EEWeb Pulse - Issue 82

description

Transcript of EEWeb Pulse - Issue 82

EEWeb PULSE TABLE OF CONTENTS

3Visit www.eeweb.com

Neeraj Pendse ELO TOUCH SOLUTIONS

Interview with Neeraj Pendse - Senior Manager, Product Management

Why the once-futuristic touchscreen interface is becoming an essential edition to any new generation of devices.

RTZ - Return to Zero Comic

Featured Products

BY ELO TOUCH SOLUTIONS

4

11

12

28

The Evolution of Touch

30

Product Overview: Rigol DM-3068 DigitalMultimeter

How Infineon’s Dave™3 app helps programmers insert application-oriented software compo-nents into their project as well as configure and connect those components.

20Apps-based Programming Approach SpeedsXMC4000 DevelopmentBY GEORG HUBA WITH INFINEON

4

EEWeb PULSE INTERVIEW

EEWeb | Electrical Engineering Community

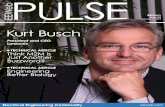

NeerajPendse

Elo TouchSolutions

5Visit www.eeweb.com

EEWeb PULSE INTERVIEW

NeerajPendse

Elo TouchSolutions

6

EEWeb PULSE INTERVIEW

EEWeb | Electrical Engineering Community

Can you tell us about your work experience before your role as Global Product Line Manager at Elo Touch Solutions?

My first professional role was to design high speed interconnects for semiconductor chips – but then I took a turn into the business world. I came to Elo Touch Solutions in 2010 from A.T. Kearney, a strategy consulting firm. As a strategy consultant I spent three years on the road working on a broad variety of projects. One was to restructure a California food processing plant facing closure to make it profitable. Another involved the restructure of the Finance function at a very large insurance conglomerate. In a third project, I developed a go-to-market strategy for a Japanese consumer electronics manufacturer who was experiencing lackluster growth in the U.S. At Elo, the role of a Product Manager is to act as a “mini-GM,” which requires an understanding of all sides of the business. So, my strategy work at A.T. Kearney has really helped me to meet the expectations of our business.

Could you give us a quick overview of Elo Touch Solutions?

Elo Touch Solutions is a privately held company. We have around 400 employees. The company was founded in the early 1970s out of the Oak Ridge National Laboratories, where the founders came up with the idea of being able to touch a screen. This was part of some other work they were doing—such as digitizing information—and this was an offshoot of that. This inventive moment led us to be one of the true pioneers of touchscreens on displays. Since the early 70s, and for about 40 years since then, nobody really cared about touchscreens.

Then, suddenly, a lot of people took interest.

So what was Elo Touch Solutions doing in those 40 years? Well, Elo touchscreens have been in commercial applications for a very long time. Most notably, our touchscreens have been in point-of-sale terminals at your grocery stores, check-in kiosks, ATMs, and gift registries. We’ve had significant technology inventions during our 40-year history that have established our value proposition and our leadership in the touchscreen space.

Where are you located?We are presently headquartered in

Menlo Park, California. In the spring of 2013, we are going to move to a new headquarters in Milpitas, California, which is about 15 or 20 miles down the freeway from here.

When it comes to products, do you just have products that you sell, or do you sell technology for other display manufacturers?

The answer is “yes” on both counts. If we step back a bit and talk about the company itself, we have four product lines. Three of the product lines are system products, which include touchscreens and touchcomputers. The third product in the systems category is interactive digital signage. This is the product

“We’ve had significant technology inventions during our 40-year history that have established our value proposition and our leadership in the touchscreen space.”

7Visit www.eeweb.com

EEWeb PULSE INTERVIEW

that I’m responsible for, and is our fastest growing technology.

Fourth, we have a component business, which basically sells licensing, but also sells things like a piece of glass with components on it that an original equipment manufacturer could take and place on a display. That display could be part of a control panel, a gaming system or a machine on a manufacturing line somewhere.

Depending on the product, we offer components outside the display as well. For example, in the interactive digital signage world, all of our displays offer an optional integrated computing module, which enables a computer to slide in and mate with

the display. It essentially becomes an accessory to the display. This requires us to do system design as well. We also offer built in remote management features to allow customers to go online and turn their display off because store number XXY called and said that something’s happening and they want to re-set. We have built these kinds of remote interfaces, and we are enhancing them.

We are also working on additional types of interactivity. In the near future, we’ll be launching an NFC/RFID-based interactive display, so that users will not only have touch, but also a proximity tag reader. That way, users can interact with

our products in more ways than just touch.

Could you tell us a little more about the touch technology that you use?

Our interactive digital signage market focus has been on large format devices, which means that projected capacitive, which is the predominant technology for small consumer smart phone devices, may not be suitable because of cost. For example, if I have a 70-inch screen, it’ll cost thousands of dollars to make a projected capacitive touchscreen.

