E Lee CK - ConSteel Seminar - 6Aug14

-

Upload

masoodkhalid -

Category

Documents

-

view

25 -

download

4

description

Transcript of E Lee CK - ConSteel Seminar - 6Aug14

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 1/44

1

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

Associate Professor Lee Chi King

School of Civil and Environmental Engineering,

Nanyang Technological University

6 August 2014

Continental Steel Public Seminar

on

“Impact of Structural Eurocodes on Steel and

Concrete Structures” A Beginner’s Guide to Simple Plate Girder

Design to EC3 Part 1-5

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 2/44

2

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

2

Topics of presentationIntroduction

OverviewBehaviors of plated structural elements

Design of plate girder

Design principles

Comparing BS5950 with EC3 Part 1-5 in plategirder design

Bending resistance

Shear resistanceStiffener and end post design

Summary and Conclusions

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 3/44

3

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

3

Introduction

Overview

Basic behaviors of platedstructural elements

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 4/44

4

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

4

Int roduct ion

Introduction Overview

• Plate girder is essentially a DIY deep I-section

• Formed by welded steel plates (at least 3) together to form adeep section

• Large distance between the two flanges gives more optimal

structural solution than rolled or compound sections (weight and

cost) to resist bending

• Span is defined by practical requirement, the maximum depth

usually fixed by headroom requirement

2nd pass1st pass

Welds on2nd pass

Welds from1st pass

fillet welds

Flange plate

Web plate

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 5/44

5

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

5

Int roduct ion

Introduction Overview

Bending is mainly taken up by the flanges => tensile/compressive stress

=> Class 1 section Breadth of flange plate from 1/5 to 1/3 of depth, web depth from 1/8 to

one 1/12 of span

Web => as thin as possible for weight control => Class 4 section

Web subjected to direct

bending stress and shearstress

Stiffeners and end posts:

To prevent buckling due to

bending and shear as well

as local failure under patchloads

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 6/44

6

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

6

Int roduct ion

Introduction Basic behaviors of plated structural elements

Plated structural element subjected to direct stress: Plate-like and

column-like buckling A thin plate subjects to direct stress (e.g. web of plate girder under

bending) tends to buckle before f y is reached for the whole plate

A thin plate with aspect ratio =a/b ≥ 1 will have sufficient post-buckling

strength => “Plate-like buckling”

Pre and post critical behaviors are obvious for a prefect plate but more

gradual for imperfect plate

(Beg: 2.4.1, Fig. 2.12)

a

b

Note: b is alwaysthe dimension of theedge where thedirect stress is

applied, in plategirder b is the depthof the girder or webheight

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 7/44

7

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

7

Int roduct ion

reduced stress method

reduced crosssection method

beff /2beff /2

b

ylimσ f

f y

b

y

σ act

limσ f

a

(Beg: 2.4.1, Fig. 2.13)

Introduction Basic behaviors of plated structural elements

Non uniform stress distribution developed when ultimate resistance reached

The Effective Width Method is used to account for the effect of plate-likebuckling by reducing the gross width to an appropriate effectivep width beff

adjacent to the edges and assume that f y is reached there

For a Class 4 thin plate, the reduced width beff should be used in section

properties calculations (More details in “ Surviving Class 4 Slender Section in

Eurocode 3” presented at the Regency Steel Asia Symposium, 5 August

2013)

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 8/44

8

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

8

Int roduct ion

Introduction

Basic behaviors of plated structural elements

Plated structural element subjected to shear stressThe thin and deep web is also subjected to large shear force and

thus vulnerable to shear buckling

Web buckling could occur before the “full” shear capacity

Shear buckling strength depends on aspect ratio, plate thickness,

imperfections, material properties and boundary conditions

Shear buckling could be delayed if appropriate rigid transverse

stiffeners are constructed to limit the extent and separate the

buckling regions

3 yv f A

Unstiffened web Stiffened web

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 9/44

9

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

References

Eurocode 3: Design of Steel Structures – Part 1-5 Plated

Structural Elements (BS EN1993-1-5:2005) Darko Beg et. al. “Design of plated Structures Eurocode 3:

Design of steel structures: Part 1-5- Design of plated

structures”, ECCS and Ernst & Sohn, 2010

[TA684.DA457sf] Lee C. K. and Chiew S. P., 2013, “ An efficient modified

flanges only method for plate girder bending resistance

calculation”, Journal of Constructional Steel Research, Vol.

