DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

Transcript of DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 1/134

U.S. DEPARTMEIT OF COMMIRCE

Natiml TecdWal II.SIUat Smic

AD-AC36 035

DESIGN AND EVALUATION METHODS FOR OPTIMIZING

EJECTION SEAT CUSHIONS FOR COMFORT AND SAFETY

FROST ENGINEERING DEVELOPMENT CORPOPATION

ENGLEWOOD, COLORADO

FEBRUARY 1977

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 2/134

AMRL-TR-68-126

0 DESIGN AND EVALUATION METHODS FOR OfTIMIZING

EuECTION SEAT CUSHIONS FOR COMFORT AN D SAFETY

0Frost Engineering Development Corporation

3900 South Kalamath

Englewood, Colorado 80110

February 1977

Approved for public release; distribution unlimited

DDC

AEROSPACE MEDI CAL RESEARCH LABORATORYAEROSPACE MEDICAL DIVISION ra 24 19 n

AIR FORCE SYSTEMS COMMAND KP ODU"E FWRIGHT-PATTERSON AIR FORCE BASE, OHIO

REPRODUCED1 TNATIONAL TECHNICALINFORMAlTION SERVICE

U.S.DEPARTMENT OF COMMERCESPRINGFIELD. VA . 2l216

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 3/134

SECURITY CLASSIFICATION OF THIS PAGE (When Dot& Entered)..... ..... E D NTRU IOSREPORT DOCMENTATION PAGE BEFORE COMPLETING FORM

1. REPORT NUMBER 12 GOVT ACCESSION NO. 3 RECIPIENT'$ CATALOG NUMBER

AMRL-TR-68-126

4. TITLE (end Subtitle) S TYPE OF REPORT b PERIOD COVERED

DESIGN AND EVALUATION METHODS FOR OPTIMIZING Final report (Jul 67-Jun 68

EJECTION SEAT CUSHIONS FO R COMFORT AND SAFETY6 PE"FORMING ORG. REPORT NUMBER

338-7 '-7. AUTHOR(#) I. CONTRACt" ON GRANT NUMBER(o)

VErnest L. tech F33615-67-C-1912

S. ERFORMING ORGANIZATION NAME AND ADDRESS 10 PROGRAM ELEMENT. PROJECT. TASK

AREA & WORK JNIT NuMbERS

Frost Engineering Development Corporation 62202F 7231-01-533900 South KalamathEnglewood, Colorado 80110

It. CONTROLLING OFFICE NAME AND ADDRESS , REPORT DATE

Aerospace Medical Research Laboratory, Aerospace Februar,' 1977Medical Division, Air Force Systems Command, 73 NUM:" OF PAGES

Wright-Patterson Air Force Base, Ohio 45433 134 .....14. MONITORING AGENCY NAME & ADDRESS(If different from Controlling Office) 15. SECUAITN LLAS., (of this report)

UNCLASSIFIED

ISa. DECLASSIFICATION'OOWNGRADING

SCIIEDULE

16. DISTRIBUTION STATEMENT (o f this Report)

Approved for public release; distribution unlimited

7. DISTRIBUTION STATEMENT (of the abstract oe,tered In Block 20. If different from Report)

IS. SUPPLEMENTARY NOTES

I9. KEY WORDS (Continue on reverse old* If necesary and identify by block number)

Seat Cushion Inflatable Seat Cushion

Comfort Ejection Dynamics

Dynamics

Comfort Testing

Passive Seat Cushion20. ABSTRACT (Conthwe on revereD side If nocesseart nd identify by blocknumber)

Two kinds of cushions, passive and inflatable, were developed using

analytic and empirical optimization procedures to enhance both comfort

and safety. Comfort tests %iere run on a series of polyurethane foams,

an inflatable seat cushion, and two operational seat cushions. Load-

deflection and damping coefficient data were also obtained. Results of

the tests showed that comfort increases as cushicn thickness or inflaticn

pressure increases. Analog computer results using a single-degree-of-

D FORM 1473 COITION OF I OV 91 ISOBSOLETE

SECURITY CLASSIFICATION OF THIS PAGE (When Data Entered)

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 4/134

SECURITY CLASSIFICAtION OF THIS PAGE("an Date Enter")

Block 20. continued

freedom model of the human body demonstrated ma i increasing overshoot withincreasing thickness or inflation pressure except for low density poly-urethane foam. Optimization curves for comfort versus dynamic overshootwere generated and used in the design of the optimized cushlons.

Str.CJR Y CLASSIFICATION OF THIS PAGE(When Data En.e,.d)

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 5/134

NOTICES

When US Government drawings. specifications. or otherdata are used for any purpose other than a definitely relatedGovernment procurement operation, the Government thereby incurs no responsibility nor any obligation what-soever, and the fact that the Government may ha%c formulated, furnished. or in any way supplied the said drawings.specifications. or other data. is not to be regarded by implication or otherwise, as in any manner licensing the holdetor any other person or corporation. or conveying any rights or permission to manufacture, use, or sll any patentedinvention that may in any way be related thereto.

Please do not request copies uf this report from Aerospace Medical Research Laboratory. Additional copies may be

purchased from:

National Technical Information Service

5285 Port Royal Road

eSpringfield. Virginia 22161

Federal Government agencies and their contraLtors -egistered with Defense Documentation Center should directrequests for copies of this report to :

Defense Documentation CenterCameron Station

Alexandria. Virginia 22314

[TECHNICALREVIEW AND APPROVAL

AMRL-TR-68-126

This report has been reviewed by the Information Office (01 and is releasable to the National Technical Information

Service (NTIS). At NTIS. it will be available to the general public, including foreign nations.

Le This technical report has been reviewed and is approved for publication.

FOR THE COMMANDER

HENNI VO N GIERKE

DirectorBiodynamics and Bionics DivisionAerospace Medical Research Laboratory

LIMd

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 6/134

SUMMARY

[A method for. optiwizing ejection seat :ushions using injury

probability and comfort data was developed. The optimization pro-cedure was used tv generate an .rtimal passive cushion consisting

of polym*ethane foam and an optimal inflatable cushion. In the

case of the inf*latable cushion, the use of rapid pre-ejection

deflation permizs maximization of comfort characteristics

Comfort testing was performed on various cushions together with

mechanical load-deflection and damping coefficient tests. In general,

increasing the thickness of a seat cushion iAcreases the comfort but

also increases the probab-1ity of injury. Analog computer studieswere used to estimate the injurl probability levels from the load-

deflection data.

The research and development program showed that comfort testingis a practical tool in seat cushion design. Existing procedures formechanical testing and dynamic analysis are adequate for cushion

optimization but further development is needed to obtain more accu-rate injury probability levels# There is a need for further research

on the physical significance of the optimization strategy, particu-

larly over a wide range of input acceleration conditions.

1(ce)

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 7/134

1

FOREWORD

This investigation was initiated by the Vibration and Impact Branch,

Biodynamics and Bionics Division, Aerospace Medical Research Laboratory,Wright-Patterson Air Force Bases Ohio. The research was conducted byf Frost Engin.rlng Development Corporation of Englewood, Colorado* with th e

dynamic analyses of cushions conducted by the Payne Division, WyleLaboratories, Rockville# Maryland. The co-principal investigators were

Mr. Ernest L. Stech of Frost Engineering and Mr. Peter R. Payne of WyleLaboratories. Captain Kenneth C. Flagg, Jr., of the Vibration and Impact

Branch, was the contract monitor fo r Aerotpace Medical Research Laboratory.

The research was performed under Contract No. F33615-67-C-1912 and insupport ot Project 7231, "Biomechanics of ospace Operations", Task

723101, rEffects of Vibration and Impact"rand Work Unit No. 723101053;

beginninlin July 1967 and ending in June £968.

.1

Ili

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 8/134

TABLE OF CONTENTS

SECTION PAGE

I INTRODUCTION 1

PROGRAM DEFINITTON 1

PREVIOUS RESEARCH AND DEVELOPrt NT TN

SEAT CUSHION DYNAMIC RESPONSE 2

RESEARCH ON SEATING COMFORT 3

VIBRATION ISOLATION CHARACTERISTICS

OF SEAT CUSHIONS 6

II Ot'rIMI2N.TION PROCEDURES t' , EJECTION SEAT CUSHIONS 8

FACTORS AFFECTING OPT:MIZATIOS 8

OPTIMIZATION CRITERIA FOR THE PRESENT PROGRAM 19

I'l TEST OF TWO '';TINAL AIA FORCE SEAT CUSHIONS 20

IDENTIFICI " .)-N OF TH E SAMPLES 20

STATIC LOAD-DEFLECTION TESTS 20

DYNAMIC REBOUND TESTS 29

CL)MFORT TESTS 29

DYNAMIC RESPONSE ANALYSIS 35

CONCLUSIONS ON THE OPERAT1O.L AIR FORCE

SEAT CUSHIONS 35

IV DEVELOPMENT OF AN OPTIMUM PASSIVE C']SHION 36

DISCUSSION 36

POLYURETHANE FOAM COMFORT TESTS 36

STATIC LOAD-DEFLECTION TESTS 46

REBOIND RES .EXCE TESTS 46

OPTIMIZATION f.1' THE PASSIVE CUSHION 46

DESIGN OF THE OPTIMUM PASSIVE CUSHICN 57

Lv

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 9/134

TABLE OF CONTENTS

(CONT.)