One of the things that we always communicate to our customers (as

8

EEWeb PULSE INTERVIEW

EEWeb | Electrical Engineering Community

a value proposition) is the number of touch technologies we offer in our products. A lot of these are technologies that we have invented. In our large screen interactive digital signage, we use our surface acoustic wave (SAW) technology, which is very reliable and also a key Elo invention. When we sell this technology as just a piece of glass or a component plate (when there is no display attached to it), we warranty the screen for a decade. That length of time is somewhat of an unheard of warranty in any kind of electronics today. It suggests that our surface

How does the surface acoustic wave technology work?

It’s actually very interesting. There is a very low-energy ultrasonic wave that is on the outside surface of the glass. We’ve placed that wave using a piezoelectric excitation device, and when you touch the screen, you absolve the ultrasonic energy slightly. Any soft object that comes in contact with the glass will absolve the energy, and on the other side of the glass, we have vectors that detect this absolvetion. Because of this, you end up with is a very

product that just keeps working and working.

Do you have interactive digital signage products that you sell to people that are only interested in buying three or four?

Given that the interactive digital signage product line is only two years old, I think we’ve garnered quite a bit of credibility in a short amount of time. We have products out in the market that you can buy in any quantity through our channel

acoustic wave technology is a very reliable technology that is suitable for large formats.

In even larger technologies, such as 70 inches and beyond, we are finding that optical touch is very interesting. Optical touch technology involves a camera that is mounted on the four corners of the screen. The cameras look in a plane parallel to the surface of the glass and can see a finger coming. Because there are four cameras, they can capture a lot of movement and we are offering the optical touch technology on our products as well.

reliable touch surface. It has no coatings or copper tracks (or any kind of conducting material) on it, so it is very cost-effective compared to capacitive technology. The reason why it is so reliable is that there is nothing to erode when you touch it.

The surface acoustic wave technology has really been the dominant technology of the commercial touch world. We took this technology and applied it to digital signage and are finding that customers really like it because there are very few components and it’s just an extremely reliable

partners. These are products that are Elo branded and are fully functional displays, so what you get in the box is a commercial-grade display that is integrated with a touchscreen and also with a slide-in computer module that you buy separately. If you wanted to obtain and display an interactive poster in a public environment like a hotel lobby or college campus, it would basically be ready to go, from the hardware end of it. We only recently introduced this innovative fully functional display and it’s already taken off in the market.

“One of the things that we always communicate to our customers (as a value proposition) is the number of touch technologies we offer in our products. A lot of these are technologies that we have invented.”

9Visit www.eeweb.com

EEWeb PULSE INTERVIEW Could you tell us a little more about the webcam implemented in this technology?

The webcam is in the display because when you think about any kind of public application for a touchscreen, it’s showing some sort of general public interest message or marketing sales promotion. Somebody at headquarters is driving all of those messages, and they really want to know the impact of their messages. Today, there are huge business models already in place to figure out how many people are watching particular shows on TV. Marketers really want to know the impact of their promotions. There are technologies available now that can do that visually, which is an important reason why we developed the webcam. It’s not very different from a typical camera that you can buy, but it’s something we made for our displays that matches our display designs. The camera is able to look at how many people are in its view, how many people are actually looking at the screen, and how many people walk by without noticing, so it will give you that ratio.

It’ll also tell you basic demographic information. The technology to do this is available from Intel, so we work with them to get them to qualify our camera. You can download an application from Intel.com today that can give you these statistics.

What challenges do you foresee for Elo Touch Solutions?

If you look at the retail stores today, there are some categories of retail that are generating more sales from online stores, like books. However, there are some categories that are going to stay offline. Consumer companies have been doing research on which categories will end up being bought online in the future and which categories will stay in the store. So how do you bridge the gap to deliver both a consistent online and offline brand experience? Can I go to the display in a store and get suggestions and take them back home with me? A lot of people have created solutions that will bridge the gaps, but they’re all proprietary solutions. There isn’t an industry standard like Bluetooth in this realm. Imagine watching TV,

seeing an ad that is interesting and saying to you, “I should remember that next time I go to the store.” So with this in mind, the next time you go to the store, you ask yourself what the ad was that interested you, and somehow you have to connect all these things and I think that’s a very interesting technological challenge in the future. Touch-enabled mobility could be the real glue in this challenge.

For more information about Elo Touch Solutions, visit their website at:

www.elotouch.com

Optocouplers are the only isolation devices that meet or exceed the IEC 60747-5-5 International Safety Standard for insulation and isolation. Stringent evaluation tests show Avago’s optocouplers deliver outstanding performance on essential safety and deliver exceptional High Voltage protection for your equipment. Alternative isolation technologies such as ADI’s magnetic or TI’s capacitive isolators do not deliver anywhere near the high voltage insulation protection or noise isolation capabilities that optocouplers deliver.

For more details on this subject, read our white paper at: www.avagoresponsecenter.com/672

Avago Technologies Optocouplers

A Superior Technologyfor High Voltage Protection!

