Duerig, Pelton Materials Properties Handbook Titanium ... · Duerig, Pelton Materials Properties...

Transcript of Duerig, Pelton Materials Properties Handbook Titanium ... · Duerig, Pelton Materials Properties...

25 March 2009 NDC Business System R2Letterhead (scale 80%) Option #1

47533 Westinghouse Drive Fremont, California 94539 t 510.683.2000 f 510.683.2001

We are Nitinol.™

www.nitinol.com

TiNiShapeMemoryAlloys

Duerig,Pelton

MaterialsPropertiesHandbookTitaniumAlloyspp.1035‐1048

1994

Product Forms Bnd

Applications

Specia l Properties

Ti-Ni Shape Memory Alloys 11 035

I Ti-Ni Shape Memory Alloys T.w. Duerig and A.R. Pelton, Nitino/ Development CofpoIation

This datasheet describes some of the key properties of equiatomic and near-equiatomic ti ta· nium-nickel alloys with compositions yielding shape memory and superelastic properties. Shape memory and superelasticity per se will not be reo viewed; readers are referred to Ref 1 to 3 for basic information on these subjects. These alloys are commonly referred to as nickel-titanium, tita· nium-nickel, Tee-nee, Memorite .... , Nitinol, Tinel"', and Flexon"". These terms do not refer to single al· loys or alloy compositions, but to a family ofalloys with properties that greatly depend on exact compositional make-up, processing history, and small ternary additions. Each manufacturer has its own series of alloy designations and specifications within the "Ti·Ni~ r ange.

A second complication that readers must acknowledge is that all properties change significantly at the transformation temperatures M

" Mr,

~, and Ar (see figure on the right and the section "Tensile Properties~). Moreover, these temperatures depend on applied stress. Thus. any given property depends on temperature, stress, and his·

''''y. Titaniwn-nickel is most commonly used in the

form of cold drawn wire (down to 0.02 mm) or as barstock. Other commercially available forms not yet sold as standard product would include tubing (dov,n to 0.3 mm 00), strip (down to 0.04 mm in thickness). and sheet (widths to 500 mm and thick· nesses down to 0.5 mm). Castings (Ref 4), forgings and powder metallw-gy (Ref 5) products have not yet been brought from the research laboratory.

Typical Conditions, Titanium·nickel is most commonly used in a cold worked and partially an· nealed condition. This partial anneal does not recrystallize the material , but does bring about the onsel of recovery processes. The extent of the postcold worked recovery depends on many aspects of the application, such as the desired stiffness, fa · tigue life, ductility, recovery stress, etc. Fully annealed conditions are used almost exclusively when a maximum Ms is needed. Although the cold worked condition does not transfonn and does not exhibit shape memory, it is highly elastic and has been considered for many applications (Ref6).

R esponse to Heat Treatment. Re<:overy processes begin at temperatures as low as 275 "C (525 oF). Recrystallization begins between 500 and 800 °C (930 and 1470 oF), depending on alloy composition and the degree of cold work.

Aging of Wlstable (nickel-rich) compositions begins ot 250 "C (525 "F), causing the precipitation of a complex sequence of nickel-rich precipitates (Ref7), as these products leach nickel from the matrix, their general effect is to increase the Ms temperature. The solvus tem;leratw-e is about 550 °C

Many shape memory-related properties are discussed in subsequent sections (transformation

Effect of phase transformation

Manensile

D-Heating

.. ' j

"

~ C~i

D Auslenile {pa.ent)

Typica lly 20 ~

M, .. Manensl1e stan temperature

A, lIAr ~ Manensite linish

temperalure A" "Stan of reverse

transformation of manGnsHe A. = Fin iS! ' ot lI!Verse transformatIon 01 martens;t

Temperature ->

Sd"Iemane "U$tra~OI'1 of It.. ",Heels on a phase transformation on !tie phySical prope~s ofT,·Ni. All ~t properties eilibit a dos· continully, d'\ar.JCt~rized by !he translormation tempe<att/fes

"""'"-Source: C.M. Wayman and ToW. Duerig. Engineenng Asped5 of Shape M!mofy Aloys. T.W. Duerig. et aI .. Ed .• BoMerworfl·Henemann,t990, ptO

(1020 oF). Applications for t itanium -nickel alloys can be

convenient ly divided into four categories (Ref 8): Free recofJery(motion) applications are thoS(' i:l which a shape memory romponent is allowed to free ly recover its original shape during he:!!ing, thus generating a recovery strain (Rcf9 .

Constrained recovery (force) applications ar!! those in which the recovery is prevented, con· straining the materiru in its martensitic, or cold, form whil~ recovering (Ref 9). Although no strain is rer,)vered, large recovery stress,'~ are developed. These applications include fa s· teners and pipe couplings and are the oldest I1J1d most widespread type uf practicru usc.

Actuators (work) applications are those in which there is both a recovered strain ar.d stress during heating, such as in the case of n titanium-nickel spring being warmed to lift n ball (Ref10l.ln these cases, work is being done. Such applications are onen further catego' rized according to their actuation mode. e.g .. electrical or thermal.

Supereiasticity (eTU!rgy storage) refers to the highly exaggerated elasticity, or springbacK. observed in mRny Ti-Ni alloys deformed abo..-e A. and below Md (Ref 11). The fundion of t I:.e material in such cnses is to store mcchan: ::u energy. Although limited to a rather small i.e perature range, these alloys cun delivcr 0' 'r 15 times the elastic motion of a spring steeL

temperatures. superelasticity, etc.). Sume properties, however, are ~ trictly peculiar to shupe men!-

1 C361 Advanced Materials

ory aUoys and cannot be conveniently categorized in standard outline fOrIDs. The more important of these properties are discussed below.

Free-recoverable stram in polycrystalline titanium-nickel can reach 8%, but is limited to a maximum of6% if complete recovery is expected.

Applied stresses opposing recovery reduce recoverable strain. Clearly, stronger alloys will be affected less by opposing stresses. Work output is mrucimized at intennediate stresses and strains.

Recoverable stresses generally reach 80 to 90% of yield stress. In fact, alloy behavior depends on numerous factors, including the compliance of the resisting force and the constraining strain (Ref 9 and 12). 1)rpical values are as follows:

Condition Recovery 5tree~. MPa

AMQlcd b;.ntoo;k Co~~~b~k~cd

OISOO ·C(930"F) Cold ""Ot\(od wi~:umr:.oJod ~l

4OQ°cnso·F)

"'" '''' '000

Effecls of opposing stresses on recovery strain

Applied stress. ksi o 10 ~ ~ ~ M W ro ~

Applied stress, MPa

T\.Nl-Fe tlarstock with SO at.% Ni and 3% Fo fUly anr.&aled, tested in unia;cialleflSiot>. Source: J.L. Proll and T.W. Ouertg, Fngneering AspecI$ 01 Shap6 Memory Alloys. T.W. Ouetlg ~, aI .• Ed., Bunerworth-Hl!Iinernatln, LoMon. 1990,p 11S

Chemistry and Density

Density, 6.4510 6.5 glcm3

Titanium-nickel is extremely sensitive to the precise titanium/nickel ratio (see figure below). ~neral1y, alloys with 49.0 to 50.7 at.% titanium are commercially common, with superelastic al· loys in the range of 49.0 to 49.4 at.% and shape

Free recovery behavior

•

•

5 10 lS " TOlal deformalion strain, 'Y.

