DIQUE FLOTANTE REPARACION

-

Upload

farihna-jose -

Category

Documents

-

view

26 -

download

0

description

Transcript of DIQUE FLOTANTE REPARACION

PORT OF SAN FRANCISCO CITY AND COUNTY OF SAN FRANCISCO

DRYDOCK NO.1 MARINE SURVEY, STRUCTURAL AND ENVIRONMENTAL ASSESSMENT (Rev. 1)

July 31 2007 PREPARED BY: MOFFATT & NICHOL LEE INCORPORATED KINNETIC LABORATORIES INC. CMS MARINE SERVICES

M&N Project No. 5276-15

TABLE OF CONTENTS

1 EXECUTIVE SUMMARY ................................................................................................................. 1 1.1 INTRODUCTION ............................................................................................................................1 1.2 KEY MARINE SURVEY FINDINGS................................................................................................2 1.3 KEY ENVIRONMENTAL SAMPLING FINDINGS...........................................................................2

2 BACKGROUND AND DESCRIPTION............................................................................................ 5

3 SCOPE OF WORK ............................................................................................................................. 6

4 MATERIAL SAMPLING, TESTING AND ASSESSMENT .......................................................... 7 4.1 METHODOLOGY ...........................................................................................................................7

4.1.1 Lead Paint and Corrosion / Debris Piles .....................................................................................7 4.1.2 Asbestos Containing Materials .....................................................................................................7 4.1.3 PCB containing materials.............................................................................................................7 4.1.4 Sediment and Water in the Hull Compartments............................................................................7

4.2 RESULTS .......................................................................................................................................8 4.2.1 Lead Paint and Corrosion / Debris Piles .....................................................................................8 4.2.2 Asbestos Containing Materials .....................................................................................................9 4.2.3 PCB Containing Materials .........................................................................................................10 4.2.4 Sediment and Water in the Hull Compartments..........................................................................10 4.2.5 Treated Wood..............................................................................................................................11

5 MARINE SURVEY & STRUCTURAL ASSESSMENT ............................................................... 12 5.1 METHODOLOGY .........................................................................................................................12 5.2 STRUCTURAL CONDITION ........................................................................................................12

5.2.1 Hull Condition ............................................................................................................................12 5.2.2 Wing Compartments Condition...................................................................................................12 5.2.3 Towing Hardware Condition ......................................................................................................13 5.2.4 Hull Strength...............................................................................................................................13

5.3 SUITABILITY FOR TOW ..............................................................................................................14 5.3.1 Wet Tow ......................................................................................................................................14 5.3.2 Dry Tow ......................................................................................................................................14

6 REFERENCE DOCUMENTS.......................................................................................................... 15

LIST OF FIGURES

Figure 1 ....................................................................................................................................................... 17

LIST OF TABLES

Table 1 - Measured water depths in buoyancy compartments.................................................................... 18 Table 2 - Estimated water volumes in wing compartments ........................................................................ 18 Table 3 – Measured Freeboards at corners of the Drydock ........................................................................ 18

LIST OF PHOTOGRAPHS

Photograph 1 – Aft, starboard view of Drydock #1.................................................................................... 19 Photograph 2 – Aft end outriggers (stowed on deck) ................................................................................ 19 Photograph 3 – Typical pontoon deck stiffening & transverse frame truss................................................ 20 Photograph 4 – Typical transverse truss frames and pillars between pontoon deck and bottom shell ....... 20 Photograph 5 – Typical water tight door access opening to wing compartment ........................................ 21 Photograph 6 – Pontoon deck condition showing heavy corrosion............................................................ 21 Photograph 7 – Port forward wing compartment interior damage from grounding.................................... 22 Photograph 8 – Port forward exterior damage from grounding.................................................................. 22 Photograph 9 – Typical corrosion and sediments in a corner wing compartment ...................................... 23 Photograph 10 – Typical patching on inside of starboard wing shell ......................................................... 23 Photograph 11 – Port side typical patching on outside shell ...................................................................... 24 Photograph 12 – Plywood patching (port, forward) ................................................................................... 24 Photograph 13 – Double mooring bitt & chock – typical at four corners................................................... 25 Photograph 14 – Close-up of mooring bit doubler plate – typical Note that the weld securing the doubler plate to the deck plate is missing ................................................................................................................ 25 Photograph 15 – Existing chain around web frames, forward starboard corner ......................................... 26

APPENDIX A..........................................................................................................................................A-1

APPENDIX B .......................................................................................................................................... B-1

APPENDIX C..........................................................................................................................................C-1

LIST OF ACRONYMS

CAM COMPLIANCE ASSURANCE MONITORING

CCR CALIFORNIA CODE OF REGULATIONS

DHS DEPARTMENT OF HEALTH SERVICES

EPA ENVIRONMENTAL PROTECTION AGENCY

HSWP HEALTH AND SAFETY WORK PLAN

LBP LEAD BASED PAINT

LCP LEAD CONTAINING PAINT

OSHA OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION

PAH POLYCYCLIC AROMATIC HYDROCARBON

PCB POLYCHLORINATED BI-PHENYL

PEL PERMISSABLE EXPOSURE LIMIT

PPM PARTS PER MILLION

PPT PARTS PER THOUSAND

RFP REQUEST FOR PROPOSAL

SAP SAMPLING AND ANALYSES PLAN

SAR SUPPLIED AIR RESPIRATOR

STLC SOLUBLE THRESHOLD LIMIT CONCENTRATION

TSI THERMAL SYSTEMS INSULATION

TTLC TOTAL THRESHOLD LIMIT CONCENTRATION

WET WASTE EXTRACTION TEST

1 EXECUTIVE SUMMARY 1.1 INTRODUCTION Drydock No. 1 is a 65 year old all riveted and welded steel floating drydock currently tied up at Pier 68 in the Port of San Francisco. The dry dock hull is approximately 584 ft. long by 128 ft. wide. It shows evidence of severe deterioration and poor maintenance. The Port wants to develop an RFP document that would allow it to obtain credible and competitive bids to dispose of the drydock. The purpose of this investigation is to develop data on certain safety and environmental hazards associated with the drydock that would impact work on the vessel or pose problems with its disposal. These data will be used in the development of the RFP. A team comprised of Moffatt & Nichol, Kinnetic Laboratories, LEE Inc. and Commercial Marine Services was retained by the Port to perform the following tasks:

• Conduct a reconnaissance survey of the drydock to identify suspected environmental/safety hazards and prepare a Health and Safety Work Plan, and an Environmental Sampling and Analysis Plan (SAP)

• Conduct the Environmental Sampling and Analyses per plan. • Conduct a Marine Survey of the drydock to assess its readiness to undergo a wet or dry

trip-in-tow to a site for dismantling. The reconnaissance survey took place in May 2006 and determined access requirements, particularly to the compartments in the wing walls and the main hull. Safety issues were evaluated for future entry into the compartments by personnel. The Health and Safety Work Plan and the Environmental Sampling and Analyses Plan were submitted to the Port in June 2006. The Sampling and Analyses Plan included the following potential environmental hazards in this investigation: Hazard Location Reporter Lead in Paint Painted Surfaces LEE, Inc. CAM-17 Metals in Corrosion Debris

Corrosion / Debris Piles LEE, Inc.

Asbestos Containing Materials Control Room Panels, Epoxy Deck Coatings, Thermal Systems Insulation, Debris Piles, Gasketing, Weather-stripping and wiring insulation

LEE, Inc.

