EEWeb Pulse - Issue 85

-

Upload

eeweb-magazines -

Category

Documents

-

view

240 -

download

2

description

Transcript of EEWeb Pulse - Issue 85

1Visit www.eeweb.com

EEWeb PULSE INTERVIEW

EEWebIssue 85

February 12, 2013

Electrical Engineering Community eeweb.com

EngineeringBetter Biology

TECHNICAL ARTICLE

Think M2M isJust AnotherBuzzword?

TECHNICAL ARTICLE

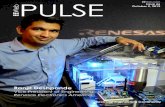

President and CEOLantronix

Kurt Busch

EEWeb PULSE TABLE OF CONTENTS

3Visit www.eeweb.com

Kurt Busch Lantronix

Interview with Kurt Busch - CEO

How Arduino’s easy-to-use hardware is being used to rethink biological tools like thermocyclers for DNA and chemical analysis.

RTZ - Return to Zero Comic

Featured Products

4

11

18

24

Engineering Better Biology

Product Overview: RIGOL DP-1116A

26

How machine to machine technology, much like the Internet of Things, allows the billions of devices available worldwide to be tailored to our individual needs.

12Think M2M Is Just Another Buzzword?By Dave Wagstaff with Lantronix

Programmable Power Supply

By aLex toombs

4

EEWeb PULSE INTERVIEW

EEWeb | Electrical Engineering Community

KurtBuschLantronix

5Visit www.eeweb.com

EEWeb PULSE INTERVIEW

KurtBuschLantronix

6

EEWeb PULSE INTERVIEW

EEWeb | Electrical Engineering Community

How did you get involved in engineering?

We always talk about whether engineers are made or born. I look back to when I was a young child—I loved to build things with whatever materials were available: wood, cardboard boxes, Legos. What really drew me into engineering was a time in high school when I read some books by Carl Sagan, and I began to see technology and science as something that was actually in reach at the time and not just science fiction like in Star Trek. I had the opportunity in 1990 to do an internship at Standard Microsystems, which is now SNC. That internship was testing local area network cards. It was in 1990 when I first connected two computers together. I learned how the usefulness of computers can increase dramatically when you connect them together. A single computer was viewed as a fairly powerful thing, so once you made a network of computers, you really saw how their usefulness increased exponentially. We see that today with the Internet. It’s a funny thing—I graduated with a degree in electrical computer engineering at a time when I didn’t even own a network computer. Today, I’d say everybody five and onwards is connected to a network computer in one way or another.

From that testing job at Microsystems, I went on to be a design engineer designing Ethernet and token ring cards. My most memorable experience was when I designed my first Ethernet card and got to visit the factory where the Ethernet cards were coming off the production line every five seconds. I looked at that and had this tremendous sinking feeling in my stomach—somewhat of a panic attack—hoping I didn’t

screw anything up. Fortunately, it did work out okay.

After several years as a designer, I moved to Silicon Valley and took a position as a field applications engineer (FAE) for Digital Equipment Corporation. An FAE is an engineer that works very closely with customers to get them into production. This was in the late 90s in Silicon Valley, which was a pretty special time. Engineering and technology permeated every aspect of life in Silicon Valley—you stood in line at the movie theater with people who were talking about a new OS in front of you, or a new ASIC behind you. It really put me in the heart of engineering during that time. I went from an being FAE into a strategic marketing role at DEC, which I continued while my division was bought by Intel. That position was all about combining engineering skills with some business skills that I picked up by talking with customers. That’s been a lot of my focus—taking the skills I learned as an engineer and applying them with my business skills through a business MBA program to address the needs in the marketplace. You typically get your best return when you fulfill your underserved need or a need that is not served at all today.

I went from Intel to a couple start-ups. One went well—we actually took the company public – but the other one ended up shutting down. Given the choice, taking the company public is much more fun than shutting one down, which took place after the dot com bubble bust in the early 2000s.

After that, I moved on to Analog Devices, and to a very different view of the communications problem. Previously to this, it was all based around digital system design, but

with Analog Devices, it was all about how a piece of silicon can interact with a physical environment. These problems were really hard, and what I learned was that in solving difficult problems, you could get a superior return. That’s why if you look at the analog companies like

“We’re allowing those devices to connect to the network and get an increased amount of productivity whereby putting a device on the network, you get the same kind of increase in productivity that you get by putting the computer on the network.”