Technology You Can Trust

IEC 60747-5-5 Certifi ed

FEATURED PRODUCTS

11Visit www.eeweb.com

120MHz MCUs for Ethernet & Dual-CAN ConnectivityAtmel Corporation announced it has expanded its ARM® Cortex™-M4 based Flash family to include the SAM4E series, which features advanced connectivity peripherals, a floating point unit (FPU), advanced analog capabilities, and higher processing power. Atmel SAM4E ARM Cortex-M4 processor-based MCUs offer more processing power with a maximum operating frequency of 120MHz, a FPU and an integrated cache providing zero wait state flash access at full speed. The high performance and high-system integration of the SAM4E addresses the growing application requirements for high-speed wired and wireless communications. For more information, please click here.

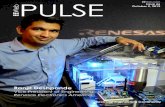

MCU Series for Hybrid and Electric VehiclesRenesas Electronics Corporation is highlighting the V850E2/PJ4-E, which incorporates an on-chip resolver sensor interface. This MCU realizes high performance and low system cost for automotive control systems including motor control for HEV/EV and other automotive applications. The MCU is a derivative of Renesas’ P-series of MCUs and belongs to the 32-bit V850™ RISC MCU Family. It incorporates Renesas’ V850E2 CPU core, which provides excellent real-time operation, and is equipped with a rich set of peripheral functions for motor control. For more information, please click here.

Industrial Fieldbus Multicore MCUsXMOS announces a range of solutions tailored specifically for designers of embedded industrial products with the launch of new industrial Fieldbus capabilities within its xCORE family of multicore microcontrollers. The company is initially introducing Fieldbus xSOFTip soft peripherals and an industrial serial bus (IS-BUS) I/O card (sliceCARD) for its modular sliceKIT development system, enabling communication via RS485, CAN and LIN. Further industrial products will follow throughout 2013. xCORE processors are ideally suited for use in industrial applications because they combine flexible and time-sensitive communications capabilities with the ability to implement latency-critical control functions. For more information, please click here.

4-Channel Multi-Rate TransceiverThe TLK10034 is a quad-channel multi-rate transceiver intended for use in high-speed bi-directional point-to-point data transmission systems. This device supports three primary modes. It can be used as a XAUI to 10GBASE-KR transceiver, as a general-purpose 8b/10b multi-rate 4:1, 2:1, or 1:1 serializer/deserializer, or can be used in 1G-KX mode. While operating in the 10GBASE-KR mode, the TLK10034 performs serialization of the 8B/10B encoded XAUI data stream presented on its low speed (LS) side data inputs. The serialized 8B/10B encoded data is presented on the high speed (HS) side outputs in 64B/66B encoding format. Likewise, the TLK10034 performs deserialization of 64B/66B encoded data streams presented on its high speed side data inputs. For more information, please click here.

Optocouplers are the only isolation devices that meet or exceed the IEC 60747-5-5 International Safety Standard for insulation and isolation. Stringent evaluation tests show Avago’s optocouplers deliver outstanding performance on essential safety and deliver exceptional High Voltage protection for your equipment. Alternative isolation technologies such as ADI’s magnetic or TI’s capacitive isolators do not deliver anywhere near the high voltage insulation protection or noise isolation capabilities that optocouplers deliver.

For more details on this subject, read our white paper at: www.avagoresponsecenter.com/672

Avago Technologies Optocouplers

A Superior Technologyfor High Voltage Protection!

Technology You Can Trust

IEC 60747-5-5 Certifi ed

EEWeb PULSE PROJECT

12 EEWeb | Electrical Engineering Community

Elo Touch Solutions

The

of TouchEvolution

EEWeb PULSE PROJECT

13Visit www.eeweb.com

Elo Touch Solutions

The

of TouchEvolution

Many years ago, touchscreens were an exotic, expensive interface for demanding applications like air-traffic and nuclear power-plant control. Not anymore! The introduc-tion of touchscreen-enabled devices such as the iPhone and iPad mobile digital devices has changed expecta-tions of how people interact with electronics and ma-chines. Now, companies across a broad spectrum of in-dustries have successfully harnessed the power of touch for a wide variety of applications. Yet the essential benefits provided by touch technology remain unchanged.

EEWeb PULSE PROJECT

14 EEWeb | Electrical Engineering Community

While one of the earliest touch sensors was docu-mented in 1971—almost 40 years ago—by Elo-graphics*, the demand for touch-enabled appli-cations has grown significantly in recent years. Market analysts estimate double-digit market growth over the next several years in all types of applications offering display and user-input func-tionality. These applications will require displays that will range in size from very small screens, such as those on a phone, to very large screens, such as those used in interactive digital signage. Touch displays will also be incorporated into low-cost, high-volume consumer products as well as highly-reliable commercial systems similar to those already in use in retail, industrial, casino, automotive, medical and other industries.

