DSMAC GNPY SERIES HYDRAULIC CONE CRUSHERDSMAC GNPY SERIES HYDRAULIC CONE CRUSHER Capacities...

Transcript of DSMAC GNPY SERIES HYDRAULIC CONE CRUSHERDSMAC GNPY SERIES HYDRAULIC CONE CRUSHER Capacities...

DS

MA

C G

NP

Y S

ER

IES

HY

DR

AU

LIC C

ON

E C

RU

SH

ER

Capacities exceeding 600 tph

High-production, low-maintenance, with the latest in cone crusher technology

Infinite adjustment under load

Adjustable stroke

Constant mainshaft alignment

Enhanced tramp iron relief

2

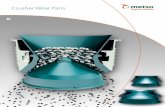

PRODUCT BRIEF INTRODUCTIONDSMAC GNPY Series cone crushers are of advanced

design with a small footprint and high capacity in

relation to size. They have high reduction efficiency

and give very good product shape. With hydraulically

adjusted CSS, the option of automation, a choice of

several different crushing chambers, and many other

high-performance features, each model is versatile,

user-friendly and highly productive.

The DSMAC GNPY Series of cone crushers have a

wide field of use as they can easily be matched to

changes in production through the proper selection of

crushing chamber and eccentric throw. Our cone

crushers are ideal for secondary and tertiary crushing

and the compact and easy-to-service design makes

them a perfect choice for mobile installations.

Our crushers provide automatic overload protection

and can be equipped with our automatic setting

system. This system optimizes cone crusher

efficiency and automatically adapts the crusher to

variations in feed conditions. By continuously

measuring and compensating for crusher liner wear,

the system allows you fully utilize crusher liners and

schedule liner replacements to coincide with planned

maintenance stops. the system also assists in

keeping your crusher choke fed. This maximizes rock-

on-rock crushing, which helps to optimize the quality

of your final product.

GNPY75 Hydraulic Cone Crusher in Nigeria.

GNPY180 Hydraulic Cone Crusher in India

GNPY110 Hydraulic Cone Crusher in Zambia .

3

MAIN CUSTOMOF THE GNPY S

ER BENEFITS ERIES CONES

High Performance - Lowest Total Cost

The hydraulically adjusted GNPY cone

crushers manufactured by DSMAC are

characterized by robust design and high

performance.

In combination with the GNPY crushing

chambers, high motor powers give these

crushers capacities which are in most cases

comparable with those of other, larger

crushers.

The GNPY advantages are:

– Constant feed acceptance capability

– Increased output

– High-quality products

– Increased liner life

– Lowest total cost

DSMAC cone crushers can be equipped with

an automatic setting system, which can

improve performance even more and also

provides integration with sophisticated plant

control systems.

Dsmac GNPY Series - fulfilling all your crushing needs

4

Easy to Handle and Maintain

Much attention has been paid to making our crushers as

easy to operate and maintain as possible. All service and

inspection is carried out from above, which makes the work

easier and the maintenance costs lower.

Robust sealing to the inner crusher mechanics provides

more effective protection against dust and other unwanted

particles – reducing maintenance and increasing the life of

the crusher.

The automatic setting regulation system, not only optimizes

production, it also keeps track of liner wear. This makes it

easy to plan liner changes and minimize interruptions in

production.

In addition to the high capacity, DSMAC GNPY Series cone

crushers are compact, which makes them very easy to move

and to install.

Customer Satisfaction

Building strong customer relationships is highly prioritized in

our daily work to help you keep your Dsmac crushing system

in operation, to improve your uptime and productivity,

lower your costs and provide you with the best, possible total

economy.

- DSMAC has vast experience and teams spanning the

globe in order to provide you with total support.

- DSMAC has a highly efficient, worldwide service and

distribution network to make sure all essential parts and

consumables are available to you according to your needs.

- DSMAC offers intensive training courses tailored to fit your

needs in order to help achieve optimum equipment

performance.

- DSMAC offers efficient, cost-effective repair and rebuilding

services when it becomes necessary, more economical or

environmentally beneficial to repair, overhaul or rebuild the

equipment.

Whatever your needs are, wherever you are and whatever

the time is, DSMAC is here to support you.

Robust sealing to the inner crusher mechanics provides more effective protection against dust and other un-wanted particles –reducing maintenance and increasing the life of the crusher.