PCB’s Light Ballasts and machinery oils LEE, Inc. Sediment Accumulation (full scan chemistry)

Hull compartments Kinnetic Laboratories

Water Accumulation (full scan chemistry)

Hull compartments Kinnetic Laboratories

1

Compositing of Samples from multiple similar locations was necessary to control the number of samples and attendant costs for analytical chemistry. The sediment and water samples were obtained from 35 compartments (2 hull compartments and 3 wing compartments were inaccessible). Proportional composites based on compartment dimensions and sediment or water depths were formed, grouping the composites by location and sediment color or water clarity. The amount of sediment or water in each compartment was estimated from depth measurements and compartment dimensions. The Environmental Sampling and Marine Survey took place in March 2007. The results of the LEE, Inc. investigations are reported in Appendix A, and of the Kinnetic Laboratories in Appendix B. The report of the Marine Survey is presented in Appendix C. 1.2 KEY MARINE SURVEY FINDINGS The Marine Survey noted that the drydock was in such poor condition that it is not practical to consider repair to continue in its intended service; the only use for which it should be considered is salvage scrap metal. The estimated scrap value given was about $600,000 (April 2007), but the market value would be considerably less because allowances must be made for the cost to clean and tow the vessel to a site for dismantling. The Marine Survey concluded that the drydock was in satisfactory condition to undergo a terminal inshore Wet Tow to a site for dismantling, provided the tow preparation repairs and the towing plan as recommended in the Commercial Marine Services Report are complied with. Among the recommendations is the requirement to evacuate all floatation compartments and prove that the compartments are tight from the sea. The Marine Survey also noted that even though the drydock could fit on the deck of a “heavy lift” ship for a Dry Tow, the price of mobilizing a suitable Dry Tow vessel to the Port of San Francisco for this purpose would likely prove cost prohibitive when compared to other options. Furthermore there is a high probability that the wasted structure of the drydock would collapse on the deck of the ship due to the stress placed on it during a sea voyage, so only an inshore trip could be considered in any case. 1.3 KEY ENVIRONMENTAL SAMPLING FINDINGS The requirements for cleaning the drydock to remove objectionable materials prior to dismantling will be determined by the acceptance criteria/contract terms of the salvage contractor and of any permits required to move the drydock to the dismantling site. The following cleaning recommendations are based on a discussion with a major metal recycler in the Bay Area. Asbestos was found in the samples of pipe thermal insulation, electric switch panel and wire insulation, woven gaskets on compartment access hatches, control room Transite panels and weather stripping, and in the epoxy deck coating. Asbestos is also assumed to be found in the brake/clutch components of the capstan units, and possibly in the packing glands of the pumps. Certain asbestos-containing materials must be remidiated prior to dismantling the drydock. The removal and disposal of the various ACM’s can be accomplished with commercially available

2

technology as recommended by LEE Inc. Details on the regulatory requirements governing the abatement of the various ACM’s is provided in the Appendix. Lead was detected in paint samples taken from both the exterior and interior surfaces of the drydock. Removal of the intact lead paint is not required according to the recycler. Nevertheless, the lead content of the paints does impact worker protection requirements during the dismantling operation. Typical dismantling operations, including torch cutting of surfaces with intact lead paint, will require worker protection including the use of SAR’s. However, cutting of the heavily corroded areas with only residual paint may not, but this would need to be confirmed by exposure monitoring at the time the work is performed. Piles of corrosion/sediment debris found on various deck surfaces contained copper and lead at elevated levels and their removal is required. While the metal content in the samples was below CCR Title 22 TTLC criteria for hazardous waste, it exceeded the trigger criteria for conducting a WET test in several samples. The results of the WET test on those samples indicated that copper and lead levels exceeded the Title 22 STLC criteria for hazardous waste. Since the occurrence of such elevated levels was not consistent, it may be that there are “hot spots” among the debris piles. However, sampling and analyses during cleaning to aid in segregating elevated lead/copper content debris is not recommended by LEE Inc. as it will likely not prove cost effective, even if the debris piles as a whole must be handled as Class I Hazardous Waste. PCB’s are assumed to be present in the control room light ballasts. There are an estimated 15 ballasts which should be removed. PCB’s were not detected in the samples of oil and grease taken from drydock capstans. Nevertheless, an estimated 25 gallons of gear oils and lubricating grease should be removed during cleaning, as well as other gross petroleum contamination, such as the estimated 10,000 to 15,000 sq ft of oily film on the port wing compartment walls. Preservative treated wood was observed in the drydock fenders, which should be removed. It is assumed that the wood was treated with Creosote, which is considered a Class II Waste in California and its removal managed accordingly. The total volume of sediments in the sampled compartments is estimated to be 1400 cu. yds. In general, these sediments contained elevated levels of petroleum hydrocarbons with oil & grease values of 9,000-41,000 mg/kg-dry, fuel volatiles of 15,000-42,000 mg/kg-dry and total PAH’s up to 23,000 ug/kg-dry. Total metals concentration were also elevated, especially copper, zinc and mercury, though none exceeded the Title 22 TTLC criteria for hazardous waste (after correction for water contents). Some samples exceeded the trigger for conducting a WET test. The result of the WET test showed that these sediments do not exceed the STLC criteria for hazardous waste. Asbestos was absent, and herbicides, chlorinated hydrocarbons and PCB’s were all below detection limits in the composite sediment samples. The sediment must be removed prior to dismantling the drydock according to the recycler. The removal of the sediments contaminated with petroleum hydrocarbons can be managed with commercially available technology. The total volume of water, which was primarily found in the hull compartments, is roughly estimated to be 1 million gallons. The sampled waters were clear and fresh to slightly brackish (max. 7ppt salinity). Oil & grease and fuel volatiles were low; total PAH’s were below the reporting limit and asbestos, organotins, herbicides, chlorinated hydrocarbons and PCB’s were all below detection limits. Removal and disposal of the water is recommended by Commercial Marine Services in preparation for the terminal tow. Disposal of the water to the Bay was not

3

being considered by the Port; hence analyses for comparison with Basin Plan water quality criteria were not performed. Consideration may be given to disposal of the clear water to the municipal sewer system in accordance with rules for industrial waste discharge. Since the water overlies sediments with elevated levels of contaminants as noted above, provisions to prevent entrainment of sediment in the clear water discharge will likely be necessary.

4

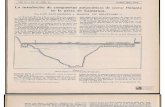

2 BACKGROUND AND DESCRIPTION The Port of San Francisco (Port) is developing an RFP for removal and disposal of their floating Drydock No.1 (the Drydock). The Port requested that Moffatt & Nichol assemble a team to perform an initial investigation of the structural and environmental issues with regard to the towing and dismantling of the Drydock. This report describes the results of this investigation. The Drydock was designed by Frederick R. Harris Consulting Engineers and built in 1942 for the US Navy. It is a steel hull structure 584’ long by 128’ wide by 54’ high (Figure 1 and Photograph 1). The wings rise above the deck plate 37 ft 6 in. There are outriggers at either end which were used for access onto the Drydock from the wharf (Photograph 2). When deployed, the outriggers extend the length of the Drydock to 664 ft. The Drydock contains 40 watertight compartments. Eight center, port, and starboard (total 24) hull compartments are referred to on the design plans as buoyancy compartments. The remaining sixteen compartments are wing compartments. The Drydock is “self docking” meaning that the end sections can be detached and used to lift the large middle section to facilitate maintenance and transportation. Also, the end sections could (originally) be detached and stowed on the deck of the middle section. The Drydock is of welded and riveted steel construction. The majority of the joints and connections are welded. However, built-up stiffening beams are riveted and the self-docking connections are bolted. Generally, the bottom, exterior sides and deck plate are (originally) one-half inch thick with longitudinal split 11-inch deep channel sections as stiffeners spaced at 2 feet on center. Transverse stiffening consists of truss frames spaced 8 feet on center between watertight bulkheads (Photographs 3 & 4). Similar shell stiffening and transverse truss frames are found between the inner and outer shell of the wing walls. Interior side plates and bulkheads are 3/8 inch thick with stiffeners spaced at 2 ft on center. Access to the compartments is either through deck hatches or watertight doors. Access to the buoyancy compartments is through hatches in the deck. Access to the wing compartments is through watertight doors in the wings (Photograph 5). Additionally, the port and starboard buoyancy compartments may be accessed through watertight doors in the wing compartment bulkheads. More details of the structure can be found in Reference 1. The Drydock was ballasted and de-ballasted by electric pumps located in the wing compartments. Piping penetrates the wing bulkheads to the compartments. Ballast / de-ballast piping penetrates the exterior shell plate at the base of the wing sections. Ballasting and de-ballasting was controlled at the control house on top of the starboard wing.

5

3 SCOPE OF WORK The investigation involved the following tasks:

1. Material Sampling, Testing and Assessment: A Sampling and Analysis Plan (SAP) and Health and Safety Work Plan (HSWP) were prepared previously in Phase 1 of this project. This task, following the procedures specified in these plans, required obtaining samples of materials on the Drydock and having them tested in a state certified laboratory for contaminants. 2. Marine Survey and Structural assessment: Complete a visual qualitative assessment of the mooring hardware supports and structure to assess the Drydocks suitability and conditions for a wet or dry tow.