89, pp. 98-106

9

References

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 10/44

10

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

10

Design of plate girderDesign principles

Comparing BS5950 with EC3 Part1-5 in plate girder design

Bending resistance

Shear resistance

Stiffener and end post design

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 11/44

11

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

11

Design o f Plate girder

Design of plate girder Design principles

Design inputs

Span (L), Loadings,Depth and width

Internal forcesBMD and SFD

Bending resistance• Effective width method Effective section area, Aeff

Effect second moment of area, Ieff

Elastic modulus Weff My,Rd

• Modified/Flanges-only method

Flange plastic modulus, Wpl,f My,Rd

Section portioningFlange (bf , tf ), Web (hw, tw)

End post type and stiffener

spacingEnd post type, stiffener spacing (a)

Shear resistance and interactions

• Shear resistance Stocky/Non-stocky check

Web contribution Vbw,Rd

Flange contribution Vbf,Rd

• Shear and bending intersection

Intermediate stiffenersShape, size and thickness

Intermediate stiffener General requirements

Effective cross section

Direct and shear stress verifications

End post and load bearing

stiffenersShape, size and thickness

End post and load bearing

stiffener Minimum requirements

Design as a load bearing column

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 12/44

12

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

12

Design of plate girder Comparing BS5950 with EC3 Part 1-5 in plate girder design

Design o f Plate girder

BS5950Most design rules found in Sections 4.4

and 4.5

Annex H for web buckling resistance

and end anchorage

Mainly “descriptive” design rules with

explicit formulae given for strength

calculation and limiting values (e.g.maximum hw /tw value)

Bending resistance: “Flanges only”

method for fast calculation

Simplified method and more exact

method for shear buckling resistance

Table provided for quick calculation

using simplified methodExplicit rules given in Section 4.5 for

web bearing and stiffener strength

calculation

EC3 Part 1-5Part 1-5 devoted to “Plated Structural

Elements” rather than plated girders only

Five Annexes for analysis/calculation aids

Annex C for FE analysis guidelines

More “performance based” design

approach: fewer explicit formulae but

more descriptions on performancerequirements

Bending resistance: No more “Flanges

only” method Effect Width Method for

bending resistance calculation

Only one method suggested for shear

buckling resistance

No table provided All calculationsbased on formulae or analysis

No explicit rule for stiffener strength

design and calculation

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 13/44

13

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

13

Bending resistance

Flange: Class 1 or Class 2, Web: Almost inevitably Class 4

EC3 Part 1-5 requires special treatment for Class 4 plate using theEffective Width Method

Part of compressive web become ineffective relocation of centroid

compressive flange yielded but tension flange remains elastics at ULS

Bending resistance: M y,Rd =W eff f y

Design o f Plate girder

Design of plate girder

Compression Tension

Flange: Class 1,2 or 3, Web: Class 4 Non effective

area

Effective area

G’ G NA: Gross

1<f y

f y

NAs: Effective

f y

f y

G’’

2 < 1

f y

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 14/44

14

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

14

Bending resistance

Effective width method needs at least one iteration to calculate W eff

inconvenience when portioning the flange sizeThe “flanges-only” method is much more convenient in flange

portioning since

M f,Rd = 2bf t f (hw /2+t f /2)f y = bf t f (hw +t f )f y = Af (hw +t f )f y

Design o f Plate girder

Design of plate girder

Flanges

Web

b f

t f

t w

hw

l w

y y G Aw =hw t w

A f =b f t f

Note that in the “flanges only” method theflanges is full plastic at the ULS

EC3 Part 1-5 does not explicitly allow or

disallow the use of “flanges-only” method

Hence, it is safe to use if we could show that for

a given section

M f,Rd W eff f y or Af (hw +t f ) W eff

C i l S l P bli S i 6 A 2014 NTUC i l S l P bli S i 6 A 2014 NTU

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 15/44

15

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

15

Bending resistance

Research done by Lee and Chiew (NTU, CEE) shown that

whenever

Design o f Plate girder

Design of plate girder

This implies that the flanges only method isconservative within most design range