Innovation

Many touch technologies have been developed and each one offers differentiated benefits based on size, performance, cost, application and envi-ronmental requirements of the market. Surface acoustic wave (SAW), bending wave acoustic, resistive, projected capacitive, surface capacitive and infrared touchscreen technologies have been widely accepted by the market. Having several options to choose from allows device designers to optimize the touch experience for where, how and by whom the device will be used. In essence, there is no perfect touchscreen technology for all applications across all devices and for all users and advances are continually being made to ex-isting technologies as well as new innovations to take the functionality one step further. For ex-ample, projected capacitive (pcap) solutions are widely accepted in portable consumer electron-ics due to high-touch sensitivity, accuracy and multi-touch interactivity. But, one of the key chal-lenges of pcap technology is that the cost rises exponentially for larger sizes due to the dual-layer substrate and indium tin oxide (ITO) coating. To address this, development efforts are underway for single-layer ITO projected capacitive solu-tions that seek to achieve cost advantages versus performance, size scalability and yield improve-ment within the manufacturing process.

EEWeb PULSE PROJECT

15Visit www.eeweb.com

Why limit the touch interface to a flat surface? Making a 3-D surface—any surface, including non-glass or film material such as composite metal or wood—a touch interface in a low-power and low-cost environment has been a dream of scientists and engineers for many years. Product platforms utilizing bending wave acoustic pulse recognition technology have demonstrated solid materials with many surface shapes to work as multi-touch interfaces. Because of its passive touch interface, this technology offers one of the lowest levels of power consumption in the indus-try. It also offers an excellent cost structure due to a lower bill of material. In short, it may open up a new door of innovation and flexibility for 3D design.

Fast, Faster, Fastest

Touchscreens provide fast access to any and all types of digital media, with no text-bound inter-face getting in the way. It takes time for the user to grab a mouse or use a keyboard or trackball and coordinate it with what needs to be activated on the display. Faster input leads to a higher level of customer service in restaurants, hotels, movie the-aters, and retail stores, which results in increased customer loyalty, not to mention the advantages of customer self-service. In other cases, such as in-vehicle control or security equipment, being even one second faster can make all the difference.

Touch Makes Everyone an Expert

Reaching out for what you want is an instinctive gesture. Using touch is just as simple: you sim-ply point at what you want. Although some peo-ple may still shy away from computer keyboards, mice, or trackballs, there is no hesitation when they can just touch a screen. Users feel comfort-able that they cannot “do anything wrong”; they instinctively understand how to use the interface. Touchscreen systems make everyone an “expert user” from the first touch-whether it’s a person consulting a self-service kiosk, a worker control-

ling an industrial process, a nurse entering a pa-tient’s information, or a waiter entering an order.

Reduced Costs

Using a touch interface can effectively increase operator accuracy, reduce training time, and im-prove overall operational efficiencies, ultimately resulting in lower costs. In the retail environment, for example, a properly designed touch interface can improve each operator’s accuracy, while maintaining optimum checkout speeds. Users can respond quickly without making significant errors. Also, touch-based point-of-sale (POS) sys-tems streamline the returns and refunds process by reducing the time it takes a customer to return merchandise; such systems also improve loss-prevention management. In addition, compared to traditional training methods, using touch-screens can drastically reduce training time, since touch technology is intuitive and requires no special skills to learn. Moreover, the flexibility of touch technology can significantly contribute to cost reductions: it creates operational efficiencies by simplifying procedures and reduces the need for additional capital investment.

Compact and Handy

Space is valuable, so it needs to be used as ef-ficiently as possible. Touchmonitors prevent wasted space by completely incorporating the input device into the display. In addition, all-in-one touchcomputer systems help save even more space by integrating the computer itself into the display. There are no keyboards or cords to get tangled or damaged, to gather dust or in public venues, to become inadvertently discon-nected.

EEWeb PULSE PROJECT

16 EEWeb | Electrical Engineering Community

Durable and Easy to Clean

Many touchscreens are made of glass or a similar hard-coated surface, which can be easy to clean and therefore well-suited for the typical environments found in restau-rants, hospitals, and the food and pharmaceutical indus-tries. Many touchscreens can be used with gloves, which is great for applications where hygiene is particularly important or where temperature or workplace safety re-quires the use of gloves. Touchscreen systems that are not affected by dirt, dust, grease, or liquid droplets are also available.

Ease of Use

Touchscreen-based systems can virtually eliminate errors because users select from clearly defined menus. The in-formation on each screen may be limited in number and options, thus providing step-by-step, fail-safe sequences to guide the user through complex procedures. This great-ly simplifies applications where voluminous databases must be accessed quickly and easily. Touchscreen-based systems are useful for self-service applications where ad-ditional staff is unavailable or cost prohibitive, and allow for after-hours business through external kiosks or store windows that themselves can be made into touchscreens. Process-control applications involving many buttons or switches and applications where system contents require protection from unauthorized entry are also simplified when touchscreens are used.

Summary

For all the advantages a touchscreen interface can deliver, there are still requirements that need to be considered to successfully implement a particular touch technology. There are strengths and weaknesses of each touchscreen technology that can determine which is the best for the particular device and software application -- cost and func-tionality are two primary considerations. Also, software de-sign may be critical. If the software is well-designed, then the touch commands are intuitive and touch can simplify the system cost and complexity by eliminating keyboards and mice. And, thanks to smart phones and tablets, vast numbers of consumers now expect to use touch to control any device they encounter in public or in a commercial environment, so virtually any audience, anywhere, regard-less of education or training can have access to and use electronics.