6

4 MATERIAL SAMPLING, TESTING AND ASSESSMENT The material sampling testing and assessment addressed the following areas:

a) Lead Paint b) Corrosion / Debris Piles for CAM-17 metals and asbestos c) Asbestos containing materials d) PCB-containing dielectrics and oils e) Sediment and water contained in the compartments

The sampling and documentation of Areas a) through d) was performed by LEE Inc., while the sediment and water characterization, Area e) was done by Kinnetic Laboratories, Inc. Methodologies and results from the material sampling and testing are summarized below. The full discussion of sampling and testing protocols and of the results can be found in Appendix A prepared by LEE, Inc. and Appendix B prepared by Kinnetic Laboratories, Inc. 4.1 METHODOLOGY 4.1.1 Lead Paint and Corrosion / Debris Piles

Samples to be analyzed for lead content were taken of paint on drydock surfaces, and samples to be analyzed for CAM-17 metals were collected from representative piles of debris accumulated on the horizontal surfaces of the decks and wings, as well as sediments in the lower wing compartments. Paint samples were analyzed for lead content using flame atomic absorption spectrometry according to the EPA’s Standard Operating Procedures 1991. Corrosion debris was analyzed using inductively coupled plasma according to EPA 6010B for total metals and EPA 7471 for total mercury for comparison against the CCR Title 22 Total Threshold Limit Concentration (TTLC). If the samples had detection limits or results 10 times the relevant Title 22 Soluble Threshold Limit Concentration (STLC), they were analyzed for the metal in question according to the Waste Extraction Test (WET). 4.1.2 Asbestos Containing Materials

Samples to be tested for asbestos were collected from various areas suspected to contain asbestos, including pipe thermal insulation, electric switch panel and wire insulation, the control room panels and weather-stripping, epoxy coatings on the upper decks of the wings and compartment hatch cover gaskets. Asbestos is also included in the analysis of the samples taken of the corrosion debris piles as described above. 4.1.3 PCB containing materials

Electric components possibly containing PCBs were also located, but not tested since the cost of testing exceed the disposal cost assuming they contain PCBs. Samples of greases and oils were collected from capstans, lubrication manifolds and a mound of grease on the upper deck of the port wing wall to be analyzed for PCB contamination. 4.1.4 Sediment and Water in the Hull Compartments

Sediment and water samples were taken from 35 accessible hull compartments (22 buoyancy compartments, 13 wing compartments) out of a total of 40 buoyancy and wing compartments.

7

For sediments within the hull compartments, samples for full scan chemistry were obtained as follows:

• Wing compartment composite (both port and starboard) since the sediments were visually similar.

• Center buoyancy compartment composite – visually similar rust colored sediments. • Port and starboard buoyancy compartment composite – visually similar Grey colored

sediments. For water within the hull compartments, samples for full scan chemistry were obtained as follows:

• Wing compartment composite (both port and starboard). • Center buoyancy compartments composite with clear water. • Center buoyancy compartment with cloudy water. • Port and starboard buoyancy compartment - composite with clear water.

A best estimate of the thickness of the sediment and depth of water in each of the compartments was also tabulated and used to obtain a rough estimate of sediment and water volume. Wing Compartments. Eight of the thirteen compartments sampled contained small areas of standing water. Since the great majority of these spaces were dry, the sediment samples taken were generally dry, caked on material that needed to be fragmented to be removed. Sediments were tan, light grey or reddish brown and usually had moderate to heavy accumulations of rust fragments mixed into them. Center Buoyancy Compartments. All center buoyancy compartments contained water. Sediment samples taken from the center deck compartments were saturated and most were difficult to sample due to their light (1-3 inch deep) accumulations. Sediments were mixes of red and black or red and grey material with one exception which was almost all black in color. Most samples contained high percentages (50-90%) of rust fragments and light to heavy amounts of petroleum product. Port and Starboard Buoyancy Compartments. All port and starboard buoyancy compartments also contained water. Sediment samples taken from these compartments were saturated with water. Sediments were generally grey in color with a silt-like consistency. The sediment samples were tested for percent solids, oil & grease, dissolved sulfides, asbestos, metals, butytins, chlorinated pesticides, petroleum hydrocarbons and polycyclic aromatic hydrocarbons (PAHs). In addition, the sediments were tested for Title 22 elements, some acids and PCBs. Water was analyzed for a similar list of analytes as the sediments, minus the sediment specific constituents. 4.2 RESULTS 4.2.1 Lead Paint and Corrosion / Debris Piles

Results for paint samples collected from the corroded, exterior surfaces of the drydock ranged from non-detect to low. The concentrations obtained ranged from <74 parts-per-million (ppm) to, 64,653 ppm with 3 of the 6 samples non-detect at 79 ppm. Results for paint samples collected from the interior walls of the upper compartments of the wing-walls with intact paint ranged from

8

5,180 ppm to 222,025 ppm. The sample results and locations are shown in Appendix A.2, including recommendations for managing the remediation of lead paint depending on the lead level in the paint. While the presence of lead in and of itself is not a major issue for metal recycling, the lead content of paints on the Drydock does impact worker protection requirements during the dismantling operation (e.g., hot work). Torch cutting of surfaces with lead paint is a Level 3 Trigger Task and will require the use of supplied air respirators (SARs). This will be the case for the intact paint on the interior walls of the upper compartments of the wing-walls where lead was detected in the hundreds of thousands of parts-per-million. On the other hand, 5 out of 6 samples from the exterior surfaces yielded values which were non-detect or below the 600 ppm level defined by Consumer Products Safety Commission as “lead-free” for residential paints. While CAL-OSHA does not uses this criterion for defined trigger tasks such as dismantling of the dry-dock, it is anticipated that disturbance of the exterior with the limited areas of residual paint and extensive areas of corrosion is not likely to generate airborne lead levels requiring SAR. Nevertheless, this must be confirmed by exposure monitoring, and in any case some level of respiratory protection would be required until data from monitoring indicated otherwise. The lead content in sampled piles of corrosion debris and sediment was below the Total Threshold Limit Concentration (TTLC) for lead. Handling of this debris is not likely to result in exposures at or above the Permissible Exposure Limits (PEL) for lead. The two sediment samples and one of the four debris samples had results exceeding the Soluble Threshold Limit Concentration (STLC) and were re-analyzed by the Waste Extraction Test (W.E.T.). The results for one of the sediment samples and the debris sample exceeded the STLC for lead. Although this will adversely impact disposal options, LEE, Inc. notes that further sampling and testing of the corrosion/debris material during the cleaning phase of the recycling effort to generate composite results that are below the STLC criteria, or to identify and segregate “hot spots” may not be cost effective, when compared to managing the entire quantity of material as a Class I Waste. CAM-17 metals results for the samples of wing-wall sediment and debris piles were all below the relevant TTLC. However, results for one or more metals in all of the samples exceeded 10 times the STLC and these samples were re-analyzed for the corresponding metal by the W.E.T. In addition to the lead findings cited above, the copper content in piles of corrosion debris exceeded the STLC in three of the four re-analyzed samples, but results for all other metals were below the STLC. Again, this will adversely impact disposal options, but it reinforces the recommendation made for the Lead results that all the material be managed as a Class I Waste. 4.2.2 Asbestos Containing Materials

The quantities and locations of Asbestos Containing Materials (ACM) are described in detail in Appendix A. Asbestos was identified in the samples of pipe insulation (Thermal Systems Insulation: TSI), electric switch panel insulation board, woven gaskets on compartment hatch covers, control room Transite panels, control room wire insulation, epoxy deck coating, and weather-stripping. Asbestos is assumed to be found in the brake/clutch pad components of the capstan motor units, and possibly in the pump packing. Corrosion/Debris pile samples from the wing-wall compartments were non-detect for asbestos. Certain Asbestos-Containing Materials (ACM) must be removed from the Drydock as a part of the dismantling effort and prior to recycling. The TSI on the pipe is a Regulated Asbestos-

9

Containing Material (RACM), and the Bay Area Air Quality Management District (BAAQMD) requires 10-day advance notification prior to removal. The TSI removal work is Cal-OSHA Class I asbestos work that requires a Cal-OSHA registered asbestos abatement contractor. The TSI is also California Hazardous Waste that must be transported under a Uniform Hazardous Waste Manifest. The gasket material on the compartment hatch covers should be handled similarly. Removal of other ACMs is Cal-OSHA Class II asbestos work, and the material is Category II, asbestos-containing non-hazardous waste. Complete recommendations for managing the remediation/removal of asbestos are provided in Appendix A.1. 4.2.3 PCB Containing Materials

Light ballasts in the control room are assumed to contain PCB. No PCBs were detected in the samples of oils and greases. Nevertheless, prior to the dismantling operation the capstan gear oils, lubricating greases, and petroleum gross contamination should be removed. There are an estimated 25 gallons of these bulk materials and an estimated 10,000 to 15,000 square feet of upper deck port wing compartment walls with an oily film. 4.2.4 Sediment and Water in the Hull Compartments

