Draft InsyaAllah FIX LaAs a dietary food brand, LaRice is a new player from the healthy food market...

Transcript of Draft InsyaAllah FIX LaAs a dietary food brand, LaRice is a new player from the healthy food market...

CHAPTER III

MANUFACTURE

3.1 Market Opportunity

As a dietary food brand, LaRice is a new player from the healthy food

market which can be a potential brand. Our main target is all those who are

interested in a healty lifestyle. But for more segmented our target, we used

recommendation from nutritionist and data from BALITBANGKES who said

about minimum age to consume dietary food is over 25 years old to minimize

malnutrition that might be occurred in people under that age. The main source of

demographic data is population census, which is conducted every ten years, so we

use data of Indonesian population aged above 25 years old according to BPS

(Badan Pusat Statistik) in 2010.

The product distribution for early years is limited to province located in

Java, like DKI Jakarta, West Java, East Java, and Central Java. The limitation is

made to make more effective about distribution cost, because we are recently

manufacturer which is not mature yet. As following are detailed for each

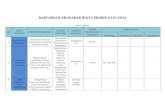

province:Table 3. 1 Population People Over 25 in Java

Province Amount of People over

25 y/o

Amount of People

DKI Jakarta 6232328 9588198West Java 27964187 43021826Central Java 21047447 32380687East java 24359407 37476011Total 79603369 122466722

Source : Badan Pusat Statistik, 2013

Based on data above, we can get approximation of percentage Indonesian

population over 25 years by this formula : Indonesian population

25y /o

Populationx100 %

and we get that market opportunity of LaRice is about 65% of the total

population.

3.2 Production Capacity

The next step is determining the production capacity for LaRice. The data

used is the number of healthy foods production from Badan Pusat Statistik in

2013, which is around 816 ton. But according to annual report of Kalbe Farma,

there are 45% (367.2 ton/year) amount of nutrition bar production from total

healthy snack production in Indonesia. As following table are nutrition bars

import and export data in Indonesia according to BPS :Table 3. 2 Amount of Imported Nutrition Bars

year 2010 2011 2012 2013

weight

(ton)

39.2 15.5 5.7 0.345

Source : Badan Pusat Statisik, 2013

Table 3. 3 Amount of Exported Nutrition Bars

year 2010 2011 2012 2013

weight

(ton)

2.1 4.9 5.3 17.3

Source: Badan Pusat Statistik, 2013

To calculate the amount of nutrition bar in Indonesia, we can use

production capacity data, imports, and exports in 2013, with the following below:

Amount of nutrition bar = Production capacity – export + import (in 2013)

= 367,2 ton – 17,3 ton + 0,345 ton

= 350,245 ton

After obtaining the amount of nutrition bar in Indonesia, we also can

calculates the percentage of nutrition bar to the other healty food by doing the

following calculation:

% nutrition bar from other healty foods =

amount of nutrition ¿̄other healthy foods production x100% ¿

= 350,245ton

816 tonx100

= 42,92%

The next step is to know data demand from healthy dietary snack. The data

that we used is the amount of other medical food in Indonesia due to lack of

healthy dietary snack demand data from BPS. So the amount of other medical

food demand per capita is :Table 3. 4 Other Medical Foods Demand

Year /capita/year (kg)

/year (kg) /year (ton)

2010 0.0156 1241813 12422011 0.0209 1663710 16642012 0.0261 2077648 20782013 0.0354 2817959 2818

Source: Badan Pusat Statisik

By obtaining a percentage of nutrition bar, we can define the demand of nutrition

bar in Indonesia:Table 3. 5 Nutrition Bar Demand

Year other medical food (ton)

nutrition bar (ton)

2010 1242 533.092011 1664 714.232012 2078 891.922013 2818 1209.55

Source: Badan Pusat Statistik, 2013

After get the nutrition bar demand in Indonesia from 2010 until 2013, we can

plots those data in graphic below :

0 0.5 1 1.5 2 2.5 3 3.50.00

500.00

1000.00

1500.00

f(x) = 220.705856617647 x + 506.138362745099

yearN

utriti

on B

ar (t

on)

Figure 3. 1 Graphic of Nutrition Bar Demand in Indonesia Each Year

By using the trendline above y = 220.71x + 506.14 we can determine the demand

for nutrition bar in 2014:

Demand in 2014 = 220.71 x 4 + 506.14

= 1388.98 ton

Using the demand equation above, we can determine the demand each

year from 2010 to 2013 and for the supply we can assume that from amount of

nutrition bar production adding with amount of import every year according data

from BPS. And we can make the chart of its as following:Table 3. 6 Nutrition Bar Demand and Supply in Indonesia

Year demand (ton)

supply (ton)

2010 506.14 406.402011 726.85 382.702012 947.56 372.902013 1168.27 367.55

1 2 3 40.00

200.00

400.00

600.00

800.00

1000.00

1200.00

demand (ton)supply (ton)

Figure 3. 2 Nutrition Bar Demand and Supply Chart in Indonesia

We can also forecasting nutrition bar demand from 2014 until 2020, as following

table:

Table 3. 7 Forecasting of Nutrition Bat Demand

Year demand (ton)

2010 506.142011 726.852012 947.562013 1168.272014 1388.982015 1609.692016 1830.402017 2051.112018 2271.822019 2492.532020 2713.24

The next calculation is to calculate the lack of nutrition bar demand

fulfillment by calculating the average of demand and supply afterward calculate

the different between both of them (demand – supply) from 2010 until 2013, and

we can get 454.82 ton. From that deficit, we assumed that the maximum

production capacity of LaRIce can fulfill 2.19% of the market share, its around

9,96 ton/year.

