D&H Colonie Shop

-

Upload

staustell92 -

Category

Documents

-

view

644 -

download

13

description

Transcript of D&H Colonie Shop

------------------------------------~=~----=~---

8 THE CALL BOARD NEWSLETTER OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S. January 1991

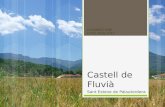

The Delaware & Hudson'sColonie ShopsBy Tim Truscott andDick Barrett

Between the turn of the century and thebeginning of the Great Depression in 1929,the railroad industry in the northeasternUnited States was at its zenith. Many of theClass I railroads, such as the Delaware &Hudson, were amassing great wealth fromthe huge amount of traffic that they werecarrying. After all, railroads were the fastestand most efficient way to carry people andgoods at that time. The nation's highwaysystem, which came to be an alternative tothe railroads, had not yet developed. Therailroads were also the chief conveyer ofthe nation's primary energy source, coal.

The railroad industry's wealth allowedit to meet the demand for new facilities, thedemand for which was brought about bythe changing railroad technology of largerlocomotives and other equipment and bythe increase in the numbers of pieces ofequipment needed for railroad operations.On the Delaware & Hudson, this change inrailroad technology and the increase inbusiness and the wealth derived from thatbusiness resulted in a number of majormodernization projects in its physical plant:

The Oneonta roundhouse, the largest inthe world at the time, was built in 1906.

A 40-stall roundhouse-in Carbondaleand a 10-stall enginehouse and engine ter-minal in Binghamton were opened in 1911.

In 1911 a 37 -mile grade-reductionproject was undertaken between NinevahJunction and Oneonta.

The D&H Building, the headquartersfor the railroad in downtown Albany whichwas unmatched for its size and architecturalbeauty, was built in 1914-15.

The compensated grade line, extendingalong the south side of the valley betweenSchenevus and Richmondville Summitabove East Worcester, was completed in1921 and facilitated the movement ofnorthbound traffic up the south side ofRichmondville Hill.

In 1911 and 1912, when it was in its peekperiod of expansion and modernization,the Delaware & Hudson Railroad con-structed a new mechanical facility andfreight yard in the Town of Colonie adja-cent to Watervliet, New York, approxi-

mately five miles north of Albany. The newColonie facility, constructed at a cost ofapproximately $2 million dollars, was thelargest railroad mechanical facility in NewYork State at the time and was said to beequal to any in the eastern United States.

Colonie replaced the railroad's locomo-tive terminal and repair shop at Green Island,just a couple of miles further north from theColonie site, as well as its coach yard fa-cilities in Albany. In fact, Colonie alsoreplaced older facilities for heavy mechani-cal work at Carbondale and Oneonta, whichwere inadequate for the size of locomotivesand volume of work required at the time.

The basic design philosophy for Coloniewas to utilize the good functional designfeatures of the leading shops around thecountry rather than to seek an architecturaleffect. Two of the chief design criteria were

to provide good ventilation and as muchlight as possible. While the largest of theDelaware & Hudson's locomotives wereworking on the southern end the railroad atthis time, the Colonie facilities were de-signed with the possibility in mind thatthese large locomotives might be used onthe northern end of the line in the future.

Unlike the New York Central's WestAlbany Shop complex, which evolvedthrough a series of stages of constructionand redevelopment beginning in the 1850s,the Delaware & Hudson's Colonie me-chanical plant was constructed as an en-tirely new facility where there were noprevious railroad structures.

