Effect of thermo-chemical parameters on the adhesion of scale layer Technical University of...

-

Upload

andrew-bryant -

Category

Documents

-

view

217 -

download

1

Transcript of Effect of thermo-chemical parameters on the adhesion of scale layer Technical University of...

Effect of thermo-chemical parameters on the adhesion of scale layer

Technical University of Czestochowa, The Department of Industrial Furnaces and

Environmental Protection

EDYTA WARWAS

Introduction

In the process of heating steel before plastic working the processes of chemical interaction also occur between the furnace atmosphere and the surface of the steel being heated. Scale forms as a result of oxidation. An important issue in the operation of heating furnaces is the adhesion of a scale layer to the surface of the steel being heated. The adherence of scale depends on heating technologies, such as temperature and excess combustion air ratio.

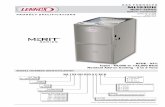

Measuring stand and testing methodology a laboratory

furnace

processing of results

a gluing stand

a stand for detaching reference

specimens

a stand for partial

knocking off scale

photographing

cleaning

weighting

weighting

photo processing

photo analysis

Fig. 1. Schematic diagram of testing stands

Measuring stand and testing methodology

Specimens “cooled down” to ambient temperature were subjected to adherence tests. In this case, the examined quantity was the tensile force which allows the scale to be detached from the steel core by reference specimens glued to the face walls of specimens tested.

The method applied to the testing of scale adhesion to the cold charge is a quantitative method allowing the numerical determination of the force that bounds the scale with the steel core. The value of force needed for detaching the scale layer from the steel surface was measured by using a testing machine.

Measuring stand and testing methodology

Fig. 2. Schematic diagram of the system for testing scale adhesion for “cooled down” specimens

Qr

Qr

a glue layer

cooling

Results of adhesion measurements

Measurements, for cold specimens, were performed by measuring the force needed for detaching the scale layer and then by calculating the adherence expressed in MPa. It should be noted that the direct adhesion measurements were preceded by cooling the specimens down to ambient temperature, followed by joining the formed scale with reference specimens using a glue of an appropriate tensile strength. The measurements were varied out with the value of combustion air excess ratio of =0.61.4.

Results of adhesion measurementsTable 1

Results of scale adhesion measurements

value of combustion air excess ratio α

temperature [˚C]

1000 1100 1200 1300 1330

scale adhesion [MPa]

0,6 0,430 0,784 1,126 2,664 3,478

0,7 0,361 0,528 0,986 2,444 3,156

0,8 0,215 0,361 0,833 1,674 2,139

0,9 0,187 0,324 0,632 0,967 1,425

1,0 0,158 0,272 0,521 0,778 1,032

1,1 0,134 0,228 0,320 0,518 0,724

1,2 0,111 0,167 0,278 0,472 0,527

1,3 0 0,027 0,062 0,127 0,158

1,4 0 0 0 0 0

Effect of thermochemical parameters

on the adhesion The mathematical analysis of testing results was reduced to deriving relationships describing the effect of heating parameters on the adherence of scale to the steel substrate. Several computer simulations were performed to approximate mathematical functions that could describe that effect. The general equation describing the effect of thermochemical parameters on scale adherence has been reduced to the following form:

T

DexpαAP C

Effect of thermochemical parameters on the adhesion

The analysis of the effect of thermochemical parameters on scale adherence has been performed and suitable relationships have been derived. Due to a different behaviour of the function P=f() for 1.0 and >1.0, these relationships will take on different forms. The following forms of Equation (1) have been obtained: for 1.0 for >1.0

T

11646expα1507P 1,9-

z

T

12013expα1764P 5,1-

z

Effect of thermochemical parameters on the adhesion

0

0,5

1

1,5

2

2,5

3

3,5

4

0,6 0,7 0,8 0,9 1 1,1 1,2 1,3 1,4

Ppom-1000 Pobl-1000-nied Pobl-1000-nad

Ppom-1100 Pobl-1100-nied Pobl-1100-nad

Ppom-1200 Pobl-1200-nied Pobl-1200-nad

Ppom-1300 Pobl-1300-nied Pobl-1300-nad

Ppom-1330 Pobl-1330-nied Pobl-1330-nad

1000˚C

1100˚C

1200˚C

1300˚C

1330˚C

1000˚C

1100˚C

1200˚C

1300˚C

1330˚C

1000˚C

1100˚C

1200˚C

1300˚C

1330˚C

measurements calculationsα1.0 α>1.0

The value of combustion air excess ratio, α

Fig. 3. Relationship of adherence vs. thermochemical parameters for measurements and calculations

Scale adhesion, Pz [MPa]

Conclusions

The performed theoretical analysis and the laboratory tests carried out allow the following conclusions to be drawn:

1.Heating parameters have an essential effect on the adhesion of scale to the steel substrate.

2.Scale adhesion increases with increasing heating temperature.

3.Scale adhesion decrease with increasing value of combustion air excess ratio.

Conclusions

4.The correlation between heating parameters (temperature and the value of combustion air excess ratio) can be described by mathematical relationships; however, a different behaviour of these relationships for 1.0 and for >1.0 should be taken into account.

5.The performed investigation of the effect of heating parameters on the adherence of scale can form guidelines for the technology of heating steel stock before plastic working.