SECTION PAGE

DEVELOPMENT OF AN INFLATABLE CUSHION 59

DISCUSSION 59

PRELIMINARY DEVELOPMENT TESTS 59

COMFORT TESTS )F THE INFLATABLE CUSHION 60

STATIC LOAD-DEFLECTION TESTS OF I.iF

INFLATABLE CUSHION 74

INFLATION/DEFLATION UNIT DEVELOPMENT AN4D TEST 74

OPTIMIZATION OF THE INFLATABLE SEAT CUSHION 75

VI CONCLUSIONS AND RECOMMENDATIONS 82

CONCLUSIONS AND RECO".JLNDATIONS ON

OPTIMIZATION METHOD 81

CONCLUSIONS AND RECOMMENDATIONS ONMECHANICAL TESTI3G 82

CONCLUSIONS AND RECOMMENDATIONS ON

CO!1FORT TESTING 83

CONCLUSIONS AND RECOMMENDATIONS ON

DYNAMIC ANALYSIS 83

CONCLUSIONS AND RECOMMENDATIONS ON PASSIVE

il;D INFLATABLE CUSHION OPTIMIZATION 84

APPENDIX A ANALOG RESULTS OF ACCELERATION INPUTS TO ASIMPLE MAN MODEL IN SERIES WITH 19 DIFFERENT

CUSHION MODELS 86

INTRODUCTION 87GENERAL THEORY 87

TEST RESULTS AN1; CONCLUSIONS 89

APPENDIX B TEST PROCEDURES 96

LOAD-DE FLECTION TESTS7 97

DYNAMIC REBOUND TESTS 99

TV,F,)SITY PRESSURE MEASUREMENTS 101

COhlPRT TESTS 106

v

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 10/134

L ST or FF1GURES

SA-ume itle Page1

TH E CFECT OF SUAT CUSHIO TUICKNESS ON 2%i? ACCELEAiT.IO .ROM BONDURAUT (2)

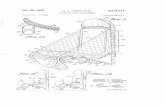

CO:FIGUP~0"10. OF TH E AM'RL 1950's INFLATABLE 4 1SEAT CUSdION - NO T DRAWII TO SCALE

3 PESSUP.E DISTRIBUTIONS ON HARD SURFACE AND O:N 5THE DEMPSEY-IERTZBERG DYNVAHIC CUSHION

HYPOT'ESIZED FELATIONSHIP OF SEAT CUSHION 9STIFFNESS AND THICKNESS TO COMFORT

5 APPROXIMATE COMFORT VERSUS STIFFNESS USING 10

DATA FROM THE STUDY BY SLECHTA ET. AL.

6 VIBRATION ISOLATION CHARACTERISTICS OF TYPICAL 11

SEAT CUSHIONS

7 PROBABILITY Or DAMAGE TO VERTEBRA Li 12

DATA ADAPTED FROM BONDURANT (2) SEAT CUSHION 13 1TESTS SHOWING ATTENUATION AN D AMPLIFICATION

9 THE PrELATIONSIIIP OF INJURY PROBABILITY TO CUSHION 14

THICKNESS FOR A LATEX CUSHION

10 AN EXAMPLE OF SUBJECTIVE COMFORT ESTI!ATES 16EXPRESSED AS A PROBABILITY REFERRED TO A NO-CUSHIONCOND)ITION

11 AN EXAlHPLE OF OPTIMIZATION USING ENDPLATE FRACTURE 17

DATA FROM FIGURE 9 AND COMFORT DATA FROM FIGURE 10

12 AN EXAMPLE OF OPTIMIZATION USING COMPRESSION 18FRACTURE DATA FROM FIGURE 9 AND ACTUAL COMFORT

TEST RESULTS

13 TRANSIENT ACCELERATION I!IPUT 19

14 LATEX FOAM FOIl LJECTION SEAT CUSHION 22

15 POLYURETHA'E F104 EJECTION SEAT CUSHION 22

16 "41L-S-27332A (USAF) LOAD-DEFLECTION VALUES 23FOR THE F101 EJECTION SEAT CUSHION

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 11/134

LIST OF FIGULS (CO9T.)

Number Title Page

17 "IL-S-27332A (USAF) LOAD-DEFLECTIO-1 VALUES 24FOR THE r104 EJECTION SEAT CUSHION

18 HU!-:AN BUTTOCK INDENTATION WITH LEGS EXTENDED AND 25LEGS TUCKED *"OR TIE P!O1 EJECTIO!N SEAT CUSHIOtN

19 HU.A BUTTOCK IIIDENTATION WITH LEGS EXTENDED A!D 26

LEGS TUCKED FOR THE F104 EJECTION SEAT CUSHION

20 IIUHA:Z BUTTOCK INIDENITATIO1 WITH LEGS EXTE3DED AID 27VARYING APPLIED LOADS FOR TH E F101 EJECTION

SEAT CUSHION

21 HUMA' BUTTOCK INDENTATION WITH LEGS EXTENDED AN D 28

VARYING APPLIED LOADS P TE 104 EJECTION

SEAT CUSHION

22 CRITICAL DAMPING RATIO FOP TW O OPERATIO-7AL SEAT 30-

CUSHIONS

23 AVERAGE HOURLY CO!IORT P-ATING FOR TW1O AIR FORCE 32

OPERATIOIAL SEAT CUSH IONS

24 ...RAE HOURLY BUTTOCK DISCOMFOTn FO R TWio 33OPERATIOIAL AIR FORCe SEAT CUSHIO:IS

25 THE NUMBER OF HOURS SUBJECTS ESTIMATED THEY COULD 34CONTINUE TO SIT FO R TWO AIR FORCE OPERATIONAL

SEAT CUSHIONS

26 AVERAGE HOURY COMFORT RATINGS FO R SIX THICKNESSES 40

OF 1.6 LB/FT POLYURETHANIE FOAM

27 TiE NUMBER OF HOURS SUBJECTS ESTIMATED THEY COULD

CONTINUE TO SIT FO R FOUR TINICKNESSES OF1.6 LB/FT 3 POLYURETiHANtF FOA.

28 TH E NUMBEP OF HOURS SUBJECTS ESTIMATED T.FY COULD 41CONTINUE TO SIT FO R TUO THICK'!ESSES OF

1.6 LB/FT 3 POLYURETHAUFE FOAM

29 AVERAGE HOURLY BUTTOCK DISCO';FORT FOR SIX THICK- 42

nESSES O 1.,6 LB/FT 3 POLYURETHA!NE FOAM

30 TUBEROSITY PRESSURE AS A rUNCTIOn OF CUSHION 43

THICKNESS FO R 1.6 L11/FT 3 POLYURETHANE. roAH

vii

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 12/134

LIST OP i1GURES (CONT.)

fltnber Title fia

31AVERAGE HOURLY COMJr,)T RATIUIG AS A FU!ICTIOH O 43

cusHiIOll zciCKFSS FO R 1.6 ,/T POLUREVHA'f FOAM

32 NUMBER or HOURS3 SUBJECTS :.STI~TED 44YCOL

CONTINUE TO SIT AS A FUNRCTION Or flIICiCESs rOR

1.6 LB/Fi 3 POLYUREXTH.fANE FOAt

33 BUTTOCK Dlsc0~o.troT FO R SIX TflICKNEj.SSES or Ulf

1.8 LB/r7'3 POLYURETHANE FOAM.

34 TH E POST-TEST COMFORT RATING or ,rHE- SEAT LV I SIX 45

TitICKESScS oP 1.6 LBFr 3 POLYURETHANE FOAM~

35LA -DELETIO!;URVES FOR !:Z:SOLITE W-.ITHf '10 49I

POLYURZTHA'fE FOAM

36 LCAD-DlEFLECTrO!' CURVES F10R E!JSOLITE tITH 1/2-IZCH 50OF POLYURIETHANE FOAM

37 LOAD-DEFLECTION CURVES FO R ENSOLITE WIT!! 1-INCH 51

OF POLYURETHANE FOAM

1.6LBFi 3 POLYURE THANE FOAM

39 ANALOG CO11MPUTER RESULTS 52

v40 INJURY RISK (CO.'PREnSSIOn FACTURE ONLY) FOR THE 53-rt PASSIVE CUSHION CONFIGURJATION TESTED

41 OPT"INIZATION CURVE OF A 1/4-INCH ENSOLITE- r"

CUSHION WIT11 POLYURETAL FA

42 DOUBLE MASS MODEL OF TH E HUNIAN BODY ON A 55

SEAT CUSHIO:;

43 HYPOTHETICAL OPTIMIZATION SITUATIONl ILLUSTRATING 56

NO0 TRUE OPTIMUMr

44 OPTI!MU?- PASSIVE CUsHIO~l GENIERAL ARPANGE'IENT 58

I.45 NON-EXTEN2SIBLE 2-NC~i SIDEW-ALL It iFLATABLE CUSHION 63

46 EXTENSIBLE InFLATABLE CUSHIONi 64

47 IN3FLATABLE CUSH IO N COurIGURATI03 DEVELORME-rr 6

TESTING

viii

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 13/134

LIST or FIGURES (CONT.)