EEWeb PULSE PROJECT

17Visit www.eeweb.comwww.partsim.com

Online CircuitSimulator

PartSim includes a full SPICE simulation engine, web-based schematic capture tool, and a graphical waveform viewer.

Some Features include:• Simulate in a standard Web Browser

• AC/DC and Transient Simulations

• Schematic Editor• Schematic Editor

• WaveForm Viewer

• Easily Share Simulations

Try-it Now!

Electric

al Engine

ering C

ommunity

EEWeb ARTICLES

JOBS

COMMUNITY

DEVELOPMENT TOOLS

Dave BaarmanDirector Of

Advanced Technologies

Making WirelessTruly Wireless:

Need For UniversalWireless Power

Solution

"Sed ut perspiciatis unde omnis

iste natus error sit voluptatem

accusantium doloremque

laudantium, totam rem aperiam,

eaque ipsa quae ab illo inventore

veritatis et quasi architecto beatae vitae

dicta sunt explicabo. Nemo enim ipsam

voluptatem quia voluptas sit aspernatur aut odit

aut fugit, sed quia consequuntur magni dolores eos

qui ratione voluptatem sequi nesciunt. Neque porro

quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur,

adipisci velit, sed quia non numquam eius modi tempora incidunt ut

labore et dolore magnam aliquam quaerat voluptatem. Ut enim ad

minima veniam, quis nostrum exercitationem ullam corporis suscipit

laboriosam, nisi ut aliquid ex ea commodi consequatur? Quis autem

www.eeweb.comJOIN TODAY

Prem Magnetics, Inc. Johnsburg, IL 60051 USA

Phone 1 (815) 385-2700 Fax 1 (815) 385-8578

Our transformers are 100% final tested for quality.

ZERO DEFECTS GUARANTEED

DIRECT LINKS Power Transformers

Switchmode Transformers Inductors

Audio & Telephony High Speed Data Transformers

Economy Audio

Line Matching Transformers Instrument & Current Transformers

CRT Display Magnetics Accessories

Factory Direct Transformers 18 Hour Express Delivery • Buy Online

Dual 15A/Single 30A Step-Down Power ModuleISL8225MThe ISL8225M is a fully-encapsulated step-down switching power supply that can deliver up to 100W output power from a small 17mm square PCB footprint. The two 15A outputs may be used independently or combined to deliver a single 30A output. Designing a high-performance board-mounted power supply has never been simpler -- only a few external components are needed to create a very dense and reliable power solution.

Automatic current sharing and phase interleaving allow up to six modules to be paralleled for 180A output capability. 1.5% output voltage accuracy, differential remote voltage sensing and fast transient response create a very high-performance power system. Built-in output over-voltage, over-current and over-temperature protection enhance system reliability.

The ISL8225M is available in a thermally-enhanced QFN package. Excellent efficiency and low thermal resistance permit full power operation without heat sinks or fans. In addition, the QFN package with external leads permits easy probing and visual solder inspection.

Related Resources• See AN1789 “ISL8225MEVAL2Z 6-Phase, 90A Evaluation

Board Setup Procedure”

• See AN1790 “ISL8225MEVAL3Z 30A, Single Output Evaluation Board Setup Procedure”

• See AN1793, “ISL8225MEVAL4Z Dual 15A/Optional 30A Cascadable Evaluation Board”

• See ISL8225M 110A Thermal Performance Video

Features• Fully-encapsulated dual step-down switching power supply

• Up to 100W output from a 17mm square PCB footprint

• Dual 15A or single 30A output

• Up to 95% conversion efficiency

• 4.5V to 20V input voltage range

• 0.6V to 6V output voltage range

• 1.5% output voltage accuracy with differential remote sensing

• Up to six modules may be paralleled to support 180A output current

• Output over-voltage, over-current and over-temperature protection

• Full power operation without heat sinks or fans

• QFN package with exposed leads permits easy probing and visual solder inspection

Applications• Computing, networking and telecom infrastructure

equipment

• Industrial and medical equipment

• General purpose point-of-load (POL) power

FIGURE 1. COMPLETE 30A STEP-DOWN POWER SUPPLY FIGURE 2. SMALL FOOTPRINT WITH HIGH POWER DENSITY

[email protected] TO 20VVOUT

4.7µF

4x22µF

ISL8225M

VIN1

VSEN2-

VSEN1+EN/FF1EN/FF2

VMON2

VMON1

SGN

D

PGN

D

VOUT1

VSEN1-

MO

DE

COMP2

COMP1

VIN

OFF 1kΩ5x100µF

470pF

1kΩ

VCC

RSET

NOTE: ALL PINS NOT SHOWN ARE FLOATING.