In fact, the flanges only method is “too

conservative” in the sense that in many cases

R = Af (hw +t f )/W eff 0.75

The modified flanges only method issuggested to improve the efficiency in design

Af (hw +t f ) W eff

0 Aw /Af 5 0t f /hw 0.2 hw /(t w ) 680

Flanges

Web

b f

t f

t w

hw

l w

y y G Aw =hw t w

A f =b f t f

yf 235ε

C ti t l St l P bli S i 6 A t 2014 NTUC ti t l St l P bli S i 6 A t 2014 NTU f

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 16/44

16

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

16

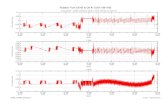

Bending resistance: Modified “Flanges-only” method

It is found that the efficiency for bending resistance could be

improved by modified the flanges only method so that

Design o f Plate girder

Design of plate girder

y f w f Rd f,

y eff Rd y,

)f t (h AR M

f W M

0.84

0.86

0.88

0.9

0.92

0.94

0.96

0.98

1

1000 1500 2000 2500 3000

BendingResistance

Ratio

hw (mm)

Flanges only resistance/ Effective modulus resistance

Modified flanges only resistance/Effective modulus resistance

2

w

w

f

w

950

ε t

h 400

0.028 A

A1 R

400 mm

25 mm

10 mm hw from

1010 mm to

3000 mm

y y G

f y =355MPa

=0.814

C ti t l St l P bli S i 6 A t 2014 NTUC ti t l St l P bli S i 6 A t 2014 NTU D i f Pl t i d

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 17/44

17

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

17

Bending resistance: Verification

• If no axial force is present, verification should be performed as a

normal section check using 1

where MEd is the maximum design moment

• To prevent flange induced buckling, we also need

Afc is the effective area of the compression flange. The factor k istaken as 0.3, 0.4 and 0.55 for Class 1, 2, 3 and 4 flanges,

respectively

Design o f Plate girder

Design of plate girder

0.1,

1 Rd y

Ed

M

M

fc

w

yf w

w

A

A

f

E k

t

h

C ti t l St l P bli S i 6 A t 2014 NTUC ti t l St l P bli S i 6 A t 2014 NTU D i f Pl t i d

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 18/44

18

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

Design of plate girder

Shear resistance

• Unless the web is Class 1, we need to check whether the web is

stocky or not for shear buckling• For unstiffened web

• For stiffened web (either transverse or longitudinal or both)

where =1.0, and for plate girder without longitudinal stiffener

72

w

w

t

h

k

t

h

w

w 31

1a/for)(34.500.4

1a/for)(00.434.5

2

2

w

w

ww

ha

hk

hahk

a

18

b

Contin ental Steel Publi c Semi nar 6 Augu st 2014 NTUContin ental Steel Publi c Semi nar 6 Augu st 2014 NTU D i f Pl t i d

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 19/44

19

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

Design of plate girder

Shear resistance

• If the web is stocky, no shear buckling of web shall occur and the

shear strength of the web is given by EC3 Part 1-1

• If the web is NOT stocky, shear buckling governs the failure

Web contribution (TFA) Flange contribution (PH formation)

19

0

,

)3/(

M

yv

Rd pl

f AV

1

,,,3 M

ww yw Rd bf Rd bw Rd b t h f V V V

a

b

Plastic hinge locationsTension field action

Contin ental Steel Publi c Semi nar 6 Augu st 2014 NTUContin ental Steel Publi c Semi nar 6 Augu st 2014 NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 20/44

20

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

Design of plate girder

Shear resistance• For the contribution from the web Vbw,Rd

w is the shear reduction factor which depends on the end post

conditions and the modified web slenderness , =1 for all steel.

20

13 M

ww yww Rd ,bw

t h f V

w

w

ww

t .

h

486

k t .

h

w

ww

437

For transverse stiffeners at

supports only (e.g. end post only)

For the presence transverse and

intermediate transverse stiffener

Contin ental Steel Publi c Semi nar 6 Augu st 2014 NTUContin ental Steel Publi c Semi nar 6 Augu st 2014 NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 21/44

21

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

Design of plate girder

Shear resistance• For the contribution from the flange Vbf,Rd

where Mf,Rd is the moment of resistance of effective area of the

flanges only (as in the “flanges only” method) and

• Verification of shear resistance is checked by calculating 3

21

2

,1

2

, -1 Rd f

Ed

M

yf f f Rd bf

M

M

c

f t bV

ywww

yf f f

f ht

f t b..ac

2

2 6 125 0

0.1,

3 Rd b

Ed

V

V

Contin ental Steel Publi c Semi nar 6 Augu st 2014 NTUContin ental Steel Publi c Semi nar 6 Augu st 2014 NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 22/44