Number Title Page

48 AVERAGE HOURLY COMrORT RATING FOR FOUR INFLATION 65PRESSURES FO R AN INFLATABLE S,!AT CUSHION

49 NUMBER OF HOURS SUBJECTS ESTIMATED THEY COULD 66CONTINUE TO SIT FOR FOUR INFLATION PRESSURES

FOR AN INFLATABLE SEAT CUSHION

50 AVERAGE HOURLY BUTTOCK DISCOMFORT FOR FOUR 67

INFLATION PRESSURES FOR AN INFLATABLE SEAT CUSHION

51 AVERAGE COMFORT RATING AS A FUUCTION OF CUSHION 68It -LATION' RESSURE FOR AN INFLATABLE SEAT CUSHION

52 NUMBER OF HOURS SUBJECTS ESTIMATED THEY COULD 68CONTINUE TO SIT AS A FUNCTION OF CUSHION INFLATIONPRESSURE FOR ANI NFLATABLE SEAT CUSHION

53 AVERAGE BUTTOCK DISCOMFORT FOR FOUR INFLATION 69PRESSURES FOR AN INFLATABLE SEAT CUSHION

54 POST-TEST COMFORT RATING FO R FOUR INFLATION 69PRESSURES FOR AN INFLATABLE SEAT CUSHION

55 RESULTS OF TESTS CONDUCTED WITH DOUBLE ELLIPSOID 76INDENTOR FOOT (MODIFIED F4C CUSHION)

56 PNEUMATIC AND ELECTRONIC SCHEMATIC OF INFLATION 77CONTROL UNIT

57 SCHEMATIC, ACTIVE CUSHION PNEUMATIC CONTROL 78

58 DEFLATION TIME FOR VARIOUS ORIFICE AREAS FOR AN 79INFLATABLE CUSHION

59 RATE OF TUBEROSITY PRESSURE INCREASE FOR AN 83

INFLA''ABLE CUSHION

60 OPTIMIZATION CURVE OF A 1/4-INCH ENSOLITE INFLATABLE ,I1CUSHION WITH POLYURETHANE FOA4

61 THE DYNAMIC MAN MODEL PLUS SEAT CUSHION 87

62 ANALOG FOR ANALYZING ACCELERATION INPUTS INTO 88

A SIMPLE MA N AND CUSHION MODELS

63 OPERATIONAL ACCELERATION INPUT 89

t ix,.i nnaas

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 14/134

LIST OF FIGURES (CONT.)

Number Title Pae

64 LOAD-DEFLECTION CURVES FOR CUSHIONS 1, 2, 39 90

AND 4 (CONSISTING OF 1/4, 1/2, 3/4, AND1-INCH

ENSOLITE)

65 LOAD-DEFLECTION CURVES FOR CUSHIONS 5, 6, 7, 91

AND g (CONSISTING OF 1/4, 1/2, -/4, AND 1-INCH

ENSOLITE PLUS 1-INCH OF 1.6 LB/Pr,3 POLYURETHANE

FOAM)

66 LOAD-DEFLECTION CURVES FOR CUSHIONS 9, 10, 11, 92

AN D 12 (CONSISTING OF 1/4, 1/2, 3/4 AND 1-INCH

ENSOLITE PLUS 2-INCHES OF i..F LB/FTS POLYURETHAqE

FOAM)

67 LOAD-DEFLECTION CURVE FO R CUSHION 13, AIR FORCE 93OPERATIONAL F104 EJECTION SEAT CUSHION

68 LOAD4DEFLECTION CURVE FO R CU..HXON 14,.AIR FORCE 94

OPERATIONAL F10 EJECTION SEAT CUSHIOI

69 TH E DYNAMIC MASS MODEL WITH TH E LOWER PELVIC 95hMASS INCLUDED PLUS SEAT CUSHION

70 STATIC TEST RIG USED TO OBTAIN LOAD-DEFLECTION 97

CURVES

71 INDENTOR FEET USED IN STATIC TGSTS OF SEAT CUSHION 98

72 IMPACT PENDULUM USED IN DYNAMIC REBOUND TESTS 100

73 MECHANICAL AN D ELECTRICAL CONFIGURATION OF THE 10 1

TUBEROSITY PRESSURE TRANSDUCER

74 ISCHIAL TUBEROSITY CAPACITANCE PRESSURE TRANS- 10 2

DUCER MOUNTED ON A TEST SEAT

75 DIODE BRIDGE CONFIGURATION USED IN SENSING 103

CAPACITANCE CHANGES

76 PORTION OF CALIBRATION CURVE FOR TUBEROSITY 104

PRESSURE TRANSDUCERS

77 TUBEROSITY TRANSDUCER, CAPACITANCE BRIDGE UNIT, 105

AND UTVM READ-OUT AS USED WITH THE TEST SEAT

78 COMFORT TEST SEAT 108

x

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 15/134

LIST OF TABLES

Number Title Page

STATISTICAL SIGNIFICANCE OF THE DIFFERENCES 31

BETWEEN TWO AIR FORCE OPERATIONAL SEAT CUSHIONS

II PHYSICAL CHARACTERISTICS OF TH E 1.6 LB/FT3 38POLYURETHAINE FOAM USED IN COMFORT TESTS

III THE STATISTICAL SIGNIFICANCE OF THE DIFFERENCE 38IN OVERALL COMFORT RATING FOR SIX THICKIESSES OF1.6 LB/FT3 POLYURETHANE FOAM

IV THE STATISTICAL SIGNIFICANCE OF THE DIFFERENCE IN 39NUMBER OF HOURS SUBJECTS ESTIMATED THEY COULD

CONTINUE TO SIT FOR FOUR THICKNESSES OF1.6 LB/FT3 POLYURETHANE FOAm

V THE STATISTICAL SIGNIFICANCE OF THE DIFFERENCE 39

IN BUTTOCK DISCOMFORT FO R SIX THICKNESSES OF1.6 LB/FT 3 POLYURETHANE FOAM

VI TH E STATISTICAL SIGNIFICANCE OF TH E DIFFERENCE IN 39POST-TEST FINAL RATING FOR SIX THICKNESSES OF1.6 LB/FT 3 POLYURETHANE FOAM

VII A COMPARISON OF SUBJECT PANELS FO R THE INFLATABLE 70AND PASSIVE CUSHIONS FO R TH E ZERO-THICKNESS CUSHION

VIII FREQUENCY OF COMPLAINTS DURING HOURLY EVALUATIONS 70OF SEAT CUSHIONS

IX THE STATISTICAL SIGNIFICANCE OF THE DIFFERENCE 71IN OVERALL COMFORT RATING FO R FOUR INFLATIONPRESSURES FO R AN INFLATABLE CUSHIO11

X THE STATISTICAL SIGNIFICANCE OF THE D7liRERCE 71IN NUMBER OF HOURS SUBJECTS ESTIMATED THEY COULD

CONTINUE TO SIT FOR FOUR INFLATION PRESSURES FOR

AN INFLATABLE CUSHION

XI TH E STATISTICAL SIGNIFICAINCE OF THE DIFFERENCE 72IN BUTTOCK DISCOMFORT FO R FOUR INFLATION PRESSURESFO R AN INFLATABLE CUSHION

XII THE STATISTICAL SIGNIFICANCE OF TH E DIFFERENCE 72IN POST-TEST FINAL RATING FOR FOUR INFLATION

PRESSURES FO R AN INFLATABLE CUSHION

x

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 16/134

_ 7--- -2>

LIST OF TABLES (CONT.)

Number Title Page

XIII A COMPARISON OF INFLATABLE CUSHION RATINGS 73AT 50 mm Hg INFLATION PRESSURE TO A 2-INCHCUSHION OF 1.6 LB/FT 3 POLYURETHANE

XIV A COMPARISON OF THE INFLATABLE CUSHION TO THE 73

F104 AND FlOl CUSHIONS

xii

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 17/134

.i

SECTION I

INTRODUCTION

PROGRAM DEFINITION

As aircraft mission durations increase, the problem of comfort assumes

importance in determining operational effectiveness, Missions last fromone to eight hours or more# particularly with inflight refueling. Simul-

taneous with the need for comfort, there exists a requirement to provide

election capabilities from zero altitude and zero speed up to high alti-

tudes and supersonic speeds. In order to achieve parachute opening at low

altitudes and speeds and also to obtain tail clearance at high speeds, the

election seat must accelerate rapidly, but without damaging the occupant.