Analog Devices and Maxim, they all have high margins and make a lot of money. I think that one of our former presidents had a good saying: “We do these things not because they are easy, we do them because they are hard.” Solving hard engineering problems often produces much superior results and superior yields for the company. Of course, you have to solve some real business problems as well, but it has been a

7Visit www.eeweb.com

EEWeb PULSE INTERVIEW good way for engineers to turn their skills into a successful business for their companies.

Prior to joining Lantronix, I had moved from Analog Devices to Mindspeed, where I was general manager and senior vice president

a similar problem—in this case core networking—in two different areas, you can yield a superior return because you are leveraging your engineering resources across multiple markets. That’s something we did very well at Mindspeed.

I joined Lantronix approximately a year ago and was able to put in place all of the experience I had over the last 20 years being a designer, as well as in sales and marketing, and general management.

Could you give us a brief overview of Lantronix as a company?

Lantronix was founded in 1989. We’re headquartered in Irvine, California and the company has been public for a little over 20 years now. The company has approximately 20% in what we call “Device Management Products,” which can also been seen as IP or information technology management products. This is where the company got started and these are devices that allow remote management of equipment in data centers and some print servers that allow you to print to items like network printers. The other 80% of our revenue is what we call “Device Enablement,” and you can see this as machine-to-machine communications. Device Enablement is all about enabling a machine to connect to the network, which is where we see a lot of the largest growth opportunities for the company. So we are enabling these machines across multiple vertical markets—anything from, say, an energy meter to a solar panel, a windmill, glucose meter, or respirator. All of these are in the M2M space. We’re allowing those devices to connect to the network and get an increased amount of productivity, whereby putting a

device on the network, you get the same kind of increase in productivity that you get by putting the computer on the network. This is one of the biggest opportunities in the space today. The first Internet wave was really people, and we believe the second Internet wave is going to be these machines. As more and more of these machines get connected to the network, we can see more usefulness, just as we saw with computers being connected to the network.

What are some of the challenges you face as the president and Ceo of Lantronix?

I think anytime a company has a turnaround story, there are a number of issues you have to address relatively quickly. If I look back and talk about the turnaround for Lantronix, when I came to the company, we had a number of challenges; we didn’t have enough cash on hand to grow the company in the way that we were expecting to. We had a morale issue because of the turnaround of the management team. For the most part, the entire management team was replaced. If I look at the eight key managers in the company, seven of the eight are brand new to their positions—everyone from the head of HR, the corporate council, the head of marketing, the head of product management, the head of worldwide sales, the CFO – pretty much all of the senior managers in the company are new to their positions. Yet all of them are very experienced, with 20 to 30 years of experience in their field, so I was very lucky to be able to hire them in a relatively short period of time.

Key to the turnaround story was that the head of engineering, who had

“We’re allowing those devices to connect to the network and get an increased amount of productivity whereby putting a device on the network, you get the same kind of increase in productivity that you get by putting the computer on the network.”

of their analog business unit. Again, that was all about solving hard problems in the communications space. My team was a group of very experienced analog designers and we solved very difficult, high-speed serial communications issues used in core networking—basically the core of the Internet as well as broadcast video, which has very similar problems. It’s a good lesson that if you can solve

8

EEWeb PULSE INTERVIEW

EEWeb | Electrical Engineering Community

been with company for 12 years, stayed with the company. Our whole strategy was about developing new products at a relatively good rhythm that enable machines to connect to the Internet or connect to the network and become more useful. We also wanted to solve problems that have not been solved or have been underserved today. Basically, the engineering team during the entire turnaround process has stayed intact, and I really have to hand it to our president of engineering, who has done a great job of keeping that team in place. Over the last nine months, that team has released seven new products, which I believe is a record for the company. The execution from that team has been nothing other than phenomenal. To do that, we had to put in place a very disciplined product development process, which is something I learned from my time at Intel and Analog Devices, where you look at the features and feasibility and can really hammer out all of the details of the program and set the expectations of the entire team. That allows the team to execute the details very true to the expectations.

In order to raise the capital needed to grow the company, we needed to have a very successful product somewhat early on in the game. During my first week with Lantronix, I did a very in-depth inventory of all the technology we had at the company, and gave some thought as to what kind of product that the technology could fit into. We needed an early win to give confidence to the investors, confidence to the employees and confidence to the industry. I got my team together and had a very interesting discussion as I asked them what the coolest machine out there was in the M2M space. The response from the

“In order to raise the capital needed to grow the company, we needed to have a very successful product somewhat early on in the game.”

