinforced 46 polymer-concrete-steel (HC-FCS) precast columns having two different footing connections. 47 The precast HC-FCS column consists of a concrete shell sandwiched between an outer fiber-48 reinforced polymer (FRP) tube and an inner steel tube. The column had an outer diameter of 49 24 inches while the steel tube had a diameter of 16 inch. The shear span-to-depth ratio of 50 both columns was 4.0. The steel tube was embedded into a reinforced concrete footing with 51 an embedded length of 1.6 times the steel tube diameter, while the outer FRP tube confined 52 the concrete shell only i.e. it was truncated at the top surface of the footing. One connection 53 included embedding the steel tube into the footing. The other one included using a corrugated 54 steel pipe (CSP) embedded into the concrete footing outside the steel tube to achieve a better 55 confinement into the footing. A high strength grout was poured between the CSP and the 56 column steel tube. This study showed that the connection included the CSP is deemed 57 satisfactory and was able to develop the plastic flexural capacity of the HC-FCS column 58 providing excellent ductility and energy dissipation. Contrary, the other HC-FCS column 59 displayed pullout rupture where the steel tube pulled out of the footing causing sever footing 60 rupture and pinching behavior. 61 62 Keyword: Column-Footing Connection, Precast Columns, Composite Columns, Fiber 63 Reinforced Polymer (FRP), Corrugated Steel Pipe, Seismic Loading, Hollow Core. 64 65 INTRODUCTION 66 The most common type of bridge column construction in the United States is cast-in-place 67 (CIP). However, CIP requires long on-site construction time, labor-intensive resources, and 68 long-term closure, which may result in traffic congestion [1]. Therefore, there is an urgent 69 need for developing rapid construction methods to address these challenges. Accelerating 70 bridge construction (ABC) reduces traffic disruptions and life-cycle costs and improves 71 construction quality and safety, resulting in more sustainable development [2]. One technique 72 to accelerate bridge construction is to use precast bridge columns. The use of precast 73 concrete bridge elements can reduce on-site construction time, field labor requirement, and 74 traffic impacts. Furthermore, several states are susceptible to earthquakes; hence, a developed 75 precast column needs to display excellent seismic performance. 76 77 A potential candidate to construct a precast column is to use the concrete-filled steel tube 78 (CFST), which consists of a hollow steel tube filled with concrete. Another candidate for a 79 precast column is the hollow-core steel-concrete-steel (HC-SCS) columns consisting of two 80 generally concentric steel tubes with concrete shell between them. The inner tube is empty, 81 i.e., unfilled with concrete to reduce the weight of the column. HC-SCS columns can also be 82 cast-in-place, with the outer and inner tubes acting as stay-in-place formwork. The concrete 83 infill is confined by both tubes, resulting in high concrete confinement and column ductility 84 [3]. 85 86 Recently, several researchers have used fiber reinforced polymer (FRP) tubes in lieu of the 87 outer steel tube in HC-SCS columns [4-6]. Hollow-core fiber reinforced polymer concrete 88 steel (HC-FCS) columns combine the three constituent materials (i.e., concrete, steel, and 89