Water The amount of water present in each accessible hull compartment was roughly estimated from water depth measurements, and drydock structure dimensions. Approximately 1 million gallons of water are present in these compartments. Chemical analyses of the composite water samples were carried out. At the request of the Port, only total metals were included in the analyte list since disposal in ambient Bay waters was not being considered and comparisons with Bay Plan criteria was not required. Waters in the hull tanks were clear, fresh to slightly brackish generally of 1-2 ppt (parts per thousand salinity) with the highest 7 ppt. Measurements of pH were typically close to 8.0. Oil & Grease values were low (<5 mg/l) and volatile fuel concentrations were in the general range of 3.5 to 4.9 mg/l. Total PAHs were measured at 2-4 ng/l which is less than the project reporting limit. Asbestos was absent and organotins, herbicides, chlorinated hydrocarbons and PCBs were all below project detection limits, Sediment The volume of sediment in each accessible hull compartment was estimated based upon sediment depth measurements and drydock structure dimensions. A total of approximately 1,400 cubic yards of sediment is present in these compartments. Results of chemical analyses were obtained from the three composite sediment samples formed from the Wing Tank samples, and from the Buoyancy Tank (Red) and (Grey) sediments respectively. Water content was highly variable among the three composite samples. The Wing Tank composite sediment sample had low moisture (10%), the Buoyancy Tank (Red) was 30% moisture, and the (Grey) had a soupy consistency with a moisture content of 70 percent. These sediment samples had elevated levels of petroleum hydrocarbons with oil & grease values of 9,000-41,000 mg/kg-dry, fuel volatiles analyses of 15,000-42,000 mg/kg-dry, and total PAHs ranging up to 23,000 ug/kg-dry.

10

Total metals concentrations of copper and zinc were also elevated in these samples. Just for comparison purposes, ambient Bay sediment quality guidance criteria and Title 22 TTLC values are also tabulated in Appendix B. Note that the TTLC criteria are on a wet weight basis. Copper and zinc values, though elevated, did not exceed the Title 22 TTLC criteria for hazardous waste after correction for moisture content. Sediment from the Wing Tank exceeded the trigger for conducting a WET test based upon STLC criteria. Mercury values were also elevated but were less than the TTLC after correction for moisture content. Two samples (Wing Tank and Buoyancy Tank Grey) exceeded the STLC trigger criteria and thus were subject to a WET Test. The results of the WET Test indicate that none of the composite samples exceed the Title 22 STLC Criteria for hazardous waste. Asbestos was absent and herbicides, chlorinated hydrocarbons and PCBs were all below detection limits in the composite sediment samples from the hull tanks,. 4.2.5 Treated Wood

The Drydock has treated wood side bumpers. The preservative is assumed to be cresote. Wood was also observed in the shaft bearings, but these are most likely a tropical hardwood referred to as “ironwood” and are not treated. Creosote treated wood is a Class II Waste in California and is not accepted for disposal at Class III sanitary landfills.

11

5 MARINE SURVEY & STRUCTURAL ASSESSMENT The structural assessment consists of two parts; a qualitative assessment of mooring hardware supports and overall structure by Moffatt & Nichol, and an assessment of condition and suitability for wet or dry tow by a marine surveyor. The structural inspection was done on March 26, 27and 28 by an inspection team including a Licensed Structural Engineer from Moffatt & Nichol and a Licensed Marine Surveyor from Commercial Marine Service. 5.1 METHODOLOGY The hull was observed from the outside, both by walking the deck and by boating around the Drydock, and from the inside by accessing wing compartments and adjacent hull ballast side compartments through open hatches. Notes and pictures were taken as necessary to document the condition of the structure. Portable lights were used to observe structure inside the compartments. Electrical fans were used to ensure proper ventilation while accessing the interior compartments. Attempts were made to measure the remaining thickness of plate at several locations, but these were unsuccessful due to heavy pitting. 5.2 STRUCTURAL CONDITION 5.2.1 Hull Condition

The steel deck is extensively corroded (Photograph 6) with many holes through the entire plate thickness. Some areas of the deck were covered by containers and other loose items and not possible to inspect, while others were covered with pallets or other wood. The condition of the deck under those areas is unknown. Although the deck is badly holed, for the most part it was safe for pedestrian loads. The majority of the rain falling onto the deck probably finds its way into the buoyancy compartments via the holes in the deck. Most of the deck hatches are loose and easily removed for observation of the central and buoyancy compartments. All of the compartments contained water – most of it fresh implying that the hull is (for the most part) watertight from the sea. Tables 1 and 2 show the approximate water depths in the buoyancy compartments at the time of inspection as recorded by Kinnetic Laboratories, and the estimated volume of water in the wing compartments respectively. It was not possible to get metal thickness readings due to the heavy metal pitting. However, based on observation, more than half of the original metal thickness appears to have been lost due to corrosion. Freeboard measurements from the pontoon deck were made at 4 locations. These measurements are provided in Table 3. The average freeboard is about 8.2 feet, with a slight list towards the forward/port side. BAE Systems indicated that no pumping had been done to maintain trim for the Drydock. This is further evidence that the hull is more or less watertight from the sea. 5.2.2 Wing Compartments Condition

Four wing compartments and three hull buoyancy compartments were entered. All accessible wing compartments were viewed from the openings to the deck. Wing compartments are extensively corroded and heavily laden with sediment. The corrosion and sediment in the bottom of the wing compartments is 3 to 6 inches thick. Some of the wing compartments have

12

standing water (perhaps due to high water levels in the buoyancy compartments). Stiffeners, channels and wide-flange beams inside of the wing compartments are knife edged in many cases. In 2002, the Drydock broke loose from its moorings and ran aground on Yerba Buena Island. The forward, starboard wing area was damaged when the Drydock ran aground. There is evidence of damage due to the grounding but no visible evidence of any repairs (Photographs 7 and 8). The forward starboard wing compartment appears to be watertight from the sea. The wing compartments above the deck are extensively corroded (Photograph 9), with extensive holing of the plate above the deck level. The upper parts of the wing compartments show numerous repairs. Mostly, these repairs consisted of patching of the corroded plating with welded steel doubler plates (Photographs 10 and 11). In addition, numerous plywood “plugs” have been attached over holes in the wing plating over the years to seal holes (Photograph 12). These repairs are sandwich plywood on the outside and inside with a rubber gasket rubber or a similar material next to the shell to get a watertight seal. The floor plate at the top of the wing sections has been repaired with patch plates. The environmental sub-contractor noted that the intermediate level floor inside of the wings had areas that were unsafe for pedestrian loads. It is not clear whether the intermediate level floor has ever been repaired. 5.2.3 Towing Hardware Condition

Four towing bitts are present on the Drydock, one each at all four corners (Photograph 13). All are double-bitts which straddle transverse deck frames below the deck plate. However, these have no additional under deck stiffening in the longitudinal direction. The bitts are mounted on one inch thick doubler plates that in turn are welded to the deck plating with a continuous perimeter weld as well as ¾ inch plug welds between the two horns. The towing bitts themselves are in fair condition, with some surface corrosion. However, the doubler plates are heavily corroded, especially along the perimeter where they are welded onto the deck plating. In most cases, the perimeter weld is completely gone (Photograph 14). The condition of the towing bitts and the attachment to the deck indicates that they are not suitable for towing. This is consistent with the findings from the Marine Surveyor. 5.2.4 Hull Strength

Originally, the Drydock was designed for a 20.4 foot head seas wave. The conditions shown on the original drawings assume that the end sections are carried by the center section when subjected to the design wave. It is considered impossible to remove the end sections of the Drydock and place them on the deck of the center section for a couple of reasons. First, it is unlikely that either the center section or the end sections can be ballasted / de-ballasted due to extensive holing and lack of pumping. Second, the center section deck is badly weakened due to corrosion and likely to fail under the weight of the end sections. As a consequence the Drydock would have to be towed or transported with the end sections attached to the hull. This will significantly increase hull moments for a given wave. As noted previously, the Drydock has undergone extensive corrosion and this loss of metal reduces the maximum wave it can withstand during a tow. This condition combined with undesirable transportation with the end sections attached further reduces the maximum

13

transportation wave height. As a consequence, the maximum allowable wave height during tow is estimated to be less than about 5 feet. Due to the deteriorated condition of the connections between the end and center sections, some connection strengthening prior to transportation may be desirable. Further analyses should be performed for the Drydock once the tow destination and tow displacement are known. 5.3 SUITABILITY FOR TOW 5.3.1 Wet Tow

The conclusion of the marine surveyor is that the Drydock is not suitable for an open ocean wet tow. With the extensive corrosion and openings in the hull, it is unlikely that the Drydock would survive ocean wave exposure, especially if foul weather is encountered. A local wet tow is possible. Alternative tow arrangements must be provided due to the poor condition of the towing bitts. One possibility is to attach the tow chains through openings in the wing compartments and around the existing transverse web frames. Penetrations in the wing compartments above the deck level (Photograph 15) have already been made in several places on the Drydock. Before the Drydock would be ready for tow, a number of repairs and prepatory steps would have to be completed to fulfill requirements from the USCG. Discussion of these items is presented in Appendix C. 5.3.2 Dry Tow

