Downhole XRF Sonde augias - liag-hannover.de · Possibilities and limits of geochemical borehole...

Transcript of Downhole XRF Sonde augias - liag-hannover.de · Possibilities and limits of geochemical borehole...

Possibilities and limits of geochemical borehole wall analyses with a

Downhole XRF Sonde

Uli Harms, Markus Reich Scientific Drilling, GFZ, Potsdam

Why?

Geochemical whole rock analyses of drill core is a usual technique in exploration, scientific and commercial drilling

The gold standard for element analytics is optical and other low-tech on-site inspection, sampling and off-site laboratory analysis (HQ analytics ensures precise resource estimates and is a requirement)

These procedures require time while the drilling may be demobilized and no onsite decision can be made about further drilling

Geochemical logs providing rock composition, ore content peaks, fluid precipitations and other specifics are crucial for on-site decisions

Available techniques

Geochemical loggings tools are available since long (e.g., GLT of SLB or GEM of Halliburton)

Analytical base is neutron activated gamma-ray spectroscopy

Radioactive sources, large size, high costs and a limited element spectrum available precluded a far-reaching application, especially in the mining industry

Analytical range

Si, Fe, Ca, S, Ti, Gd, Cl, H and some others are directly analysed several other elements are calculated

Halliburtons GEM

Laboratory XRF instruments

Excellent standard tool in most labs Large-size instruments Complex sample preparation (glass

discs for main elements, pressed powder tablets for traces)

HQ analyses of most metal elements starting from Na

Present x-ray tube size

Small Low power

(10–50 kV, 5–200 µA)

Fast Stable output Variable

current and voltage

Continuous operation

Runs w/ USB & AC adaptor

Consume 10 W

New possibilities: Raw materials „online XRF“

APPLICATION - Online XRF raw materials conveyor belt analyses identify and measure the concentration of elements Al (Z=13) to U (Z=92) FEATURES - Online non-destructive analyses of material composition directly above the conveyor belt with HQ and stability in a hostile environment including impacts, dust, low/high temperature and humidity; measurements are independent of lump size, relative humidity and distance within a range of some cm

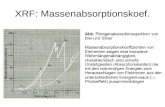

Design constraints A. Absorption, and distance Water is strongly absorbing – the thickness must be max. 0.5 mm The sonde must be pressed onto the borehole wall and a mudplow

must clear the borehole wall immediately before data acqusition The X-ray window must be as thin as possible to minimize

absorption, either Be or Cdiamond need metal support

B. Geometry White and characteristic X-ray paths must be as short as possible

C. Window inset The X-ray window must be pressure tight connected into the tool housing

D. Cooling Detector must be cooled through Peltier element, copper block, heat pipe

Handycap X-ray penetration depth in borehole wall is micrometers Only clean borehole walls will provide useful data Borehole wall must be clean AND straight without breakouts Utilization is limited to mining-style or other „clean“ drilling X-ray window will illuminate only a small area of borehole wall

Benefit X-rays will analyse all elements Na – U Density data will be provided as well HQ analytics possible Fast, simple and reliable technique No international transport issue No environmental issues

Range

Up to 2000 m water depth pressure 80° C environmental temperature 53 mm OD Data acquisition via wireline (or memory)