Dremel eMag

Transcript of Dremel eMag

-

8/12/2019 Dremel eMag

1/29

DREMEL

PROJECTS& SKILLS

Fixes for Wobbly Chairs,

Grout, & More!Scroll saw tipsand puzzles

Perfect Trim Joints

Gotta-have-emaccessories5

The DremelDreamWorkshopFixes for Wobbly Chairs,

Grout, & More!Scroll saw tipsand puzzles

Perfect Trim Joints

Gotta-have-emaccessories5

The DremelDreamWorkshop

http://www.dremel.com/http://www.dremel.com/http://www.dremel.com/http://www.dremel.com/http://www.dremel.com/http://www.dremel.com/ -

8/12/2019 Dremel eMag

2/29

1 DREMEL PROJECTS & SKILLS

CONTENTS

3

Scroll Saw

Hints & Tips14Crown MoldingSimplified16My weekend with the

new XPR18A day in the life of this new high-performance tool.

8 Three FurnitureFixes22Repairs made faster and easier.5 for the Shop26Gotta-have-em woodworking

accessories.

Dremel Savesthe Day!28A true rotary tool adventure.

DREMEL

PROJECTS& SKILLS

COVER STORY

The DremelDream

Workshop 3Space, storage and comfortits all here!

RegroutBathroom Tile8Replace that ugly old grout in one day.

Scroll Saw Puzzles10Take family photos and turn them into

great gifts.

http://www.dremel.com/http://www.dremel.com/http://www.dremel.com/http://www.dremel.com/http://www.dremel.com/http://www.dremel.com/http://www.dremel.com/http://www.dremel.com/http://www.dremel.com/ -

8/12/2019 Dremel eMag

3/29

Welcome!!!

In this day and age where tax

forms are so complicated we

have to turn them over to

accountants and cars so complexwe need to have them analyzed by

computer, I find great comfort in

tackling tasks I can perform with

my own two hands. After aSaturday afternoon of wood-

working or making headway on

some home

improve-

ment

project,

2 DREMEL PROJECTS & SKILLS

I love standing back and seeing

real results.

And of course, anything

that helps speed up or improvethose real results is a welcome

addition. Thats why we think

youll love this newsletterand

the new Dremel 400 Series XPR.This newsletter is filled with tons

of ideas, and the new XPR is

filled with features youll love as

well. Features like a high-per-

formance motor for better han-

dling and control, a more

PUBLISHED BY HOME SERVICE PUBLICATIONS, INC., 260 Madison Ave, Fifth Floor, New York, NY 10016. Copyright 2005. Unauthorized reproduc-tion in any manner, is prohibited. Art Direction: Evangeline Ekberg. All photography by Bill Zuehlke except for p. 2 (top right), p. 7 (top right),p. 20 (left), p. 26 and 27 (all), courtesy of Dremel.

ergonomic design for comfort,

and new accessorieslike the

planer and MultiSaw attach-

mentsthat will help bring yourskills and projects up a level.

So read on and work away.

At the end of the day youll be

able to turn around and say withpride, Look! I actually made

or fixedor improved that

____. And you didnt need a

computer or accountant to do it.

Andrea AshDirector, Marketing Communications

http://www.dremel.com/HTML/products/tools/xpr.htmlhttp://www.dremel.com/HTML/products/tools/xpr.html -

8/12/2019 Dremel eMag

4/29

The DremelDreamWorkshop

Build yourself a greatplace to do great work.

M

y first workshop was more of anightmare than a dream. It wasin a basement with a low ceil-

ing, so dark that the one bare bulbseemed worthless, and with a dirt floorthat kept it permanently dank. It wasthen that I started dreaming of the per-fect shop.

There is no such thing, of course, butover the years (and a handful of shops),Ive learned that there are some elements

that go into every great shop. Some ofthem, like character, are hard to engineer,but others you can have, even in thesmallest space. Here are four of the cen-tral elements that you can use to makeyour own dream workshop.

3 DREMEL PROJECTS & SKILLS

-

8/12/2019 Dremel eMag

5/29

A Great Workbench

Locking casters make this bench mobile. Italso has a low shelf at one end that allows

the bench to double as an outfeed table for a

table saw. Shelf hardware makes it even

more adaptable.

This bench maximizes storage. The benchstop folds down on special hardware, and the

two side wings swing in on piano hinges to

close up and lock. Hooks hold the open doors

securely to the wall.

A classic workbench for small shops is onethat folds down from the wall. This one uses

a solid-core door for a top, and 1-1/2-in. pipe

for legs. The pipes screw into pipe flanges

on the door.

4 DREMEL PROJECTS & SKILLS

The heart, soul, and often a gooddeal of the guts of a great work-shop are in the bench. Here aresome tips on how to plan, build andimprove your workbench: Against the wall or out in the open?

