Eagle Point Landfill HBTU Project Definition 5-2011 Point Landfill HBTU Project... · High BTU LFG...

Transcript of Eagle Point Landfill HBTU Project Definition 5-2011 Point Landfill HBTU Project... · High BTU LFG...

PROJECT DEFINITION

FOR THE

EAGLE POINT LANDFILL, BALL GROUND, GA

HIGH BTU LFG TO ENERGY

PROJECT

Date: May 2011

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 2 - 19 Confidential

PROJECT DEFINITION

EAGLE POINT LANDFILL HIGH BTU LFG TO ENERGY PROJECT

Table of Contents

DATE: MAY 2011 PROJECT DEFINITION 1

PROJECT DEFINITION 2

1.0 PROJECT OVERVIEW AND DESCRIPTION 3

1.1 GENERAL 3

1.2 LANDFILL DESCRIPTION 3

1.3 PROJECT SCOPE 4

1.4 AMBIENT DESIGN CONDITIONS 6

1.5 LANDFILL GAS ANALYSIS 7

1.6 DESIGN CODE REQUIREMENTS 7

APPENDICES 8

Appendix A – Site Map 9

Appendix B – Preliminary Flow Diagram Pipeline 13

Appendix C – Preliminary Project Layout 16

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 3 - 19 Confidential

1.0 PROJECT OVERVIEW AND DESCRIPTION

1.1 GENERAL The Eagle Point Landfill is a Subtitle “D” landfill that is owned by Advanced Disposal Services, Inc. (ADS) The facility opened in 2001 and is currently scheduled to close in 2048. The site is located in Forsyth County, Georgia and waste is managed by a regional waste district. SES installed a new gas collection and control system (GCCS) on the landfill in 2009 that included wells, leachate handling and air supply to well activities. The GCCS was activated in 2009 and in conjunction to typical activities for gas collection; SES developed all requirements for a successful voluntary capture program and implemented a carbon capture and sale agreement for CRT’s through 2014. Currently the GCCS design incorporates a new LFG Specialties blower flare station, Siemens Ultramat gas monitoring and logging system with direct communications to our Georgia field personnel and offices in Florida. The Eagle Point High BTU LFG (HBTU) project will consist of a design build project that incorporates the following preliminary design characteristics.

3000 SCFM raw gas design Air Liguide Biogas© membrane plant 3000 SCFM raw gas design Medal© Nitrogen Removal system 0-350 psig compression / dehydration/ and all associated equipment Thermal Oxidizer for Air Liquide and Medal tail gas units Sulfur Removal for 3000 SCFM at 180 PPM H2S design Gas Chromatograph and Measurement for both system and sales gas monitoring Redundancy in power and efficiency in compression design VFD and high power feed design for all electrical systems, motors and coolers Air Liquide Heat Exchangers for membranes

The pipeline interconnect for sales gas from this project has been both identified and surveyed, including the interconnect requirements to Atlanta Gas Light (AGL) and their local gas distribution system. The current interconnect is designed for a point located approximately 12,500’ from the back of the new EPLF plant. AGL has submitted preliminary design and cost estimates for the measurement, regulation and metering facility to be constructed at the tail gas side of the new EPLF plant. 1.2 LANDFILL DESCRIPTION Eagle Point Landfill (EPLF) is owned and operated by Advanced Disposal Systems, Inc. of Jacksonville Florida. The facility opened in 2001 and is scheduled to close in 2048. The landfill is a Subtitle “D” solid waste facility. Current waste acceptance is approximately 5000 tons per day of MSW. Some minor C&D and sludge materials are included but not significant in tonnage. The landfill is located at 8880 Old Federal Highway, Ball Ground, GA

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 4 - 19 Confidential

1.3 PROJECT SCOPE Provide a Sales Gas that is in full compliance with the requirements of AGL over a very wide range of raw landfill gas compositions (See Appendices)

Incorporates several features to minimize power consumption during the part load operation which is expected during the initial years of the project, and whenever the landfill’s output may be impaired. These features include variable speed drives and inlet flow controllers.

Minimizes current rush effects on the electric utility interface by use of reduced voltage starters on large motors in addition to the VFD’s mentioned above.

Is based upon optimizing the life cycle cost of ownership and operation. Particular attention has been given to selection of materials of construction (stainless steel to resist carbonic acid) and incorporation of dry inert gas purging during shutdown,

Provides fully integrated and automated control of all plant systems with the ability to record and recall data history.

Incorporates capacity to monitor the facility from offsite via the internet Provides automated valves to transition flow of landfill gas from landfill to the

processing plant and when the processing plant is shutdown back to the flare. Monitors incoming landfill gas for oxygen content to provide early warning of landfill

collection problems that could lead to facility shutdown. Includes an automated plant safety shutdown system that isolates the processing plant.

Multiple manual trip stations are also provided so that an operator may initiate an emergency plant shutdown.

Includes a nitrogen inerting system for equipment that must be purged to prevent corrosion in non operating compression and vacuum equipment, and to safely purge the facility prior to maintenance and to remove oxygen afterwards.

Removes moisture that may be conveyed by the flow of landfill gas prior to its initial introduction into the gas processing facility This knockout pot will be fabricated from carbon steel, lined with epoxy and equipped with a stainless steel coalescing element.

Raises gas pressure from “0” to ~15 psig utilizing 2 variable speed driven multi stage centrifugal blowers. The blowers will be fitted for landfill gas service and be manufactured by Houston Service Industries, or equal. The variable speed drives will be utilized to balance flow into the plant with flow from the landfill in an energy efficient manner.