Seat cushions can increase the hazard of ejection by providing undesirableresiliencies between the pilot and the seat.

Added to the comfort and safety requirements is the need to minimize

discomfort and pilot performence degradation due to inflight vibrations.

The ideal seat cushion should serve as a vibration isolator among its

other functions.

A pr..vm was conducted to study the optimization of seat cushions

fo r both comfort and safety. One portion of the study constrained the

optimization process to a passive system, while the other portion allowed

consideration of active systems. The historical background, optimization

techniques, test methods, and development results are presented in sub-

sequent sections.

For the purpose of this report, seat cushions are divided into two

separate classes as followsi

PASSIVE A conventional-type seat cushion that con-

sists of a foam insert and a cloth cover.

INFLATABLE A conventional-type seat cushion plus an in-flatable section with a manual or automatic

means for inflate/deflate. During normal

flight the cushion is inflated to vhe most

comfortable level for the individual.

A third type of cushion is feasible, the active cushion that vibrates

or pulsates at a rate of one cycle every five seconds or more. Since the

inflatable cushion developed in this program can be automatically inflated

end deflated only for thirty seconds or longer periods, it is not a truly

active cushion# but more properly a cycling inflatable cushion. Therefore,

the terminology "passive" and "inflatable" is used exclusively in this report.

1

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 18/134

-72W_

PREVIOUS RESEARCH AND DEVELOPMENT IN SEAT CUSHION DYNAMIC RESPONSE

The two earliest studies of the effect of cushions on election seatsafety were performed by Latham (1) and Bondurant (2). In both reports,the effect of the seat cushion on acceleration loads was demornstratud.Figure I shows test data analyser, y Bondurant to show a relationship

between acceleration measured on the subject and the thickness of a

specific type of seat cushion.

Latham concluded in his discussion that "It is apparent that the partplay.,;d by the seat cushion or pack is of major significance. A soft uppersurface is required to achieve spreading of the load-orer a wide rea ofthe body-9 yet at- he same time full compression of the pack should beapproached with the-normal Veight of the-pilot (180 to 200 lbs.)* A slowrespondig foam plastLc mateiial 2 to 2-1/2" thick is very-suitable as aseat cushion fo r this urpose. In -addition, the compressibility of theremalder of the seat pack should be reduced to a minimum * . . .

Laiham--recognised the need to tchiovt virtually full compression of thec"ihi6n Under normal I-& loads, a factor to which reference is made- laterin the p'sent tudy.

i'°- TE EEG ON SEAT -USH-ON TH - -NESS

<OF

ILI

CUSHIOI4 THICPKNESS (INCHES)11 FIGURE 1THE EFFECT OF SEAT CUSHION THICKNESS

ON HIP ACCELERATION MROM BONDURANT (2)

2

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 19/134

z - - ' - \' - - , . -

Bondurant summarized his findings as follows: "1. Ejection seat

cushions of low compression resistance and/or great thickness may signi-

ficantly magnify the force acting on the seat occupant during headward

acceleration. 2. During any specific headward acceleration, this magni-

fication of force increases the likelihood of injury, e.g., compression

fracture of a vertebra. 3. The standard MC-l and MC-2 cushions (mediumdensity foam rubber) are not thick enough to constitute such a hazard.

The limited standard A-5 cushion may magnify the force acting on the

subject during headward acceleration. 4. The best available cushions

are made of plastic, with a compression resistance high enough to safely

permit a thickness adequate for comfort." The assertions on accelerationamplification made by Latham and Bondurant indicate the undesirable safety

features of soft, thick cushions.

Cadaver tests were conducted by Hodgson, Lissner, asid Patrick (3) to

determine, among other things, the effect of cushions on observed spinal

loads. They found an increase in the ratio of peak to mean response for

all types of cushions tested when compared to a no-cushion condition.

In 1959, an Air Force technical report dealing with new materials for

seat and back cushions was published (4). Urethane foams were recommended

as seat cushion materials as a result of the reported developments. Mean-

while, the Royal Air Force was also investigating the properties of poly-

urethane foam (5). Both the U. S. and British reports dealt with static

load-deflection data and dynamic damping data.

In the late 1950's and early 1960's, nore attention was focused on

the dynamics of the human body. Goldman and von Gierke (6) summarized

the available information in a review of the area. Subsequently, Payne (7)developed a sophisticated theory of personnel support system dynamics.

Payne's results permitted at least rough estimates of the effect of seat

cushion dynamics on the response of the human body to acceleration input.During the present program, Payne performed additional work on the analysis

of seat cushion dynamics, the results being discussed subsequently (8).

RESEARCH ON SEATING COMFORT

Comfort has been a major problem in seat design for as long as man has

used seats. There is an intuitive notion among seat designers and seat

cushion designers that softness is related to comfort and that it is

effective primarily because it spreads the load across the buttocks,

Latham (i) for example, says "a soft upper surface is required to achieve

spreading of the load over a wide area of the body . . . , . ."

Bondurant (2) makes the following suggestion on cushion optimization, "thebest available cushions are made of plastic, with a compression resistance

high enough safely to permit a thickness adequate for comfort".

However, automobile seat designers were interested in evaluating riding

comfort and proposed specific criteria as early as 1935 (9). In

Sweden, Akerblon published a monograph (10) on the standing and sitting

3

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 20/134

7 I

posture as related to chair design, and he discussed the principles of

comfortable seating and their application in he design of comfortable

seats. Commercial aircraft designers were also concerned with seating

comfort, Cumberland and Bowey (11) published a paper or passenger seat

comfort in 950. Dreyfuss (12) summarized the principles of comfortable

seatdesign in 960. His main points were the provision of a large seat

pan, seat back tilt, and a hip angle of 900 or more. Where possible, a

seat should include th e possibility of sitting in evgral positions

since some discomfort arises out of imnobility, For the bottom cushion,

Dreyfuss feels the body weight should be supported on -the tuberositiesof the pelvis.

Active attempts at improving seating comfort through contouring were

made by Aertzberg i. he late 1940's (13, 14). Pulsating seat cushions

were studied as comfort enhancement devices by Hertzberg as reported in

1956 (15) and 1958 (16). In 1962, Dempsey described in ore detaildevelopment of an inflatable seat cushion for long duration flights (17).

The configuration of the cushion is shown in Figure 2. It consisted of

a foam cushion with two inflatable areas underneath the occupant's tuber-osities, the pressure distribution being varied in his way. The change

in tuberosity pressure with the cushion inflated and deflated is shown in

Figure 3. Dempsey reports a 20 second inflation and 20 second deflation

cycle used on this seat. It as flown in a B47 which incorporated avariable geometry ejection seat. Total mission duration of the B47 flightwas 80 hours and the results of this flight were reported by van Wart in

1961 (18).

A' A

4r A'J_ _

FOAM RUBBER CUSHIOM- 1 ,INLATABLE BLADDER

SECTION A-A

FIGURE 2CONFIGURATION OF THE AMRL 1950's INFLATABLE

SEAT CUSHION - NO T DRAWI TO SCALE

'4

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 21/134

100 LEGE ND

CU~HON APPROXIMATE 01WS~ftuTiomI ON A HARD Su1A$ACE

--APPROflIMATE WSTRI15UTION

ON A bVAi CUS41014

IS60

Th rnil ~HNPRESSUREISTRIBUTIONS ON HARD SURFACE I

therelefplotdisomfrtHisfactors aned orintensnfl that

t relieving seating pressure on th e soft part of the thighs could help tojsome extent*

5

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 22/134

Hertzberg (15) and Dempsey (17) reported attempts at direct measure-

ment of the pressures applied by the buttocks to the seat cushion or seat

pan. Kohara, a Japaners Investigatordiscussed the problems of seating

comfort and the measuren.ent of buttock/seat loads In an unpublished reportin 1965 (23) and subsequently In a magazine article In 1966 (24). Kohara

was able to weasure pressures by means of chemical contact as well as withelectrical Instrumentation, Hertzb rg and Dempsey utilized a she@. ofrubber pressed against a thick piece of plastic with a special lighting

arrangement to obtain pressure gradient data.

Hertzberg obtained subjective evaluations in some of his early work(16)9 but the major attempt at the subjective evaluation of aircraft

seating was accomplished by Slechta and his colleagues at Tufts Universityin 1957 (25). This study Involved the comprative evaluation of 7 seatsin a carefully conceived and executed experimental program* Unfortunately,Slechta and his fellow investigators did not obtain mechanical buttock/

cushion Interface data or tuberosity pressure data. Thus, no physicalinformation existed against which tho comfort evaluations could be

analyzed.