Against the wall is convenient, becauseyou can have a wall of tools right above it,or a window, but better suited for narrowor small work. A bench out in the open,though farther from tools, can handlelarge pieces on top of it. Build an assembly table. It may seem

odd, but with another table to put yourproject on, its easier to keep your work-bench organized. Assembly tables can beas simple as plywood on a pair of saw-horses, or as complex as the workbench.Many people choose to make the assem-

bly table lower than the bench, so largerwork is at a more comfortable height. Add a vise. Either a woodworkers vise,adjustable-base Dremel D-Vise, or a metal-workers vise, depending on your work.Typically it goes at the left front corner, ifyoure right-handed. If you put in a wood

vise, you can mount a metal vise on a pieceof wood and hold that in the wood vise. Store tools below. Its an efficient use ofspace, it keeps tools and supplies right athand, and it weights down your bench so itwont move around when you pound on it.

A strong top. A layer or two of 3/4-in.plywood or mdf, edged with solid wood,makes an excellent top. A piece of 1/4-in.mdf or hardboard tacked to the top givesyou a replaceable surface if youre hard onthe bench. Old solid-core doors are excel-lent. The best top is tough, flat and stiff.

The DREMEL Dream Workshop

http://www.dremel.com/productdisplay/accessory_template.asp?SKU=2214&Color=99CCFFhttp://www.dremel.com/productdisplay/accessory_template.asp?SKU=2214&Color=99CCFF -

8/12/2019 Dremel eMag

6/295 DREMEL PROJECTS & SKILLS

A Place for Everything

Pegboard rocks. Mount it 1/2 in. from thewall so the hooks have room. In this garage

shop, there are two layers, with the outside

hinged so it reveals the one inside, doubling

the storage space.

Use commercial hardware. These broomholders are perfect for paint brushes and

other handled tools. Magnetic knife racks

are wonderful, as are fishing tackle trays and

plastic parts bins.

Reuse leftovers. Plastic pipe. Scrap lumber.Coffee cans. Detergent jugs. Baby food jars.

Anything you can get a bunch of is fair game.

Though sometimes great work cancome out of a shop that looks likea storm blew through, most peo-ple find it easier to work in a shop whereeverything is neatly stored. Here are sometips to make your shop an organizationalwonder: Use a sample for a label. If youre stor-ing screws in an opaque container, glueone screw to the outside with hot-meltglue to tell you whats inside. Line your walls with wood. Strand-board or plywood, thats 3/4 in. thick,

makes great shop walls because you canattach anything anywhere without hav-ing to worry about finding a stud. Itdoesnt have to go all the way to thefloor or ceiling. Just working height. Doors for deep storage. Useshelves for the things you get at regularly,but closed storage for the rest. The dustwont accumulate so quickly. Buy a plastic parts cabinet. You know,the ones with a bunch of small plasticdrawers. Theyre invaluable for bringingorder to those small screws and bits of

hardware. Make wooden bins. An afternoon spentmaking bins out of pine and plywoodwill give you years of service. You canmake a pile out of a small amount ofmaterial.

On the new

Dremel 400 Series XPR,

slide-out plastic trays keep

all the bits perfectly organ-

ized and accessible.

The DREMEL Dream Workshop

http://www.dremel.com/HTML/products/tools/xpr.htmlhttp://www.dremel.com/HTML/products/tools/xpr.html -

8/12/2019 Dremel eMag

7/296 DREMEL PROJECTS & SKILLS

Make it Comfortable

Task lighting is crucial. You cant do a goodjob on what you cant see. This rig can be

adapted to just about any work surface. A

flood lamp on the wall or ceiling can do

wonders.

Cut the dust. Collect dust at the tool when-ever you can. In this setup, a miter saw has a

small, inexpensive shop vacuum as a dedi-

cated dust collector. Both are plugged into

the same power strip.

Pamper your feet. Standing for hours on aconcrete floors is no fun. Soften the floor

with rubber tiles like these, rubber mats, a

piece of plywood with beveled edges, or

even a sheet of building foam.

A great workshop must be a pleas-ant place to be. Everyone willhave a different wants-list, buthere are a few things to consider: A comfortable chair. Whether its a fold-ing lawn chair an old recliner, its good tohave a place for a visitor to feel comfort-able, or for you to admire your work. Task lighting. You should have lots oflightthe more the better. And whenworking in confined spaces or on proj-ects requiring fine detail, use a DremelFlexLite attachment (#FL400).

A bulletin board. It doesnt have to befancy, but everyone needs a place to keepan inspiring photo or two, shopping lists,and important phone number. A good ventilation fan. Its not the itemthat most people would want to spendtheir dough on, but its worth it. Blowthe dust out, keep it cooler, and mostimportantly, get rid of toxic fumes fromfinishes or solvents. When you use it,make sure theres a source of incomingair somewhere on the other side of theshop. Cross ventilation is best.

Tunes and TV. Gotta have em!! Good clean-up tools. Too many peopleskimp on these, to spend their hard-earned cash on more exciting tools. Butfor us non-saints, if cleaning up is hardwork, it doesnt happen as much. Safety equipment that works. We allknow its better to wear safety glasses,hearing protection and a dust mask. Buttheyre such a pain! The solution is tofind some comfortable ones. Trust us,theyre out there. Its much easy to wearsafety gear if they feel good.