The Colonie project was under the im-mediate supervision of Mr. V. Z. Caracristi,Consulting Engineer of the Delaware &Hudson. Its size and modem design were

An aerial view from the south of the Delaware & Hudson's ColonieShop complex. Note the roundhouse and smoke stack of the powerhouse at the center of the photo, as well as the locomotive shop at theright (the large building above the locomotive shop is the WatervlietArsenal). To the left of the roundhouse is car shop, planing mill andtruck shop. The mainline extends diagonally to left of center. Partiallyconcealed by the smoke from the roundhouse are the coal trestle andash pits. The date of the photo is unknown. (Collection of the authors)

January 1991 NEWSLETTER OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S. THE CALL BOARD 9

equal to any other in the east at the time.The Colonie facility was constructed

with a north-south orientation on a 160-['.....;~•• 'acre tract of land, and comprised a general

omotive repair shop (including a mainshop, foundry and hammer shop), a loco-motive repair terminal (including a round-house with the necessary facilities for coal-ing, watering and storing steam locomo-tives), a large coach yard (in which passen-ger cars were cleaned and classified), afreight car receiving yard and repair shop,a paint shop, and a stores department. All ofthe buildings were constructed with theirlong dimension on a north-south orienta-tion and designed so that they could beexpanded in the future, if necessary, with-out interfering with one another. Of par-ticular interest, the locomotive shop andthe car shop were provided with expansionpotentials of at least 50 percent, while theroundhouse could be expanded by 11 or 12stalls (over 30%).

Outdoor craneways served the principlebuildings within the facility and were situ-ated on either a north-south or east-westaxis. Some of these craneways 'Wereequipped with more than one crane. Thepurpose of these cranewa ys was to providefor the efficient movement of materials

between buildings and between outdoorlocations, as well as into and out of thebuildings. A high-speed craneway, with aspan of 671/2 ft. and a capacity of 5 tons, ranin an east-west direction on the north sideof the car shop all the way to the easternedge of the property, a distance of 1,162 ft.This craneway tied the entire Colonie fa-cility together. Another craneway with a100-ft. span and a capacity of 10 tons ran inan north-south direction and separated thelocomotive shop from the foundry and storesbuilding. A third crane, 450 ft. long with an85-ft. span and a 5-ton capacity, served asa yard crane south of the planing mill forthe purpose of moving lumber in thestockpile.

The locomotive shop, located on theeast side of the property, was by far thelargest building constructed in the Coloniecomplex. With a north-south dimension of510 ft. and and east-west dimension of 387ft., it housed all units of the locomotivedepartment except the hammer shop andfoundry. The building consisted of sevenbays across its 387 ft. width, with the centerbay (transfer bay) and the two bays adjoin-ing the center bay (erecting bays) on eachside being 69 ft. wide, while the side bayswere 59 ft. wide and the outside bays were

An aerial view from the north of the Delaware & Hudson's ColonieShop complex. At center is the 3D-stall roundhouse with the locomotiveshop to the left of it. To the right of the roundhouse is the truck shop,'planing mill and car shop. The mainline extends diagonally to theright of the roundhouse. The date of the photo is unknown. (Collectionof the authors)

30 ft. in width. The outside bays had secondstory "galleries" (more recently referred toby D&H personnel as "balconies") alongthe outside walls.

Steam locomotives brought into the shopfor overhaul entered the building on one oftwo tracks through doors near the middle ofthe west side of the building. Engines werede-greased with hot water under pressureon a washing table just outside the buildingbefore entering. This arrangement replacedthe use of lye vats for de-greasing, whichhad been the customary method, and wassafer and more economical.

Unlike most locomotive shops of theperiod, the Delaware & Hudson's ColonieShop used a I50-ton capacity Shaw electriccrane to position steam engines within theshop, rather than the customary transfertable and pit. This procedure provided aneconomy of space so that other functionscould be performed within the building.

The 150-ton, 65-ft. span transfer cranewould lift a steam engine and place it in aneast-west position over a pit in the centerbay (transfer bay) in the north half of theshop, where it was to be stripped. Shoptrucks were placed under the engine after itwas stripped, and the engine moved eithereast or west into one of the two erectingbays (one erecting bay on either side of thetransfer bay) by means of an electric winch.

The erecting bays each had 12 pits, whilethe transfer bay had a total of seven pits.Two of the pits in the transfer bay were inincoming and outgoing tracks, while theremaining five pits in this bay were situatedin alternating tracks of the other ten trackpositions of this bay. Each of the erect-ing bays was equipped with a 100-ton ca-pacity Shaw overhead electric crane whichhad a 65-ft. span.