Wachsler and Learner (26) re-analyzed the Slechta data using corre-

lational an d factor analysis techniques* Among other findings, the re-

analysis showed that buttock discomfort was the major eeterminant in

overall seat comfort ratings. The remainder of the Wachsler and Learnerresults are discussed subsequently in this report.

On the basis of the previous research conducted in seating comfort,

the present program was oriented toward the collection of subjectivecomfort judgments and simultaneous physical measurements in an effort

to relate the two. The methods involved an d the results are reportedIn subsequent sections.

VIBRATION ISOLATION CHARACTERISTICS OF SEAT CUSHIONS

Road vehicle designers use seat design to minimize the effects of

vLbration on drivers and passengers. Goldman an d von Gierke (6) re-viewed and summarized the information on road vehicle seating. Most

road vehicle seats consist of two major mechanical deflection segments.There Is usually a layer of material directly in contact with the person'sbuttocks that serves as a load distribution technique. This upper surface

Is then supported by springs that serve as vibration isolators. Engelhadt

*t. al. (27) have published data that Indicates the actual frequency of

seats in at least some automobiles is in the vicinity of three cycles per

second. PrevIous research has shown a major fundamental frequency of the

human body in the vicinity of six cycles per second, so that a 3-cpe seatfrequency would provide reasonable attenuation.

6

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 23/134

Tractor seat design has also been studied intensively in terms of

vibration Isolation. Kohara has also studied the vibration Isolation

requirements in high speed trains (23, 2'). Howeveri the seat cushion

has been used only rarely in military aircraft as a vibration isolator.severe aircraft vibration problems are usually tackled through gustalleviation schemes an d more recently by vibration Isolation tech-niques (28).

21

e

gI

r:

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 24/134

SECTION II

OPTIMIZATION PROCEDURES FOR EJECTION SEAT CUSHIONS

FACTORS AFFECTING OPTIMIZATION

As pointed out previously, a seat cushion is primarily a comfortenhancement device with a possible auxiliary function of providingvibration isolation. However, a poor cushion results in xcessivedynamic overshoot during ejection. Optimization must balance comfort

against risk.

Three hypotheses, based on earlier published research on cushions,were advanced to form a preliminary definition of the problem as

follows:

(1) Increasing th e thickness of a cushic.-, w;.ll increase itscomfort value.

(2) Increasing the thickness and/or decreasing the stiffness mayor may no t increase its vibration isolation effectiveness.

(3) Increasing th e thickness will increase the probability ofinjury during ejection.

These statements were based upon the assumption of a cushion withlinear load-deflection characteristics and linear damping, In reality,

most cushions are nonlinear in lastic an d damped response. Therefore,

tests and analytic procedures had to be used to find how close the hy-potheses on comfort, isolation, and risk were to reality, and the tests

and procedures had to be based on th e best available data and theory.

Comfort

A hypothetical relationship of comfort to cushion stiffness,

shown in igure 4, was generated based upon the opinions and limitedtest results found in the relevant research articles. The line of

reasoning used in enerating the hypothesis explains the shape of thecurves in Figure 4. If a cushion material has a very low stiffness# it

does not support the occupant, and the seating situation is equivalent

to no cushion at all. At the other extreme, a cushion with very high

stiffness supports the occupant away from the rigid seat pan but is in

itself as stiff as the seat pan. Between these two extremes, a maximum

comfort point exists9 being a function of both stiffness and thickness.

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 25/134

The hypothesized relationship was supported, in part, by the

results of Slechtats work (25) on seating comfort. A graph of Slechta's

data is presented in Figure 5. Since no stiffness data was provided

directly and the thickness measurements were hard to interpretq Figure

5 represents a very crude evaluation of comfort versus stiffness.

MAXIMUM

IIITHWICK CUSHICO4 3 To 6 INCH)

MEDIUM CUSHION (2 INCH)

14IN CUSHION. (I INCH)

Z

0

MINIMUM

STIFFNESS OF THE CUSHION (CUSHION RESTING

ON A RIBIb SEAT PAN) - ARSITRAR-Y SCALE

FIGURE 4HYPOTHESIZED RELATIONSHIP OF SEAT CUSHION

STIFFNESS AND THICKNESS TO COMFORT

9

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 26/134

VOLLINThR-4 SITTING 71ME

All ~By 80%/ 0OF SuBJEC-T&

V O SOF04

TOO HARD

DISCOMFORT

OTE FALSE ZERO

0o 100 1000

STIFFNESS (LaS/IN)

FIGURE 5APPROXIMATE COMFORT VERSUS STIFFNIESS

USING DATA FROM THlE STUDY BY SLECHTA ET. AL.

10

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 27/134

Vibration

To act as a vibration isolator, the seat cushion must have aresonant frequency below that of the system to be isolated. Previousresearch (30t 31) has shown the upper body of the human being to havea natural frequency of 6 to 8 cps. Therefore, the cushion should have

a natural frequency of less than 6 cps. with a man sitting on it.

A linear spring deflected to a value, XSt, under one g bya mass, mg has a natural frequency (29) found from

,~- . IU (1)

fh == natural frequency, cps

X = static deflection, inches

The curve for this equation is lotted in igure 6 together with thezone of human body resonance and the approximate maximum thickness rangeof current operational seat cushions. This graph shows the limitedamount of vibration isolation available from a reasonable cushionthickness.

NOTS: FREQuENCYV GtALE - CPSTHICKNESS SCALES .INCMS

w+ t0 ,-APPROXIMAME MAXIMUM RGMAIWNWGS-/1 i TICKNF.SS OF CURRENT CUSHIORS

ZONE OF NATURAL FREQUENCY

W 1:0 1 I '

bE DOOFTHe HUMAN BODY

U ZOETO IEATTEN4UAT6D

bE 0e24 6 10

w REMAIWNN9 CUS14ION -rPICKN4ESS U bJt~a 16A++ 0 DO IS90

TOTAL CUSHION THICKNESS

FIGURE 6VIBRATION ISOLATION CHARACTERISTICS

OF TYPICAL SEAT CUSHIONS

__ _ _----

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 28/134

Another consideration is mportant. Cushion bottoming is un-

desirable from an injury risk standpoint (7). Clearly a large stroke,

soft cushion will bottom out under sustained ejection loads. Any

attenuation of vibratory inputs below 6 cps. will result in a higher

injury probability than a stiffer, thinner cushion. For this reason

plus the practical limit on cushion thickness, the use of a seat cushion

as a vibration isolator should be limited to the attenuation of fre-quencies of 10 cps. or higher.

Injury Probability

The risk of spinal injury during ejection has been evaluated

previously by Stech (31). Vertebra Ll was found to be the weakest

element in the spinal column. The probability of endplate damage, pro-

portional limit failure, and compression failure are shown in Figure 7.

1.0.

ENDPLATEFRACTURE

0.6

PROPORTIONAL

0 LIMIT -

0CCOA.

a.

0.2

.ZRCOMPRESSION

) FRACTURE

00 5 10 15 20 25

STEADi STATE ACCELERATION (G)

FIGURE 7PROBABILITY OF DAMAGE TO VERTEBRA Ll

12

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 29/134

In order to evaluate the effect of cushion dynamics on injury risk,

data published in Bondurant's report were converted to overshoot ratio$ that

is, input peak acceleration divided into peak acceleration on the occupants

Th e resulting curve is shown in Figure 8

An input peak acceleration of 15 G's was taken as an arbitrary butrepresentative value of ejection seat loads. Multiplying the overshootvalues from Figure 8 times 15 G~s gave art estimate of Ithe peak acceleration

applied to the occupant which in turn was used with Figure 7 to obtain

probability of injury values, Throe curves, one for each mode of failure,are presented in Figure 9,

1.4[

I°

1A

1.00

W

.K~

0.I4

04 N TL FALE ZERO

C.USHtON THICK(NESS (INCHES)FIGURE 8

DATA ADAPTED FROM BONDURANT (2) EATCUSHION TESTS SHOWING ATTENUATION AND AMPLIFICATION

13

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 30/134

tNoTrm: BASED 0H4 15 6"S PLAKFEAU AND

USING BONbURA1NIS OVEitsHooT

DATA (2)

ENDPLATE FRACTURE

PROPORTIONAL LIMIT

V L COMPREMOVAt FRACTURE-0

R-40.4

4

0

0 1 2 4

CUSHION THICKNESS (INCH116)

FIGURE 9TH E RELATIONSHIP OF INJURY PROBABILITY

TO CUSHION THICKNESS FO R A LATEX CUSHION

14

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 31/134

Optimization of Inury Probability and Comfort

To summarize, the relationship of cushion thickness (or stiff-

ness) to the important parameters of comfort and injury risk can bemeasured while vibration isolation is a minor function of a cushion.The optimization problem is how to quantify comfort and injury risk.