The DREMEL Dream Workshop

http://www.dremel.com/HTML/products/attach.htmlhttp://www.dremel.com/HTML/products/attach.htmlhttp://www.dremel.com/HTML/products/attach.htmlhttp://www.dremel.com/HTML/products/attach.html -

8/12/2019 Dremel eMag

8/297 DREMEL PROJECTS & SKILLS

Make Everything Portable

Clamping tables are a great way to makeportable power tools handier. Mount each on

a piece of plywood, with some 2x2 cleats on

the bottom. Clamp the cleats in the

Workmate.

Locking casters can be added to many toolbases. Often, two locking casters with

swivels, and two non-locking casters are the

easiest solution. Larger wheels are always

better.

Some of my favorite portable tools are fold-ing metal sawhorses. A piece of 2x4 screwed

to the top makes sawing safer. Here they are

attached to a piece of plywood for an easy-

to-store assembly table.

In the real world, we fight for space inour shops, no matter how big theyare. Here are some survival tips: Get double use out of anything you can.If a stool can function as a work support,you just saved some space. Consider benchtop power tools. Thesehave come a long way, and are now morepowerful, more accurate, and more fullyfeatured than ever. Commercial mobile bases. Wood-working suppliers sell super-strongrolling bases for $50, that are sturdy

enough to hold anything, and lock inplace rigidly. Some can even be cus-tomized to hold large workbenches ortable saw/outfeed setups. Know your casters. Larger casters gen-erally roll easier, especially if your floor isless than perfectly flat. Normal lockingcasters that you can get in any home cen-ter are great for most uses. However, theyonly lock the wheel, not the swivel, sothey can still wiggle. When you wantcomplete rigidity, look for locking castersthat lock both parts.

Think wheelbarrow. Many items can bemade portable by putting two non-swiveling casters at one end, and twohandles at the other, so the rig acts like awheelbarrow. When you set it down, itsvery stable. Organize your scraps. Make some binsto hold useable wood, and throw outwhatever doesnt fit.

When it comes toportability, few tools compare to the

Dremel XPR system.The tool, all acces-

sories, and every bit and blade youll

ever need in one easy-to-carry case.

The DREMEL Dream Workshop

http://www.dremel.com/HTML/products/tools/xpr.htmlhttp://www.dremel.com/HTML/products/tools/xpr.html -

8/12/2019 Dremel eMag

9/29

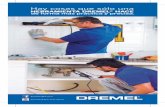

Does the grout in your bathroom

look mildewy and gross? Piecesof it falling out?? In the past,renewing old grout has involved longhours of hacking away at it with a tinygrout saw. You can simplify the job bypurchasing a $20 grout removal attach-ment that attaches to a Dremel rotarytool. It has a high-speed carbide bit that

effortlessly chews away old grout, andguides that keep you from chipping thetile edges. Make sure to wear safety glass-es while grinding (Photo 1). Youll stillneed to purchase a grout saw ($15). Use itto scrape out edges and corners and toclean out the joints.

The first step is to protect the surfaceof your tub. Use a plastic tarp or drop-cloth, held in place with masking tape,with cardboard or thin plywood on top.

8 DREMEL PROJECTS & SKILLS

RegroutBathroom

TileNew-looking tile in anafternoon

-

8/12/2019 Dremel eMag

10/299 DREMEL PROJECTS & SKILLS

1Remove areas of chipped or stained groutusing a Dremel tool grout removal attach-ment and 1/16-in. grout removal bit.

2 Mix new grout to peanut butter-like con-sistency, then use rubber grout float towork grout into seams and clean face of tile.

Then grind and scrape all the old groutyou can get out. Vacuum up any dust or

debris left after the grinding process. Takea chunk of your current grout to a homecenter or tile shop to find a match. Whileyoure there, buy a latex additive to mixinto the new grout to make it moredurable. Mix the grout slightly thickerthan peanut butter and then apply it tothe tiles, using a grout float (Photo 2). Letthe grout set up for approximately 20minutes until a film develops over thetile, then clean the area as shown inPhotos 3 and 4. This is not a good time togo on a break and get distracted, becauseif the grout dries too long, it can be diffi-cult to remove from the tiles.When using

the float and the sponge,move at a 45-degree angleto the grout lines. Thiswill keep the tools fromremoving too much.After the grout hasdried for a week,protect it with a

acrylic groutsealer.

3 Once grout has firmed, use a sponge tosmooth grout lines and remove grouthaze from face of tile.

4 Use a coarse cloth to remove remaininggrout haze and to buff the tile. Seal groutseams following manufacturers directions.

-

8/12/2019 Dremel eMag

11/29

Is there a puzzle fancier among yourfamily or friends? Maybe a puzzleaddict?If so, heres a great gift project: a cus-

tom puzzle made from a vacation photo,school photo, or even a thick magazine

page. Its easy to make, once you get theknack, and even a beginning woodwork-er will be making great puzzles in just afew hours.

You do need a scroll saw, however, tocut out the puzzle pieces. Scroll sawsused to be expensive tools for specialists,but several models are on the market

now that sell for under $250, and accord-ing to our tests, they work fine for cut-ting puzzles.

You can make a puzzle from almostanything thats printed on good-quality,heavy paper. Enlargements of photo-graphs work fine, but stay away frompictures printed on thin paper, likenewspaper, because they wrinkle easilywhen glued.