'T1·NI-Fe berslock wi\tl SO a1.% NI8/1d 30/. Fe fuU)' annealed. tested In unlilldal tltf"lslon. An", deforming 'T1-Ni to various lotal slrnil'lS Ixaxis). the malerial S!>f\ngs bae!< to \tie ptastic strain I~"s shown by \lie open cirdes. A~er hea~ng above A,. most oI"e strain Is recov· ered, but $OffiO amonla pertlSIS. lhedifferenoe between the plas· tie slrain IW'd the amnesia is the reoove<abIB Slrain (dosed ordes). Source: J.L Proft and T.W. DuerIg. E:ngi1eeMg Aspects 01 Shape MemoIy Alloys. T. W. Duerig fll 8/" Ed., Bunerworfl·Heinemann, London, 1990.p 115

Work output of a li·NI alloy

Applied stress. ksi o 10 ~ ~ ~ ~ ~ ro ~

O'~~~~ __ ~ __ ~ __ ~--J

o tOO 200 300 400 500 600 A~plied stress. MPa

To·Ni·Fe barslock wil:l150 al.~~ Ni and 3"10 Fe in II wor!<·harclened condition, tesled in unill.lllatlens4on. Source: J.L Prof! and T.W. Outlig. Enginee<fngAspeclsolSt!ape ~ AIof$. TW. OuePg e/ 61 .• Ed. BuftetWOllh·Heinemann. London. 1990,plIS

memory alloys in the range of19. 7 to 50.7 at. %. Binary alloys with less t han 49.4 at.% titanium are generally Wlstable. Ductili ty drops ropidly A8 nickel is increased.

Binary alloys are commonly available with :\Its

Central Portion ofTi-NiPhase

Diagram

temperat.ures bet.ween -50~ and +100 ·C (-58 to 212 -F). Commercially available temary alloys are available wit.h M .. temperatures down to-200·C (-330 -F). Tit.aniwn·nickel is also quite sensitive to alloying addibons.

Oxygen forms a Ti.Ni20.., inclusion (Ref 13). tending to deplete the matrix in titanium. lower Ms, rct.o.rd grain growth, and increase strength. Levels usually are cootrolled to <500 ppm. Nitrogen forms the same compound and has an additive effect to ox.ygen.

Fe. AI, Cr, Co, an.d V tend to substitute for nickel, but sharply depress Ms (Ref 14 to 16), with V and Co being the weakest suppressants and Cr the strongest. These elements are added to suppress M, while maintaining stability ar.d ductility. Their practicu.l effect is to stiffen a supereJastic al· loy, to create a cryogenit: shape memory alloy. or to increase the separation of the R-phase from martensite.

Pt aDd Pd tend to det:rease M, in small quan· tities (-5 to 10%), then tend to increase :'vI •• eventually achieving temperatures as high as 350 °C(660 ' F)(Refl7).

Zr acd Hi occasionally have been reported to increase M., but are generally neutral when sub· stituted for titanium on an atomic basis.

Nb Illld Cu are used to control hysteresis and

Ti·Ni Shape Memory A lloys 11 037

Effect 01 composition on M.

~ ,. "'"

,~ • ,.. p • , • • ,; •

, ", ~ ~ .P ", '00

~b' i & ~ ~ .' " • • .5( • • ·'00

.'0< .'

. '5( , ·200

., os ., 50 " " " Nick,l. al.%

M. lemptralu,os 111 niek4ll ·til;nivm alloys alII extremery s.er1silive 10 CIOI'IIposIllonl! Y8~a~on, per1ievlarty al rll!1'er nIc~el conlenls_ SoYroo: K.N. Mollon, E~ Aspects Of SI!SOe Mer7IOt'Y Alloys, ToW. Ouerlg (II iii., Ed., avn(ll'WO<1h-~. 1990. p 10

martensitie strength. Nb is added to increase hys.· teresis (desirable for coupling and fastener appli· cations), and copper (Ref 19) is added to reduce hysteresis (for actuator applications).

.. , , W(,lgh : Percent Nickel .. UOO

J

1 300~

, ;

IWO i I ,

~

,:1 • , , • , • ~ E , t!. too~

eoo~

lOOj , ..,I

"

0 $4""

o 148.,

o I'P<or

• •

L

, ,

AS)(. IS87 i

TINI

•

o II-."IO-C . -.. _. -_ .. -_ ..... _-_ ... -.... _-.. -.-- -. ---._-------_ .. -._-_. ---_ ..... ; 10 d so $!o .. " Atom ic Percent Nick('1

Phases and Structures •.

Crystal Structure

The high·temperature austenitic phase (Jl>' has a B2. oresCI ordered structure with no ",,3.015 A. The most common martensitic structure !BIg') hu a complex monoclinic structure with 4 = 2.889 A. 0 = 4.120 A. c = 4.622 A, and ~ = 96.8" (Ref 20), The Ms can range from <-200 to +lOO°C (-328 to 212 ~F). It

is worth noting that there is aho a "trnnsitioll~ structure that preceded the mllltcnsite. called the R.phssc with n rhomboheUral StruL1.ure (Ref 2U. Although this R phose e:<.hiiJils a number of inU'" ('sting properties, it will not be reviewed e:dem· sivcly here.

10~ I Advanced Materials

Transformation Products

Ti me-lemperature-transformation curve

0 TiN; OOO--~~----------------------------------------------~'100 • 0

• TiN; . Ti!!Ni!.,," r~iJ 0 TiNi • 11zNiJ .. rlN~ • • TiNI "" TinNi!. • TiN;. r~~

0

• ~ • TiNi . TiN~ 0 0

~ • •

i 0 • 0 •

• • • • • r • ~ IlOO • • •

. , • •

500 • •

...,

0

• • • • . · . . • 0

• •

• ''' .. •

0

• •

• • •

'''''' • •

HOO ~

t200 f J

'000

0.01 0.' 10 100 "00 "000 Aging dm" h

r.,...t,""*,,tur&-transfonnalion CUMlIor Ti-51Ni, 'o'dIictt shows p-ecipiIallorl reacIiOo& IS a lunctiOn 01 ten..-arure and lime. Source: M. N"1Shida. C.M. Wa~ andT. Horma, MetaII. ThIns.. A. Vol 17 , 1986, P 1505

The T-T-T diagram shows the aging reactions in tulstable (>50.6% Ni) titanium-nickel alloys (Ref 7). in general, TiNi -t TiuNil", -+ 112Ni3 ~ TiNi3 as the aging temperature increases or aa

time increases at a constant temperature. Thesc precipitation reactions can be readily monitored via transformation temperature or mecharucaJproperty measuremenle.

Physical Properties

Damping Characteristics

Elastic Con stants

Internal friction and damping of titaniwnnickel alloys are dramatico.lly affected by temperature changes (see figure on left). Cooling (or heating) produces peaks, which correspond to the trnnsformation temperatures. At higher temperatures, a very sharp increase is observed during

Dyno.m.ically measured moduli (Ref23 and 24) change markedly with the martensitic transformation and premartensitic effects (see figure on

TI-NI-Cu alloy damping characteristics

T emperatu.e. "F

".~~-".~>oo~-". '~OO"-~'"--"';OOC-"2~00"--"~~--, 10" !""