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

3

FRP) in an optimal manner to achieve several advantages, including superior corrosion 90 resistance, excellent ductility, and lightweight [5]. 91 In high to moderate seismic regions, large ductility demands are imposed on bridge columns. 92 A column-footing connection is crucial for precast columns to provide the ductility 93 requirements and to improve its siesmic performance. The connection must be effective to 94 develop the ultimate strength of the column without significant slip, the connection needs to 95 be simple and economic to be used for (ABC). Different types of connections that were 96 propsed in the literature for CFST columns includes welded and bolted steel plate, embeded 97 base and rebars, and embeded structural steel connections were used for precast column-98 footing connections [7-10]. These solutions were either insufficient or slowed the 99 construction. 100 101 Simple socket connections were also developed in the past for CFST [11]. For cast-in-place 102 footing, a precast column is embedded into the footing; then, the footing is cast. In the case 103 of a precast footing, the concrete footing is cast first with a socket of a larger diameter than 104 the column’s diameter and the required embedment length; then, the column is inserted into 105 the socket, followed by grouting the gap between the column and sides of the socket. 106 Experimental investigations have revealed that socket connections of this type have three 107 distinct potential failure modes depending on the embedment length [12-14]. Pullout failure 108 occurs when the embedment length is not sufficient. Punching shear failure occurs with a 109 shallow footing depth below the CFST column. Otherwise, the connection may develop the 110 full strength and displacement capacity of the column with sufficient embedment length; 111 hence, the failure occurs in the column. 112 113 Abdelkarim et al. [15] investigated two columns, namely F4-24-E324 and F4-24-E344. 114 The columns’ label used in their experimental work consisted of three segments. The first 115 segment is a letter F, referring to flexural testing followed by the column’s height-to-outer 116 diameter ratio of 4. The second segment refers to the column’s outer diameter (Do) of 24 117 inches. The third segment refers to the GFRP matrix, using E for epoxy; this is followed by 118 the GFRP thickness in 1/8 inch, steel thickness in 1/8 inch, and concrete wall thickness in 119 inches. Each column had a socket connection with an embedment length of 25 inches 120 corresponding to 1.6 Di (where Di is the inner diameter of the steel tube). Two distinct modes 121 of failure occurred for the same steel tube diameter and embedment length depending on the 122 steel tube thickness. For column F4-24-E324 with a thin steel tube of 0.25 inch, the socket 123 connection was able to develop the full capacity of the column and the steel tube yielded with 124 no pinching in the hsyteretic curve (Fig. 1 (a)). The column’s footing did not suffer any 125 significant damage. For column F4-24-E344 [15] with a thick steel tube of 0.5 inch, the 126 socket connection was not able to develop the full capcity of the column and pullout failure 127 occurred with pinching was clealry observed in the hysteretic curves (Fig. 1 (b)). The 128 column’s footing suffered severe damage. The column removed and retested again during the 129 current investigation. 130 131

132

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

4

(a) (b) 133

FIGURE 1 Moment vs. lateral drift for column: (a) F4-24-E324 [15] , and (b) F4-24-134 E344 [15] 135 136 The main objectives of this study are (1) to investigate the performance of socket connection 137 having an embedded corrugated steel pipe (CSP) into the footing for precast columns; (2) to 138 investigate whether embedded corrugated steel pipe (CSP) into the footing will compensate 139 for the insufficient embedment length of the steel tube. 140 141 EXPERIMENTAL PROGRAM 142 In this study, the column F4-24-E344 originally tested by Abdelkarim et al. [15] was 143 inserted into a newly constructed footing including a CSP to form F4-24-E344-RS column 144 (Fig. 2) and was retested using the loading regime that was used by Abdelkarim et al.[15]. A 145 0.4-scale HC-FCS column, F4-24-E344-RS, having an embedment steel tube length of 25 146 inches corresponding to 1.6 Di was tested, under constant axial load and lateral cyclic load. 147 The F4-24-E344-RS column had a circular cross-section with an outer diameter of 24 inches 148 and a clear height of 80 inches. The lateral load was applied at a height of 95 inches with a 149 shear span-to-depth ratio of approximately 4.0. The column consisted of an outer filament-150 wound GFRP tube with a thickness of 0.375 inch and an inner steel tube having an outer 151 diameter of 16 inches and a thickness of 0.50 inch. A concrete shell having a thickness of 4 152 inches was used between the steel and FRP tubes. 153 154 To determine the diameter and depth of the embedded CSP, Abdelkarim et al. [15] carried 155 out FE study and following earlier work on CFST to derive equation (1) 156 157

3.3 , (1)

where Di is the steel tube outer diameter (inch), ts is the steel tube thickness (inch), Fu is the 158 ultimate stress of steel tube (psi), Do is the outer diameter of an annual ring welded with the 159 bottom of steel tube or the outer diameter of the corrugated steel pipe (inch), le is the 160 development length (inch), and , is the unconfined cylindrical compressive strength of 161 the concrete footing (psi). 162 163