Scroll SawPuzzlesTurn your favorite photo

into a puzzle.

10 DREMEL PROJECTS & SKILLS

-

8/12/2019 Dremel eMag

12/29

PUZZLES FOR ADULTS OR CHILDREN

Preschool children can assemble puzzlesconsisting of 25 larger size pieces. Foradults, a puzzle with 250 to 400 piecesmakes for a moderately challengingevening of entertainment. However,

dont try to cut more than two pieces persquare inchits too hard to cut andhandle such tiny pieces.

You can easily cut an 11 x 14-in. photointo 300 pieces using a scroll saw with athroat depth of about 15 in. A 16 x 20-in.picture can be cut into 600 pieces, but thesaw must have a throat of about 20 in.The saws throat depth is the distancebetween the blade and the back of thearm that holds the blade.

Caution: Puzzle pieces that aresmaller than 2 x 2-in. are a chokinghazard to children under 3, so eithermake the pieces larger, or warn therecipients of your puzzles not to letthe pieces get in the hands of chil-

dren under 3 years old.

SCROLL SAWS AND BLADES

Besides a scroll saw, youll need at least 10thin, fine-tooth blades ($3) for everypuzzle. The blades break frequently asthey get dull or pinched, and though thenoise will startle you the first few times,after a while you get used to it. We foundthat common 5-in. plain-end blades likeDremels 16440 worked well. Visit

11 DREMEL PROJECTS & SKILLS

1Apply three coats of any wood finish toone side of a piece of thin plywood. Thiswill be the back of the puzzle.

2 Press the picture into the glue with asqueegee. Use light pressure to workout any air bubbles trapped under the paper.

www.dremel.com for more information.Use blades that are less than .030 in. wideand .011 in. thick, with 25 to 30 teeth perinch.

Its important to adjust the blade ten-sion correctly. If you cut some scrap ply-

wood into practice puzzle pieces, you canexperiment to find the right tension.Before you start cutting, adjust the sawstable so its exactly perpendicular to theblade.

USE THE RIGHT KIND OF PLYWOOD

Your photo must be glued to a ply-wood backer. The best material is 1/8-in.or 5mm plywood thats flat and smoothon both sides. The core should be made

3 Apply two coats of clear acrylic floor waxwith a paper towel wetted with the wax.Apply the wax with straight, light strokes.

http://www.dremel.com/html/products/accessories/plain_end_blades.htmlhttp://www.dremel.com/http://www.dremel.com/http://www.dremel.com/html/products/accessories/plain_end_blades.html -

8/12/2019 Dremel eMag

13/29

-

8/12/2019 Dremel eMag

14/29

Random cutting is slower, but more funto do, and it makes puzzles that are more

challenging to assemble. Try both ways.With either method, you should first

determine the average size of the puzzlepieces by dividing the area of your pic-ture by the number of puzzle pieces youwant. Dont cut more than two pieces persquare inch.

Good puzzles have pieces that locktogether with little ball-and-socketjoints (Fig. A). As you cut your puzzle, tryto have at least one ball or socket on eachside of every piece. A puzzle piece withfour sides, for instance, should have atleast four balls or sockets.

CUT OUT THE PUZZLE

Its easy to describe how to cut out yourpuzzle, but it does take practice. Use thetest picture you mounted earlier, and per-haps some scrap plywood, for practice.

Make all your scroll saw cuts withthe picture side facing up. Start by cut-ting away the excess plywood and pic-

ture borders, and any edges damagedby the binder clips. If youve chosenstrip cutting, follow the steps shown inFig. B.

If you decide to random-cut yourpuzzle, start by cutting the picture intofour smaller sections (Photo 4), makingplenty of balls and sockets as you cut.Knowing the average size of the finalpieces will help you gauge the numberand placement of these joints. Then,

working with one section at a time, cutoff each puzzle piece to its final size(Photo 5), just cutting balls and socketsfreehand. As you cut off the pieces,reassemble them on a piece of card-board or plywood so you wont misplacea piece.

If you break a blade, replace the bladeand start cutting from another edge

until you meet the point where theblade broke.

Once the entire puzzle is cut, place apiece of cardboard or plywood on top ofthe puzzle and flip the puzzle over.Inspect the puzzle back for any rough sawcuts, and sand them smooth.

Put the pieces in a good box, and thepuzzle is ready to gift wrap.

13 DREMEL PROJECTS & SKILLS

FIGURE A Random Cutting

Begin by cutting the plywood into four

pieces. Then cut each piece into smaller

ones, by eye, so there is a ball-and-socket

joint on each side. This method takes prac-

tice, but produces a challenging puzzle.

FIGURE B Strip Cutting

With this method, cut the plywood into

strips, making a ball-and-socket joint at reg-

ular intervals. Then cut each strip into

pieces, making a joint on each piece. This

method is easier, but so is the puzzle.

-

8/12/2019 Dremel eMag

15/29

14 DREMEL PROJECTS & SKILLS

Scroll Saw Hints & TipsIron On a PhotocopyIf you normally use spray adhesiveto attach patterns to the wood forscroll sawing, consider this alterna-

tive. With an iron set on high andno steam, transfer a photocopiedpattern right onto the wood.