. , L~ ____ -"~ ______ "-______ -',-____ -,J ·200 -100 a 100 200

Temperature. "C

Internal friction of 44.7T .. 29.3N"26 Cu (wt'!\.) du~ng coofing wi", rne6suretnet\t trequeney of - t Hz. Source: O. M,rtilll' arxl E. lOr6k, J. Phys., Vol C·4 (No. 43). 1982, p C~'"

cooling through the M •. These usuaJly high damping characteristics (Ref 22) havc been studied for some time, but have not been used un a commercial basis due to their limited temperature range and rapid fatigue degradation.

right). Tytca1 values of clastic modul i are 40 GPa (5.8 x 10 psi) for martensite and 75 CPa nO.8 x 106 psil for uustenitc. From a pmctical point of

DynamiC Young's modulus vs temperature Ttmptratur,. OF

·200 -100 0 100 200 300 400 .. • I:J ~ • • 0 .; • ~ ~ .~

, -• 0 >

12 ~ -/---':f-----=---l .;

, II i --- --'--- "1 _170 ·10 30 '" Tempenlture. ·c

A: n.s6Ni (wr"o). 8 : 44.7T .. 29..3N1·26Co (wI'I'.). C: 44_9T .. S1.7Ni-3.4Fe ('<01%). SoJroe: O. MerOer. K.N. Melton, R. Gontlartl. i!f1d A. Kulik. Proc..InL CMl. StJid.-Sotia PPIa:M TllWroommions. .... I. AAr01SOl. D_E. 1..aug>lin, A.F. s..6fka, andC.M. Wa.,man, Ed.AtME. 1982, P t259

Electrical Resistivity

Magnetic Characteristics

Corrosion

General Corrosion

Hydrogen Damage

view, however, modulus is oClittie value; apparent elasticity is more controlled by the t ransfonnation and by mechanical twinning. Poisson's ratio, Jl., is 0.33 (Ref25).

General values fo r electrical resistivity of the two primary phases are as follows (Ref26):

p (martensite) = 76 x 10-6 n · cm p (austenite) = 82 x 10-6 n· cm Variations in resistivity with temperature are

complex functions of composition and thermomechanical processing (see figure). Note also the pronounced effect of the R-phase on resistivity.

Magnetic susceptibility also undergoes a dis· cont inuity during phase transition (Ref 26). Typi. cal values are:

X (manensite) = 2.4 x 10-6 emu/g X (austenite)::: 3.7 x 10-0 emuJg

Titanium·nickel generally fonns a passive TiD2 (rutile) surface layer (Ref27). Like titaniwn alloys, there is a transition temperature of about 500 °C (930 oF), above which the oxide layer will be dissolved and absorbed into the material. Unlike titaniwn alloys, however, eoa case is fonned. Titanium-rockel will also react with nitrogen during heat tnatments, fonning a TiN layer.

The rest potential oftitanium~nickel in a dilute sodium chloride solution is around 0.23 V (SCE), which compares with 0.38 V Cor type 304 stainless steeL This puts titanium·nickel on the noble or protected .side of strunless steel in t he galvanic series. A passive oxide/nitride surface film LS the ba· sis of the corrosion resistance of titani1,;ltt·nickel all oys, similar to stainless steels. Specific environmcnts can cause the passive film to break down, thus subjecting the base material to attack. A8um~

mary ortitaniwn·nickel reactions in various environments rollows (Re[28).

Seawatcr. Titanium-nickel is not affected when immersed in flowing seawater; however, in stagnant 5eawater, such as found in creviccs, the ~rotcctive film can break down, which results in pitting corTosion.

Acetic acid (CH3CDDH) attacks titaniumnickel at a modest rate of 2.5 x 10-2 to 7.6 x 10-2 mm/year (mpy) over the temperature range 30 °C (86 oF) to the boiling point and over the concentration range 50 to 99.5%.

Methanol (CH3DHl appears to attack tita~ mum nickel only when diluted with low concentra· tions of water and halides. This impure methanol solution leads to pitting and tunneling corrosion simi lar to that found in titanium alloys.

Cupric chloride (CuCI2 ) at 70 "C (160 oF) at-

The interaction between hydrogen and tita· nium·nickel is sensitive to both concentration and lemperat~e (Ref 31). In general, hydrogen levels

Ti~Ni Shape Memory Alloys / 1039

Electrical resistance vs tempera ture Temperature, OF

-200 -I" 0 '" 200

"I M, I A

• , ~

M,~ • • • T, ~ • r-J-• , • • ~ ~ , " ~ M. T, T-

1 ,

"I 1 T-• • I ' c '\~

·170 · 140 · 110 ,80 ·SO ·20 10 40 70 100 130

Temperature, · C

Electrical resistance \IS ternperalure <;IJI'Ves lor a TI-50.6N; (at."-) al· loy IhlIt WIIS thermomecha"ie8~y treated as ;r'!d;cated. A: Ouend1ed tram l ooo ·C (1830 .F). B: Oue;'1dledfrom l(xx)'C (1830 'F), aged at400 "C (750 ' F). C; Dlr&dIy aged at 4OO "C (750"F). T R;$ thetran· s1tlon tempertltUfe from austenite lQ the rOOmbohedral A pt1as.e. r R is the shifted transition temperature IrQ(ll prcx:essing eMects. Arbitrary units lor ~eef1ical resistance. Soun::.: S. Moyauki 3nd K. Otsulo.a . Melal. Trans. A.VoI 17. 1986. ,53

tacks titanium-nickel at 5.5 mpy. Feme chlorid e (FeCI3) at 70 "C (160 OF) and

8% concentration attacks titanium-nickel a t 8.9 mpy. Titaniwn·nickel is attacked at a rate of 2.8 mpy in a solut ion of l.5% FeCla with 2.5% HCI.

Hydrochlo ric acid (HC!) has a variety of ef· fects on the corrosion of titanium· nickel alloys depending on temperature, acid concentration, and specific alloy composition. With 3% He l at 100 "C (212 OF) and a range of alloy compositions, t he rate of attack was as low as 0.36 mpy and as high as 3.3 rnpy. At 25°C (77 OF) and 7M solution, titanium· nickel~iron alloys can lose up to 457 mpy.

Nitric acid (HND.1) is more aggressive toward titanium-nickel than type 304 stainless steel. At 30 °C (86 OF), 10% liND3 attacks at a rate of2.5 x 10-2 mpy; 60% solution attacks at 0.25 mpy; 5% HND3 at its boiling point attacks at 2 mpy.

Biocompatibility studies have been oonducted in various media chosen to simulate the conditions of the mouth and the human body. In general, no corrosion of titanium· nickel "!loy.'! has been reported. For example, in tests where cou' pon! oftitaniwn-nickel were sealed at 37 °C (97 "F) for 72 h, the mass corrosion rute was on the order of 1~ mpy for such media as synthetic saliva, :lyn · t hetic sweat, 1% NaCl solution, 1% lactic acid,.llld 0.1% HNaS04 acid (Hef29); see also Ref30.

in excess of 20 ppm by weight can ue considered detrimental to ductility, with levels in ~xce!\s of200 ppm severely impru!ing. Undcr certain conditions,

1040 I Advanced Materials

hydrogen can be absorbed during pickling, plating, and caustic cleaning. The exact conditions required for hydrogen absorption are not well defined , 80 it is advisable to exercise care when perfonning any ofthese operations.