The conclusion of the Marine Surveyor is that even though the subject vessel could be lifted aboard and fit within the capacity bounds of the deck of a heavy lift “Dry-Tow” vessel such as the M/V “BLUE MARLIN”, the price of moving such a vessel from Norway to the Port of San Francisco would be cost prohibitive when compared with the other options such as a Wet Tow to a local facility for dismantling. There is also the high probability that the wasted structure of the subject dry dock would collapse upon the deck of the ship due to the stress placed upon it by swaying in a seaway therefore only inshore towing routes should be considered in any case. Report prepared by: Jim Brady, CA Structural Engineer SE 3652, July 31, 2007

14

6 REFERENCE DOCUMENTS

1. Drawing Nos. D-176-1 and D-176-3 through D-176-24, 21,000 Ton Steel Floating Dry Dock, Frederick R. Harris, Consulting Engineers, 1942

15

FIGURES, TABLES AND PHOTOGRAPHS

16

Figu

re 1

– D

rydo

ck #

1 Pl

an, E

leva

tion

& S

ectio

n Fi

gure

1

17

Compartment LocationDepth

(Inches)4 A 25 A 26 A 67 A 78 A 59 A 610 A 6411 A 2214 A 3516 A 5617 A 2618 A 7520 A 3021 A 4112 B 5013 B 6215 B 6219 B 40

998000

Table 1 - Measured water depths in buoyancy compartments

(A = Forward end of compartment) (B = Aft end of compartment)

Compartment Location Volume (cf)3 W 157 W 7010 W 14412 W 36013 W 28015 W 54616 W 28018 W 1144

00

Table 2 - Estimated water volumes in wing compartments

(W = Wing compartment)

Measured Freeboards

Location FreeboardFwd - starboard 8' - 2.5"Fwd - port 7' - 10"Aft - starboard 8' - 7"Aft - port 8' - 3"

Table 3 – Measured Freeboards at corners of the Drydock

18

Photograph 1 – Aft, starboard view of Drydock #1

Photograph 2 – Aft end outriggers (stowed on deck)

19

Photograph 3 – Typical pontoon deck stiffening & transverse frame truss

Photograph 4 – Typical transverse truss frames and pillars between pontoon deck

and bottom shell

20

Photograph 5 – Typical water tight door access opening to wing compartment

Photograph 6 – Pontoon deck condition showing heavy corrosion

21

Photograph 7 – Port forward wing compartment interior damage from grounding

Photograph 8 – Port forward exterior damage from grounding

22

Photograph 9 – Typical corrosion and sediments in a corner wing compartment

Photograph 10 – Typical patching on inside of starboard wing shell

23

Photograph 11 – Port side typical patching on outside shell

Photograph 12 – Plywood patching (port, forward)

24

Photograph 13 – Double mooring bitt & chock – typical at four corners

Photograph 14 – Close-up of mooring bit doubler plate – typical

Note that the weld securing the doubler plate to the deck plate is missing

25

Photograph 15 – Existing chain around web frames, forward starboard corner

26

APPENDIX A

DRYDOCK #1 – ASBESTOS, LEAD AND CAM-17 METALS INSPECTION AND SAMPLING

A-1

PORT OF SAN FRANCISCO CITY AND COUNTY OF SAN FRANCISCO

REPORT ASBESTOS, LEAD AND CAM-17 METALS INSPECTION

AND SAMPLING DRYDOCK NO.1, PIER 70

JULY 2007

LEE INCORPORATED Engineers Scientists Contractors

SECTION 1 - SUMMARY OF FINDINGS ASBESTOS The quantities and locations of Asbestos-containing materials (ACM) are given on the accompanying asbestos table and plan. Materials Asbestos was identified in the samples of pipe insulation (thermals systems insulation: TSI), electric switch panels insulation board, woven gaskets on deck access panels, control room cement panel siding, control room wire insulation, epoxy coating, and weather-stripping. Asbestos is assumed to be found in the brake/clutch pad components of the capstan motor units, and possibly in the pump packing. Sediment samples from the lower wing-wall compartments were non-detect for asbestos. Removal Asbestos-containing materials (ACM) must be removed from the dry-dock as a part of the dismantling effort and prior to recycling. The TSI on the pipe is Regulated Asbestos-Containing Material (RACM), and the Bay Area Air Quality Management District (BAAQMD) requires 10-day advance notification prior to removal. The TSI removal work is Cal-OSHA Class I asbestos work that requires the use of respiratory protection, 4-day asbestos trained workers under the supervision of a 5-day competent person, all employed by a Cal-OSHA registered asbestos abatement contractor. Removal of other ACMs (i.e., electric switch panel insulation boards, cement panel siding, etc.) is Cal-OSHA Class II asbestos work. Disposal The TSI and access panel gaskets are California Hazardous Waste that must be transported under a duly executed Uniform Hazardous Waste Manifest. Other ACM are Category II, asbestos-containing non-hazardous waste and can be transported under a non-hazardous waste manifest.

1

LEAD The results and locations of lead samples are given on the accompanying table and plan. Materials Results for paint samples collected from the corroded, exterior surfaces of the dry-dock ranged from non-detect at 74 parts-per-million (ppm) to 64,653 ppm with 3 of the 6 samples non-detect at 79 ppm. Results for paint samples collected from the interior walls of the upper compartments of the wing-walls with intact paint ranged from 5,180 ppm to 222,025 ppm. The sample results and locations are shown in the appendices. Removal The presence of lead in and of itself is not a major issue for metal recycling according to staff at Schnitzer Steel in Oakland, and in fact they indicated that their major concern with the dry-dock is the sediment in the lower wing-wall and hull compartments. According to Schnitzer Steel, the dry-dock must be “pre-cleaned” of the sediment as a condition for acceptance at their facility, in addition to removal of the asbestos and any other hazardous materials identified that are excluded by their contract terms and conditions. Nevertheless, the lead content of paints on the dry-dock does impact worker protection requirements during the dismantling operation (e.g., hot work). Torch cutting of surfaces with lead paint is a Level 3 Trigger Task and will require the use of supplied air respirators (SAR). This will be the case for the intact paint on the interior walls of the upper compartments of the wing-walls where lead was detected in the hundreds of thousands of parts-per-million. On the other hand, samples from the exterior yielded mainly non-detect to low (<600 PPM) levels of lead. These exterior areas with residual paint and the heavily corroded areas covering most of the exposed surfaces of the dry-dock are not likely to require SAR, but this must be confirmed by exposure monitoring. The lead content in sampled piles of corrosion debris and sediment was below the Total Threshold Limit Concentration (TTLC) for lead. Handling of this debris is not likely to result in exposures at or above the permissible exposure limits (PEL) for lead. This can be argued based on a hypothetical exposure to total “nuisance” dust at the 10 milligram per cubic meter of air (mg/M3) PEL. This is a substantial, vision impairing, cloud of dust that, if formed from the highest lead content debris found, would still only contain 0.3 micrograms of lead per cubic meter of air (ug/M3) as compared with the 30 ug/M3 “action level,” and the 50 ug/M3 PEL.

2

Disposal High lead content paint debris should be segregated from corrosion debris, sediment and other waste and disposed of as Class I lead-containing hazardous waste. The paint debris may also be considered RCRA waste. The two sediment samples and one of the four debris samples had results exceeding 10 times the Soluble Threshold Limit Concentration (STLC) and were re-analyzed by the Waste Extraction Test (W.E.T.). The WET result for one of the sediment samples and one of the debris samples exceeded the STLC for lead. Based on the TTLC and STLC findings together, it may be that there are lead “hot spots” in the deck debris, but that in the aggregate the total lead concentration in the debris is below the STLC. Handling the debris as Class I California Hazardous Waste would seem to be simpler and more cost effective than trying to define the portions of debris with high lead content. CAM-17 METALS (Compliance Assurance Monitoring) CAM-17 metals results for the samples of wing-wall sediment and corrosion debris were all below the relevant TTLC. However, results or detection limits for one or more metals in all of the samples exceeded 10 times the STLC and these samples were re-analyzed for the corresponding metal by the W.E.T. In addition to the lead findings cited above, the copper content in piles of corrosion debris exceeded the STLC in three of the four re-analyzed samples, but results for all other metals were below the STLC. It is recommended that the debris be handled as Class I California Hazardous Waste, as it would be simpler and more cost effective than trying to define the portions of debris with metal content. As with the airborne lead exposure scenario, the copper content in the debris would not generate exposures above the copper PEL under the nuisance dust “worst case scenario” with 1.6 ug/M3 of copper to be found in a 10 mg/M3 dust cloud generated from debris containing 1,600 ppm of copper, the highest concentration detected in the bulk samples. PCBs Light ballasts in the control room are assumed to contain polychlorinated biphenyl (PCB). It is estimated that there are 12-15 ballasts including those in lights and behind the instrument panel, but an exact number could not be determined without dismantling equipment. No PCBs were detected in the samples of oils and greases. Nevertheless, prior to the dismantling operation the capstan gear oils, lubricating greases, and petroleum gross contamination should be removed. There are an estimated 25 gallons of these bulk materials.