9Visit www.eeweb.com

EEWeb PULSE INTERVIEW team overwhelmed me—it was the iPad, and I agreed with them. From there, I asked what the iPad doesn’t do. The response I got back was that it doesn’t print, and I said, “Exactly.” So from there, I said we were going to revise the Lantronix print servers, which is where the company got its start 20 years ago, with a print server for iOS devices to allow iPhones, iPads and iPods to connect to any printer and other devices in the network to increase their usefulness. We kicked off that project, and by leveraging the technology inside the company and the hardware platforms with an entirely new software platform, we were able to come up with the XPrintServer product, which is—at least in recent history—the most successful product launch Lantronix has had, and we did it in record time. We announced it after four months, and within six to eight months we had added significant revenue and received quite a few awards—everything from an ABA award to Best in Show at MacWorld. That early success resolved the morale issues within the company, showing that you can execute something well and see very early successes with that. I think that’s really a testament to how well the team executed. It also allowed us to go to the investment community and show them that we had an early win, which, in turn, allowed us to raise money. We actually raised an additional 9.5 million dollars to strengthen our balance sheet and give us the working capital we needed to execute all of our growth plans.

What are some of the other types of products you’ve been working on?

We put a strategy in place relatively early, which was to take advantage

of the trends of the M2M market by leveraging the existing platforms within the company to both expand our market share as well as get into some new markets. When I walked in the door, there were some very good platforms in the company—some low-end platforms and some mid-range platforms. I saw these hardware platforms and saw a way that we could leverage them to get into some new markets. One of these products—on the high end—is a product called the PremierWaveXC that allows cellular connectivity for machines. Again, this is a very nice, secure and easy-to-use connectivity solution for machines that may not have connection to Wi-Fi. We think that’s a good growth opportunity for us.

One of the exciting new products that will allow us to expand into new markets is called xSenso. It is based on our PremierWave platform that allows you to put physical stimuli onto the network. Before, we were looking at digital interfaces and now, with the xSenso product, I can put on, say a temperature sensor or any kind of physical stimuli, and connect sensors to the network and monitor everything from temperature, to pressure, humidity, distance, and vibration.

What kind of challenges do you foresee in the industry?

In the M2M space, the biggest challenge is that there are a huge number of machines, but can’t be connected to the network. It’s been said in our industry that there are approximately 8 billion people today and 2/3 of those people are connected to the Internet in one way or another. There are 50 billion connectable machines and less than 1% of those are connected to the Internet. I believe that was

first said by the CEO of Ericsson. That statistic shows that there’s a lot of opportunity for us, but today, most of the machine-to-machine communication involves a project. We have to move from it being a project to solving the hard engineering issues with companies such as Lantronix. We need to provide solutions to the companies and solutions to the machines that can truly make it easy to connect. I look back to my beginnings, when I connected my computer to another computer over the network, which was a relatively specialized skill. It took hours of training and lots of hands-on experience and some natural abilities. But today, my 5 year-old can connect to the Internet by picking up the iPad and touching it in a few different places. We have to achieve the same thing in the machine-to-machine space that the rest of the Internet has achieved today.

What are some of your hobbies outside of work?

Being the CEO of a turnaround company is almost an all-consuming job, but I have three children ages 5, 8, and 9 and try to spend all of my outside time with my kids doing things like cub scouts and father-daughter camping trips. In addition, I’m a rather avid cross-fitter, which has been a very good outlet for all of the activities that we are doing at work.

For more information about Lantronix, visit their website at:

www.lantronix.com

Optocouplers are the only isolation devices that meet or exceed the IEC 60747-5-5 International Safety Standard for insulation and isolation. Stringent evaluation tests show Avago’s optocouplers deliver outstanding performance on essential safety and deliver exceptional High Voltage protection for your equipment. Alternative isolation technologies such as ADI’s magnetic or TI’s capacitive isolators do not deliver anywhere near the high voltage insulation protection or noise isolation capabilities that optocouplers deliver.

For more details on this subject, read our white paper at: www.avagoresponsecenter.com/672

Take the Risk out of High Voltage Failure with Certifi ed Avago Optocouplers

Technology You Can Trust

IEC 60747-5-5 Certifi ed

FEATURED PRODUCTS

11Visit www.eeweb.com

Lowest ohmic value Chip resistorVishay Intertechnology, Inc. announced that it has extended its MCW 0406 AT Precision series of wide terminal thin film chip resistors with ohmic values down to 1 Ω, the industry’s lowest for such a device in the compact 0406 package. The resistors combine their low ohmic values with precision tolerance of ± 0.1 % and precision TCR of ± 25 ppm/K. Vishay’s MCW 0406 AT Precision resistors feature high-temperature performance to + 155 °C and high power dissipation of 250 mW at an ambient temperature of 70 °C. Samples of the enhanced resistors are available now. For more information, please click here.