Substantial amounts of hydrogen also can be

Thermal Properties

Heat Capacity

Latent Heats

Thermal Expansion

A typical plot of specific heat (C ) versus temperature fo r a 50.2% Ti alloy (see figure) shows a discontinuity at the M! temperature of90 °C (195 OF) (Ref 3). The peak and onset temperatures for the peaks are often used to characterize the transfonnntion temperatures of an alloy. Care must be taken however, (Ref 33), because the presence of an R-phsse prior thermal cycling, and residual stresses from sample cutting can tend to complicate the CW""Ves and introduce spurious peaks.

The latent heat of the martensitic transfonnstion strongly depends on the transformation temperature and stress rate (doldT) through the formula

doldT = iiliKOF.n Typical values for 6H are 4 to 12 caUg and val

ues for do/dT range from 3 to 10 MPaJOC. The latent heat of fusion can be expressed 8S:

llH = -34,000 J/mol (Ref34).

The thennal coefficient of linear expansion can be expressed 8s(Ref23):

(l (martensite) = 6.6 x lO--orC a (austenite) = 11 x l~I"C The volume change on phase transformation

(6 V) (from austenite to martensite) is -0.16% (Ref 35).

Transition Temperatures

Melting Point

Martensitic Transformation

Temperatures

Characteristic transformation temperatures depend strongly on composition (see table on next page and the previous section on chemi,try). Typical hysteresis widths range from 10 °C (18 OF ) for certain titanium-nickel-copper alloys, to 40 to 60 °C (72 to 108 OF ) for binary alloys, to 100 °C (180 OF ) for titanium-nickel-niobium alloys.

Transformation temperatures are measured by a number off.echniques, including electrical resistivity, latent heat of transformation by differential scanning calorimetry, elastic modulus, yield strength, and strain. However, the most useful measurement technique is to monitor the strain on cooling under a constant load and the recovery on heating.

Other important relationships of transforma-

absorbed in hydrogenated waleI' at elevated temperatures and pressures, such as would be found in pressurized water reactor primary water sys· terns. Relatively short exposure times have been shown to produce hydrogen levels well in excess of 1000 ppm (Ref32).

SpecifiC heal (Cp)

Temperature. ' F

• 00 200 0 200 400 600 900 -3 , , I , i" i : I , ,

-t-_L~~ _-25 - -,-- ,---- t-- , , 5

, , I - - " , , I I , ,

I

, I , ,

5

! ! I " , !

" I " : ,

I : , ~

I I I i ,

, , ·270 · 180 ·SlO 0 90 1110 210 360 "50 ~O

T,mper.uu-e. ~

SpedIc tltat (II T0-49.8Nj (at ~.l. with a sharp peak ~ he spociIic heiLt at 90 "C (195 ' F) GOTeS4)Ol'ld"ng tl t-.e M. ~ture_ Scurc.: C.M. hd< __ • H.J. W;q>er. and R.J. wasilewski. NASA fIepott. NASA-SP5110. 1912

tion temperatures are as follows. Applied stre!lses increase transformation temperatures according to the stress rate (see the next section on tensile properties). Martensitic deformations increase the stress-free A, temperatures, particularly in alloys with low yield stre!lS(>S. The increase is temporary, returning to the previous value after the first heating cycle. Increasing cold work tends to reducc transformation temperatures. The R-phase trans· formation temperature is much more constant thao those for marten site, typically 20 to 40 °C (68 to 105 OF ) in binary alloys.

Md, which is dertncd as the temperature above which martensite cannot be stress-induced, may be about 25 to 50 °C (50 to 100 OF) higher than Af·

Strain of a Ti-Ni-Nb specimen

Tempera t ... re. 'F ·300 -200 · 100 0 100 200

,.r;~~~C--"~--~--~~--~

.' ~

.;; 2

, - -"-,.L-____________________ --J

·200 "00 o '00 Temperat ... re, ' C

Strain after delOfmlng and unloading, measured on tne first and MCOrld h.ating cyd es. Note lMe cl"1ange in A, and 1M. rteOVfIry strain . Scuret: K.N. Menon, J.L. Prell. and T.W. DtJerlg, MRS Int. Mee~ng on Actvanoed Materiats. \1019, K. Otsukaand K. SNmiru, Ed., Mat,. fIaIs Rtseartll Scciely, 1989. p 165

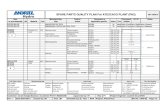

Ti·NI shape memory transformation temperatures

Ti-Ni Shape Memory Alloys I 1041

M. temperature as a function of cold working

~

~ " • &

! .. " -2

·20

" " 20 25 30 " " Cotd work, %

Q1angeln lt1e M. temperatureol a Ti·SO.eNi aioy cold worked 9 .2 to 4004 and 5ubseq ... ently anneated at 500 'C (9X1' F) tor 30 min. SoI.Irot: G.A. Zact10 and T.W. o...erig, """p"'b'is.hed rI!$earch

Mel. which is defined as the temperature above which martensite cannot be stress induced, may be abo ... tlrom 25 10 50 "C (SO to l00 "F) higher than At-

[SIMcll

IBOMiJI

[68 W;anl

[79OlcI

Compa.ition • t,':iN; .... ". ... "'2

" ,,~ ,,.. .9.4 "., "'., 49.7

'" "'. , "'., " 48.1 48.6 49.0 ,,~

"'~ ".

"-

" )7

D

-" -'" ~

21

" '" _liO ., .. " - 9._29

2O tol!i

' 00

'" .. ., , .:!!

Thn\perature. "C >f, A.

" " " " " " '" ))

-'" 0 _lI -" -" .. , 03 - lO " ->l -"

" '''' " -" "" ., '" " ". " " " ,.,

- lO • .., -'"

'" '" '" J2

-" .. m

'''' " ,

" .. , '" " " .. -J'

T""'hniq ....

Elcc1ri.:al. ""'8n<:lic

fIRlPCn"" Eb:ui<:>.l ""i'livi!)'