When the engine was stripped in thetransfer bay, the parts which required re-pair were transported from the transfer bayto their respective departments while theremaining parts not needing repair werestored in the transfer bay until they wereneeded for re-assembly (erecting).

Under the east gallery in the south end ofthe building was a small work smith shop.The south end of the transfer and erectingbays was used as a boiler shop, while aportion of the easterly bay served as atender shop. Each of the bays in the southend was served by lO-ton Shaw overheadelectric cranes. Heavy machine work wasperformed in the north end and centralportion of the two 59-ft. bays, which wereserved by lO-ton and 30-ton cranes. Lightmachine work was performed on both theground floor and the gallery level of the

10 THE CALL BOARD NEWSLETTER OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S. January1991

r"'<0~~I/>:l"0"D•.a..:l"•.C.•;;~ •~ ~.•II>

rJ: ~~c::Co q..0

"0 Ii Ir"

R.. ~~~ ~"..•• 71n"

~

I,i> vr- \j~'?-<

I

m'~ ~ ~ ~ ~ ~ I:!lit~

~i~;~~

--~------".------------,

if I4---",,=,-,=-, ----t I

, , • 1.I- --1--- !JIJ7' -' - -- --l.--I ! T 1~1! I I -

~

~I~ h 7- I•• .-

I~, ~ -,f ... ::!

~I , ~ '"\' -~-~ - - i I;~ ~- ~ ~' ,.,

~~IJ. •••.>J' ~. -~'~ ~""'- ~=Ayf~ ~,:;Q1~ .(1~

I(~ u-() Ton () It>'> IC~

~~[r_ (f- er_

III 1

L..J l'r : -..;1

IT

An enlarged schematic of theColonie locomotive shop show-ing the transfer bay at center withthe erecting bays on either side.Adjacent to the erecti ng bayswere the machine shops, withgalleries over the outermost bays.(Collection of the authors)

ou ide bay, with the ground floor han-dling the rods, pistons, valves and associ-ated parts, while the galleries contained themanufa turing tool room, brass room, elec-tric room, paint shop, cab shop, tin shop,et .Overhead cranes in the 59-ft. machinebay erved the galleries by means ofplatforms projecting 9 ft. from the galleriesat intervals.

The foundry measured 91 ft. by 180 ft.and was located west of the main locomo-tive shop. The foundry building was con-nected with the main shop by means ofindustrial tracks. The main bay of thefoundry building, which was 60 ft. wide,

A schematic of the Delaware &Hudson's Colonie Shop complexas it was builtin 1911-1912.Notethe 30-stall roundhouse at centerand locomotive shop to the right.To the left of center (west) andbelow the roundhouse is the truckshop, planing mill and car shop.Also note the loop track at lowerright, as well as the coal trestland ash pits above (north of) theroundhouse. (Collection of theauthors)

January 1991 NEWSLETTER OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S. THE CALL BOARD 11

A section through the Delaware & Hudson's Colonie locomotive shop as it was built in 1911-1912. Notethe transfer bay at the center, with an erecting bay on either side. The machine shops were locatedadjacent to the erecting bays. (Collection of the authors)

included a 10-ton overhead crane whichserved the cast iron and cast steel mouldingfloors. The iron foundry had a capacity of20-tons per day and the steel foundry'Sr--~ ••apacity was 2 tons per hour. A second bay

consisted of a ground floor and second-floor gallery, with the gallery including thecharging floors and brass foundry. Theground floor beneath the gallery includedthe core ovens, tumblers and other func-tions. Washrooms, together with the blow-ers, were located on a mezzanine floor be-tween the ground floor and the gallery. Thegallery was served by an elevator from theground floor, as well as by the lO-ton foundrycrane and a general storage crane by meansof overhanging platforms. The gallery ofthe foundry was also served from the exte-rior by means of the lO-ton, 100-ft. spancraneway which separated the foundrybuilding from the main shop. North of thefoundry was a two-story building 53 ft. by82 ft. which served as a pattern shop.