VIN2 VOUT2VIN2

ON

17mm 17mm

7.5mm

December 3, 2012FN7822.0

Intersil (and design) is a registered trademark of Intersil Americas Inc. Copyright Intersil Americas Inc. 2012All Rights Reserved. All other trademarks mentioned are the property of their respective owners.

Get the Datasheet and Order Eval Boards

http://www.intersil.com

EEWeb PULSE TECH ARTICLE

20 EEWeb | Electrical Engineering Community

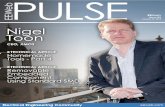

Georg HubaEngineer

Apps-based ProgrammingApproachSpeedsXMC4000DevelopmentWhen developing new software, existing, tested software components can save a great deal of time. However, this approach can present its own challenges if these software components are closely related to the microcontroller hardware layer.

Infineon

EEWeb PULSE TECH ARTICLE

21Visit www.eeweb.com

Georg HubaEngineer

Apps-based ProgrammingApproachSpeedsXMC4000Development

EEWeb PULSE TECH ARTICLE

22 EEWeb | Electrical Engineering Community

Imagine you are a software developer for embedded microcontrollers and your boss presents you with an evaluation board equipped with an interesting new microcontroller, asking you to design a BLDC motor as quickly as possible. You take a look at the board to check the type and manufacturer, confident that any reputable microcontroller manufacturer will offer support for motor drive control.

Within a short space of time, you have access to a collection of projects with ready-to-run drivers for the peripherals. The motor you are using is supported, and you can complete the assignment after a day or two. Delighted with the positive and rapid outcome of your efforts, your boss now asks you to add another motor to control a second axis and to display the control data via an SPI on an LCD. Bolstered by your initial success, you root through project repositories, libraries and reference designs for solutions to each of your design challenges. While you will probably find reference projects or software modules for each individual function, a piecemeal solution is not ideal. The idea was to create a system where everything works together – simultaneously – on a single chip

To meet design goals, you must ensure that the software modules used and the underlying hardware do not interfere with each other – and that is where things can get complicated. The available hardware resources, including the pin configuration, must be correctly mapped. Then the initialization code in the software modules and the register accesses must be adapted to the hardware map. And once you have done all of that, you may have to start mapping resources all over again if your boss pops along and suggests adding another function.

The solution: constraint logic programmingThe situation described above illustrates the dilemma embedded software developers often face when trying to reuse predefined components in the development of new hardware-oriented software projects. This methodology is generally known as “component-based programming” or “component-based software engineering.” It is based on the assumption that a design challenge is best broken down into largely independent steps that can then be solved with predefined and tested software components. This concept is also closely linked to object-oriented programming.

It should – in theory – be possible to combine these

software components without conflicts. And this is generally possible if the software components do not have exclusive use of hardware resources. This is definitely not the case when programming micro-controllers: a PWM channel is usually permanently assigned to one motor and cannot address the second motor at the same time.

To extend the benefits of “component-based programming” (for example, simple, fast, secure and flexible software development) to hardware-oriented microcontroller programming, it must be possible to adapt hardware resource mapping to ever-changing design requirements. Many current approaches based on the use of standard libraries or sample programs fail in this regard. Even the AUTOSAR method – also a component-based development method from the automotive sector – has more or less elegantly side-stepped the issue by deliberately separating the component-based concept from the microcontroller hardware. The interface to the hardware is defined by the MCAL programming interface (Microcontroller Abstraction Layer) and hardware resources must be manually assigned during the configuration phase.

By contrast, FPGA design tools were early to propose a solution to the challenge of adapting hardware resource mapping to ever-changing design requirements. A simple FPGA design for a flashing LED in the schematic editor could be like that shown in Figure 1: a clock generator, a counter and a multiplexer controlled by an external button, whereby LEDs are connected to the button’s (specific) output. When generating the VHDL code and the FPGA bitstream, the tool checks the hardware requirements and maps them to the available resources of the selected FPGA chip, taking all general constraints such as the signal connection, electrical characteristics and pin configuration into consideration. The FPGA design can be extended or transferred to another FPGA at any time as long as the resources available are sufficient to cover resource requirements. The underlying software concept used to resolve resource mapping is commonly referred to as “constraint logic programming.”

Development made easy with DAVE™ 3Infineon’s new development platform DAVE™ 3, inspired by FPGA tools, is used to program applications built on the XMC4000 family of microcontrollers. Depending on individual requirements, programmers can use DAVE™ 3 to insert application-oriented software components into their project, and also configure and connect the

EEWeb PULSE TECH ARTICLE

23Visit www.eeweb.com

components. A resource solver automatically allocates resources without creating conflicts, taking general constraints such as the signal connection between the peripherals or pin configuration into consideration. Based on the resource allocation, DAVE™ 3 then automatically generates code. In other words, programmers only need to implement the defined hardware-independent APIs in their software in order to achieve the desired functionality. So your boss can pop by with new functionality requests any time – you simply compose and combine new application-oriented SW components– so-called DAVE™ Apps – to deliver the required functionality and eliminate time-consuming code generation and resource management tasks.