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

5

The concrete footing that was used in this study had a length x width x depth of 60 inches x 164 48 inches x 34 inches with bottom reinforcements of 7#8, top reinforcements of 6#8, and 165 shear reinforcement of #4 bar at 2.5 inches which is similar to the footing used by 166 Abdelkarim et al. [15]. The steel cage of the footing was installed into the formwork. A 36-167 inch outer diameter (Dcsp) corrugated steel pipe (CSP) having a height of 25 inches and 168 thickness of 0.168 inch was placed inside the footing. The diameter of the CSP was 169 determined using equation (1). The CSP was embedded with its full height of 25 inches, i.e., 170 similar to the steel tube embedded length. Then, four small spots were cut atop of the CSP, 171 allowing the reinforcing rebars to sit on the top of the CSP. To this end, it would be possible 172 to cast the footing, insert the column, and pour grout in-between the 36-inch diameter CSP 173 and the 16-inch diameter inner steel tube of the column. However, this would require a 174 significant amount of grout. To avoid this large amount of grout, another 20-inch diameter 175 CSP was placed into the footing inside the main CSP before casting the footing (Fig. 2 (b)). 176 177 Once the CSPs were installed, the footing was cast including the space between the two CSP 178 (Fig. 2 (d)). After 24 hours, the temporary CSP was removed, leaving a corrugated concrete 179 surface (Fig. 2 (e)). For field implementation, both CSP would be kept in place. However, 180 during, the current work the inner CSP was removed as it was used for other projects. 181 Fourteen days after casting the footing, the column was erected with an embedment length of 182 25 inches, similar to what was used by Abdelkarim et al. [15]. The 2 inches left between the 183 corrugated concrete surface and the column inner steel tube surface was filled with high 184 strength flowable grout. One inlet pipe and two outlet pipes were used in order to ensure 185 filling all the space around the column inside the footing (Fig. 2 (e)). 186 187 Grout was placed using a 1.5-inch clear flex PVC pipe and funnel, located 10 ft high, above 188 the level of the footing top surface, using the gravity pipe method. The grout was 189 continuously placed through the funnel until it came out of the outlet pipes in order to ensure 190 complete filling of the gap between the column inner steel pipe and the surrounding concrete 191 surface. The final F4-24-E344-RS column layout is shown in (Fig. 2 (b)). 192 193 Material properties used GFRP tube had elastic modulus (ksi)=677, hoop elastic modulus 194 (ksi)=3,020, axial ultimate stress (psi)=12,150, hoop rupture stress (psi)=40,150. 195 The steel tube had yield stress (psi)=47,000, ultimate stress (psi)=70,000, and ultimate 196 strain=0.19. The steel rebars had yield stress (psi)=60,000, ultimate stress (psi)=90,000, and 197 ultimate strain=0.08. The rebar properties are based on the manufacturer’s data sheet while 198 the steel tube properties were determined through tensile steel-coupon testing according to 199 ASTM A 1067. Pea gravel with maximum aggregate size of 3/8 inch was used for concrete 200 mixtures. The unconfined concrete strengths ( ′ ) for F4-24-E344 [15] at 28 days and at the 201 day of test were 5,770 (psi) and 7,787 (psi) for the column, while 8,117 (psi) and 8,605 (psi) 202 were obtained for the footing at the same age, respectively. The unconfined concrete strength 203 for F4-24-E344-RS at 28 days and at the day of test were 7,973 (psi) and 8,152 (psi) for the 204 footing, while 9,280 (psi) and 9,650 (psi) was obtained for the high strength grout at the same 205 age, respectively. The effects of the footing concrete strength on the performance of the test 206 specimens will be discussed later in this manuscript. 207 208

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

6

209

(a) (b)

(c)

(d)

(e)

210 FIGURE 2 General arrangement of the column-footing connection for column F4-24-211 E344-RS: (a) without CSP, (b) construction sequence with CSP, (c) Column cross-212 section, (d) after pouring of the concrete footing, (e) after removing the temporary CSP 213 form 214 215