22

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

Design of plate girder

Interaction of bending and shear

• If and MEd<Mf,Rd, the design resistance to

bending moment need not be reduced to allow for the shear force

• Otherwise, addition verification are needed, it is necessary that

where Mpl,Rd is the design plastic resistance of the cross section

consisting of the effective area of the flanges and the fully

effective web irrespective of its class

• The above interaction check should be done at all sections other

than those located at a distance less than hw /2 from a supportwith vertical stiffener , as normally the shear force is

overestimated there.

22

5.0,3 Rd bw Ed V V

0.112-12

3

,

,1

Rd pl

Rd f

M

M

Rd pl

Ed

M

M

,

1

Contin ental Steel Publi c Semi nar 6 Augu st 2014 NTUContin ental Steel Publi c Semi nar 6 Augu st 2014 NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 23/44

23

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

Design of plate girder

Stiffeners and end post design• Intermediate transverse stiffener

Takes no direct external loading but subjected to internal direct andshear force

Creates compartments to increase web buckling resistance

Provides rigid support for TFA and flange resistance (PH) for web

buckling

23

• Load bearing stiffener Prevent yielding, crushing, local and global failures at

where heavy patch loads are applied

• End Post A special form of load bearing

stiffener As “anchor” supports for TFA,

flange resistance (PH) and

reaction forces

Rigid and non-rigid end posts are

possible

Contin ental Steel Publi c Semi nar 6 Augu st 2014 NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 24/44

24

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

Stiffeners and end post design

• General requirements of all stiffeners

Independent design check needed

Cross section of the stiffener consists of

(1) gross area of the stiffener itself, and

(2) contribution width of 15tw on each side (but no overlapping)

Normally, thin-walled open section (at least Class 2) are used

Ist

Ist

Design o f Plate girder

Design of plate girder

24

Contin ental Steel Publi c Semi nar 6 Augu st 2014 NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 25/44

25

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

Stiffeners and end post design

• General requirements of all stiffenersTwo general performance requirements for ALL transverse

stiffeners (intermediate, load bearing and end post) at section

where MEd0

Requirement (A) Stress and deflection limits: To verify

using a second order elastic analysis that at the ultimatelimit state

and

max is the ultimate stress (elastic) and w is the ultimate lateral

deflection while b is the panel height (or web height)

1 M

ymax

f

300

bw

Design o f Plate girder

Design of plate girder

25

Contin ental Steel Publi c Semi nar 6 Augu st 2014 NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 26/44

26

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

Stiffeners and end post design

• General requirements of all stiffeners Requirement (B) Torsional buckling: The stiffener will not

fail by torsional buckling which requires either

where

IT is the St. Venant torsional constant of the stiffener aloneIp is the polar second moment of area of the stiffener alone

around the edge fixed to the plate

Or when warping stiffness is considered

where cr is elastic critical stress for torsional buckling

E

f .

I

I y

P

T 35

ycr f 2

Design o f Plate girder

Design of plate girder

26

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 27/44

27

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

Stiffeners and end post design • General requirements of all stiffeners For a stiffener consist of flat plates, the requirement for

torsional buckling could be simplified to limit the width (B) to

thickness (t ) ratio of the plates to those values shown below

Limiting B/t values to prevent torsional buckling

Note: if B/t > the above suggested

values, normally is it very hard to

satisfy the requirement unless

more advance analysis (e.g. FEA)

is used.

Steel

grade

235 275 355 420 460

B/t 13.0 12.0 10.6 9.7 9.3

Design o f Plate girder

Design of plate girder

27

B

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 28/44

28

Co t e ta Stee ub c Se a , 6 ugu st 0 , U

Stiffeners and end post design • Design of intermediate transverse stiffener The main function of intermediate transverse stiffener is to

provide rigid boundary supports for the panel and prevent

web buckling due to direct stress (plate-like buckling) and to

shear stress (axial force from TFA and PH formations)

Both Requirements A and B should be verified for bothdirect stress and shear stress

Direct stress Shear stress

Design o f Plate girder

Design of plate girder

28

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 29/44

29

, g ,

Stiffeners and end post design

• Design of intermediate transverse stiffener

• Verification for direct stress

For intermediate stiffeners that is not subjected to external

axial load, Requirement (B) can be ensured by simply

limiting the B/t ratio

In general, verification for direct stress for Requirement (A)

needs a second order elastic analysis but it is not

convenient in practice.