Comfort must b' evaluated subjectively. Injury probability can beestimated using the approach illustrated previously. The two measures

appear to be incapable of useful combination into an optimization pro-cedure.

The only possible method available is o convert cushion com-fort measures into probability values, a procedure which is feasible.In act, one of the best and only ways to evaluate subjective estimates

is to compare them to a standard condition evaluation through a t ratio

test or some similar statistical measure of significance. If he bench-

mark condition is a rigid seat pan, all foam cushions can be comparedto the stiff pan using the average comfort estimate for each conditionplus the variance in estimates. The result is a probability that the

cushion is in act more comfortable than a rigid seat pan. An example

is shown in Figure 10, taken from comfort tests conducted in this programand to be discussed in more detail later.

Using the data from Figure 9 on injury probability and from

Figure 10 on comfort probability, the curves in Figures 11 and 12 were

generated for endplate fracture and compression fracture respectively.

rocedure involves subtracting the injury probability from th ecomfort probability and plotting the resulting points. For endplate

fracture as an injury mode, the optimization curve is reasonably flat

from 1-1/2" to 2-1/2" with a sharp cutoff at 3".* The curve for com-pression fracture is flat from 2" o 3" ith a sharp drop from 3" to 4".In terms of either endplate or compression fracture, there is no parti-

cular advantage to a thickness greater than 2". So the result of th e

optimization is a thickness of 2" f polyurethane foam for the ejection

conditions specified.

15

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 32/134

I. O

.4Io

~O2i0

a '1 0

0 I 2 3 4

CUSIoN rHIcKNESS (INCHES)

FIGURE 10

AN EXAMPLE OF SUBJECTIVE COMFORT ESTIMATES EXPRESSED

AS PROBABILITY REFERRED TO A NO-CUSHION CONDITION

V 16

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 33/134

OPTIMUM POINT

'TO AVOID ENbPLAT'E

OPTIMIZATION I

i ,

0.

t ~ O.4

0.2 PRtOBABILITY- I01F INJ URtY

0w0I

CUSHION THICKNESS (INCWES)

FIGURE 11AN EXAMPLE. OF OPTIMIZATION USING ENDPLATE FRACTURE

DATA FROM FIGURE 9 AND COMFORT DATA FROM FIGURE 10

17

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 34/134

OPTIMUM "IICKNESS rO AVOID

COMPRESSION FRACTURE

1.0

O'OPROBABILITY i

OFcmOF INr URY-....

I '

0.6.

0.2 PROB AILI.TY

0 I s 4

CUSHION THICKNESS (INCHEs)

FIGURE 12

AN EXAMPLE OF OPTIMIZATION USING COMPRESSIONl FRACTURE

DATA FROm FIGURE 9 AN D ACTUAL COMFORT TEST RESULTS

18

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 35/134

OPTIMIZATION CRITERIA FOR THE PRESENT PROGRAM

In preceding paragraphs, data from various sources were used toillustrate the general procedure to be employed in optimizing the passive

or active developmental cushions which were the goal of the presentprogram. Injury risk estimates for th e developmental cutiions weremade using the acceleratic:n-time history of an operational ejection

seat. Figure 13 shows the acceleration pulse supplied by the Contract

Monitoring Agency and th e smoothed version employed in he analog com-

puter studies, results of which are reported later in his report.

The analog work was performed by Payne Division of Wyle Laboratories

and the methods employed are summarized in ppendix A.

CURVE USED

0.=8 sac 06 IN ANALOG.O r O.B ,E¢.IGSTUDY,

z 0

Q I0

4'4

0 o o.1o 0.19 0.2

~FIGURE 13

TRANSIENT ACCELERATIONI INPUT

1ii

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 36/134

T 4

SECTION III

TESTS OF TWO OPERATIONAL AIR FORCE SEAT CUSHIONS

.IDENTIFICATiOg OF THE SAMPLES-

Two seat cushions from operational aircraft were provided as Govern-ment Furnished Property by th e Contract Monitoring Agency to serve asa comparative baseline for subsequent cushion optimization. Beforeperforming mechanical and comfort tests of the operational seat cushions,a detailed visual inspection was made an d dimensions were taken.

On e cushion was identified as FSN 16607909760, with a Contractor'sPart No. F3460167-C9709. This was a molded latex foam cushion with5/8" cores on 1-1/8" centers. The cushion was contoured with a thickerfront edge than rear edge. Two tuberosity depressions, approximately1/2" to 3/4" deep an d on

8"centers,

were formed into the bottom of thecushion. The shape of the cushion and its general configuration areshown in igure 14. The measured density of the cushion was 4.83 lbs.per cubic foot.

The other cushion was identified as FSN 16609192790. This cushionbore a Contractor's Part No. 140452-1. The cushion was molded of poly-

furethane with a contour similar to that of th e latex cushion. A photo-graph showing the general configuration of this cushion is presentedas Figure 15. The measured average density of the total cushion was6.44 lbs. por cubic foot. On e of these cushions was cut up for visualexamination of its interior after testing, and rather large densityvariations were apparent in the cross-section. Large voids or holesoccurred along the material flow pattern during molding and a high densitycrust was evident along the bottom surface of the cushion.

The first cushion described above was identified as an FIOl ejectionseat cushion, while the second cushion was identified as a F104 ejectionseat cushion. In the remainder of this report, these cushions will bereferred to as th e FlOl and F104 cushions respectively.

STATIC LOAD-DEFLECTION TESTS

A series of load-deflection tests were run using the test methoddescribed in Appendix B to this report. Three indentor feet were used,and the results are plotted in Figures 16 and 17 for the F10

and F104respectively. The load-deflection requirements of MIL-S-27332A(USAF) have been included in the graphs for comparison purposes.

Since the MIL-b-27332A tests are arbitrary laboratory procedures,data were needed on the indentation of human buttocks into the twocushions for c.omparison purposes. Six subjects in turn were seated oneach cushion. Deflection was measured by means of two pins, one under

20

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 37/134

each tuberosity, which were pushed downward through holes in the seat pan.

Measurements were made with the legs in the extended and tucked positions.

The averages for six subjects are plotted in Figures 18 and 19. There

is little difference between the two sitting conditions for the soft latex

foam F1O1 cushion. Tucking the legs does make a difference on tae F104

cushion, and the tucked position approximates the deflection obtaiAed

with all three indentor feet on the static test rig, coming closest to

the double ellipsoid curve. Indentation of the F104 cushion with live

human subjects is less than that obtained in static tests.

Another series of tests were run in which various loads were applied

to the subjects' buttocks in the legs extended position. This was done

by having the subjects relieve part of their sitting weight by raising

themselves on an overhead bar. Then seti of weights ranging from 25 to

100 pounds were held by the subject to obtain higher buttock loads.

The results of these tests are shown in Figures 20 and 21. For the

FIOl cushion, the load-deflection curve obtained in this way is not

the same shape as the laboratory test machine curves. The F104 cushionrom the human subject tests appears to be similar to the indentor

foot curves, although the limited range of testing possible with th e

human subjects does not permit a very adequate evaluation.

The static load-deflection tests plus the human buttock indentation

tests lead to several conclusions that are important to seat cushion

design. First, different indentor foot shapes give different load-

deflection curves. Second, the human buttocks may indent seat cushions

differently when the legs are extended and tucked. Third, human buttock

load-deflection curves may differ from all three of the indentor feet

used in the static tests in this program. These conclusions show that

results obtained in mechanical laboratory tests must be evaluated

cautiously and used with extreme care in design analysis.

21

-___ _-__

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 38/134

Ir

ii FIGURE 14LATEX FOAM F101 EJECTION SEAT CUSHION

I-.F

FIGURE 154 POLYURETHANE F104 EJECTION SEAT CUSHION

22

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 39/134

300NOT: MIL,96-2715%LP4

REQUIR6E UTF

Is ftit A so0mINDEKTfO It SOOT

AHD A4- VAINI~5 ~ T1hC.K SAMPLE

05

~2 0 0 50 SQUARE INCH

w~rswoomI MINIMUM

0L 5%18ms

} ~~REQUIREIWIEV~

pr 5o.

SING1. L IP6*Ib

L0 20 4or s o

0EPLICTION (PERCENT)

FIGURE 16MIL"JS-27332A (USAF) LOAD-DEFLECTION

VALUES FOR THE F101 EJECTION SEAT CUSHION

23

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 40/134

600.i

6 NOTE: MIL- S 2733. A

fREQUIREMENT IsFOR A 50 14.2

INbENTOR FOOT

500ANi A A t Va IN.

400 TH4CK SAM4PLE DOUBLE ELLtPSOIb

dlii INDENTOR FOOT

l 400

8|GNGSLE EL~IPSC=IO

MINIMUMA( sS%, 18o be..)