Compilation UoIXI Ph.;..DiavamsofBiruu:- TIlaniu", A/kIyI, (J .L :'dW11l),. Ed.), ASM InternotionAl, 1987, p203. la )CiIed rcl.-~ &I'\!

loS rouo ..... : 11 Kor. LL Kornilo¥, Yo:. V. Kachur, ... d O.K. &010\11.0", "Dilatation An.a]ys;,O!'1"ran'(omIltion in the CompoundTlNi: F iz. Md . Mrl41UwtJ. . 32(2), 42().422 (1971) in Ruuian; TR: Phyr. Mff. MnolkKr .• 32(21, 19I)..193 ( 197U. 81 l i e! : KX Melton and O. l l emer. "'The MechaNcal Propertiet o(NiTI.Bued Slape Memory AlIo)'t.~ llcIo MtloU., 29. 393-3981 19811. 80 Mil: RY. l{;lI ipn. "O.lf!rmination of Phue n.nsroro>ation 'ThlXlperat.u.resor TI.'1i U.mg Oilfef"eflti.a] Thmn.al An.a]y.i •• ~1'i tani ... m"80. Ti Sci.1kh .. Proc. lnt. Con(. Kyoto, J". pM. M.yl8.22, T. Kiltluzi, Ed., 14S1-1467f1980J. 68W&n: F.£. Wang,B.r. OeSa"age,MrlW.J. But'hler. lllo: ' n-evtTSibl .. Critiaol RIInJ{f' ;" the Til'll n-..osltion: J . Appl. PII)'$ .• 39(5). 216&2115 (l9681. "19Che: D.B. Chlll"TlO'l', Yu .l . p"pal, V.E. G)'\lnter.LA ~"",,sevio:h. "nd E.~1.

lMvil-lkii. 1"he Mwtiplicity or Stroctunoll'raMil.ioaa iD A1 10)'t &5o:d on n:-o,: DoIIL lU .. d. NOIlIt. SS$R, 24;.854-851 ( 19191 in It .... i . .. ; 'I"R:Sot.r. Ph:#- DolL, 24{SI. 664-066(19i91

1042/ Advanced Materials

Tensile Properties

Above M.;t

BelowMs

In general, a superelastic curve is characterized by regions of nearly constant stress upon iooding(referre<i to the loading plateau stress) and wliooding (unloading plateau stresa). These plateau stress values are better indicators of mechanical strength than the traditional yield stress. Typical values ace shown (see table).

Ti-Ni shape memory: Typical loading and unloading characteristics

l.oadi:Il pl:lllliIU UIIIoadin. pI=u MIUimwn ~prtn8~k MWrnum defQrm;l.tiQI1 with % pcrmanc:m~

M.ulmwn lIOItd enon'

45OlO1OOMh Up.o 250 MP>. , .. ..

$our«: T.W. Dumng and C.R. Zadno. E~TlffriT16 Mptc1' of Slwtpe M~mcryNlay., T.W. Dueriget ... 1., Ed., Butterwon..b.t!4m. mann, London. 1990, p 369

~ is defined as the temperature above which martensite cannot be stress-induced. Consequently, titaniwn-nickel remains austenite throughout an entire tensile test above~. Tensile strengths depend strongly on alloy condition, and the ultimate tensile strength, yield strength, and ductility of cold worked titanium-nickel 'Ni.re depend on final annealing temperatures (see figure).

Ductility drops sharply as compositions become nickel-rich. A review of othec facton controlling ductility can be found in Ref36.

Mechanical properties vs anneal temperature

Temperature, OF

;800~,,~'~"~ __ '"OCO~ __ C'~'''ec __ ~''~''~ __ '~'~'' le'" _ SO --UTS r Ducti~ty

" I • ,; 109

I l%YS I

...... --- I

.. ~~.~.~--~j~::::::::::::::::::J" 300 <CO 500 600 700 800 900

&

Tempal3ture , 'C

Theinlluenceol~*'9lemperal\.O'uonrned\arOcal~HoI 0.5 111m (0.02 In.) T~SO.6Ni wire ..... '" 40% eok1 WOI1t and aMNlecI 3Ominat~tur.. ~: G,A. Zact-o and T.W. Duerig.l..I"IpUbIished research

Titanium-nickel yield stresses are controlled by the "friction& of the martensite twin interfaces. Typical yields stresses are 120 to 160 MPa (17 to 23 ksi) for binary alloye and as low as 60 to 90 MPa (9

Schematic of superelasticity descriptors

"

Strain

SthemllIie dilgam ~ key dHcrIptors 01 superetastidty: 0u (l.WlIOIIcing jtateau mtasured aslhe inIe<:tionpoinl), o,(IoDIg pta. tQu rne&$Ul'1!d IS 1M ;"tIection point). (, (lota! deIofmation sIrai'I). I, (permanent se~ or ..-mesiaJ and Ihe stored energy (shftded ~ •. Soutce: T.W. OIJerig tnd GR Zachl. Et>ginetriJg ~ cI Shape Memcvy -/'So T.W. Duerig ef ai. Ed~ 8uUeI .. OI1h-4Ieinemam. LoncIon. 1990. P 369

Aging of nickel-rich alloys increases llu!>terutic strength to a typical peak strength of800 MPa ( 11 6 keD. Surprisingly, ductility is also increased duro ing the aging process.

Yield strength vs anneal temperature

.,,, ,

'co • • • " • ~

"00 ,

Temperature. OF 100 200 300

, "'

,co

roo

500

'" '" '" , ,

" • • ~

300

Theinll..e-lcedll'f'ttoa6rlg~on/1"!fd"larblproperliesolli· 50.6Ni """40"'10 ($j -..o1<.....-.eMd 30 ...... at 1emper.1IUu. Scuroe: G.A. Zadno and T.W. Ouerig. t.npUbished re$eardl

to 13 \esi) foe titanium-nickel-copper alloys. Ultimale tensile strengths and ductilities nre similar to austenitic values.

Superelasticlty (Between M. and Mdl

Effect of Between M. and ~, the material transrorms Temperature from austenite to martensite during tensile test·

ing. Yield strengths vary continuously from Ma to Md (see figure). The rate of stress increase is called the stress rate, varying from 3 to 20 MParC, with rates generally increasing with M •.

Superelasticity, or pseudoelasticity. is an en· hanced elasticity when unloading between ~ and ~'1ct. The Md transition is generally defined as the temperature above which stress-induced marten· site can no longer be formed. On a stress·tempera· ture graph, Md is the temperature where the stress begins to level off.

Superelasticity is also highly temperature de· pendent (see figures). Changing alloy composition and heat treatment can shift the temperature range of superelastic behavior from -100 to +100 °C (-148 to 212 OF).

This datasheet describes some of the key properties of equiatomic and near-equiatomic titanium-nickel alloys with compositions yielding

Permanent set 01 superelastic wire

Temoera!ure. OF

-300 ·200 ·100 0 100 200 300

" ~ •

~

-200 -'00

\ o

Temperat",re. "C '00 200

Pt!Tn¥oent 5et 01 sup8felU!ic: binary titari~..we defotmld 8.3% Ind..no.ded al various t~hJt'M. TI-N ~.....". 50.8 lit % NI CCIIdv.olled 4(W.and amealed a!500 "C (930 oF) fOI' 2 min. The wperNoStic window is roughly <10°C (70 oF} In wiatrI. Sam;,,: T.W. Outrig lI/'Id G.R. la(ho, EngineMlg Aspects 01 SNpe ~ Aloys. T.W. Ouerig el aL. Ed.. eunerworth-~ fT\8M, l.ondo'\. 1 gg(j. P 3S9

Ti-Ni Shape Memory Alloys /1043

shape memory and superelastic properties. Shupe memory and superelnticity per se will not be reo viewed; readers are rererred to ncf 1 to 3 for basic information on titanium·nickel, Tee'MI', Memorite™, Nitinol, Tine'nl, and FlexonTIoI. These terms do not rerer to single alloys or alloy compositions, but to a family of al loys with properties that greatly depend on exact compositional make·up, processing history, and small ternary ad· ditions. Each manufacturer has its own series or alloy designations and specifications within the "Ti.·Ni" range.