Life cycle services -adding customer value

Forging process of Mantle and Concave

5

CRUSHING CHAMBER DESIGN

Crushing cavities are available to suit fine, mediumor coarse crushing duties.

Fine crushing duties. Medium crushing duties.

Coarse crushing duties.

CRUSHING COMPONENTSMechanical Sealing The internals of the Rockstar are fully protected by an advanced sealing arrangement, comprising upper and lower piston rings and twin banks of upper and lower replaceable labyrinth seals.

EccentricThe eccentric is steel casting machined on special fixtures to achieve the optimised throw to maximise production and product shape. The unit is jig drilled to accommodate the rotary seal ring and gear.

All Roller Bearing ConstructionThe Rockstar is equipped with a proven combination of Taper and radial roller bearings. These provide long trouble free service, and minimise friction losses. Utilising these generously proportioned heavy duty bearings also eliminates the need for a large oil tank and ensures consistently accurate alignment of gears, sealing rings and the crushing members themselves.

Cone headThe cast steel cone head in machined internally to accept a large capacity taper roller bearing, and a top radial roller bearing. Externally the lower section is machined to accept the mantle and shaped to allow plastic metal backing to be poured behind the mantle during re-metals.

Concave Support BowlThe cast steel concave support bowl is accurately machined to support the concave ring and is shaped to receive a plastic metal backing for the crushing member. Is lower face is provided with a machined tapered face to form a locked engagement with the upper frame.

Mantle and ConcaveBoth mantle and concave are cast from high grade manganese steel. The both parts are machined to ensure accurate location in their mating parts.

MainshaftThe mainshaft is an alloy-steel forging, fully heat treated for strength. The lower section of the shaft is shrunk into the central boss of the mainframe whilst the upper section is machined and ground to carry the roller bearings.

Gear and PinionThe machine cut bevel gear and pinion are manufactured form alloy steel forgings, the teeth of both c o m p o n e n t s a r e i n d u c t i o n hardened to ensure long life. The pinion is located on the counter shaft by a special locking ring, and the gear is keyed and capscrewed to the eccentric.

Induction hardening of gear teeth provides both enhanced resistance to wear and greatly improves fatigue resistance.

6

GNPY SERIES SPECIFICATIONS

7

Type GNPY 75 GNPY 110 220GNPY 315GNPY

Motor Power, Kw 75-90 110-160 160-250 250-315

Stroke, mm 16,20,25 18,25,32 25,32,40 25,32,40

Feeding size, mm 50(Fine)150(Coarse) 70(Fine)130(Coarse) 70(Fine)180(Coarse) 80(Fine)220(Coarse)

Weight, t 8.5 13.6 19.5 34.7

8

35-45

40-50

60-70

100-120

100-130

150-170

Type

GNPY 75

GNPY 110

GNPY 220

GNPY 315

160-190

Stroke, mm

Capacity, t/h

12 16 20 24 30 36 40

16 50-60 65-75 75-85 80-90

20 55-70 70-85 85-100 100-110

25 60-75 75-90 95-115

18 75-95 80-105 100-125 130-145 150-170

25 90-105 110-130 130-155 155-175

32 140-160 170-190 180-220

25 120-140 140-160 160-180 175-200 200-220 240-265 260-290

32 130-160 170-200 190-225 210-250 250-280 300-330

40 215-245 240-270 270-305 310-350

25 160-185 190-210 230-250 250-270 280-300 320-340 340-370

32 200-220 220-250 265-290 290-320 360-385 450-490

40 230-250 260-280 320-350 370-400 400-430 470-500

CRUSHER PRODUCTION CAPACITY

ZHENGZHOU DINGSHENG ENGINEERING TECHNOLOGY CO.,LTD

ADDRESS:National HI-TECH Industry Unit B Torch Building, Zhengzhou,China.

TEL 0086-371-67897103 0086-371-53738757

FAX 0086-371-60535395 0086-371-65948723

SKYPE dscrusher

Email [email protected]

WEBSITE

::

:::

:www.dscrusher.com

scanning the code above and then entering the website

Questionnaire

To enable us to quote for equipment relative to your particular requirements, it will greatly assist us if all essential information is supplied with the initial enquiry. For your guidance we tabulate the information required : Material .................................................................. Material hardness, or chemical content? ............................................ Feed size ? (mm) ................................................ Your required output size? (mm) .................... Capacity required in tonnes / hour ........................... For more requirement, you can send to me now, or later, to our expert mail [email protected]