100-

I.-.-MIL- 5- ./3 A

A.EQUREMENT

0

. 0 20 40 .00 O0

I DEFLECTION (PERCENT)

F.TGURJ 17MIL-S-27332A (USAF) LOAD-DEFLECTIOM

VALUES FOR THE F104 EJECTIONI SEAT CUSHION

24

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 41/134

a00 -I

I

-- LOAb- DEFLECTIOV4

DATA FROM IG. I

250I

~I

1I50I

0ioo LEGS TUC:ED

w/, / I

50 /

_00 0... 0 ,0

0 0.5 -0 1.5 2.0 2.5

BUTTOCK INDENTATI0OIM (It )CH

FIrliRE 18

HUMAN BUTTOCK INDENTATION WITH LEGS EXTENDEDAND LEGS TUCKED FOR THE riol EJECTION SEAT CUSHION

25

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 42/134

(00I

- --- LOAb- DEFLECT ON IDATA FROM FrG.17

I

II I4ooI

I

I- II

'C 00

4J00 I

sodIII0/

20o

ISI

LEGS EKrENbfiP I,

- j.I

300 /~/NLEeS -tUCKEb

3 .000

0

S-- N

04.510 1.0 SO.1

HUMAN BUTTOCK INDENTATION WITH LEGS EXTENDEDAND LEGS TUCKED FOR THE F104 EJECTION SEAT CUSHION

26

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 43/134

300 II

- - -- -- LOAb-bELFLCTION

250 DATA FROM F15.16

0

150 0 --

I

I'.,I

_ 1

t w

S/ / I

/ /

0. 00 - 0 0-

FIGURE 20

HUMAN BUTTOCK INDENTATION WITH LEGS EXTENDED AND

VARYING APPLIED LOADS FOR THE F101 EJECTION SEAT CUSHION

27

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 44/134

600I

..... -- LOAD- DEFLECTIONDATA FROM FIe.1

I

I

II400 I

ILI ImP,

0 oo I I

-_ _ _I I I

a2oo 0 I

(5 200I II

//1

6/ //

100--

0--00 ,

20 4o 6o so 100DEFLECTIOK (PER.EmWr)

0 0.5 I.O i.6 2.0BUTTOCK INDEN-TATION (himcm.ss)

FIGURE 21: HUMAN BUTTOCK INDENTATION WITH LEGS EXTENDED AN D

VARYING APPLIED LOADS FOR THE F104 EJECTION SEAT CUSHION

28

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 45/134

71' T --U- F -K_

DYNAMIC REBOUND TESTS

Since the damping of the seat cushion can affect the dynamic overshootexperienced in the ejection, tests were conducted on the F104 and F1

cushions to obtain an estimate of the damping coefficient for each. Theresults of the rebound resilience teats are shown in Figure 22. The F1O1

cushion, consisting of cored latex foam, exhibits a gradually increasingdamping ratio from impact velocities of 3 feet per second up to 8 or 9feet per second. Th e F104 cushion, with slightly different characteristics,has a constant damping ratio up to 8 or 9 feet per second. Both curves

increase sharply between 8 or 9 feet per second due to bottoming effects.When the cushion bottoms, the pendulum arm is impacting, for all practicalpurposes, Into the rigid support stage used to hold the cushion specimens.Beyond the bottoming point, the damping ratio values are a combination of

the damping of the pendulum arm and structure and of the seat cushions.

These tests illustrate the difficulty in obtaining reasonable damping

coefficient estimates with highly non-linear materials which also exhibit

sharp bottoming characteristics. The difficulty is quite serious. Forexample, the FO14 cushion is bottomed to all intents and purposes at 1Gwith a 200-210 lb. subject on it. This can be seen in Figure 17. Becauseof this characteristic, the damping ratio values shown in Figure 22 for

the same cushion represent the damping from no deflection to to the 1.0 -

1.5 G deflection point for average size occupants. The damping ratio, with

the cushion bottomed, cannot be tested adequately without an extremelystiff impact pendulum.

These tests illustrate the difficulty in obtaining damping coefficient

estimates, but they also raise the question of how important the dampingcoefficient is in real nushions. The precise magnitude of the damping

ratio probably is not very important in analog computer studies, a typicalratio of 0,2 being adequate for such analyses.

COMFORT TESTS

Comfort testing was conducted by having a panel of 14 subjects rate

the cushions over a four-hour sitting period as described in the appendix

on test methods. Each subject was given a pre-test and post-test question-

naire plus an hourly questionnaire. In addition to subjective ratings,

measurements were made of the pressures underneath the ischial tuberosi-

ties of each subject for each cushion.

The average tuberosity pressure for the F104 cushion was 1,21 psi and

for the FO1 ushion, 1.89 psi. These averages represent 28 data points,representing the right and left tuberosity pressures for 14 subjects, Amore complete discussion of the tuberosity pressures and comfort ratings

is presented later in this report, at which time the tuberosity pressurevalues are interpreted more fully.

29

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 46/134

NOTE: MEASUREMENTS MADE WI14 A REBOUND

PEV40ULUM WITH AN EQUtWJALG-T4 MASS

Or- 65 POUNDSS.

BOTTOMINGPOINT (S.FPS)

KJ

0

0FIoI CUSHION(CORED LATEX FOAM)

91

1 I

(MOLDED POLYURITHANE)

0 -

0 2 4 8 to

IMPACT VELOCITY (FPS)

FIGURE 22CRITICAL DAMPING RATIO FOR

TWO OPERATIONAL SEAT CUSHIONS

30

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 47/134

The two cushions were compared using four different measures. Each

subject was asked to rate the degree of comfort of the seat on an overall

basis, to estimate the number of hours he could continue to sit in theseat, and to rate the degree of discomfort of the buttocks. These ques-tions were asked at the beginning of the first hour of the test, andthereafter at the end of each hour. Figures 23, 24, and 25 show the timetrend for each of these three ratings.

Each subject was also required to rate the overall degree of comfortof the seat as part of the post-test questionnaire. The statistical

tests of significance on this rating plus the overall comfort and buttockdiscomfort showed no significant difference between the cushions. Asummary of the statistical tests is presented in Table I.

TABLEI

STATISTICAL SIGNIFICANCE OF TFE DIFFERENCES BETWEENTWO AIR FORCE OPERATIONAL SEAT CUSHIONS

FIOl F104 Molded

Latex Foam Polyurethane

Mean Standard Mean Standard Difference t Signifi-

Rating Error Rating Error in Means Ratio cance

Overall

Comfort 0.90 0.21 0.80 0.18 0.10 0.3616 0.7

Buttock

Discomfort 0.74 0.10 0.74 0.12 0.00 0.0000 None

Post-TestFinal Rating 2.18 0.78 3.15 0.91 0.97 0.8093 0.4

a1

31

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 48/134

i ,..

2(

I.FIG! CUSHION

0 F104 CUSHION 1"

0I DURATION (HOURS )

I -%

w u, CUSNiON

-

FIGURE 23AVERAGE HOURLY COMFORT RATING FOR

TWO AIR FORCE OPERATIONAL SEAT CUSHIONS

32

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 49/134

NO CUSHION

e00

IL

f0 JPo4 CUSHION 010

0 00

0DURAT ION (LUS

HUL FIGURE 24FO

TWO OPERATIOAL F CUSHIO4S4

33

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 50/134

4 .. I..........h

w-

0

NO0 CUUSHION

0 NO CUSHION

0

S 0 2

D URATION 1 URS

0FIGURE 25

THE NUMBER OF H O U R S SUZJECTS ESTIMATED THEY COULD

CONTINUE TO SIT FOR TW O AIR FORCE OPERATIONAL SEAT CUSHIONS

34

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 51/134

DYNAMIC RESPONSE ANALYSIS

Analog computer studies of the tw o cushions were conducted to obtain an

estimate of dynamic response effects. Details of the analog procedures arepresented in Appendix A as reported by Payne Division of Wyle Laboratories.The operational ejection seat acceleration-time history presented earlier

as Figure 13 was used as the forcing function in the computer. Both cush-ions resulted in an amplification of 1.15 times the input peak acceleration,so no difference in dynamic response was found.

ICONCLUSIONS ON THE OPERATIONAL AIR FORCE SEAT CUSHIONS

The F1O1 and F104 cushions can be compared on the basis of the static

load-deflection tests, dynamic rebound tests, comfort tests, and analog

computer results. The F1O1 cushion, manufactured of latex foam, showed anonlinear load-deflection curve which exhibited a damping ratio whichincreased from 0.2 to 0.3 over the range of impact velocities used in thedyanmic rebound tests. Th e F104 cushion deflected to a lesser extent,having approximately 50% of its total thickness left under a 120-poundload. Th e damping ratio of the F104 cushion was relatively constant at0.20 until bottoming began with the impact pendulum. Analog computer

results showed that both cushions exhibited a dynamic amplification of1.15 over a rigid seat pan, no-cushion condition.