A second compucation that readers must ac· knowledge is that all properties change signifi· cantly at the transfonnation temperatures M

" Mr,

A., and Ar (see fib'Uro). Moreover, thege temperatures depend on applied stres!. Thus any giv~n property depends on temperature, stre!II, and his· tory. Superclasticily is an enhanced elasticity oc· curring when unloading between AI and ?t'ld (see the section '!ensile Properties~ in thls da1asheet.l

Loading and unloading plateau heights in Ti·Ni wire

Tempe"lu' •. OF .:)00 ·200 ·100 0 100 200 JOO

.-, , " i

_~,oo[==:_,:oo=:::::-·o~-=-=,~oo::::_J,,;, Te-mper~lVra. "C

SO.8 at.'" Ni cold ~.., <IO"o;Jt'tl ameaIed al SOO "C 1m "F) lor 2min. Slres$rat • • 5.7 t.!Par'C. SooIcI: T.W. Duerig and G.Ft Zedno. EngirIeering Asperu 01 Shape Memory A.Io)s. T.W OI.oerig ., ... Ed .. e",netWOf#l·Heir'oemann.LondOn.lgg(j.p369

10441 Advanced Materials

High-Temperature Behavior

Creep, Very few creep measurements have been made on titanium-nickel, although creep mechanisms have been proposed (Ref37),

Stress relaxation is critical in many constrained recovery applications. Several measurements have been made (Ref9, 12, 38). 'Ib summarize, relaxation of stable titanium-nickel alloys is extremely slow below 350 "C (660 "F) and becomes very rapid by 425 "C (795 oF).

Fatigue Properties

Stress Controffed

Strain Controlled

Thermal Fatigue

The fatigue behavior of titanium-nickel alloys is extremely complex and encompasses m8J)Y dif· ferent topics. 'Ib summarize, titanium-nickel excels in low-cycle, strain-controUed environments, and does relatively poorly in high-cycle, stress·

Isothennal stress-controlled testing is important in many constrained recovery applications in which the shape memory effect is only \;sed as a mode of installation, e.g., fasteners and couplings, in which the nlloys are used exclusively Ilhove the Md temperature. Although fatigue has been exten-

Isothermal strain-controiled behavior is highly dependent on the testing temperature relative to the alloy transformation temperature, Fracture follows the Coffin·Manson relationship:

NI' • .,,=C where C and p areconstants;N is the number of cycles to failure; and 6£p is the applied strain amplitude (see figure). One specific example of particu-

Thermal cycling both with and without applied loads such a s found in actuators or heat engines, is certainly the most complex mode to analyze. Although it has been studied extensively. it remains difficult to predict failW'e, largely because failure can consist of fracture, ratcheting, migTation of transformation temperatures, changes in reset force, etc. Moreover, damage accumulation depends on stress, strain, temperature change, heat-

Stress relaxation

,. ~----------------, o. o. o.

o. i o.

0.'

0.'

o

0.'

CJo " 564 MPa

o .. ~~~~~~~ __ ~~~ ·1.0 ·0.5 0 .0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Jog (". h

Stress rel&lCOlion 01 a Ni.rll",Fe) attoy at 375 ' e (705 ' F) measured ir1 a dynamieally oontroll&d Cteep mact1ioe. Round specimens YAIh gage lengIh 01 6 mm. hAy annealed. Source: J. Pro!! and T.W. Duerlg. Engineering Aspet;1s 01 SI!~ Memory AIo}'$. T.W. Ouerig e/ aI., Ed .• Butte<WOl1h·He!nemam, 199Q,pl15

controlled environments. The superclastic meehl!.msms accommodate high strains without excessive stresses , but cannot accommodate high stresses without excessively high strains.

sively characterized by the coupling and fastene r industries , much of the data remains largely unpublished or highly application specific. Typical S· N behavior for vruious alloy compositions tested weH above lheir Md temperatures is shown below (see figure on next pnge).

lar interest is superelastic cycling (strain-control · led testing between AI and l'v1.!:). There are severnl modes of degradation that occur under these cir· cumsto.nces (see figure), Again, these depend strongly on specific alloy conditions and the needs of the application, Further data arc provided in Ref39.

ing methods , heating and cooling rates, and even orientation (hori:tontal or vertical I.

Failure too is nebulous. Various degradation modes can occur, including a shift. in transforma' tion temperature, a reduction in the avnilablc strain, walking (or rntcheting), and fracture itself. Thermo.! cycling with no applied lood can even result in some degradation. See Ref 10 to 13 for fur ther information.

Typical S·N curves

".""--- - - - - --- --...,

Electron beam melting ,.".~::;~t::-,,:~~~:.~-, o T;'5O.5 Ni ... . o T .. 5O.7 Ni

• Ti·5O.9 Ni • r..so.& Ni High--lrequency

• T;'51.0 Ni vacuum induction melting

-30,,'L __ ~_~~_~:__-...J

101 10) 10' 105 10'

Cycles 10 failure

titanium-niCkel aIToys of varioo.s CO'TIposiUons (at.~.) prepared In varioos fashionsl! lsothermaJlytested in sI1eet form. Tes~ng is done well above M~. SMeal specimens loaded and unloaded (R = 0). Cy· de-dat 6O · C (140 ·~. Source: S. Miyazaki. Y. Sugaya. and K. Otsuka . MRS 1,,1. MeeUng on Adv.moed Male<'lals, Vd 9. 1(. Otsu<a arid 1(. ShimizU, Ed., Metetlals Researd'l Soeiely, 1989.p2S7

Effects of isothennal superelastic cycling

• • • • • , • , • • , , ,

, , • , , , , , • , , , 0 , 0 • • ,

• < • 12°C

• ,,'C ,.'C " .. ,

" '00 '" Cycles to failure

(.)

Ti·Ni Shape Memory Alloys 11045

Low.c:ycle fatigue behavior

• ~ ~10" , • ~

, • • 0

,

M.2.70 · C M, .. .. 7.S · C M..,·oo~

M.,,·t20~

II = 0.155

j} ,,0. 176

(l &11.216

j},,0.167

10·tL _ _ ~ ___ ,-;-_ _ ...,:-_-1 10 lot 103 10'

Cycles to failure

l.J:lw-.<:yOe lallgue bMal'lor of titanium·nlckel alloys at room tern· perature testGCI in tllnsion-eompression (R ", -1). The M, tempera· turM 01 the alloys are ill(iiQJted. SOurce: K.N. Melton and O. Mercier. SIrength of Marais and Alloys. P. Haa$eO ellJl., Ed., Pergi'lmon Pres.s. 1979. p 1246

-2 , 12°C

• 26 °c , " ·C • .. , , .. '. 4(FO,--GN

• 2 • • > • '. g- o • • " • • • • "

• • • • , • • • o 0 0 0

• • 0 ••• , . , 25 " '00 '" '" Cycles 10 railllr~

(b)

,,------------------------,

~ooo 0 .... 0 0 • • o • • • • • 12 • • • ,

, , . . • • • • • • ,

• • 0 • o •

• t -•

• ,

50 "" '" Cycles to 'a~ure

(.)