3

There is an estimated 10,000 to 15,000 square feet of upper deck port wing compartments walls contaminated with an oily film. During torch-cutting the oily film is likely to evolve smoke, or even ignite, which makes it an environmental and worker protection issue during the dismantling phase. This condition may be an issue for the recycler with pre-cleaning a requirement for acceptance. TREATED WOOD Treated wood was observed in the form of the side-bumpers on the dry-dock. Wood was also observed in the form of shaft bearings, but these are most likely a tropical hardwood referred to as “ironwood” and are not treated. Preservative treatment of the wood bumpers was most likely to have been using creosote. Creosote treated wood is Class II waste in California and not accepted for disposal at Class III sanitary landfills.

4

SECTION 2 - SAMPLING AND ANALYTICAL PROCEDURES The inspections and sampling were performed under previously approved Sampling, Health and Safety Plans. Initial access into the upper compartments on the wing-walls was under a permitted confined space entry procedure, using a 4-gas monitor and self-contained breathing apparatus (SCBA). After accessing the Starboard side compartments under this protocol, it was determined that the horn-ventilators on the deck were providing adequate ventilation. Subsequent entries into the upper and lower wing-wall compartments were performed without the use of SCBA but preceded by initial screening with the 4-gas monitor which was also worn inside the compartment during the inspection. Asbestos, lead and CAM-17 Metals analyses were performed by Micro Analytical Laboratories in Emeryville, California. Micro Analytical is a successful participant in the American Industrial Hygiene Association (AIHA) Proficiency Analytical Testing (PAT) program, and California Department of Health Services California Department of Health Services Environmental Laboratory Accreditation Program (ELAP) certified lab. PCB gas chromatographic (GC) analysis was performed by Curtis & Tompkins in Berkeley, California. Curtis & Tompkins is a California Department of Health Services National Environmental Laboratory Accreditation Certification (NELAC) certified lab. Inspections, and asbestos, lead, CAM-17 Metals and PCB bulk sampling were performed by Al Clancy, MPH, Certified Industrial Hygienist (ABIH CP#3879), Certified Hazardous Materials Manager (IHMM #2381 Master Level), Certified Asbestos Consultant (Cal-OSHA #92-0486), and Lead-Related Construction Certified Inspector (DHS #2239). Inspections and asbestos sampling were also conducted by Monte Deignan, Certified Asbestos Consultant (Cal-OSHA #93-0879). ASBESTOS Samples for asbestos were collected from suspect materials including the control room, epoxy-type coatings on the upper decks of the wings, gaskets on manholes in the upper decks and compartments of the wing-walls, and from the corrosion debris piles below pipes on the main lower deck. No gasket material was observed on valve flanges and other such types of joints, therefore no samples were collected. A minimum sample area of one square inch was collected for suspect ACM where feasible, and samples of corrosion debris consisted of a minimum of one cubic inch. Sample analysis was by polarized light microscopy (PLM). The bulk samples of suspected asbestos-containing materials are first examined by stereoscopic, dissecting microscope for determination of homogeneity and preliminary evaluation of composition and presence of fibers. Fibers noted during stereoscopic examination were mounted in

5

6

various refractive index oils for identification; homogenized portions of the entire samples were also mounted in R.I. oils for identification and quantification of all components. All minerals and/or man-made materials were identified and percentages of each estimated and/or counted. Bulk sample analysis was according to EPA-600/M4-82-020. LEAD AND CAM 17 METALS Samples for lead analysis were collected from paints on dry-dock surfaces, and samples for CAM-17 analysis were collected from representative piles of corrosion debris accumulated on the horizontal surfaces of the deck, and sediment in the wing lower compartments. A minimum sample amount of 5 grams was collected for lead paints, and 100 grams for the corrosion debris. Individual paint samples were collected from various areas on the deck and wings. Paint samples were analyzed for total lead using flame atomic absorption spectrometry (FAA) according to the EPA’s Standard Operating Procedures 1991. Corrosion debris sample analysis was by inductively coupled plasma (ICP) according to EPA 6010B for total metals and 7471 for total mercury for comparison against the Total Threshold Limit Concentration (TTLC). Samples with detection limits or results 10 times the relevant Soluble Threshold Limit Concentration (STLC) were re-analyzed for that metal according to the Waste Extraction Test (W.E.T.). POLYCHLORINATED BI-PHENYLS (PCBs): Bulk samples of oils and greases were collected from the capstans, lubrication manifolds, and a mound of grease on upper deck of the port wing wall. A wipe sample was also collected from the interior sidewalls below the upper deck of the port wing wall that was visibly coated with an oily film. The sample was collected using filter paper soaked in hexane that was wiped over the surface and then placed in a glass jar. PCB sample analysis was performed according to EPA 8082. Samples were given unique identification numbers that were entered in the field notes along with the locations which are shown in Table X. Samples were transported to the laboratory under a duly executed chain-of-custody (COC) that included sample identification numbers and descriptions. COCs accompany the analytical reports that are contained in the appendix to this report.

APPENDICES

APPENDIX 1

ASBESTOS

LOCATION PLAN AND LAB RESULTS

Asbestos Inspection and Recommendations Facility: Drydock #1, Port of San Francisco 20th and Illinois Streets, San Francisco, CA Date : 3-26-07 to 4-6-07 Inspectors: Alfred Clancy, CIH and Monte Deignan, CAC

Comments / Notes : 1: The sample logs show the prefix LEE 032607. The LEE part of the prefix is not shown on this page. 2: Construction estimates should not use this estimate for price / cost calculations. A site visit is required for verification by any contractor. 3: The material described is found in small amounts over a wide area. A site inspection is the only way to quantify this item. 1 of 3

Sample # Material Description Locations Area Asbestos % Recommendations

32607-01 Wire Insulation, Tan/ Black Switch Box NA None Detected No asbestos removal work required

32607-02 Insulation Board,Brown Starbd Wall NA None Detected No asbestos removal work required

32607-03 Non Skid Deck Surface,Brown Starbd Wall NA None Detected No asbestos removal work required

32607-04 Epoxy Deck Surface,Green Starbd Wall 680 sf 5% Chrysotile Abate following Class II regulations if disturbed

32607-05 Transite Cement Board, Gray Control Room 480 sf 20% Chrysotile Abate following Class II regulations if disturbed

32607-06 Insulation Fabric, Gray Control Room 28 lf 80% Chrysotile following Class I regulations if disturbed

32607-07 Wire Insulation, Gray Control Room Note 3 40% Chrysotile Abate following Class I regulations if disturbed

32607-08 Wire Insulation, Tan Control Room NA None Detected No asbestos removal work required

32607-09 Transite Elec. Debris, 1/2" Starbd Wall Note 3 20% Chrysotile Abate following Class II regulations if disturbed

32607-10 Weatherstrip/ Gasket, Gray Supply Cab 12 lf 70% Chrysotile Abate following Class I regulations if disturbed

32607-11 Deck Coating, Gray Starbd Wall NA None Detected No asbestos removal work required

32607-12 Cement / Mortar, Gray Starbd Wall NA None Detected No asbestos removal work required

32607-13 Cement Transite Board, Gray Starbd Wall Note 3 20% Chrysotile Abate following Class II regulations if disturbed

32607-14 Woven Gasket, Gray Starbd Hatch Note 2 70% Chrysotile Abate following Class I regulations if disturbed

32607-15 Exterior Caulking, Red Starbd Hatch NA None Detected No asbestos removal work required

Asbestos Inspection and Recommendations Facility: Drydock #1, Port of San Francisco 20th and Illinois Streets, San Francisco, CA Date : 3-26-07 to 4-6-07 Inspectors: Alfred Clancy, CIH and Monte Deignan, CAC

Comments / Notes : 1: The sample logs show the prefix LEE 032607. The LEE part of the prefix is not shown on this page. 2: Construction estimates should not use this estimate for price / cost calculations. A site visit is required for verification by any contractor. 3: The material described is found in small amounts over a wide area. A site inspection is the only way to quantify this item. 2 of 3

Sample # Material Description Locations Area Asbestos % Recommendations

32607-16 Resilient Gasket, Black Starbd. Hatch NA None Detected No asbestos removal work required