But for the estimate of our production in first year, we used 1.00% of the

market share, its around 4,55 ton/year. And we planned to grow the production

capacity according to the forecasting growth rate of one of the nutrition bar

manufacturer which is 15%, so our production capacity throughout 6 years of the

lifetime of plant before reach the maximum of capacity production:Table 3. 8. Forecasting Maximum Capacity Production

Year production capacity ton/year

2014 4.552015 5.232016 6.012017 6.922018 7.952019 9.15

3.3 Main Process

Process production of LaRice consist of raw material handling, storage,

heating and drying process, grinding process, mixing additional material process,

flattening process, filling process, compression process, cutiing process, until

packaging process. Purpose of raw material handling is to avoid damage and to

facilitate the preparation of production process. One of the raw material that we

use is red rice. Yet because of shorter shelf life red rice than white rice, then

applied the method of JIT (Just in Time), with reducing in-process inventory and

associated carrying costs. Beside that, there are several additional material like

dry fruits, mung bean along with binder substance as caramel.

After storage raw materials, afterwards mixing the materials into a container

like mixer. And then the mixture removed from it, then the mixture split into two

separated part, one of them given jam then do the compression process so that

they stick together with jam in the middle. Afterwards cutting process do made to

adjust size of the required, with total weight around 60 gram and one serving there

are 12 pieces, so that size of one piece LaRice around 5 gram. The explanation of

each process are listed below.

3.3.1 Process Description

The ingredients in making LaRice, as red rice, mung bean, dry fruit,

jam, sugar, and othe ingredients like preservative are sent from supplier

according to the supply chain. The materials are saved in the storage that have

temperature and time control. For each material have different handling.

Puffing Red Rice

We try to modified the method stated from the patent (US Patent no

4233327) to produce desired puffed red rice. First we must soaking

rice in water in 2 hours for make rice more moist; reducing the

moisture content rice by exposing it to air at temperature of 40-1200C;

pressing the reduced-moisture rice without cracks and fissures therin;

drying the pressed rice by exposing it to air at a temperature of 20-

1000C; aging the dried rice in a closed storage at temperature of 15-

350C for at least 30 minute to equalize the moisture distribution within

the rice; and puffing the aged rice with hot air at temperature of 160-

4500C.

Grinding Fruit

To be able to get the appropriate size pieces of fruit, which is less than

one cm we have to adjust the size of the cutter. Time of grinding for

apple, pineapple and mungbean is little bit different. It is due to

differences in the size and type of the fruit itself.

Drying Fruit

We have to order selected fresh and fully ripened fruits from suppliers.

Immature fruit can produce lacks flavor and color, overmature fruit

can be tough and fibrous or soft and mushy. Afterward for drying

process, first arrange pretreated fruits on drying trays in single layers.

Dry at 600C in dehydrator or tray dryer. The length of time needed to

dry fruits will depend on the size of the piece being dried, humidity

and the amount of air circulation in tray dryer or dehydrator. For us,

we dried apple and pineapple for 12 hour.

Heating Mungbean

The purpose of boiling the mungbean is to damage the epidermis is

still on, despite the mungbean have been grinding before. The boiling

lasts for 1 hour per batch, and next mungbean move to storage for

lowering the temperature.

Caramelization Sugar

Caramel occurred when we reach temperature around 1700C for 10 to

15 minute. when the sugar was melted and approaching the highest

temperature, the molecules of sugars is broken and shape the sticky

component.

Mixing Preperation

For dry fruits we used apple and pineapple, first grinding it into thinner

shape and then drying in 700C for 9 hours, and for the mung bean, first

we have to grinding it, and after that poach it in around 800C for 10

minute, in order to breaks the wall cell of mung beans. Afterwards,

both of them mix with the previous puffed red rice in mixer,

temperature in around 1700C, and temperature out 800C for 2-8 hours.

Flattening

After manufacturer blend puffed rice with caramels and fill its, the

next process is about to flatten the mixture in order to cooled. After

that split it into two separated part, and one of them given jam

Filling

For the filling, we assume that we have already order the specific jam

to supplier according to supply chaim

Size reduction

After the product is harden, manufacturer do some reduction in size in

order to full filled the manufacture composition, that is 5 gram per

piece.

Packaging

Finally, the product is ready to marketed, and for the packaging its

self, we order to supplier of packaging and storage company with

specific composition like the packaging include anti-bacterial film.

Drying buah, grinding (kacang hijau dan buah), heating (kacang

hijau),