THIs 01 a superelastic ~tamm~ "'r8 at Itvee tempeBtures. AJloyccnl:illf\$ 50.6 at.% noc~e .. Throe modes of deg'adalion oa:ur' sirooItan&ously do..oing Itre isolhennal superelastic eycIing 01 titanio..nl·nidte! alloys: v.9I<.ing. 01 an aocumulallon 01 permanent Sol! (lOp). a chaoge in yield s!JeSS (middle) and a reduction in :tle hysteresis wiaIrr (bottom). Source: S . Miyazaki, EngiIleemgAspecfsolShapeMemotyAlloy$, T.W. Ouerig ~ aI., Ed., BuHerworths, 1990. p400

,0461 Advanced Materials

Fracture

Fatigue Crack Propagation

Toughness

Processing

Bulk Working

Strcss-inducing martensite at the tip of a propagating crack has been shown to significantly

Although Charpy impact testing on titaniwnnickel has been conducted (Ref3, 46). very little Kfc or JIc data exist. Indications are strong that a

Fatigue crack propagation

,,' 0

• ,,' •

i "J ,

.! 10 r

i,,{ • •

3 10"~ 10'''[

Stable marten$ite Stable austenite Irreversible stress-induced mallMsite Reversible stress·induced marteMite

• o

• •

slow crack growth (Ref 44). Othcr sources ofdala include Ref 45.

sharp toughness minimum exist.OJ at Md (see fig· ure).

One laltice spaOng eer eycI.!... __ """"

" ,,.

Slless-itU:ensity range (,6,,1(). MPa,:m

FaSg\:e crac;Ii: ptepaga:ion ra:esin 1000titanit.m.ndlel iIIIo)'$.(~ staJ:H~~le"';:hM. > tOoI'\'I ~tufe. stabl6'3USkYIiIe"';lh M" « room tempetalu'e. ~ stress~manMSiIiJ-M!h M. < room tempefalVrc < I\- and ~e sR$.$-it)ducedmar/ensi9..,;th 1\ < roorn:~1\.We <M". fHtedwilh R .. 0.1 on 10mm~Cf~ at SOH! lJI"oI$efCQlldlion$oIckocJusingM SoI.roe: RH. Oaus!caIl1t. lW. Ouerig. and A.O. RIChie, MRS tnt. Mee~ngon Mvanced Mate<lals, 'lot 9, K. Otsuka and K. Shimi~u. Ed. Ma!CIials Rcsearctl Society, t 989, P 243

Flow Stress. Upset forging tests conducted on seven different alloys at strain rates ranging from 10~ to 102 indicate that the material has a very high hot ductility and is not highly strain rate dependent. The £low stresses can be characterized by the relation:

a=kr.m exp(-Q1R11

where a is the flow stress; r. is the strain rate; Q is an activation energy (50,000 cal/mole); and m andk are constants. Values for m were found to range from 0.1 to 0.17 with increasing temperature (see figure for typical data of an equiatomic binary alloy).

Extrusion. Both solid bar and large tube (50 mm mameter with 8 mm wall truckneB$) have been extruded from titanium-nickel. Parameters remain proprietary.

Forging. Titanium-nickel has been succesfully forged into large cups. Parameters remain proprietary.

Rolling. Titanium-nickel can be hot rolled with relative ease, but iB difficult to cold roll, especially in thin, wide sections.

Fracture energy vs temperature

•

Temperature, ' F

, '"

Fracture energv

~-.-' - Yiekl ~rength (0.2%)

·eo , eo Temperature. 'C

200 OS

0,30

• 0.25

E

~ .'" " ! . " • • " J OS

00

'''' Vac:u!.m ~ meiled alloy hot VoOI1Ied and <'Mea!ed lor I h;l.1 950 "C and aircooled. SlandardCha'll'lV.1'IOId1 impacl speeirnen$ were mac:hine<l The ~ 01 ~I",", on IracIUfa ~ ness 01 44Ti-4gN:·5Cu·2F. (~). No:e tha i It>a n'Iir'oImo,.on in the tractu-e energyoccut'S ju1! below M". "Qetermined lrom theQ)IJ~ sponcing O.r.'. ~tld ~ and Ultimate len5ile slronglh meas· """""". Soun::e: K.N. Mellon and O. Mertier, Ada Metal .• Vd 29, t962, P

""

Fabrication Casting. Although some unreported experi·

References .

ment:i have been conducted, casting has not been done on a commercial leveL

Powder Metallurgy. Although a great deal of experimentation has taken place wit h both ele· mental and prealloyed powders, nothing hns reached near·production levels. Refe rence 5 provides a review of methods.

Forming. Titanium-nickel sheet has been successfully fonned into a range of complex shapes, both in the martensite and austenitic phases. Springback is high, as is die wear and friction. Pa· rameters remain proprietary.

Machining. Titanium-nickel is very difficult to machine. Very low speeds and a great deal of coolant is required, and tool wear is very rapid. Milling and drilling are particularly difficult. Producers of couplings have demonstrated that largescole machining production is possible.

Heat Treatment. Titonium·nickel can be heat treated in air up to -500 "C (930 "F). No 0: case is formed, but a surface oxide of rutile develops quickly. Above 500 °C (930 oF), the oxide layer be· gins to flake (depending on time). Nitrogen and hydrogen at mospheres are not recommended. Argon, helium, and vacuum heat treatments are com· monly used to preserve bright finishes.

Recrystallization is ext remely rapid above 700 °C (1290 OF ). Solution treatment requires tern· peratures of at least 550 "C (1020 "F). Stress relief is usually accomplished at temperatures as low as 300 °C (570 oF). A Tn' diagram is shown in the previous section "Phases and Structures. ~

Fully annealed bar stock has a typical hardness of 60 HRA. Vicker numbers range from 190 HV in the annealed condition to 240 HV after 15% cold work (Ref3).

1. T.W. Duerig et al.. Ed .. Engineering Aspects of Shape Memory Alloys, Butterworth-Heine· maM, London, 1990

2. J. Perkins, Ed .. Shape Memory Effects in Allay.';;, Plenum Press, 1975

3. C:M. Jackson . H.J. Wagner, and RJ. Wasilewski, NASA Report, :-iASA·SP 5110, 1972

4. J. Takahashi, :\1 Oka;reki, K Hiroshi, and Y. FUIllta. private communication. 1984

5. T.W. Duerig, in Aduan.ced S_vnthesis of Materi· als, J. Moore, Ed., 1993, to be published

6. G.R Zadno and T.w. Duerig. Engineering As· pects of Shape .\femory Alloys. T.W. Duerig et ai.. Buttenvorth-Heinemann. London, 1990, p 4 14

7. M. Nishida, C.M. Wayman and T. Honma, Met· all. 1rans. A , Vol 17, 1986, p 1505

8. TW Duerig and KN. :Vlelton,?roc. ofSMA'86, C. Youyi et ai., Ed., China Academic Publishers. 1986, p 397

9. J.L. Prott and T.W. Duerig, Engineering As· pects of Shape Memory Alloys. T.W Duerig et al., Butterworth·Heinemann. London, 1990, p 115

10. A. Keeley, D. StOckel, and T.\V. Dueng, Engineering Aspect.~ of Shape .vfemory Alloys, T.W. Duorig et of., Ed., Butterworth-Heinemann ,

Ti·Ni S hape Memory Alloys 1 1047

Flow stress measurements

• , ~ > 5. o ; ;;: 5. S

..