High Performance spectrum analyzersAgilent Technologies Inc. announced the availability of real-time spectrum analysis (RTSA) for its PXA X-Series signal analyzers. Agilent’s RTSA delivers unmatched probability of intercept (POI), analysis bandwidth, sensitivity, and frequency range-capabilities that make it the best way for system developers and signal analysts to see, capture and understand highly elusive signals. In applications such as radar, electronic warfare and military communications, POI is the key benchmark for RTSA. When configured for real-time spectrum analysis, the PXA can detect intermittent signals with durations as short as 3.57 µs, which is the best POI currently available. For more information, please click here.

Digital Controller for solid state LightingNext week at Strategies in Light, the premier conference and exhibition for solid-state lighting (SSL), emerging fabless company, Ikon Semiconductor, will debut its digital controller IC technology for the dimmable LED retrofit market. The new technology is designed to meet cost and performance standards for today’s LED lighting products, while also enabling greater design simplicity for bulb manufacturers and OEMs. Central to the IC’s value is an innovative digital architecture that eliminates costly components – a benefit that reduces the form factor and improves reliability. For more information, please click here.

IC Validator Provides 28nm Hot-Spot VerificationSynopsys, Inc. announced that United Microelectronics Corporation (UMC) has selected Synopsys’ IC Validator physical verification product for lithography hot-spot checking at the 28-nm process node. UMC standardized on IC Validator pattern matching, a patented technology enabling ultra-fast detection of manufacturing-limiting layouts, which can dramatically accelerate final design signoff. As part of Synopsys’ Galaxy™ Implementation Platform, IC Validator is an ideal add-on to Synopsys’ IC Compiler™ solution for In-Design physical verification, enabling place-and-route engineers to accelerate time to tapeout by preventing late-stage surprises and minimizing manual fixes. IC Validator pattern matching extends the In-Design flow with automatic repair of lithography violations, further optimizing design turnaround time. For more information, please click here.

Optocouplers are the only isolation devices that meet or exceed the IEC 60747-5-5 International Safety Standard for insulation and isolation. Stringent evaluation tests show Avago’s optocouplers deliver outstanding performance on essential safety and deliver exceptional High Voltage protection for your equipment. Alternative isolation technologies such as ADI’s magnetic or TI’s capacitive isolators do not deliver anywhere near the high voltage insulation protection or noise isolation capabilities that optocouplers deliver.

For more details on this subject, read our white paper at: www.avagoresponsecenter.com/672

Take the Risk out of High Voltage Failure with Certifi ed Avago Optocouplers

Technology You Can Trust

IEC 60747-5-5 Certifi ed

EEWeb PULSE TECH ARTICLE

12 EEWeb | Electrical Engineering Community

Dave WagstaffChief Solutions Architect, Lantronix

Think

Can anyone say“SoLoMoBYODM2M”

M2MIs Just Another Buzzword?

Two years ago, buzzwords and phrases such as ‘M2M’ (machine-to-machine) and ‘Internet of Things’ had got-ten increased attention thanks to predominate media

coverage from the likes of The New York Times and Read Write Web, and vocal support from large companies, includ-ing Verizon, AT&T and Cisco.

The concept is not new, it’s simply reached primetime. The “Machine” in M2M and the “Things” in the Internet of Things are the billions of devices that are currently deployed in hospi-tals, factories, power generation plants, businesses, stores, ve-hicles and others worldwide. And the more we leverage tech-nology to become more social, more local, and more tailored to our individual needs, the more exciting M2M becomes.

Chief Architect, Advanced Solutions, Lantronix

EEWeb PULSE TECH ARTICLE

13Visit www.eeweb.com

Dave WagstaffChief Solutions Architect, Lantronix

Think

Can anyone say“SoLoMoBYODM2M”

M2MIs Just Another Buzzword?

EEWeb PULSE TECH ARTICLE

14 EEWeb | Electrical Engineering Community

What’s really driving M2M today?