Hence, EC3 allows two simplified methods for direct stress

verification for intermediate transverse stiffener in theabsent of external axial force

Design o f Plate girder

Design of plate girder

29

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 30/44

30

, g ,

Stiffeners and end post design • Design of intermediate transverse stiffener

Verification of direct stress: Method I: Refined Ist requirementRequirements (A) is considered to be satisfied if Ist is greater

than

where

ubw

b

E I

m

req , st

300 1

0

4

2 1

11

aab

N Ed

p ,cr

c ,cr m

0 1300

1

2

.b f

Eeu

M

y

max

Design o f Plate girder

Design of plate girder

30

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 31/44

31

g

Stiffeners and end post design • Design of intermediate transverse stiffener

Verification of direct stress: Method I: Refined Ist requirement

The elastic critical stresses for column and plate like buckling

and limiting values of their ratio:

k

is the plate buckling coefficient and dependent on the stress

ratio and can be calculation from Table 4.1 of EC3 Part 1-5,

Section 4.4

300 300 300 2 1

0

a ,

a ,

bminw

2 2

2 2

112 a )( Et wc ,cr

2 2

2 2

112 b )( Et k w

p ,cr

0 15 0 .. p ,cr

c ,cr

Design o f Plate girder

Design of plate girder

31

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 32/44

32

Stiffeners and end post design • Design of intermediate transverse stiffener

Verification of direct stress: Method I: Refined Ist requirementemax is the maximum distance from the edge of the stiffener to the

centroid of the stiffener

NEd is the maximum force of both adjacent panels and should be at

least equal to the maximum compressive stress at the edge of the

panel times half of the effective compressive area of the panel.

In checking, calculate u first, if u<1.0 displacement check is decisive

and set u=1.0. Otherwise, a strength check governs.

Ist

emax

g g

Design of plate girder

32

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 33/44

33

Stiffeners and end post design • Design of intermediate transverse stiffener

Verification of direct stress: Method II: Equivalent uniformlylateral load

In this method, a first order elastic analysis is carried out on the

stiffener which is loaded laterally with an equivalent u.d.l force

qdev,Ed such that

wel is the elastic deflection of the stiffener (which could only be

determined iteratively). In practice, it could be taken as the

maximum deflection = b/300

All other terms are defined in Method I

el m Ed ,dev wwq 0 4

g g

Design of plate girder

33

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 34/44

34

Stiffeners and end post design • Design of intermediate transverse stiffener

Verification of shear stress When shear force is present in a section, in addition to direct

stress, intermediate transverse stiffener also act as rigid support

for the interior panel.

EC3 1-5 also requires that verification for shear stress for

Requirement (A) should be carried out using second order

elastic analysis.

If both direct stress and shear stress are present at the same

section (i.e. both MEd and VEd are not zero), then the effects of

direct stress, which tends to produce additional deviation forcesand lateral deflection, must be taken into account in the analysis

g g

Design of plate girder

34

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 35/44

35

Stiffeners and end post design • Design of intermediate transverse stiffener

Verification of shear stress: Minimum stiffness requirementFor intermediate transverse stiffener acts as rigid support for

panel, on top of the general Requirements (A) and (B), the

following minimum stiffness is also required for its second

moment of area for the axis parallel to the web plate, Ist

However, the above conditions does not demand very strongstiffener and does not ensure that Requirements (A) or (B)

could be met.

2a/hif 75.0

2a/hif 5.1

w3

w2

33

ww st

ww st

t h I

a

t h I

35

g g

Design of plate girder

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 36/44

36

Stiffeners and end post design • Design of intermediate transverse stiffener

Verification of shear stress: Axial force generated by TFAIt can be shown that when shear force is present, under the

action of TFA, an axial force Nst,ten will be imposed on the

intermediate transverse stiffener such that

VEd is design shear force in the adjacent panels.