216

EXPERIMENTAL SETUP AND INSTRUMENTATION 217 Sixteen linear-variable-displacement-transducers (LVDT) and string potentiometers (SP) 218 were used to measure displacement along column F4-24-E324-RS (Fig. 3 (a)). Four LVDTs 219 were mounted on each of the north and south faces for the vertical displacement 220 measurements at the potential plastic hinge region. Two more LVDTs were used to measure 221 the uplift and sliding of the footing during the test. 222 223 Forty strain gauges were installed on the FRP tube at five levels with 5-inch spacing. Four 224 horizontal and four vertical strain gauges were installed at each level (Fig. 3 (b)). Fifty-six 225 strain gauges were installed inside the steel tube at seven levels with spacing of 5 inches 226

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

7

(Figs. 3 (c) and (d)). Four horizontal and four vertical strain gauges were installed at each 227 level. A high definition webcam was hung inside the steel tube vertically at 25 inches from 228 the top of the footing level to broadcast buckling of the steel tube and any internal damage 229 (Fig. 3 (d)). 230 231 232

(a) (b)

(c)

(d)

233 FIGURE 3 Instrumentation layout of the tested column F4-24-E344-RS (a) LVDTs 234 installation; (b) Strain gauges mounted on GFRP tube; (c) Strain gauges mounted on 235 Steel tube; and (d) Webcam inside the steel tube before erecting the column 236

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

8

LOADING PROTOCOL AND TEST SETUP 237 The axial load capacity Po of an equivalent RC-column with the same diameter (24 inches) 238 and 1% longitudinal reinforcement ratio was calculated using equation (2) [20] : 239

0.85 (2)

where = the cross-sectional area of the longitudinal steel reinforcements, = the cross 240 sectional area of the concrete column, = the yield stress of the longitudinal steel 241 reinforcement, and = the cylindrical concrete’s unconfined compressive stress. 242 243 Constant axial load, P, of 110 kips corresponding to 5% of the calculated Po was applied to 244 the column using three external prestressing strands on each west and east side of the column 245 (Fig. 4 (a)). The prestressing force was applied using two servo-controlled jacks to keep the 246 prestressing force constant during the test. The prestressing strands were supported by a rigid 247 steel beam atop the column and the column’s footing. After applying the axial load, static 248 cyclic lateral load was applied in a displacement control using two hydraulic actuators 249 connected to the column loading stub (Fig. 4 (a)). The loading regime is based on the 250 recommendations of FEMA 2007. Two cycles were performed for each displacement 251 amplitude. Fig. (4 (b)) shows the loading regime of the cyclic lateral displacement. 252 253 254

(a)

(b)

255 256 FIGURE 4 (a) Layout of the test setup; and (b) Lateral displacement loading regime 257 258 259

260

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

9

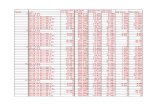

RESULTS AND DISCUSSIONS 261 The moment versus lateral drift plot is shown in Fig. 5. The lateral drift was calculated 262 by dividing the lateral displacement measured from the actuators displacement transducers 263 by the shear span of 95 inches. The moment (M) at the base of the column was obtained by 264 multiplying the force measured by the actuators’ loading cells by the column’s shear span. 265 Fig. 5 shows that the average moment capacity of the column was 965.8 kip.ft which 266 occurred at a lateral drift of 10.7%. Gradual stiffness degradation occurred beyond that until 267 the end of the test. At a lateral drift of 14.5%, the FRP ruptured at the south direction (Fig. 7). 268 Cycling continued toward the north direction untill a lateral drift of 15.1% when the test was 269 stopped because the actuator had reached its displacement capacity limit. Figure 6 shows 270 steel tube buckling captured through the camera inside the steel tube at different lateral drifts. 271 272 273

(a)

(b)

(c)

(d)

274 FIGURE 5 Moment vs. lateral drift (a) for column F4-24-E344-RS; (b) for columns F4-275 24-E344-RS and F4-24-E344 [15]; (c) Idealized elasto-plastic curve for column F4-24-276 E344-RS; and (d) Idealized elasto-plastic curve for column F4-24-E344 [15] 277