Is it technology? Of course. After all, you ARE reading EEWeb! Without some of the major break-throughs in the past few years, M2M would still be a pipe dream. There are several reasons why M2M is getting so much play. Global wireless networks are becoming faster by the day. Device components and modules are available at record-low prices. Security is more bullet-proof than ever. Carriers (wireless operators such as Verizon and AT&T) are finally on board and recognize the po-tential – and larger, more established players are jumping into the ecosystem. But perhaps the big-gest reason behind the excitement in M2M is the BYOD phenomenon (or, as IT managers refer to it, the “BYOD Nightmare!”). Who’s to thank? Let’s at least start with Apple, Facebook and Google.

KEY DRIVER of GLOBAL M2M ADOPTION:

SoLoMo + BYOD

Ridiculous? Maybe. But the high-tech arena has never fallen short on absurd acronyms. In this case, it actually makes sense:

1. So. As in “Social.” (Think Facebook, LinkedIn and YouTube)

2. Lo. As in “Local.” (Think Google and lo-calized search and services)

3. Mo. As in “Mobile.” (Think smart phones, tablets and notebooks)

4. BYOD. As in “Bring your own device.” (Think iPad)

The rapid adoption of mobile devices, especially tablets such as the iPad, has piggy-backed on and accelerated the use and consumption of social me-dia. Users of all ages, geography and user-type (business or personal) leverage their devices to access and tailor custom content to their local and more immediate needs, in a format and manner,

and on a device that best suits their personality and desires. This obsession with information has cre-ated havoc for IT professionals in the near-term – but like all disruptive technologies, it will drive the most exciting changes in the longer-term. And that change is in the form of true M2M.

Let’s Talk Numbers

The numbers are staggering, regardless of source. Berg Insight reports the total number of M2M wire-less (device) connections will soar to 359.3 million in 2016. Additionally, research shows shipments of cellular M2M devices increased 35.3 percent in 2011 to a record level of 50.8 million units. Ad-justed for churn, this resulted in net additions of 29.3 million M2M connections in 2011, taking the worldwide number of cellular M2M subscribers alone to an estimated 108.0 million. Ericsson has repeatedly cited a number of “50 billion devices in market, ready to be connected.”

Network connectivity itself is being expanded with new technologies such as IEEE 802.11n, ensuring

“This obsession with information has created havoc for IT professionals in the near-term – but like all disruptive technologies, it will drive the most exciting changes in the lon-ger-term. And that change is in the form of true M2M.”

EEWeb PULSE TECH ARTICLE

15Visit www.eeweb.com

data safety with improved security protocols and improved business models enabled by lowering the cost of network access. This synergistic effect is now playing a key role in allowing devices to be connected to the Internet, to truly reap the rewards of M2M communications.

But the sheer volume of potential devices for con-nectivity isn’t the exciting part. Nor is the adding of ‘intelligence’ to these devices so they can be remotely managed and controlled. Most exciting, and important, is the end-result – the customer and end-user benefits derived from the secure trans-mission of vital information across networks for col-lection, analysis and decision-making.

While it’s exciting to think about all the ‘futuris-tic’ M2M applications for consumers-at-large, the business opportunity for M2M is equally stagger-ing. For example, hospitals can now network-con-nect infusion pumps, which send information back to the hospital IT system, with pharmaceutical in-formation validating the correct dosage levels for a particular patient. Consider industrial applica-

tions, where a technician can check on the status of a robotic welding machine no matter where in the world the equipment is located.

At Lantronix, we’ve spent the last 20 years mak-ing M2M a reality. We’ve worked with cities to im-prove traffic flow (which saves time and improves safety), we’ve worked with government contractors to use M2M to remove humans from dangerous flight missions—and every day, we’re working on concepts to make the average person’s life just that much easier. But there is so much more information that if “mined” or “harvested” could fundamentally change the way companies and individuals con-duct business. This is the basic promise of M2M – getting the right information to the right people at

“This obsession with information has created havoc for IT professionals in the near-term – but like all disruptive technologies, it will drive the most exciting changes in the lon-ger-term. And that change is in the form of true M2M.”

EEWeb PULSE TECH ARTICLE

16 EEWeb | Electrical Engineering Community

NXP’s proven interface products enable medical and health system designers

to add features with minimal modifications. Within our portfolio you’ll find LCD

displays and capacitive touch interfaces, system connectivity bridges & UARTs, LED

controllers, real-time clocks, and I2C-bus peripherals & enablers.