How it works in real lifeTo see DAVE 3 at work, let’s look at how a PWM signal is generated in relation to an impulse generator (Figure

2). The DAVE™ 3 development platform (Figure 3) can be downloaded for free from the Infineon website and then installed [1]. The application-oriented software components are known as DAVE™ Apps, scaling from small application elements up to complete applications. Similar to smartphone apps, they can be easily downloaded from the web. Once available locally on a PC they can be selected using the app selector and added to the project. The steps involved in developing software that fits the required specs are described below.

The DAVE™ Apps selected include:

- A counter app plus an I/O app for counting the signals of the clock generator

- PWM app to generate the PWM signals

- Another counter app to switch off the PWM signal after

Figure 1. Graphical design interface of an FPGA tool. The different function compo-nents (hardware and software) can be configured and connected. The tool automatically resolves resource mapping on the FPGA chip without creating conflicts.

Figure 2. Driven by an external impulse source, a PWM signal with a sampling rate of 1 % is to be triggered after exactly 10 impulses. The sampling rate is to be steadily increased up to 90 % and the PWM signal is then to automatically stop after 500 impulses. The impulse counter should be reactivat-ed for another run.

EEWeb PULSE TECH ARTICLE

24 EEWeb | Electrical Engineering Community

500 impulses with a 90% sample rate Two interrupts (NVIC apps) to update the sample rate and for reinitialization.

Figure 4 shows an interesting highlight of this process: More DAVE™ Apps are seen than were actually selected. This is because a DAVE™ App can request the resources of another DAVE™ App. This is the case for the clock generator app, since the counter and PWM instances also need a configured clock tree, which is provided by the clock generator app.

The next step involves connecting the hardware signals. DAVE™ Apps are not just simple software components that only provide a programming interface (API); they also include hardware signals that can be directly connected with the signals of other DAVE™ Apps. To achieve the required functionality, the following signals must be connected:

- The status output of the counter app (instance 0) with the start input of the PWM app.

- The status output of the PWM app with the counter input of the counter app (instance 1).

- Event signals with the corresponding interrupt input of the two NVIC app instances.

Figure 5 shows the signal connection view in which the different hardware signals have been connected.

The DAVE™ Apps are then configured using the graphical user interface. The interface is opened by double-clicking a DAVE™ App. The required functionality and the initialization status can be set using the configuration options offered by the corresponding DAVE™ App.

A count match event is defined after 10 impulses for the counter app instance 0, while a count match event after 50 impulses is defined for the app instance 1. Figure 6 shows the configurations of the PWM app. The interrupt priority and the name of the handler function are defined for the NVIC apps.

Manual pin configurationThe DAVE™ App settings and configurations thus far are not tied to specific hardware resources. Until now it was left up to the solver to select the peripheral resources. In the case of pin selection, it is often necessary to configure certain settings manually in order, for example, to port the software to an existing board. For these scenarios, there is a manual pin configuration

Figure 3. Shot of the DAVE™ 3 development platform with different views for the DAVE™ Apps.

Figure 4. Shot of the selected DAVE™ Apps (IO002, CNT001, PWMSP001, NVIC001) plus DAVE™ Apps that were automatically called to provision re-sources for the selected DAVE™ Apps.

Figure 5. Connected hardware signals. Signals displayed in green are those that are automatically connected, while those in blue are signals con-nected by the developer.

EEWeb PULSE TECH ARTICLE

25Visit www.eeweb.com

in which, for example, the PWM output signal and the impulse input can be assigned to a specific pin (Figure 7).

To ensure that the required functions also “fit” onto the chip, the resource solver is automatically started after specific resource-relevant events. It can, however, also be started manually. The result is that the DAVE™ Apps are automatically assigned without conflict to the available chip resources while taking all general conditions into consideration. In accordance with the allocated resources, the code is then generated. Depending on the DAVE™ App, specific header files and C source files are created that contain the initialization functions and the API for the different function calls.

Although the code generated is in C, the generation process complies with the specifications of object-oriented programming. The generated code is independent of the number of DAVE™ App instances: a data structure is generated for each instance and this stores the corresponding configuration and resource information. Basically, DAVE™ Apps are classes that are instantiated as objects when they are added to a project.

Using the API in user code After the steps shown above, all hardware-relevant tasks for the software development are completed and you can now concentrate fully on the abstract programming. In this example, just two interrupt handler functions need to be defined. The first function triggered by the PWM period match event updates the duty cycle of the PWM signal and starts the counter app instance 0 after the duty cycle of the pwam signal has reached 90%. The second function – triggered by the count event match of the counter app instance 1 – is mainly responsible for preparing a new sequence.

Figure 8 shows the two code sequences. Each of the function names starts with the app name as a prefix, followed by a functional suffix; the first argument is always a pointer to the data structure of the corresponding app instance. The code can be compiled using the free GNU compiler available in DAVE™ 3 and tested on the target system with the TASKING debugger. (NOTE: This example project can be loaded from the online DAVE™ project library – the keyword is Elektronik-17.