Removes the heat of compression generated by the blowers by cooling the gas in a stainless steel air-cooled heat exchanger.

Compress’s the landfill gas to about 200 psig using a custom designed landfill gas compression system. The compression system will utilize 2 compressors with independent oil systems and a common gas knockout pots and moisture separator. Stainless steel components are used extensively in this compression system to minimize potential of corrosion. The system will be as manufactured by Enerflex (Toromont) or equal. The gas compressor cooler includes a 3-circuit air cooler (one circuit for each compressor’s oil system) and a common circuit to cool the compressed gas. The cooling system is stainless steel to provide trouble free service.

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 5 - 19 Confidential

Removes the hydrogen sulfide in a 2 vessel lead-lag system using SulfaTreat (or equal) media. The vessels will be epoxy lined carbon steel and piping will be stainless. An eleven valve manifold will be provided to permit:

o Switching lead and lag o Provide a double block valve on inlet and outlet piping so that media can be

safely changed while the system is operating o Permit bypassing the system if the H2S levels are below 20 ppm.

Utilizes the Air Liquide Biogas system to dry the gas to pipeline standards. The Biogas system incorporates pressure swing adsorption to remove siloxanes and

VOCs, then carbon adsorption to remove any residual VOC’s and trace H2S, and finally membrane separation to remove CO2 and O2.

Removes Nitrogen to produce a pipeline quality gas via the Guild Molecular Gate Process.

Compresses and cools the product gas to the required condition for the Atlantic Gas Light pipeline.

Provides a thermal oxidizer, requiring only a small pilot gas stream of enriched gas, for proper destruction of the low volume % methane in the high flow rate CO2 elimination gas stream from the Air Liquide membranes.

Requires only 0.56 kW per SCFM on incoming landfill gas to deliver sales o gas to the Atlantic Gas Light pipeline.

Landfill Gas Pipeline The following are preliminary design characteristics for the sales gas system pipeline. SES intends to process and produce landfill gas at the Eagle Point Landfill near the intersection of Old Federal Rd at Blanton Lane in Forsyth County, Georgia. SES will provide a 4” above ground flanged connection at the southeast side of the proposed LFG building (see Three Phase Route Drawing for building location). AGL will provide a 4” above ground insulated flange, valve and riser to connect to the SES provided flange listed above. From there the pipeline will travel southwest along the Eagle Point Landfill utility R/W until it intersects with Old Federal Road. AGL will work with SES and Sawnee EMC to determine the best location for the pipeline along this section. The optimal route along Old Federal Road will be within the existing Road R/W (R/W varies from 60 feet to 80 feet in width, the transmission power line that traverses along the roadway from side to side is owned by Georgia Transmission Corporation and is on a private easement varying in width (typically 25 feet) and is parallel and contiguous with Old Federal Road R/W. The North side of Old Federal Road will be optimum route, we will encounter a water line and u/g telephone along this side from Nicholson Road to Matt Highway, the South side of Old Federal Road R/W contains Sewer Force main and u/g telephone line. The county has no fees associated with lying within the Old Federal Road R/W, but would prefer we lay in the back of their R/W. We would need to acquire one permit for the HDD Crossing of the Etowah River from the State and possibly USACE as in most locations this is considered a Navigable waterway. The preferred location for the receipt facility site is located on the northeast corner of the Matt Highway at Old Federal Road Intersection.. This site location

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 6 - 19 Confidential

provides a direct tie-in point with AGL’s main 6” high pressure line, which allows for better distribution of the LFG throughout the system. Interconnect Modifications

Engineering design and specification of landfill gas on-site utilization including: o Gas metering, regulation, and distribution; o Civil/Structural site and building work; o Electrical and Communication system modifications;

Installation, startup and commissioning of LFG meter station. TYPICAL RECEIPT POINT CONFIGURATION

1.4 AMBIENT DESIGN CONDITIONS The facility will be designed for the ambient conditions consistent with Ball Ground, Georgia.

Site Elevation 1050 ft ASL Summer 1.0% Design Dry Bulb Temperature 86.5oF Winter 1.0% Design Dry Bulb Temperature 45.3oF

Producer’s surface lease with rights shared with Pipeline Company

Pipeline existing right of way

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 7 - 19 Confidential

1.5 LANDFILL GAS ANALYSIS The landfill gas currently being produced at the landfill is between 50% and 54% methane, balance Carbon Dioxide, and 6% by volume of total inerts. The Gross Heating Value is approximately 520-550 Btu/cubic foot on a dry gas basis. Further landfill gas characterization and analysis will be required as well as the updating of gas production forecasts. Existing Gas Analysis as of 2011:

1.6 DESIGN CODE REQUIREMENTS The facility design shall be in accordance with all applicable city, state, and federal codes, regulations, and standards. It shall be the responsibility of the SES contractor and engineers to validate and conform to these codes. A preliminary list of permits and codes has been developed.

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 8 - 19 Confidential

APPENDICES

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 9 - 19 Confidential

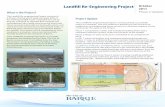

Appendix A – Site Map

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 10 - 19 Confidential

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 11 - 19 Confidential

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 12 - 19 Confidential

New Flare Station by SES

New GCCS area as installed by SES

GCCS Flare station and new HBTU plant area

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 13 - 19 Confidential

Appendix B – Preliminary Flow Diagram Pipeline

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 14 - 19 Confidential

Appendix C – Preliminary Project Layout

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 17 - 19 Confidential

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 18 - 19 Confidential

High BTU LFG to Energy Project Eagle Point Landfill Confidential Information Project Definition

Eagle Point LF 5-2011 19 - 19 Confidential