32607-17 Woven Gasket, Brown Starbd. Hatch NA None Detected No asbestos removal work required

32607-19 Residual Debris, Brown Main Deck NA None Detected No asbestos removal work required

32607-20 Residual Debris, Brown Main Deck NA None Detected No asbestos removal work required

32607-21 21 Insulation Board, Brown Port Compt. Note 2 30% Chrysotile Abate following Class II regulations if disturbed

32607-22 2.5 " Pipe Insulation, White Strbd Compt. 450 lf 20% Chry.10% Amos Abate following Class I regulations if disturbed

32607-23 Insulation Board Debris, White Starbd Wall Note 3 50% Chrysotile Abate following Class I regulations if disturbed

32607-24 Insulation Debris, White Starbd Pump Note 3 30% Chrysotile Abate following Class I regulations if disturbed

32607-25 Woven Gasket, Gray Port Hatch Note 2 50% Chrysotile Abate following Class I regulations if disturbed

32607-26 Exterior Wall Paint, Silver Port Wall NA None Detected No asbestos removal work required

32607-27 Exterior Sealant, Red Brown Port Wall NA None Detected No asbestos removal work required

Asbestos Inspection and Recommendations Facility: Drydock #1, Port of San Francisco 20th and Illinois Streets, San Francisco, CA Date : 3-26-07 to 4-6-07 Inspectors: Alfred Clancy, CIH and Monte Deignan, CAC

Comments / Notes : 1: The sample logs show the prefix LEE 032607. The LEE part of the prefix is not shown on this page. 2: Construction estimates should not use this estimate for price / cost calculations. A site visit is required for verification by any contractor. 3: The material described is found in small amounts over a wide area. A site inspection is the only way to quantify this item. 3 of 3

Sample # Material Description Locations Area Asbestos % Regulatory

32607-04 Epoxy Deck Surface,Green Starbd Wall 680-750 sf 5% Chrysotile Class II regulations apply

32607-05 Transite Cement Board, Gray Control Room 480-650 sf 20% Chrysotile Class II regulations apply

32607-06 Insulation Fabric, Gray Control Room 28-40 lf 80% Chrysotile Class I regulations apply

32607-07 Wire Insulation, Gray Control Room 200-360 lf 40% Chrysotile Class I regulations apply

32607-09 Transite Elec. Debris, 1/2" Starbd Wall 100-160 sf 20% Chrysotile Class II regulations apply

32607-10 Weatherstrip/ Gasket, Gray Supply Cab 12-16 lf 70% Chrysotile Class I regulations apply

32607-13 Cement Transite Board, Gray Starbd Wall 50-100 sf 20% Chrysotile Class II regulations apply

32607-14 Woven Gasket, Gray Starbd Hatch 160-200 lf 70% Chrysotile Class I regulations apply

32607-21 Insulation Board, Brown Port Compt. 100-180 sf 30% Chrysotile Class II regulations apply

32607-22 2.5 " Pipe Insulation, White Strbd Compt. 450-550 lf 20%Chry.10% Amos Class I regulations apply

32607-23 Insulation Board Debris, White Starbd Wall 2-10 sf 50% Chrysotile Class I regulations apply

32607-24 Insulation Debris, White Starbd Pump 10-20 sf 30% Chrysotile Class I regulations apply

32607-25 Woven Gasket, Gray Port Hatch 160-200 lf 50% Chrysotile Class I regulations apply

APPENDIX 2

LEAD

LOCATION PLAN AND LAB RESULTS

Lead Inspection and Recommendations Facility: Drydock #1, Port of San Francisco 20th and Illinois Streets, San Francisco, CA Date : 3-26-07 to 4-6-07 Inspector: Alfred Clancy, CIH and Monte Deignan, CAC

Comments / Notes : 1 LBP: Lead Based Paint at levels above 5000 ppm. LCP: Lead Containing Paint at levels between 600 and 5000 ppm Paint with lead levels below 600 ppm is classi. ed as Lead Free. Any sample result above the limit of detection may pose a risk if performing certain "Trigger Task Activities", such as grinding, torch cutting, rivet busting.

1 of 1

Sample # Material Description Locations % Lead / ppm Recommendations 32607-A Paint: Gray, Green, Orange Starbd Wing Wall, Stern 22.2% / 222,025 Follow Cal / OSHA & DHS regulations for LBP

32607-B Paint: Brown, Green Starbd Wing Wall, Stern 0.52% / 5180 Follow Cal / OSHA & DHS regulations for LCP

32607-C Paint: White, Gray Starbd Wing Wall, eBox 4.04% / 40,381 Follow Cal / OSHA & DHS regulations for LBP

32607-D Epoxy / Paint: Green Starbd Wing Wall, Deck 0.68% / 6806 Follow Cal / OSHA & DHS regulations for LBP

32607-E Paint: Orange / Silver Starbd Wing Wall, Stern 9.2% / 91,993 Follow Cal / OSHA & DHS regulations for LBP

32607-F Paint: Red / Orange Starbd Wing Wall, Stern 6.47% / 64,653 Follow Cal / OSHA & DHS regulations for LBP

32607-G Paint: Tan / Brown Starbd Wing Wall, 475’ 5.31% / 53,067 Follow Cal / OSHA & DHS regulations for LBP

32607-H Paint: Green Control Room Interior 9.26% / 92,560 Follow Cal / OSHA & DHS regulations for LBP

32607-I Paint: Blue / Gray Control Room Exterior 0.04% / 422 Follow Cal / OSHA & DHS regulations for LFP

32607-J Paint: Black Starbd Wing Wall, Bow 3.98% / 39,818 Follow Cal / OSHA & DHS regulations for LBP

32607-K Paint: Black Main Deck @ 50’ <0.01% / <75 Classified as Lead Free Coating, < report limits

32607-L Paint: Silver Port Wing Wall, Bow <0.01% / <79 Classified as Lead Free Coating, < report limits

32607-M Paint: Tan / Gray Port Wing Wall, Bow 0.25% / 2473 Follow Cal / OSHA & DHS regulations for LCP

32607-N Paint: Brown Port Wing Wall, Bow 1.86% / 18,562 Follow Cal / OSHA & DHS regulations for LBP

32607-O Paint: Silver / Black Port Wing Wall, Bow <0.01% / <74 Classified as Lead Free Coating, < report limits

32607-P Paint: Silver Port Wing Wall, Bow 0.01% / 123 Follow Cal / OSHA & DHS regulations for LFP

40307-A Paint: Gray, Green, Orange Starbd Hatch#3 Gear 14.2% / 142,176 Follow Cal / OSHA & DHS regulations for LBP

APPENDIX 3

CAM17

LOCATION PLANS, TTLC AND STLC LAB RESULTS

Facility: Drydock #1 Port of San Francisco 20th & Illinois Street San Francisco, CADate : 03-26-07 to 04-04-07 Inspector: Alfred Clancy, CIH

Comments / Notes : Note:1 For the fi rst line listing TTLC values, results or detection limits at or above 10x the Soluble Threshold Limit Concentration are shown in Bold text. Gray text is < 10x STLC. For the second line listing STLC values, results or detection limits at or above the Soluble Threshold Limit Concentration are shown in Bold text. Gray text is < STLC.The units for all of the sample results are parts per million (ppm) Version 5: July, 2007

CAM-17 Metals STLC and TTLC Results Listing

Page 1 of 1

Sample ID # Ag As Cd Cr/ CR+6 Cu Pb Sb Se Tl Zn Hg

TTLC Value, ppm 500 500 100 2500 / 500 2500 1000 500 100 700 5000 20STLC Value, ppm 5 5 1 5 25 5 15 1 7 250 0.2

32607-A, TTLC <30 <120 19 25 200 240 <240 <60 <240 3400 3.432607-A, STLC NA 4.8 <0.2 NA NA 7.6 3.0 <0.3 5 190 0.001 32607-B, TTLC <31 <470 21 61 160 90 <250 <12 <250 2400 3.032607-B, STLC NA <0.5 <0.2 <0.5 NA <0.3 <1 <0.3 <4 160 <0.001 32607-CO1,TTLC <120 <470 14 110 250 33 <200 <12 <47 550 0.332607-CO1, STLC <0.3 <0.5 NA 0.5 16 NA <1 <0.3 NA NA NA 32607-CO2,TTLC <120 <470 56 200 1600 33 <200 <12 <47 550 1.432607-CO2, STLC <0.3 <0.5 <0.2 0.5 120 NA <1 <0.3 NA NA NA

