Diamond Wire Saw DW 291 - meyerburger.com · Diamond Wire Saw DW 291 Smart slicing technology for...

Transcript of Diamond Wire Saw DW 291 - meyerburger.com · Diamond Wire Saw DW 291 Smart slicing technology for...

Diamond Wire Saw DW 291Smart slicing technology for mono- and multi-silicon

We

rese

rve

the

right

to m

ake

chan

ges

refle

ctin

g te

chni

cal p

rogr

ess

(05/

2018

)

Increased throughput

870 mm web length (+34%) 33 m/s wire speed (+10%) 10 m/s2 acceleration (+25%) 2x 68 kW motor power (+95%)

Thin wire capability

Diamond Wire Management System (DWMS) High-end motion control technology 93% lower pulley and load cell inertia 40% shorter wire path – shortest in industry 40% higher wire tension accuracy

Robustness and durability

Compact mineral cast machine frame Lowest temperature and vibration dependency Rigid coupling of wire guide roll and bearing Automated central lubrication system

Higher degree of automation and easy operation

75% less HMI interaction for machine operation Dialog based operation Best accessibility for operation and maintenance personnel Industry 4.0 capable

All figures compared to DW 288 Series 3

Conventional DWMS

Working area / Storage area

Highest throughput at lowest cost

Market-proven and award-winning DWMS including resharpening technology and extended winding feature

Patented in China (Patent No. CN 104411434B) Lowest wire consumption Enables faster cutting times Optimized for thinner wire Lowest wire breakage rate

Cropping Bricking Grinding Gluing Wafering De-gluing Separation Cleaning Inspection

M4 capableOptimized for M4 (161.7 mm) wafer format

HMINew HMI on 19" touch screenProduction assistantGlobal process recipesEasy to train, easy to use

High throughput33 m/s wire speed 10 m/s2 acceleration

Cleaner wafer 490 l cutting fluid tank

Thin wire capability

More wafers per kilogram of silicon

Thinner wire Less silicon kerf More wafers

60 µm80 µm 70 µm

60 µm core wire 50 µm core wire 40 µm core wire

Future

DWMS50 µm wire managementcapability

High capacity 870 mm web length

Shortest wire pathOnly < 1.9 m on one sideEasy wire set-up and constant tension

Diamond Wire Management System (DWMS)

Robust machineMineral castLow vibration, low noisePerfect alignment of all relevant machine parts

Slicing process expertise

Established slicing recipe for mono- and multi-Si Optimized consumables and wear parts to attain best wafer quality at lowest cost of ownership

Turn-key process solution– Latest developments of thin diamond wire – Blaser water-based cutting fluid – Beam and glue for thin wire and thin wafer capability

Dedicated wafering R&D line and laboratory Exclusive partnership from leading consumable suppliers

Cropping Bricking Grinding Gluing Wafering De-gluing Separation Cleaning Inspection

Human Machine Interface (HMI)

New HMI (MBVis) enables intuitive operation Highest automation degree for preparation, slicing and retraction

User friendly and fast dialog based production assistant

Configurable user levels Multilingual interface Integrated offline help menu

Shorter cutting time, higher throughput, excellent wafer surface and quality

– Wire speed 33 m/s – Wire acceleration 10 m/s2

Lower wire bow due to higher wire tension Suitable for 3 multi-Si brick load Multi-SiMono-Si

Higher average wire speed

Maximized uptime lowers costs

Efficient and proactive service Highly skilled local service engineers Optimized Total Cost of Ownership with long-lifetime parts

Condition monitoring and predictive maintenance to avoid downtime

Swift response time with local parts warehousing Local overhaul service for quick processing of wire guide roller (WGR) regrooving, recoating and bearing overhaul

Customized technical training and process support, HMI assisted

Technical data at a glance

Meyer Burger (Switzerland) AG, [email protected], www.meyerburger.com

Options & Dimensions

We

rese

rve

the

right

to m

ake

chan

ges

refle

ctin

g te

chni

cal p

rogr

ess

(05/

2018

)

Cropping Bricking Grinding Gluing Wafering De-gluing Separation Cleaning Inspection

Options

Wire speed, acceleration (33 m/s, 10 m/s2) Thin wire capability 50 µm Re-sharpening feature

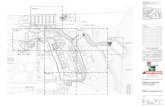

Dimensions (mm)

unit DW 291 Features DW 291 Options

Web length [mm] 870

Max. workpiece dimensions [mm] 165 × 165

Wire speed [m/sec] 30 33

Wire acceleration [m/s2] 8 10

Min. wire diameter [µm] 60 50

Min. wafer thickness [µm] 100 (mono-Si), 140 (multi-Si)

Workpiece holders [mm] 860

Wire guide roller axis distance [mm] 390

Wire on working spool [m] max. 7000 (60 µm)

Cutting fluid tank [l] 490

Machine weight [kg] 7900

~ 2

500

~ 2

300

Side viewFront view

~ 1200 ~ 1600

~ 2000 ~ 3700

Extended winding Automatic Cutting Fluid Exchange Utility Consumption Measurement MES interface based on PV2 protocol