To learn more, visit http://www.nxp.com/campaigns/medical-interfaces/2248

Breathe new life into medical product interfaces

EEWeb PULSE TECH ARTICLE

17Visit www.eeweb.comwww.partsim.com

Online CircuitSimulator

PartSim includes a full SPICE simulation engine, web-based schematic capture tool, and a graphical waveform viewer.

Some Features include:• Simulate in a standard Web Browser

• AC/DC and Transient Simulations

• Schematic Editor• Schematic Editor

• WaveForm Viewer

• Easily Share Simulations

Try-it Now!

EEWeb PULSE TECH ARTICLE

18 EEWeb | Electrical Engineering Community

Engineering

Biology

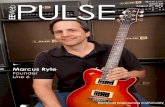

Alex ToombsElectrical Engineering Student

BetterAs electrical engineering knowledge and tools become more widespread, new innovations

have come about in fields that were seemingly untouchable due to their high barrier of entrance before. Components have gotten cheaper, designs are being released as open source, and knowledge about microcontrollers has disseminated in a way that anyone with an internet connection can pick up a dev board and start to create something very powerful. One of the tools that has recently become available is the Arduino open source microcontroller, popular with hobbyists both beginner and advanced. The Arduino’s easy-to-use hardware and software has made it simple for designers to create complex devices without previous knowledge of programming or hardware development. With these advancements, people have begun rethinking biological tools as well—specifically, thermocyclers for polymerous chain reaction, gel electrophoresis for DNA analysis, and chemical analysis.

EEWeb PULSE TECH ARTICLE

19Visit www.eeweb.com

Engineering

Biology

Alex ToombsElectrical Engineering Student

Better

EEWeb PULSE TECH ARTICLE

20 EEWeb | Electrical Engineering Community

Polymerous chain reaction, or PCR, is the process of replicating DNA using simple mixes of DNA samples, primers matching base pair sequences found on the DNA to be replicated, polymerase enzymes, and a few other chemicals. By following specific heating and cooling cycles, DNA is first denatured, then bound to primers during the annealing phase, then extended by the DNA polymerase enzyme. As a result, with each full cycle, the amount of that specific DNA sequence is doubled. The doubling process results in 2n total copies of DNA—where n is the number of cycles run; it is a relatively simple process.

The process might be simple, but the thermocyclers used to perform PCR in labs are cumbersome, high-current, and expensive machines, costing between $10,000 and $20,000 for the better computer-controlled systems. The great costs and equipment required means that, traditionally, only large institutions have been able to afford the capability to replicate DNA using PCR. The simple process is made complex by the equipment required to carry out the replications.

However, better electrical engineering tools, such as the Arduino series of open source microcontrollers, have brought down the cost considerably. One instance of a much cheaper PCR being built is the Open PCR (http://openpcr.org/) project, which provides a kit to build a 16-well thermocycler for under $600. The entire design, from hardware up to the software used, is open sourced via a GPL license—so that you can replicate or improve upon the design without even purchasing the kit from them. The box is smaller sized, but still powered from a Walmart, and calls for using a desktop computer power supply unit to provide enough current for the resistive heating and fan cooling systems. Additionally, a laptop or other computer is required for USB-based communication, which allows you to program the device and receive feedback on how the PCR cycle is going. The system monitors the temperature set points and cycle numbers. The picture in Figure 1 is a typical PCR recipe on display in the OpenPCR software, courtesy of the OpenPCR website.

The real engineering that goes into these thermocyclers is managing the heat that is required. As shown in Figure 1, denaturing the proteins requires uniform temperatures of around 100 degrees Celsius, while other stages require much lower temperatures. In order to ensure that the DNA is kept at each temperature for the proper time, digital sensors that monitor the temperature of the aluminum heating block must constantly poll and reply to the microcontroller. If the heating element is too

hot, the water-based solution in the vials may begin to boil, causing significant problems for the process. The OpenPCR also ensures that heating is kept uniform with a locking lid also covered with an aluminum block. As the cycle is run, the heating elements also heat and cool the lid.

Other groups than Open PCR have made forays into improving thermocycler technology, much by the same thought process. Working from plans originally produced as a side project by Templeman Automations, founder Chris Templeman and the Notre Dame PCR Team (https://github.com/ND-HowardGroup/pcr), under Dr. Scott Howard, set about creating an open source, low cost, and portable thermocycler for the Notre Dame Biology Department. The team, consisting of several undergraduate and graduate students across both the computer science and electrical engineering departments, created a platform for DNA replication costing less than $200 overall.