278 279 280

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

10

Fig. 5 (b) illustrates a comparison between the cyclic response of the two columns F4-24-281 E344-RS and F4-24-E344 [15]. As shown in the figure, using a CSP significantly improved 282 the performance of F4-24-E344-RS compared to F4-24-E344 [15]. Column F4-24-E344-RS 283 displayed 10% greater flexural strength and 20% greater lateral drift compared to column F4-284 24-E344 [15]. The existance of CSP controlled the diliation of the concrete in the footing, 285 and hence reduced concrete cracking delaying the pull-out of the column. The prevention of 286 the pull-out and slip resulted in fat hysteretic loops indicating high energy dissipation, which 287 is an essential characteristic for seismic applications. 288 289 The flexural strength of HC-FCS columns can be calculated used Bernoulli–Navier’s 290 assumptions assuming elasto-plastic model for the steel and linear elastic model for the FRP. 291 The confinement model developed by [16] was used for concrete shell in the column. Using 292 this approach the strengths of the columns were calculated as 1,050 (kip.ft) for columns F4-293 24-E344 [15] and F4-24-E344-RS, respectively. Hence, as shown in Fig. (5 (b)), the model 294 underestimated the flexural strength by 17% and 10.7% for columns F4-24-E344 [15] and 295 F4-24-E344-RS, respectively. The underestimation is much higher for column F4-24-E344 296 [15] due to the early slippage that took place early during testing. This underprediction 297 observed to be less for column F4-24-E344 equal to 10.7% due to the existance of the CSP 298 which reduced the slip of the steel tube out of the footing and thereby higher flexural 299 capacity was achieved. 300 301 Figs. (5 (c) and (d)) shows the backbone curves of the two columns. Also, shown on the figures 302 are the idealized elasto-plastic curves [17]. The idealized curves were used to calculate the 303 displacement ductility of the columns. As shown in the figure, the columns reached 304 displacement ductility values of 6.80 and 7.20 for columns F4-24-E344 [15] and F4-24-E344-305 RS, respectively. Both values exceed the maximum anticipated displacement ductility demand 306 of 5 imposed by AASHTO Guide Specifications for LRFD Seismic Bridge Design on single 307 bridge column bent [18]. It also exceeds the minimum requirments displacement ductility of 3 308 imposed by caltrans [17]. 309 310 Several small cracks occurred in the footing during the test. Figure 8 shows a comparison 311 between column F4-24-E344-RS and column F4-24-E344 [15]. The footing of column F4-312 24-E344-RS displayed cracks having widths ranging from 0.006 to 0.008 inch which is 313 within the ACI 224R-01 limits for a structure in contact with soil. However, the footing of 314 column F4-24-E344 [15] suffered severe damage due to pullout indicating that the existence 315 of the CSP precluded pullout failure, crack propagation, and footing damage. 316

317

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

11

(a) (b) 318 FIGURE 6 Local buckling of the steel tube of the column F4-24-E344-RS at lateral 319 drifts of: (a) 11.3%, and (b)14% 320

321 Fig. 9 illustrates the cumulative energy dissipation-lateral drift relation for the columns F4-322 24-E344 [15] and F4-24-E344-RS. The energy dissipation at each lateral drift was 323 determined as the area enclosed in the hysteretic loop of the first cycle at this drift level. 324 Dissipating greater hysteretic energy increase the ability of a structure to sustain higher 325 magnitude earthquakes. As shown in the figure, both columns had almost the same energy 326 dissipation until lateral drift of approximately 5%. Beyond this drift, column F4-24-E344 327 [15] displayed severe pinching and limited energy dissipation due to the steel tube pullout. At 328 a drift of 11.6% when the column F4-24-E344 [15] failed, column F4-24-E344-RS dissipated 329 64% greater energy. Furthermore, column F4-24-E344-RS was able to continue carrying the 330 lateral load until a drift of 14.5%. At failure, column F4-24-E344-RS dissipated 270% greater 331 energy than column F4-24-E344 [15], indicating better seismic performance. 332 333 334