Stay-in-place scroll saw patternsHeres a great way to speed up scroll sawing jobs. Apply all-purpose sprayadhesive in a light, uniform layer on the back of the pattern, then pick it up

and immediately apply it to the wood youll be sawing. The pattern remainsadhered as you saw but easily peels off when youre done.

-

8/12/2019 Dremel eMag

16/29

15 DREMEL PROJECTS & SKILLS

Blade CaddyHeres a handy tote for ScrollSaw blades fashioned from ascrap of 2x6, a piece ofplywood, and two peg-board multiple-tool hold-ers. Cut the curved tips offthe multiple-tool holders

with a hacksaw so theywould sit flat against theplywood. Attach the hold-ers to the caddy withcable staples. Thesesmall plastic tubes areperfect for holding Scroll

Saw blades. Wrap some mask-ing tape around each tube andwrite the blade size on it.

Scrollwork Finishing BathFor all you scroll sawers out there, heres a slick finishing

tip. You know how tough it can be to brush or spray finishinto all those tiny sawed-out areas? Well, give your handi-work a bath instead! The finish will get into all those littleareas and seal the wood nicely. Wipe off drips and excessfinish with a clean shop cloth and set your project asideto dry. Then, brush or spray the final coats on the facesand sides only. Trying to build up the finish on the insideareas is unnecessary.

Sanding with the Scroll SawHeres an ingenious way to sand intricate scroll sawwork. Take a strip of emery cloth (a gray sanding clothused by plumbers and machinists), 1/16 to 1/2 in.wide, and clamp it in your scroll saw just as you

would a blade. You may have to fiddle a bit to get thelength of the strip just right, but once you do, it workslike greased lightning.

-

8/12/2019 Dremel eMag

17/29

16 DREMEL PROJECTS & SKILLS

Crown MoldingSimplified

Tips and techniques forelegant results

Few things can transform the look ofa room as quickly as crown mold-ing; and few tools can transform

crown molding as quickly as a Dremeltool. You can use the Dremel tool to cut,sand and fine tune. Here are a few tips forperfect results:

COPINGTHE SECRET TO GREAT-

LOOKING INSIDE CORNERS

You might think the best way to installcrown molding on an inside corner is tomiter both pieces at a 45 degree angle andbutt them to one another. The problemis, most inside corners arent square or

straight, making it almost impossible toget a clean looking joint that way.

The secret to tight inside corners is to

-

8/12/2019 Dremel eMag

18/29

-

8/12/2019 Dremel eMag

19/29

My WeekendWith an XPRA tool so busy it needs a

Palm Pilot

My wife is a queen of multitask-ing, running her business,being there for our not-quiteadult kids, and managing our busyhousehold. But if shes the queen of mul-titasking, our Dremel XPRis the king. It

seems like every weekend Im using it forhome improvement, woodworking andfurniture repairs. This one little tool cangrind, cut, clean, sharpen, smooth,engrave and more.

Im a weekend warrior, and havebeen for about a thousand weekends. Andsince our latest house is over 150 years

old, theres no end in sight. In our house,there isnt a floor, wall or ceiling thatslevel, plumb or straight. That means lotsof fine-tuning when it comes to installingnew stuff or fixing the old. Heres how aweekend of home improvement went forme recently, and some of the jobs I didwith with this new Dremel XPR.

18 DREMEL PROJECTS & SKILLS

http://www.dremel.com/HTML/products/tools/xpr.htmlhttp://www.dremel.com/HTML/products/tools/xpr.htmlhttp://www.dremel.com/HTML/products/tools/xpr.htmlhttp://www.dremel.com/HTML/products/tools/xpr.htmlhttp://www.dremel.com/HTML/products/tools/xpr.htmlhttp://www.dremel.com/HTML/products/tools/xpr.html -

8/12/2019 Dremel eMag

20/29

FIX AN OUT-OF-ALIGNMENT

DOOR STRIKE

When doors dont latch, chances are thetongue or throw of the doorknob ordeadbolt doesnt align with the strikeplate; another common old house ail-ment. My first step was to tighten thescrews holding the hinges to both the

door and door jamb. Two holes werestripped, so I replaced the screws withlonger ones that could bite into the 2x4framework beyond he jamb.

That helped, but didnt completelyremedy the problem, so I enlarged theopening in the strike plate so the tonguewould fit. I used a small grinding stone to

enlarge the lower edge of the opening in thestrike plate, tested, then repeated as needed.

One down, six more tasks left to go.

19 DREMEL PROJECTS & SKILLS

PLANE DOORS AND

INSTALL CABINETNo matter how many shelves we install orhow much stuff we get rid of, we neverhave enough storage space; especially inthe bathroom. Installing a simple cabinetand laminate top seemed to be the per-fect solution; we could store suppliesbelow and fold clothes above.

The double doors on the cabinet wewere installing rubbed one another whenclosed. (Okay, okay, doors on a new cabi-net should align, but the price at the cab-inet outlet store was just so irresistible!)The solution? Break out the XPR Planerand shave a little off the edge of each

door where they meet. Back-beveling

angling the planer in order to remove alittle more wood off the back than frontof the door edgecreated a smaller-looking gap while still allowing the doorsto swing freely.