Running off an Arduino Uno, a development board from the Arduino family powered by an Atmega32 AVR

Figure 1: Typical OpenPCR Recipe (Courtesy of OpenPCR)

microprocessor, the device made by the Notre Dame PCR Team sources current to several high-wattage resistors, designed to transfer heat to the machined aluminum block. Using digital temperature sensors similar to those in the OpenPCR, the temperature of the block is closely monitored. A proportional integral

EEWeb PULSE TECH ARTICLE

21Visit www.eeweb.com

derivative (PID) controller is included in the program to maintain a flat amount of current flowing through the resistor, achieved with feedback provided by the same temperature sensors. A PID controller operates by measuring the present error, integral accumulation of past errors, and the estimated future error, presenting an interesting control solution to solve the problematic temperature management of the device. When the thermocycler cools down to another temperature step, a small computer fan is turned on, uniformly cooling the aluminum block.

take an hour or longer to replicate the DNA, adequate replication can be achieved with these cheaper devices.

Beyond the academic applications, cheaper and portable thermocyclers open up a wealth of possibilities. For instance, fruit farmers in western Africa often export their crops to Western Europe. A mango farmer in Mali might ship crops to Spain that, when they arrive at the port, are found to be contaminated with a parasite that was invisible to the naked eye before shipment. Then, the farmer is on the hook for both the shipping costs and the costs of the destruction of the fruit, while also losing the potential sales. Using a PCR mix designed to replicate only the DNA common to parasites of that crop would allow a small sample to be run prior to shipment. Those samples found to be contaminated after analyzing the resultant DNA would be held back, while the rest could be shipped. Beyond that, the US Fish and Wildlife service has expressed interest in developing better technology for the detection and tracking of invasive species, such as Asian carp, in the Great Lakes region and other parts of the country.

Better engineering has lowered the barrier of entry for those looking to replicate DNA, providing similar results to the devices used in academic settings for a fraction of the cost. The open source aspects of the involved projects mean that over time, the devices produced will only become better, with input from many on the best way to move forward. ■

Figure 2: First iteration of Howard Group PCR (courtesy of Aamir Ahmed Khan of the Howard Group)

A simple board designed in KiCad, an open source board layout tool, brings together all of the elements and connects to the user interface. In lieu of a laptop or tablet controller, the ND PCR thermocycler is operated using a 12-digit keypad and 16×2 character serial LCD display, which allows for selection of several hardcoded recipes, easily customizable to whichever application the device is to be used for by modifying the fields in the openly available source code. The LCD displays the number of seconds the program has run, the cycle number, the temperature set point, and the current temperature of the first temperature sensor. The ND PCR’s first functional prototype may be seen in Figure 2, courtesy of the Howard Research Group Google site.

Technology improvements like these hold promise for research, instructional, and practical applications. The idea behind the ND PCR was that the biologists did not often want to wait weeks to test a sample while they were in the field tracking the behavior of specific fruit flies. As a result, the device can be powered by a battery half the size of a car battery, which is easily charged with a commercially-available and inexpensive solar cell. Amongst the many applications of the OpenPCR is the idea that high schools and colleges with limited funds will be able to use the device as a teaching tool. As there is no substitute for experience and the device functions much in the same way as a commercial, benchtop PCR would, it can prepare many for eventually using the same equipment in a professional setting. The results offered by both thermocyclers shows that while it may

BeStar®

ACOUSTICS & SENSORS

Teamwork • Technology • Invention • Listen • Hear

PRODUCTSSpeakers

Buzzers

Piezo Elements

Back-up Alarms

Horns

Sirens/Bells

Beacons

Microphones

Sensors

INDUSTRIESAutomotive

Durables

Medical

Industrial

Mobile

Fire / Safety

Security

Consumer

Leisure

QS9000 • TS/ ISO16949 • ISO14001 • ISO13485 • ISO9001

bestartech.com | [email protected] | 520.439.9204

Preferred acoustic componentsupplier to OEMs worldwide

Electric

al Engine

ering C

ommunity

EEWeb ARTICLES

JOBS

COMMUNITY

DEVELOPMENT TOOLS

Dave BaarmanDirector Of

Advanced Technologies

Making WirelessTruly Wireless:

Need For UniversalWireless Power

Solution

"Sed ut perspiciatis unde omnis

iste natus error sit voluptatem

accusantium doloremque

laudantium, totam rem aperiam,

eaque ipsa quae ab illo inventore

veritatis et quasi architecto beatae vitae

dicta sunt explicabo. Nemo enim ipsam

voluptatem quia voluptas sit aspernatur aut odit

aut fugit, sed quia consequuntur magni dolores eos

qui ratione voluptatem sequi nesciunt. Neque porro

quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur,

adipisci velit, sed quia non numquam eius modi tempora incidunt ut

labore et dolore magnam aliquam quaerat voluptatem. Ut enim ad

minima veniam, quis nostrum exercitationem ullam corporis suscipit

laboriosam, nisi ut aliquid ex ea commodi consequatur? Quis autem

www.eeweb.comJOIN TODAY

Transform Your iPhone, iPad or iPod into an Oscilloscope

with the iMSO-104

Experience the iMSO-104 as Joe Wolin, co-founder of EEWeb,

gives you an in-depth look into the future of oscilloscopes.

2012

UBM ELECTRONICSUBM ELECTRONICS

WINNER

Begin Your Experience NowBegin Your Experience Now

EEWeb PULSE PRODUCT REVIEW

24 EEWeb | Electrical Engineering Community

Overview of theOverview of the

eewebt e c h L a b

Chris AndersonEMC EngineerLab Manager

RIGOL DP-116AProgrammablePower Supply

RIGOL DP-116AProgrammablePower Supply

EEWeb PULSE PRODUCT REVIEW

25Visit www.eeweb.com

Display Screen & InterfaceWith the DP1116A, Rigol did a fresh take on the user interface. The first thing you might notice when you pull the power supply out of the box, is that, rather than using and alphanumeric screen, Rigol used an LCD screen. That lets them put a lot more information on the screen. You always have all of your parameters displayed. You can see your voltage, your current, and you can actually see your power, as well — all of your current values. You can also see what you’ve set your voltage and current too, as well as your over-voltage and over-current.

The background of the display is colored red for the high voltage, and blue for the low voltage range. That’s nice, because now, from across the room, you can see what range you’re in.

Rather than using a knob to dial in your voltages, Rigol has included a keypad, in the upper right hand of the instrument. If you want to set the instrument to 5V, simply press “5” and the “V”(volt) key, which is on the set of controls to the left of the keypad.

You’ll notice that the keypad — the controls at the top right of the display screen — serves multiple purposes. If you want to insert voltages in a way that is similar to using a dial, you can simply click the “up” and “down” keys to change to volts. This keypad is also convenient because if you want to switch from the default — perhaps from 5 volts, depending on how the different instrument is set up — to, let’s say, 500 mv, — rather than dialing down, you can simply input “500mv,” and there you’ll have it set.

Another interesting feature to the DP1116A is the alternate display which they employ, using dials instead of numbers. This might not be something you’ll personally use, but it is neat.

Wave DisplayOne thing about the DP1116A that you may not have seen another power supply is the “wave display,” which is located on the bottom right menu on the front of the power display. What this does is show you somewhat of a history of the voltages that have been programmed and used. If you put on your output to .5V, and then go ahead and increase that to 20 V, you will see it jump on the display. This lets you see a sort of time-based variation in your voltage current and power.

Built-In Timer FeatureAnother feature that Rigol has included with the

DP1116A is what they call the timer function, which is also located on the menu on the bottom right hand side of the power supply. If you bring up the timer function for the first time, it will kick you over to the utility function to set it up. If, for instance, you set it for 5V and 1Amp, and wanted it to set there for 5 seconds, but then want to switch it to 10V, 1Amp, and sit there for 5 seconds, the timer feature allows you do all of that.

You can also loop on these settings multiple times, or even infinitely, if you would like. Rigol calls that a circle function, which you can set using the grey softkeys below the display screen, and the two key pads at the top of the power supply. Say you set it for 3V, if you want it to loop infinitely, you would select “Infinity” using the grey softkey, and then start the function by pressing the “Timer” button (it will warn you that it might change your output, depending on what it is now), and press “okay.” You’ll see that it begins countdown on the first setting, and will move on to the second setting. You can also see this in the wave display. After pressing the “Wave Disp” button, you will see where it went from 0V, to 5V, to 10V, and then back to 5V and back to 10V. It will keep doing that, which you can also view on the main display.

ConclusionThe Rigol DP1116A is easy to use — it has all the parameters on screen at the same time, and a unique timer feature.

To watch this review and others from EEWeb Tech Lab:

Click Here