335 FIGURE 7 FRP rupture of the column F4-24-E344-RS at a lateral drift of 14.5% 336

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

12

337

(a) (b) 338

FIGURE 8 (a) minor cracks in the footing of column F4-24-E344-RS at lateral drift 339 14.5%, and (b) severe damage in the footing of column F4-24-E344 [15] at lateral drift 340 11.6% 341 342 343

344 FIGURE 9 Cumulative energy dissipation vs. lateral drift for columns F4-24-E344-RS 345 and F4-24 E344 [15] 346 347 348 349 350

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

13

THE EFFECTS OF ′ OF THE FOOTING ON THE PERFORMANCE OF THE HC-351 FCS COLUMNS 352 353 3D finite element models were developed using LS-DYNA software to address the effects of 354 footing concrete strength on the performance of the investigated connection. The 3D-FE 355 models (Fig. 10) were validated versus the CFST column with corrugated pipe into the 356 footing [19]. 357 358 As shown in Fig. 11(a), footings having concrete strength ranged from 3 ksi to 8 ksi were 359 investigated. Fig.11 (b) showed the slip of the steel tube inside the footing with different 360 concrete strength. F4-24-E344-RS column with ′ equal to 3,000 psi psi exhibited concrete 361 footing damage and thereby less moment and displacement capacity (Fig. 11 (a)). The high 362 slippage started at drift of approximately 5.5%; then, it significantly increased by a drift of 363 approximately 10% reaching about 0.65 inches at approximately 12% drift. For specimens 364 having f’c of 4,000 psi or higher, the concrete strength had limited effect on strength or 365 deformation capacity indicating that the CSP was effective in triggering the steel tube plastic 366 strength rather than pullout failure. Increasing the f’c from 3,000 psi to 8,000 psi increased 367 the column strength by 13.5% and the displacement by 41.5%. 368 369 370 371 372 373 374 375 376 377 378 379 380 381 382 383 384

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

14

(a) (b)

(c) (d) 385 FIGURE 10 FE modeling of F4-24-E344-RS column: (a) 3D view, (b) the column, (c) 386 concrete footing with grout, and (d) corrugated steel pipe (CSP) 387 388 389

(a) (b) 390 FIGURE 11 (a) Moment vs. lateral drift for F4-24-E344-RS column with different f’c 391 values, and (b) Slip vs. lateral drift for F4-24-E344-RS column with different f’c values 392

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

15

CONCLUSION 393 This paper presents the experimental results of hollow-core fiber reinforced polymer concrete 394 steel (HC-FCS) precast columns. Each column was subjected to constant axial load and 395 lateral cyclic load. The steel tube of each column was embedded into a reinforced concrete 396 footing with an embedded length of 1.6 times the steel tube diameter, while the FRP tube was 397 truncated at the top surface of the footing face, i.e., the FRP tube confined the concrete shell 398 only. While both columns had the same embedment length, one column had corrugated steel 399 pipe (CSP) inserted into the footing to improve the pullout perfromance of the column while 400 the other column did not. 401 402 The column with CSP did not suffer visual damage while the other one displayed signifcant 403 footing damage due to pullout failure. Furthermore, using the CSP was able to triger the 404 plastic capacity of the column and ruture was due to FRP rupture. The flexural beam theory 405 was able to underpredict the flexural strengths of the test specimens by 17% and 10.7% for 406 columns F4-24-E344 [15] and F4-24-E344-RS, respectively. 407

408 ACKNOWLEDGEMENT 409 Missouri University of Science and Technology conducted this research with funding 410 provided by Missouri Department of Transportation (MoDOT). Gratefully, contribution from 411 ATLAS Tube is appreciated. Discounts on FRP tubes from Grace Composites and FRP 412 Bridge Drain Pipe are also appreciated. However, any opinions, findings, conclusions, and 413 recommendations presented in this paper are those of the authors and do not necessarily 414 reflect the views of the sponsors. 415 416 417 418 419 420 421 422 423 424 425 426 427 428 429 430 431 432 433 434 435 436