For the case of variable shear force, the value at the distance of

0.5hw from the edge of the panel with the larger force shouldbe taken

0

31

12,

M

w yww

w

Ed ten st

t f hV N

Design of plate girder

36

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 37/44

37

Stiffeners and end post design • Design of intermediate transverse stiffener

Verification of shear stress: Interaction with direct stressIf direct stress is present (i.e. MEd≠0), a small lateral deflection

will be induced and the deviation forces can be transformed into

additional axial force in the stiffener:

After both Nst,ten and Nst,ten are calculated, an appreciate

second order elastic model should be employed to check for the

performance of the stiffener for Requirement (A)However, EC3 1-5 does not suggest any simplified model for

the verification of Requirement (A)

2

2

,

wh N mten st

Design of plate girder

37

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 38/44

38

Stiffeners and end post design • Design of intermediate transverse stiffener

Model for double-sided stiffener An appropriate mechanical for double-sided stiffener is available

from (from Beg: 2.9.2.3, Fig. 2.69)

38

Design of plate girder

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 39/44

39

Stiffeners and end post design • Design of intermediate transverse stiffener

Model for double-sided stiffenerBy using this model, the lateral deflection and maximum stress

can be calculated as

elastic buckling (Euler) load of the stiffener

300

1

1

,,

,

0w

Ed st Ed st

st cr

h

N N

N ww

1

,

,,

0max,,,

max

1

1

M

y

st cr

Ed st Ed st st

Ed st Ed st

st

Ed st f

N

N N w

I

e N N

A

N

Design of plate girder

2

2

,

w

st st cr

h

EI N

39

Requirement A

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 40/44

40

Stiffeners and end post design • Design of end post Two types of end posts: Rigid and Non-Rigid To provide support for TFA and support reaction

Rigid end post should comprises of two double-sided

transverse stiffener which forms the flange of a short column of

length hw

and the following two requirements should be met

Design of plate girder

40

e

t h A A ww

ue

24),min(

whe 1.0

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 41/44

41

Stiffeners and end post design • Design of end post

Requirements (A) and (B) should still be satisfied for the endpost and the double-sided model mentioned could be used.

As end post often subjected to large reaction force, satisfaction of

Requirement (A) which limits the maximum stress to f y may not

able to prevent the buckling of the end post as a strut

EC3 requires separate checking of the end post as a column withbuckling length not less than 0.75hw.

Curve c from EC3 Part 1-1 should be used for buckling check

The total force acting on the end post should equal to the sum of

reaction, force due to TFA and interaction with direct stress

If both ends of the end post are fixed laterally, the buckling lengthcould be taken as 0.75hw. Otherwise, a larger value should beused.

Design of plate girder

41

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Design o f Plate girder

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 42/44

42

Stiffeners and end post design • Design of load bearing stiffeners

Patch loads and concentrated loads are common in plate girder Sufficient bearing resistance is needed to resist transverse

force acting on the flange plate

In case that the bearing strength provided by the web plate is

insufficient, load bearing stiffener should be constructed.

In general, Requirements (A) and (B) are also needed to besatisfied for loading bearing stiffeners.

Again, the total force acting on a load bearing stiffener should

equal to the sum of reaction, force due to TFA and interaction

with direct stress

Similar to end post, their design is often government by the

buckling resistance as a strut (with buckling length ≥0.75hw) but

without the compulsory use of two double-side plates

Design of plate girder

42

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU Summary and conc lus ions

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 43/44

43

Summary and conclusions• EC3 Part 1-5 is devoted to “Plated structural elements”

• While the basic principles for design (limited state design) is

the same, the design procedure of EC3 Part 1-5 is differentfrom BS5950

• In general, EC3 may require higher level of analytical and

numerical modellings for the design of plated structural

elements• Important topics that are not covered here:Deflection (serviceability limit state): [EC3 Part 1-5: E.2]

Interactions between transverse forces, bending moment and

axial force [EC3 Part 1-5: 7.2]

Welded plates, cut outs in stiffener [EC3 Part 1-5: 9.23 & 9.24]Web to flange weld [EC3 Part 1-5: 9.3.5]

Guideline for finite element analysis: [EC3 Part 1-5: C]

43

Contin ental Steel Publi c Semi nar, 6 Augu st 2014, NTUContin ental Steel Publi c Semi nar, 6 Augu st 2014, NTU

7/17/2019 E Lee CK - ConSteel Seminar - 6Aug14

http://slidepdf.com/reader/full/e-lee-ck-consteel-seminar-6aug14 44/44

End of presentation

Thanks for your attentions!

All questions are welcome!