Few (if any!) walls in our old houseare straight or plumb, so to get a tight fitwhen installing a cabinet, scribing an

edge to fit the contour of the wall wasnecessary. I butted the cabinet to the wall,used a compass to transfer the angle tothe scribe strip on the edge of the cabinet,then used the XPR Planer to removewood right up to the line.

Ahh, perfect fit.

After butting the cabinet against the walland scribing the angle along the edge, use

the XPR Planer to remove wood until the

cabinet fits tightly.

Remove an equal amount of wood from theedges of both doors until the gap between

the two is even. Apply a clear finish to the

planed edges for protection.

Saturday, 9:08 AMFriday, 8:24 PM

StrikePlate

BackBevel

http://www.dremel.com/HTML/products/attach.htmlhttp://www.dremel.com/HTML/products/attach.htmlhttp://www.dremel.com/HTML/products/attach.htmlhttp://www.dremel.com/HTML/products/attach.htmlhttp://www.dremel.com/HTML/products/attach.htmlhttp://www.dremel.com/HTML/products/attach.html -

8/12/2019 Dremel eMag

21/29

stone made the job a snap. For informa-tion on removing and balancing theblade, visit www.dremel.com/projects-display/Display.asp?ID=151 .

And since I really dig sharpen-ing, I tuned up a few other tools

while I was at it. I customized myshovel by cutting a root-cutting notchinto the tip, then sharpening the bladefor easier working. My know-it-allneighbor tells me now it will be eveneasier for me to cut through his cabletelevision line for the third time.

With an old house theres one guarantee:

Every bolt in the joint will either be rust-ed or rounded over. When I encounterhard-to-remove bolts, I use this trick: Iuse my Dremel with a fiberglass-rein-forced cutting wheel to cut a slot into thehead of the stubborn bolt. Then I use thebiggest straight-slot screwdriver I canfind to loosen it. If that doesnt do the

trick, I apply penetrating oil to thethreads, wait a while, and try again.

20 DREMEL PROJECTS & SKILLS

SHARPEN LAWN TOOLS

Sharp tools work faster and produce bet-ter results. Ive finally learned that a fewminutes spent sharpening now will savetime and frustration down the road.

My know-it-all neighbor tells me asharp mower blade is critical for a

healthy, attractive lawn. Dull blades shredgrass, leaving it more susceptible to dis-ease and in need of more nutrients andwater to repair the damage. He sayssharpening a blade three times a year isusually enough to maintain a good cut-ting edge; unless you mow lots of rocks!Balancing a blade, so its of equal weight

on each side, is also critical. The DremelLawn Mower Sharpener (model 675)along with an aluminum oxide grinding

Saturday, 10:32 AM Saturday, 1:27 PM

Root-cuttingNotch Cutting

Wheel

I know this was supposed to be a whole

weekend of home improvement, but aguys gotta have a little time to relax. Sothis evening, Im putting my XPRaway towatch a movie with the family.

Saturday, 3:37 PM

http://www.dremel.com/projectsdisplay/Display.asp?ID=151http://www.dremel.com/projectsdisplay/Display.asp?ID=151http://www.dremel.com/projectsdisplay/Display.asp?ID=151http://www.dremel.com/productdisplay/att_template.asp?SKU=675&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=675&Color=99CCFFhttp://www.dremel.com/HTML/products/tools/xpr.htmlhttp://www.dremel.com/projectsdisplay/Display.asp?ID=151http://www.dremel.com/projectsdisplay/Display.asp?ID=151http://www.dremel.com/HTML/products/tools/xpr.htmlhttp://www.dremel.com/productdisplay/att_template.asp?SKU=675&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=675&Color=99CCFF -

8/12/2019 Dremel eMag

22/29

KEEP PLUGGING AWAY ON THE

FAMILY ROOMThe thought of finishing the family room(before the kids head off to college andwe still have a family) seems like a logicalgoal. So I love tips and tools that makethe job go faster.

The task at hand this weekend washanging drywall and installing paneling.

Again the Dremel XPR was a real timesaver.

In the past when Ive installed dry-wall, the most time consuming partand the part where I was most likely tomake a mistakewas cutting holes for

cutting the paneling and is much moremaneuverable than my big jigsaw. Itsvery good for complex shapes, like theedge I had to cut where the paneling

meets the stone around the fireplace.

21 DREMEL PROJECTS & SKILLS

Sunday, 1:19 PM

Start in the center, find the inside edge with

the bit, hop 1/8-in. over to the outside of the

box and trace around it counterclockwise.

the electrical boxes. Id measure and

mark the location of each box, cut theopening with a keyhole saw, then installthe drywall and hope the opening was theright size and in the right place. But Ivelearned an easier way is to simply markthe approximate center of the box withan X, then use a Dremel tool to do thejob. I install the cutting guide shroud

(model 565)and drywall cutting bit andplunge it into the center of the X. I movethe tool until the bit touches the insideedge of the box, then hop over to the out-side and trace the edge of the box in acounterclockwise motion. I get a perfectcutout each time.