I Th e comfort evaluation showed no statistically significant differencebetween the tw o cushionsv although the F104 cushion gave a lower tuber-osity pressure value. No consistent trend was evident in the comfort

I evaluations either, so the cushions must be judged as equivalent in com-

fort ter,

35

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 52/134

Pit

SECTION IV

DEVELOPMENT OF AN OPTIMUM PASSIVE CUSHION

DISCUSSION

Based on a review of literature and the tests conducted on the opera-

tional seat cushions, there was an obvious need for more data on the rela-

tionship of comfort to cushion thickness. Some information was available

and test techniques had been worked out, but very little was known about

comfort characteristics of cushions. The test procedures developed by

Slechta, st. al. (25) and discussed in Appendix B in this report seemed

appropriait for obtaining subjective evaluations. The passive cushion

optimization was initiated by running comfort tests.

POLYURETHANE FOAM COMFORT TESTS

The initial polyurethane foam comfort tests were conducted on 1.6 lb.

per cubic foot foam in thicknesses of 1/2, 1, 1-1/29 and 2 inches. Sub-

sequently, the tests were run on 3 and 4 inch thick foams.

The foam samples were obtained from a local supplier and identified as

.-a.'co Chemical Company, Type 1.75 SE , with a measured density of 1.68

lbs/ft 3 . The material wa s tested in ccordance with MIL-S-27332(A) for

tensile strength, elongation, compression set, and tear resistance. The

results are shown In Table II and the material met all the specification

requirements. The data plotted in Figures 26, 27, 28, and 29 represent

the average hourly ratings for the zero-thickness or no-cushion conditionand th e 1/2", 1", 1-1/2", 2", 3", and 4" thick foam samples. These data

represent the averages for 14 subjects except for the 1" thickness. Inthe latter case, data from only 13 subjects were used since the 14th sub-ject did not stay in the seat for the full four hours.

In Figure 26# the average hourly comfort ratings show a steady decrease

with the thinner cushions being less comfortable almost all the way through

the sessions. The no-cushion condition and the thicknesses up to 1-1/2"

become asymptotic between three hours and four hours. This also occurs for

the 2" foam, although the asymptote is at a much higher rating. The 3" and

4" thicknesses are not asymptotic at the end of four hours.

Figure 27 shows the number of hours subjects estimated they could con-tinue to sit for four thicknesses of the foam. Only the thinner cushions

are shown on this graph. A steady decrease in the number of hours subjects

estimated they could continue to sit is shown in the figure. The data for

the two thicker cushions are shown in Figure 28. The reason for the

difference between the graphs is that the estimating procedure was changed

fo r the subjects after the thinner cushions had been evaluated. During

the tests on the 0" - 2" foam thicknesses, the subjects were allowed to

provide any Initial estimate of hours that they desired. This seemed to

36

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 53/134

lead to a rather variable estimating situation with very little difference

between the cushions as can be seen in Figure 27. Therefore, the pro-cedure was changed on the 3" and 4" cushions. The change involved having

each subject begin his estimation at 8 hours, a direction included in the

subject's initial instructions after being seated on the cushion. Unfor-

tunately, this change did not affect the variability of the scores inthe desired direction.

Th e average hourly buttock discomfort for the four hour sitting periodis hown in igure 29 and as expected, the discomfort increases steadily

over the entire sitting period. Again, the curves for the thinner cushionsseemed to become a.symptotic between three and four hours. In he caseof the buttock discomfort rating, the thicker cushions also seemed tohave reached an asymptote.

Another mode of analysis of the data is o relate the subjective

comfort ratings to cushion thickness. The tuberosity pressure measuredwith the cushion ca n be related to its thickness 9 the data for the

1.6 lb/ft3

foam being shown in Figure 30. As expected, the tuberositypressure decreases as the thickness of the foam increases. In Figures

31, 32, 33, and 34, the average hourly comfort ratingg number of hourssubjects estimated they could continue to sit, buttock discomfort, andpost-test comfort rating are plotted against cushion thickness. The datapoints represent an average of th e hourly ratings presented in he pre-ceding graphs. Each point represents the ratings of 14 subjects on five

different questionnaires for a total of 70 estimates.

The preceding data are of interest in terms of the time trends, thicknesstrends, and tuberosity pressure trends exhibited in the graphs. However,the data are relatively difficult to interpret from a design standpoint.

The comfort rating data can be analyzed by statistical procedures and

additional insight gained into the importance of cushion thickness. Theprocedure adopted was a comparison between the zero-thickness conditionand the six thicknesses of foam tested. A t-test of significance was per-

formed on the data.

Results are shown in Tables III, IV, V, and VI. The values reported

in the tables can be interpreted easily. For example, the differencebetween a zero-thickness cushion and 1/2" of polyurethane foam was foundto be significant at the 0.40 level. This means that there is about a 40%chance that th e two conditions would be rated as equal or that the zero-thickness condition would be rated more comfortable than 1/2" of foam byanother subject panel. The difference between the zero-thickness conditionand 1" of foam gives a significance of 0.10. Again, this implies that

there is a 10% chance that the 1" foam is ot truly different from nofoam at all. In the case of 2" foam versus no cushion, the nhances areonly one in 1,000 that the no-cushion condition is actually more comfortable.

The same form of interpretation is possible with Tables IV, V, and VI.

In effect, these tables provide a basis for evaluating the importance of

the subjective evaluation in terms of human average judgments. Adopting

37

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 54/134

the convention of a 5% significance level, it is evident that the designer

must use at least a 1-1/2" foam thickness and preferably a 2" thickn-ssto achieve a statistically significant improvement over the zero-thickness

condition.

TABLE II

PHYSICAL CHARACTERISTICS OF THE 1.6 LB/FT 3

POLYURETHANE FOAM USED IN COMFORT TESTS

MIL-S-27332 TESTS

Density, Average: 1.68 lb/ft3

Tensile Strength: 18.2 ib/inch

Elongation: 187%

Compression Set: 7.0%

Tear Resistance: 2.78 ib/inch

TABLE III

THE STATISTICAL SIGNIFICANCE OF THEDIFFERENCE IN OVERALL COMFORT RATING

FO R SIX THICKNESSES OF 1.6 LB/FT3 POLYURETHANE FOAM

Difference t Significance

Between Level

0"-1/20 .095 0.400"-1" 2.10 0.050"o-o-/2" 2.18 0.05

4.O-211.76 0.001-31 7.108 0.001

O1-4" 12.287 0.001

38

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 55/134

TABLE IV

THE STATISTICAL SIGNIFICANCE OF THE DIFFERENCE IN NUMBER

OF HOURS SUBJECTS ESTIMATED THEY COULD CONTINUE TO SIT FOR

FOUR THICKNESSES OF 1.6 LB/FT 3 POLYURETHANE FOAM

Difference t Significance

Between Level

01"-1/2" 0.73 0.50

O"-i" 2.63 0.020"-1-i/2" 1.73 0.100"12" 2.83 0.01

TABLE V

THE STATISTICAL SIGNIFICANCE OF THE

DIFFERENCE IN BUTTOCK DISCOMFORT FOR SIX

THICKNESSES OF 1.6 LB/FT3 POLYURETHANE FOAM

Difference t Significance

Between Level

01-1/21 0.68 0.50Off-it 1.41 0.20

0-1-1/2" 1.55 0.200-20 2.77 0.01

o"0-3" 6.275 0.0010"-41" 7.635 0.001

TABLE VI

THE STATISTICAL SIGNIFICANCE OF THE

DIFFERENCE IN POST-TEST FINAL RATING FOR SI X

THICKNESSES OF 1,6 LB/F7 3 POLYURETHANE FOAM

Difference t Significance

Between Level

01-1/2" 0.70 0.50oil 0.47 0.700" - 1-1/2" 1.09 0.30

2.68 0.02

2.789 0.010"-4" 3.368 0.01

39

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 56/134

1.0

0

0

So~~ur,.AT ,(Kuits3 2

0

wNO CUSHiON---

-2.0- FIGURE 26

4AVERAGE HOURLY COMFORT RATINGS FOR SIX

THICKNESSES OF 1.6 LB/FT3 POLYURETHANE FOAM

6Aa

0FOAtA rHCKNESS (INCHES)

0" 2

Iz

0

DURATION (HOURS)

FIGURE 27

THE NUMBER OF HOURS SUBJECTS ESTIMATED THEY COULD CONTINUE

TO SIT FOR FOUR THICKNESSES OF 1.6 LB/FT3 POLYURETHANE FOAM

40

8/3/2019 DTIC Design and Eval of Methods for Optimizing Ejection Seat Cushion for Comfort and Safety 2007

http://slidepdf.com/reader/full/dtic-design-and-eval-of-methods-for-optimizing-ejection-seat-cushion-for-comfort 57/134

I0

1

f o

I,~ 6 % 2 4

Lu

0 FIR-IE-IN THICKo

0Z

o6

itIw

0

DURATION (HOURS)