32607-CO3,TTLC <120 <470 63 200 830 48 <200 <60 <9 670 0.932607-CO3, STLC <0.3 <0.5 <0.2 <0.5 60 1 <1 <0.3 NA NA NA

32607-CO4,TTLC <120 <470 56 140 820 300 <200 <60 <9 880 0.932607-CO4, STLC <0.3 <0.5 <0.2 <0.5 70 30 <1 <0.3 NA NA NA

APPENDIX 4

PCBs LAB REPORTS

PCBs Inspection and Recommendations Facility: Drydock #1, Port of San Francisco 20th and Illinois Streets, San Francisco, CA Date : 3-26-07 to 4-6-07 Inspectors: Alfred Clancy, CIH and Monte Deignan, CAC

Comments / Notes : 1: The sample logs show the prefix LEE 032607. The LEE part of the prefix is not shown on this page. 2: Construction estimates should not use this estimate for price / cost calculations. A site visit is required for verification by any contractor. 3: The material described is found in small amounts over a wide area. A site inspection is the only way to quantify this item. 1 of 1

Sample # Material Description Locations Notes Lab #

32707-01 Lube / Grease Pile Top Deck Port Wing Wall PCB 193997-001

40307-01 Wipe of Oily Compartment Walls Top Compartment Hatch #4 Port PCB 193997-002

40307-02 Bulk Lube Grease from Dispensing Canister Top Compartment Fore-Port Side PCB 193997-003

40307-03 Gear Oil in Capstan Gear Box Starboard Side Forward PCB 193997-004

40307-04 Wipe of Compartment Walls Top Compartment Starboard PCB 193997-005

APPENDIX 5

INTERIOR AND EXTERIOR CONSTRUCTION MATERIALS

AND EQUIPMENT

The interior walls of the drydock are painted steel, with substantial oxidation and corrosion. The floor of the top compartment in the wingwall is also steel with advanced corrosion that has resulted in holes and openings through the floor plane. Working in the compartments represents a possible fall hazard and must be addressed by any contractors at the site. The mechanical equipment in the compartments consist of electrical pumpmotors, capstan motors, valve actuators, switch gear, electrical conduits,and piping. The switch gear is found in multiple switch boxes and contains Transite backing boards and insulators that contain asbestos. The capstan units appearto have brake shoe assemblies that are assumed to contain asbestos.

Photo 1 shows the starboard wingwall compartment, with the corrosion visible on the walls and floor. The inspector is in front of one of the electricalboxes that uses an asbestos containing backing board. The overhead piping consists of conduit and an insulated steam line. Photo 2 shows one of the expansion loops at another part of the same steam line. The insulation on the line contains asbestos and will need to be abated using Class I abatement practices. See the complete report for more information.

Photo 2

Interior Construction Materials and Equipment Facility: Drydock #1, Port of San Francisco 20th and Illinois Streets, San Francisco, CA Date : 3-26-07 to 4-6-07 Inspectors: Alfred Clancy, CIH and Monte Deignan

Photo 1

The electrical and mechanical equipment for the drydock use a number of components that contain asbestos. The wiring shown in Photo 3 above is typical of the wiring found in sample number LEE 32607-06. The wire insulation contains up to 80% asbestos. Most of the interior walls in the control room are Transite asbestos. Most of the pumps and valves are controlled by switches and relays. The switch gear is found in multiple switch boxes and contains Transite backing boards and switch insulators that contain asbestos.

Photo 4 shows the starboard wing wall compartment, with the capstan moto rand gearbox. A large shaft extends to the capstan drum that is located above the deck. The capstan units appear to have brake shoe assemblies that are assumed to contain asbestos. The brakes are the red colored units at the left side of the photo. The capstan gearbox also contains a significant amount of 90 weight gear oil. Some of the other units have leaked and spilled oil on the floor of the compartments. See the complete report for more information.

Photo 4

Interior Construction Materials and Equipment Facility: Drydock #1, Port of San Francisco 20th and Illinois Streets, San Francisco, CA Date : 3-26-07 to 4-6-07 Inspectors: Alfred Clancy, CIH and Monte Deignan

Photo 3

The exterior of the drydock is predominantly painted steel. The top of the The exterior of the drydock is predominantly painted steel. The top of the wing walls are coated with a variety of non skid paints and epoxies. A number of steel hatches are placed along the length of both wing walls. Piping, conduits, and vents are also found along the wing walls. A series of electrical switch boxes are found on the top of the wing wall. The control room for the raising and lowering of the dock is located on the stern end of the starboard wing wall. The control room houses the switches, gauges, and systems to run the drydock. The exterior and interior walls of the control room are Transite asbestos board. Many of the wire insulators and the door gaskets contain asbestos.

wing walls are coated with a variety of non skid paints and epoxies. A number of steel hatches are placed along the length of both wing walls. Piping, conduits, and vents are also found along the wing walls. A series of electrical switch boxes are found on the top of the wing wall. The control room for the raising and lowering of the dock is located on the stern end of the starboard wing wall. The control room houses the switches, gauges, and systems to run the drydock. The exterior and interior walls of the control room are Transite asbestos board. Many of the wire insulators and the door gaskets contain asbestos.

Photo 5 shows the deck from the control room. The green colored epoxy Photo 5 shows the deck from the control room. The green colored epoxy coating near the control room contains asbestos. The other gray and brown non skid surfaces were non asbestos. The electrical boxes that contain phenolic backing boards are along the side of the wall. The gaskets and seal used on doors and hatches appear as a woven fabric and most contain asbestos.

coating near the control room contains asbestos. The other gray and brown non skid surfaces were non asbestos. The electrical boxes that contain phenolic backing boards are along the side of the wall. The gaskets and seal used on doors and hatches appear as a woven fabric and most contain asbestos. Photos 6 and 7 are of the starboard wing wall. The paints typically contain high levels of lead but do not contain asbestos. A series of wood rails are located on the outside or on the corners of the walls. The wood appears to be creosote treated.

Photos 6 and 7 are of the starboard wing wall. The paints typically contain high levels of lead but do not contain asbestos. A series of wood rails are located on the outside or on the corners of the walls. The wood appears to be creosote treated. See the complete report for more information. See the complete report for more information. Photo 7 Photo 7

Photo 7

Interior Construction Materials and Equipment Facility: Drydock #1, Port of San Francisco 20th and Illinois Streets, San Francisco, CA Date : 3-26-07 to 4-6-07 Inspectors: Alfred Clancy, CIH and Monte Deignan

Photo 6 Photo 5

Interior Construction Materials and Equipment Facility: Drydock #1, Port of San Francisco 20th and Illinois Streets, San Francisco, CA Date : 3-26-07 to 4-6-07 Inspectors: Alfred Clancy, CIH and Monte Deignan

The electrical and mechanical equipment for the drydock use a number of components that contain asbestos. The switch box backing shown in Photo 8 above is typical of the panels found in sample number LEE 32607-21. The board contains up to 20% asbestos. Most of the pumps and valves are controlled by switches and relays. The switch gear is found in multiple switch boxes and contains Transite backing boards and switch insulators that contain asbestos. Photo 9 shows a series of white or gray colored insulation parts that are Transite. Many of the these insulator parts are scattered around the deck and compartments.

Photo 9 shows the starboard wing wall compartment, with the pump motor. A large shaft extends to the pump that is located below the deck. The pumps are located in compartments near the waterline. It is assumed that the pumps may contain packing on the shafts that contain asbestos. Due to the condition and location the pump packing was not sampled. The base of the pump motor also contains a significant amount of lube or gear oil. Some of the other units have leaked and spilled oil on the floor of the compartments. See the complete report for more information. Photo 8 Photo 10

Photo 10 Photo 9 Photo 8

Interior Construction Materials and Equipment Facility: Drydock #1, Port of San Francisco 20th and Illinois Streets, San Francisco, CA Date : 3-26-07 to 4-6-07 Inspectors: Alfred Clancy, CIH and Monte Deignan

APPENDIX 6

SAMPLING LOCATION SCHEMATIC DIAGRAM

Mechanical Compartment

Mechanical Compartment

Control Room

Starboard Wing Wall

Port Wing Wall

Bow

Stern

Sampling Location Schematic - 1

Asbestos SurveyMarch- April 2007

PLM-01Wire Ins.

PLM-21Board

PLM-03Deck

PLM-02Board

PLM-04Deck

PLM-05Transite

PLM-06Wire Ins.

PLM-07Wire Ins.

PLM-08Wire Ins.

PLM-09Transite

PLM-10Gasket

PLM-11DeckPLM-12Mortar

PLM-14Gasket

PLM-13TransitePLM-15

CaulkingPLM-16Gasket

PLM-17Gasket

PLM-19Debris

PLM-20DebrisPLM-22

TSI Pipe

PLM-23Debris

PLM-24Insulation

PLM-25Gasket