For cutting the electrical box openingsin the paneling, I simply trace the outlineof the electrical box onto the panel, thenuse a multi-purpose bit to cut out theopening freehand. For larger taskslikecutting out heat register openings or

curvesI install the MultiSawattachment (left) and cut

away. The XPR hasplenty of power for

Mark out the location of the box, then use

the cutting guide and multipurpose bit to

saw out the opening.

OK, thats it. Im done for this weekend.Ive still got the trim to put up, but Ivegotta leave something for next week!

Sunday, 6:37 PM

http://www.dremel.com/HTML/products/tools/xpr.htmlhttp://www.dremel.com/productdisplay/att_template.asp?SKU=565&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=565&Color=99CCFFhttp://www.dremel.com/HTML/products/attach.htmlhttp://www.dremel.com/HTML/products/attach.htmlhttp://www.dremel.com/HTML/products/tools/xpr.htmlhttp://www.dremel.com/HTML/products/tools/xpr.htmlhttp://www.dremel.com/HTML/products/attach.htmlhttp://www.dremel.com/HTML/products/attach.htmlhttp://www.dremel.com/productdisplay/att_template.asp?SKU=565&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=565&Color=99CCFFhttp://www.dremel.com/HTML/products/tools/xpr.html -

8/12/2019 Dremel eMag

23/29

1Fix a Wobbly

Chair 3Reupholstera Slip Seat3 Furniture Fixes

2ReplaceVeneer22 DREMEL PROJECTS & SKILLS

-

8/12/2019 Dremel eMag

24/29

23 DREMEL PROJECTS & SKILLS

1Hold chair upside down. Strike the seatfirmly with a dead-blow hammer. Workaround the chair, slowly loosening each joint.

2 Remove dried glue from mortise using adrum sander and Dremel tool. Dont over-enlarge the mortise or the joint will be loose.

4 Clamp legs, rungs and seat all at once.Draw joints tight and wipe off glue with adamp cloth. Check alignment on a flat surface.

Awobbly chair means one thing:Joints between the legs and therungs have broken free. Not justoneseveral. The only fix is to complete-

ly disassemble the chair and reglue it.Youll save time and avoid frustration

if you label every part to make it easier toput them back together). Use maskingtape and a simple numbering and letter-ing pattern on the rungs, with all num-bers and letters facing forward. Left andright are as you face the front of the chair.

A deadblow hammer ($14; Photo 1) isa must for easy chair disassembly. Somejoints easily fly apart. Others refuse to letloose. Always start lightly and increase theforce as needed. Youll clearly see, and feel,the joint move when the glue bond breaks.

Many legs have nails or screws hold-

ing them to the seat. Not all are obvious;look for small screw or nail holes filled tomatch the chair finish. Youre likely tobreak the rung if you miss a well-hiddenfastener. You may have to dig them out.

New glue wont bond with old glue, sosand down to bare wood in the joints.The key to reassembly is to work quickly,

because the glue begins to set in a fewminutes. When youre finished, yourchair will be as solid as it was when new.

3 Apply a light coat of yellow carpentersglue to both the ends of the rungs andthe mortises (holes). Reassemble quickly.

Fix a WobblyChair

Mortise

-

8/12/2019 Dremel eMag

25/29

24 DREMEL PROJECTS & SKILLS

1Cut a straight-lined edge on the chippedveneer using a utility knife or Dremel tool.Cut parallel to wood grain to hide the seam.

2 Test stains on a scrap piece of veneer toget a good color match. Sand the back ofthe veneer if you need to adjust the thickness.

4 Test-fit patch and trim as necessary. Applycontact cement to both surfaces, allow todry, then install and press patch firmly in place.

5 Hide the seam with a furniture touch-upputty stick. Varnish the patch beforehandsince finish wont adhere to the oily putty.

Chipped or missing pieces ofveneer can be replacedit justrequires patience and careful fit-ting. You can use your Dremel for prep

work (Photo 1), cutting the replacementpiece (Photo 3), or shaping the veneeronce its in place (Photo 4).

The contact glue applied to the veneerand furniture surfaces makes pieces hardto reposition once contact is made, sowork carefully.

3 Cut a replica of the damaged area from atemplate. Make the template from a paperrubbing of the chip-out using the side of a pencil.

ReplaceVeneer

-

8/12/2019 Dremel eMag

26/29

25 DREMEL PROJECTS & SKILLS

1Cut new batting, 2 in. oversized on allsides, using the seat bottom as a pattern.Most large fabric stores carry batting.

2 Secure the batting by pulling it tightaround the chair bottom and fastening itwith 1/2-in. staples. Trim the excess.

4 Staple fabric, completing front edge first,back edge next, the two sides last. Startstapling at center and work towards corners.

5 Fold fabric at corners, then secure withstaples. Trim excess fabric with sharpscissors after all corners are complete.

3 Mark center lines on chair bottom andfabric, then match them so fabric pat-tern runs straight from front to back.

ReupholsteraSlip Seat

Chairs with removable seats canusually be reupholstered with theold fabric in place. If the screwssecuring the seat to the chair frame are

stripped or stuck, cut through themusing a Dremel tool and cutting wheel. Ifthe old material is shot, remove it, cut apiece of 1-in. foam the exact shape of theseat bottom, then apply it along with thenew batting and upholstery as shown. Besure to mark center lines on both chairbottom and fabric, and line up the marks.