Although the example given here is very simple, it clearly illustrates the potential savings offered by DAVE™ 3. Even experienced software developers would need

Figure 3. Shot of the DAVE™ 3 development platform with different views for the DAVE™ Apps.

Figure 6. Graphical user interface to configure DAVE™ Apps – the PWMSP001 app in this case, for example.

Figure 7. Manual assignment of the pins so that the resource solver can take the general conditions of an existing PCB into account when allocating resources.

EEWeb PULSE TECH ARTICLE

26 EEWeb | Electrical Engineering Community

considerably more time to get the job done without DAVE™ 3. If the requirements were then to be extended or changed, the programmer can simply build on the existing project by adding additional DAVE™ Apps. The DAVE™ Apps library offers a wide and expanding choice of apps covering a broad range of scenarios. This library is constantly being expanded.

The DAVE™ 3 concept allows programmers to make full use of hardware resources on a component basis without needing an in-depth understanding of the hardware. It also supports the integration of existing software modules and commercial third-party software solutions. The main aim here is to ensure that the required hardware resources do not use the software modules of the resource solver. In future, this will be realized by a hardware reservation option or by supporting such components with a dedicated DAVE™ App – for example, for configuration (using generated header files) or flexible allocation of resources.

Many software developers who have worked for a long time with an existing tool chain may have reservations about switching to something new to explore the benefits of DAVE™ 3. But DAVE™ 3 is also flexible in this respect. Although it is a full development plat-form, it can be restricted to the functions of component-based code

generation and used to import code to other tool chains. Some tool vendors are even working on integrating just the DAVE™3 plug-in for code generation into their own Eclipse-based tool chain.

DAVE™3 currently supports the chips in the XMC4500 series. All relevant DAVE™ Apps are being speedily ported to the XMC4400, XMC4200 and XMC4100 series. The number of available DAVE™ Apps continues to grow steadily. More components mean more options to satisfy your needs.

Literature[1] Website for the DAVE™ 3: www.infineon.com/dave

[2] Website for DAVE™ 3 support: www.infineon.com/dave-support

[3] Wikipedia website on component-based programming: http://en.wikipedia.org/wiki/Component-based_software_engineering

[4] Wikipedia website on constraint logic programming: ht tp:/ /en.wikipedia.org/wiki /Constraint_logic_programming

[5] Altera, FPGA Design Tutorial

Figure 8. This example can be programmed with just a few function calls. Each of the functions provided by DAVE™ begin with the name of the DAVE™ App, followed by a functional description. The first argument is always the pointer to the structure of the DAVE™ App instance.

EEWeb PULSE TECH ARTICLE

27Visit www.eeweb.com

NXP is a leader in low power capacitance touch sensors, which work based on the fact that the human body can serve as one of the capacitive plates in parallel to the second plate, connected to the input of the NXP capacitive sensor device.

Thanks to a patented auto-calibration technology, the capacitive sensors can detect changes in capacitance and continually adjust to the environment. Things such as dirt, humidity, freezing temperatures, or damage to the electrode do not affect the device function. The rise of touch sensors in modern electronics has become a worldwide phenomenon, and with NXP’s low power capacitive sensors it’s never been easier to create the future.

Learn more at: touch.interfacechips.com

World’s lowest power capacitivesensors with auto-calibration

EEWeb PULSE PRODUCT OVERVIEW

28 EEWeb | Electrical Engineering Community

Overview of theOverview of the

RIGOL DM-3068Digital MultimeterRIGOL DM-3068Digital Multimeter

EEWebT e c h L a b

EEWeb PULSE PRODUCT OVERVIEW

29Visit www.eeweb.com

LayoutThe display of the DM3068 is large and easy to read, and is especially useful if you’re testing and probing from a distance.

The port layout that Rigol has maintained is consistent with other manufacturers, with the ports all where you would expect them to be on the far right of the unit. Likewise, the measurement buttons are located below the display screen and are backlit, so it’s easy to tell which one you’re using.

Measurement FunctionsAll the standard measurement functions, such as DC Voltage, DC Current, Resistance, AC Voltage, AC Current, Shorting, Frequency, can be found below the display screen. Some other measurement functions, which are not typically found on a low-cost scope are also included, such as a capacitance meter, and some thermocouple functions.

There’s a lot already built in to the thermocouples. You can use the soft grey keys above measurement functions to select the type of thermocouple you would like, and all the standard thermocouples are built in. Once you navigate back to the main menu, if you already have a thermocouple set up, you’ll see the temperature that it’s reading.

Features and Price:- 6 ½ Digit Multimeter

- 8000 MPS

- Connectivity: LXI, USB, GPIB, RS232 Serial

- $799.00

ConclusionWhile the Rigol DM3068 does not have the connection ports in the back, it does follow the industry standard interface in the front, and includes additional measurement functions that are not typically found in low-cost DMMs.

To watch this review and others from EEWeb Tech Lab:

Click Here