Dimension system-hosts-colony-of-cranes

-

Upload

tensar -

Category

Engineering

-

view

97 -

download

0

Transcript of Dimension system-hosts-colony-of-cranes

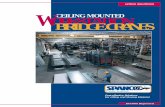

Dimension® System Hosts Colony ofCranes at California Bridge Project

Issue 14.2 — fall 2004Tensar Earth Technologies, Inc. geoC

Geosynthetics Applications Newsletter

Crane watching in northern California isn’t for the birds – at least not at the site of a three-year interchange/bridge project

currently underway on Interstate 680.

The cranes there aren’t the feathered, water-loving variety; they’re a colony of Manitowocs busy with pile operations

and construction in the major expansion of the Benicia-Martinez bridge east of San Francisco. And they’re doing it atop

TET’s Dimension® Foundation Improvement System.

The $42 million California Department of Transportation project, awarded to FCI Constructors in the summer of 2002,

specifies a new five-lane approach for northbound traffic. The approach will flare to 17 lanes through a new toll plaza

and return to four lanes on a new northbound bridge. The project site, described as “brackish marshlands” in an industrial

area, required construction of a working platform to support critical crane activity.

“We initially tried a coated polyester geogrid product with little success,” commented David Niese, P.E., senior project

manager at FCI North, a subsidiary of Netherlands-based HBG Constructors. About that time, Ron Illium, P.E., TET

business development manager for the Pacific region, submitted a value-engineered Dimension System proposal to FCI –

one that Illium felt was “a more cost effective and efficient way to handle the platform than FCI’s original solution.”

The Dimension System was developed to provide a stable foundation at a lower cost than conventional methods. The

system’s components include Tensar BX Geogrids and cohesionless soil, working together to create a stiffened platform

and distribute loads over weak, compressible soils. Among its benefits, the Dimension System increases bearing capacity

while it reduces differential settlement, undercutting, and backfilling.

“The foundation soil at the site included clay and silt, and groundwater was located at the bottom of the embankment,”

said Jong Lee, TET design engineer. To accommodate these conditions, the design featured two layers of BX1200 Geogrid,

with 1 foot of 1-inch aggregate sandwiched in between and 3 feet of 3-inch drain rock on top. The structure was designed

to support crane weights up to 560 kips and pick loading up to 150 kips. To date, the project has required more than

30,000 square yards of geogrid, according to Lynn Friesner, technical manager at Reed & Graham, TET’s regional distributor.

The majority of the installation took place over the first month and has continued as needed. FCI’s Niese, who had

worked with other Tensar Systems prior to the project, has been delighted with the results.

“I didn’t envision it performing as well as it has,” Niese said. “We’vehad no settlement or pumping issues. Settlement

has ranged from 1/2 to 3/4 of an inch with 3,000 pounds per-square-foot loads.

“The installation was originally intended for job access. But with load testing, we’ve been able to eliminate temporary

piles for supporting bridge formwork — it’s now supported on pads placed directly on the fill. We’re talking about 740,000

pounds of crane load.”

Located in sensitive wetlands, the Benicia-Martinez project may not

feature cranes from the animal kingdom, but it has garnered quite a bit

of interest -— and not just from other contractors who have come to

observe the work. The Discovery Channel’s Canadian outlet visited the

site to film the “Big Stan” drill rig for its “Monster Machines” series!

™

The Dimension Foundation Improvement System

was used to support extremely heavy crane loads

at the Benicia Bridge expansion project.