-

8/12/2019 Dremel eMag

27/29

PlungeRouter BaseThis handy littlegizmo allows you to

turn your rotary toolinto a plunge router;super handy for carving signs orcutting grooves. The clear base pro-vides good sight lines, while a spe-cial edge guide helps you cut deco-rative grooves parallel to theedges. Guides for cutting circular

patterns are also available.

Our old house doesnt have roomfor a big workshop with a lot oflarge stationary tools, but thatdoesnt mean I cant tackle my favoritepastime: woodworking. Ive found lots ofways to optimize space in a small area(see page 7 for some examples), and if Ipick the right project and tools I can cut,carve, sand and create to my hearts con-tent.

The most critical accessory to have inwoodworking is good old common sense.Wear safety goggles, dust mask and hear-ing protection, and always keep your

hands and body away from spinning bits.Keep blade guardslike those shown onthese two pagesin place. Here are a fewother great Dremel tool woodworkingaccessories.

Router TableRouters are a fun, versa-tile tool; they can take aho hum project and turnit into something with

flair. They can createdecorative edges andadd grooves and other profiles topicture frames, signs and toys.

Using the Dremel tool in ashaper/router table (#231)allows forgood visibility while working. Itsalso the most accurate way to add

decorative edges to narrow pieceswhere a hand-held router would bedifficult to hold level.

26 DREMEL PROJECTS & SKILLS

5 For theShopGotta-have-em

woodworking accessories

1 2

http://www.dremel.com/productdisplay/att_template.asp?SKU=335&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=335&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=231&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=231&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=335&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=231&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=335&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=231&Color=99CCFF -

8/12/2019 Dremel eMag

28/29

Circular SawAttachmentWhile you cant ren-ovate your house

with this circular sawaccessory, you canentertain the idea of remodeling adoll house with it! Small, accurateand simple to use, its the idealaccessory when it comes to cuttingstraight lines through thin material.The clear blade guard keeps fingers

safe while providing good sightlines.

ShaperWheelsWhen the amount ofwood you need to

remove is too muchfor sanding, but notenough for cutting, grab a shaperwheel; they remove wood aggres-sively, yet accurately. Theyreunmatched when it comes to theirability to carve curved or scoopedshapes, or work in tight spaces.

27 DREMEL PROJECTS & SKILLS

Right-AngleDrillAttachmentThis is one of thoseattachments you maynot use very often, but

when you do need it, you REALLYneed it. It excels at working in hard-to-reach places like in between stairor chair spindles. And if you need todrill a small hole in an awkward

space, it can be a real lifesaver.3

4

5

http://www.dremel.com/productdisplay/att_template.asp?SKU=670&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=670&Color=99CCFFhttp://www.dremel.com/productdisplay/bit_template.asp?SKU=801&Color=99CCFFhttp://www.dremel.com/productdisplay/bit_template.asp?SKU=801&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=575&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=575&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=575&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=670&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=575&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=575&Color=99CCFFhttp://www.dremel.com/productdisplay/bit_template.asp?SKU=801&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=670&Color=99CCFFhttp://www.dremel.com/productdisplay/att_template.asp?SKU=575&Color=99CCFFhttp://www.dremel.com/productdisplay/bit_template.asp?SKU=801&Color=99CCFF -

8/12/2019 Dremel eMag

29/29

The bookshelf was late. Itwas Sunday. I was sup-posed to be done with itthe week before, but one little problem

after another slowed it down, and now I

was facing a roadblock. I only needed to

drill some holes for shelf pins in the

sides of the bookcase. But wouldnt you

know it, I couldnt find my 1/4-in. brad-

point bit.

Now I dont know if youve ever

tried to drill a hole in hardwood ply-

wood, where the face veneers are only

about three atoms thick. An ordinary

twist bit will tear the veneer to shreds.

But a brad-point bit, with its sharp

point and spurs on the outside edges,

makes a clean hole. At this time of

night, though, where would I find

one?

My Dremel rotary tool saved the

day. I took an ordinary twist bit and

carefully ground the edges with a con-

ical grinding bit so each edge rose to a

point. Voil, a brad point bit! It drilled

cleanly, and I got the job done! Thanks

to my Dremel tool.

Jean Bartholome

P.S. Now I keep a Dremel brad point bit

set (#631)close at hand. I reach for this

quartet of small bits whenever I need a

crisp, clean hole.

28 DREMEL PROJECTS & SKILLS

Dremel Saves the DayMy kingdom for a brad point drill bit!!

http://www.dremel.com/productdisplay/bitpack_template.asp?SKU=631&Color=99CCFFhttp://www.dremel.com/productdisplay/bitpack_template.asp?SKU=631&Color=99CCFFhttp://www.dremel.com/productdisplay/bitpack_template.asp?SKU=631&Color=99CCFFhttp://www.dremel.com/productdisplay/bitpack_template.asp?SKU=631&Color=99CCFF