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

16

REFERENCES 437 438 1. Tran, H.V., Drilled shaft socket connections for precast columns in seismic regions. 439

2015, University of Washington. 440 2. Dawood, H., M. Elgawady, and J. Hewes, Factors affecting the seismic behavior of 441

segmental precast bridge columns. Frontiers of Structural and Civil Engineering, 442 2014. 8(4): p. 388-398. 443

3. Anumolu, S., O.I. Abdelkarim, and M.A. ElGawady, Behavior of Hollow-Core Steel-444 Concrete-Steel Columns Subjected to Torsion Loading. Journal of Bridge 445 Engineering, 2016: p. 04016070. 446

4. Abdelkarim, O.I. and M.A. ElGawady, Analytical and finite-element modeling of 447 FRP-concrete-steel double-skin tubular columns. Journal of Bridge Engineering, 448 2014. 20(8): p. B4014005. 449

5. Abdelkarim, O.I. and M.A. ElGawady, Behavior of hollow FRP–concrete–steel 450 columns under static cyclic axial compressive loading. Engineering Structures, 2016. 451 123: p. 77-88. 452

6. Teng, J. and L. Lam, Behavior and modeling of fiber reinforced polymer-confined 453 concrete. Journal of structural engineering, 2004. 130(11): p. 1713-1723. 454

7. Grauvilardell, J.E., et al., Synthesis of Design, Testing, and Analysis Research on 455 Steel Column Base Plate Connections in High-seismic Zones. 2005. 456

8. Hitaka, T., K. Suita, and M. Kato. CFT Column base design and practice in Japan. in 457 Proceedings of the International Workshop on Steel and Concrete Composite 458 Construction. 2003. Citeseer. 459

9. Marson, J. and M. Bruneau, Cyclic testing of concrete-filled circular steel bridge 460 piers having encased fixed-based detail. Journal of Bridge Engineering, 2004. 9(1): p. 461 14-23. 462

10. Morino, S., et al., Strength and stiffness of CFT semi-embedded type column base. 463 Proceedings of ASSCCA, 2003. 464

11. Roeder, C.W. and D.E. Lehman. An economical and efficient foundation connection 465 for concrete filled steel tube piers and columns. in International conference on 466 composite construction in steel and concrete. 2008. 467

12. Kingsley, A., Experimental and analytical investigation of embedded column base 468 connections for concrete filled high strength steel tubes, in Univ. of Washington. 469 2005, Univ. of Washington: Seattle, WA. 470

13. Lee, J.R., Experimental Investigation of Embedded Connections for Concrete-filled 471 Steel Tube Columns Subjected to Combined Axial-flexural Loading. 2011, University 472 of Washington. 473

14. Williams, T.S., Experimental investigation of high strength concrete filled steel tubes 474 in embedded column base foundation connections. 2006. 475

15. Abdelkarim, O.I., et al., Seismic Performance of Innovative Hollow-Core FRP–476 Concrete–Steel Bridge Columns. Journal of Bridge Engineering, 2016: p. 04016120. 477

16. Yu, T., et al., Flexural behavior of hybrid FRP-concrete-steel double-skin tubular 478 members. Journal of Composites for Construction, 2006. 10(5): p. 443-452. 479

17. Caltrans, S., Caltrans seismic design criteria, v. 1.7. 2013, April. 480

Abdulazeez, Gheni, Abdelkarim, ElGawady, and Sanders

17

18. Imbsen, R.A., AASHTO guide specifications for LRFD seismic bridge design. 481 American Association of State Highway & Transport Officials, Subcommittee for 482 seismic effects on bridges, 2007. 483

19. Lehman, D.E. and C.W. Roeder, Foundation connections for circular concrete-filled 484 tubes. Journal of Constructional Steel Research, 2012. 78: p. 212-225. 485

20. AASHTO. AASHTO-LRFD Bridge Design Specifications – Customary US Units, 486 sixth edition, Washington, DC, 2012 487