V18ls~

•

•

-- 0.11315

O.OIZ3Is

' .5,'-"-_ _ ___ _____ -' 0.' 0.' '.0 " " " lfT x 1000

Nal~(81Iog (In) al fiow stress is shown la var, linea ~y with the in· Yellie al abSOllile temperalvre. 12. mm x 8 mm diameler specimens lesfed In oompres.si()n I.nder isothermal condilKlf1S (healed dies) at !hit I!!mp&ralvres and slraon ra les shown. SOvree: T.W. Dvttti9. unputllisheddala

Joining. Titanium·nickel is difficult tojoin be· cause most mating materiuls cannol tolerate the large strains experienced by the alloy. Most applications rely on crimped bonds. It can be welded to itself with relative ease by resistance and TIC methods. Welding to other materials is ext remely difficult. al though proprietary methods do exist and are practiced in large volumes in lhe produc. tion of eyeglass frames.

Brazing can only be accomplished after re-en' force ment and plating. Again , methods are pro· prietary; large-scale production is practiced by the eyeglass frame industry.

London, 1990, P 181 11. T.W. Dueng ami G.R. Zadno. Ellyincl'nnl! A~·

peets of Shape JJemory All())".~. T.w. Duerig cl al .. Ed., Butterworth-Heinemnnn, London, 1990, p 369

12. C.R Such. 'The Charnctenmtion of the Reversion Stress in XiTi," M.S. Thesis. Naval Post Graduate School. Monterrev. CA. 1974

13. M.V. r>:evitt. Thln.~. Met. SOC. AlME, Vol 218, 1960, p327

14. D.M. Goldstein, W.J. Buehler. and R.C. Wiley, Effects of Alloying upon Certain Properties of 55.1 Nitinol, NOLTR 64·235, 1964

15. H.K Eckelmever. Sandia Labs Report 74-04 18.1974 .

16. D.D. Chemovet ai.. Dohl. Aked. ,va.uk. SSSR , Vol 245 (:'-io. 2). 1979, p 360

17. P.G. Lindquist and C.M. Wayman. Enginccr. ing Aspects of Shape Mem,:.-y Alloys. TW. Dueng et al.. Butt.cI"Worth-Heincmann, Lon· don, 1990, p 58

18. T.w. Dueng and KN. Melton. The Marten.~i!c Transformu.ti!lTl in Science and Technology, E. Hom~l.!Ien und H. Jost, Ed ., Deutsche Gesell· schall. :l..!r !Iiolclallkunde, Gcrmuny. 1988, p 191

19. W. MO!H.! rly and K. Melton, Engineering A~ · pcc:l.~ ot" S hnpe .\femllry Alloys. T \V. Duorig et

1048/ Advanced Materials

ai., Ed., Butterworth.Heinemann, London, 1990,p46

ZO. O. Matsumoto, S. Miyazaki, K Otsuka, and H. Tamura,Acta Meta ll ., VollS, 1987, p 2137

21. H.C. Li.ogand R. Kaplow,Metall. ThJn$. A, Vol 12,1981, p 2101

22. L. Kaufman, SA Kulin, P. Neshe, and R Salzbrenner. ShaIN Memory Effects in Alloys, J. Perkins, Ed.., Plenum Press, 1975, p 547

23. S. Spinner and AG. Hozner, J. Acoust. Soc. Am., Vol 40, 1966, P 1009

24. R.J. Wasilewski, 'Ihm.s. AIME, Vol 233, 1965, p 1691

25. O.K Belousov,Russ. Metall.. Vo12, 1981, p 204 26. J .E. Hanlon, S.R. Butler, andR.J. Wasilewski,

']}ans. AlME, Vol 239, 1967, p 1323 27. CoM. Chan, S. Trigwell, and T.W. Duerig, Surf.

InterfaceAncl. Vol IS, 1990, p 349 28. J.D. Harrison, ~ychem Report, 1991 29. S. Lu, Engineering Aspects of Shape Memory

Alloys, T.W. DuerigetaI., Ed .. Butterworth-Heinemann. London, 1990, p 445

30. L.S. Castleman, S.M. Motzkin. F.P. Alicandri, VL. Bonawit, and AA Johnson, J. Biomed. Mater. Res., Vol 10, 1976, p 695

31. R Burch and N.B. Mason, J.e.s. FarcuJ.ay I, Vol 75, 1979, p 561; RB. Burch and N.B. Mason,J.e .S. Faraday I, Vol 75. 1979, p578

32. AR Pelton and TW. Duerig, "'AIl Analysis of Crofit Couplings After One·Year Service at Seabrook,8 Raychem Proprietary Report, 1991

33. G. Ai.roldi and B.Rivolta,Phys. Scn'pto , Vol 37, 1988, P 891

34. J.C. Gachon and J. Hertz, CALPHAD, Vol 7, 1983, P 1

35. K Otsuka, T. Sawamura, K Shimizu, and

C.M. Wayman, Metail. '1h:Jns., Vol 2, 1971, P 2583

36. S. Miyazakiet al., Mater:. Sci. Fomm, Vol 56-58, 1990,p765

37. A.K MukhcJjee, J . Appl. Phys., Vol 39 (No. 5), 1968.p2201

38. A. Thrui et ai., Nip. Kihai Gakhai ROllbunshu, A Hen, Vol 51 (Nu. 462), 1985, p 488

39. G.R Zadno. W. Yu, and T.W. Duerig. MaU!rials Scknce Forum, Vol 56-58, D.C. Muddle, Ed., 1990, p771

40. H. Tamura, Y. Suzuki and T. 'Ibdoroki, Prot. lot. Con£. MartensiticTro.nsrormations, Japan Institute orMetals, 1986, p 736

41. Y. Furuya et ai., MRS Int. Meeting on Advanced Materials, Vol 9, K. Otsuka and K. Shimizu. Ed., Materials Research Society, 1989, p269

42. Y. Suzuki and H. Tamura, Engineering A<;pect.<; ofShapeMemoryA1.10ys, T.w. Dueriget 0.1. , Ed., l3utterworth-Heinemann, London, 1990, p 256

43. J.L. Pratt, K.N. Melton, and T.w. Duerig, MRS Int. Meeting on Advanced Materials, Vol 9, K Otsuka and K Shimizu. Ed., Material s Research Society, 1989, p 159

44. R.H. Dauskardt, TW. Duerig. and RO. Richie. Jl..{RS Int . Meeting on Advanced Materials, Vol 9, K Otsuka and K Shimizu. Ed., Materials Resetl.n:h Society, 1989, p251

45. S. Miyazaki. Y. Sugaya, a.nd K. Otsuka, MRS lnt. Meeting on Advanced Materinls, Vol 9, K Otsuka and K Shimizu, Ed .. Materials Hesearch Society. 1989, p 251

46. K N. Melton and O. Mercier, Acta Metall ., Vol 29, 1982, p 393