The hammer shop, located south of themain shop, measured 68 ft. by 158 ft. andwas utilized for heavy forging work. Astandard gauge track passed through thebuilding's entire length and into the mainshop for the handling of heavy material.

The 30-stall roundhouse was 379 feet iniameter with a 20-foot extension on theuter circle over five bays, with this exten-

sion housing the equipment necessary forlight repairs. A 90-foot turntable served theroundhouse, as did the facilities for coaling,watering and storing, along with oil supply,water supply and ash pits. The roundhousewas 90 feet between its inner and outer

walls with two rows of steel columnsequally spaced between the inner and outerwalls. A clerestory 30 feet from the innercircle allowed light and permitted venti-lation through two windows and a louverabove each stall. The hinged wooden doorson the inner circle opening into the turntablearea did not have windows. Asbestos smokejacks 20 feet from the outer wall conveyedeach locomotive's smoke through theroundhouse roof. The roundhouse was de-signed so that it could be expanded on thenorthwest quadrant at a future date.

A "rest house", attached to the round-house on its north side and measuring 38by 52 feet, contained a restaurant, sleepingroom, rest room, wash and locker room foruse by trainmen. It also contained the of-fices of the roundhouse foreman and en-gine dispatcher, as well as the switchboardfor the telephone system of the entire shopcomplex.

North of the roundhouse were locatedcoal pockets for fueling steam locomo-tives, while further north four concrete ashpits each 160 feet long were arranged inpairs with a depressed ash track betweenthe two pits of each pair. Between the twopairs of ash pits were the tracks for coalpockets with one for the loaded cars andone for the empties. Cars were hauled upthe coal trestle by means of a Fairbanks-Morse electric hoist and emptied intopockets with a capacity of 600 tons. Thepockets had air operated automatic gravitymeasuring chutes of two- and four-toncapacity. Sand storage, as well as sanddrying and handling equipment, was 10-

Section 01 Machine and Erecting Shop, Watervliet, N. Y.

cated with a 100,000 gallon water supply atthe south end of the coal pockets so thatlocomotives could take sand and water si-multaneously. All ingoing and outgoingtracks converged into three main tracksbefore entering the roundhouse.

The locomotive terminal also includedan oil house with dimensions of 34 ft. by 60ft. and a capacity of over 45,000 gallons.The oil house served the entire facilitythrough underground pipes.

The coach yard with over two miles oftrack was outfitted with underground pipetunnels conveying air, hot and cold water,steam, filtered drinking water, gas and avacuum cleaning system. A stores and of-fice building 20 ft. by 96 ft. served thecoach yard, along with an ice house 22 ft.by III ft. just north of the car departmentoffice building. A complete loop in thesouth end of the property facilitated theturning of locomotives, cars or completetrains.

The car department consisted of a carrepair shop, a planing mill, a truck shop,repair tracks and a "bad order" storageyard. The car repair shop, located on thewest side of the complex of buildings, was104 ft. by 268 ft. and was divided into twobays, each bay being served by a 15-tonoverhead electric crane. Two tracks, to-gether with an industrial track, served eachbay. The building was constructed in sucha way that another bay with two tracks anda crane could be added on the west side ofthe building.

The car department included additionalfacilities. A small machine and blacksmith

12 THE CALL BOARD NEWSLETTER OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S. January 1991

EUVATIO/i

Section Through Roundhouse, Watervliet Shops.

I..J..

ELEVAT.'ON

A section through the Delaware & Hudson's Colonie roundhouse as it was built in 1911-1912. Note thesmoke jack over the engine's stack. To the left is shown an elevation of the doors and clerestory facingthe turntable. To the right is shown an elevation of the outside of the building with its large windows.(Collection of the authors)

shop southwest of the car repair shop, mea-suring 22 ft. by 88 ft., was available forperformance of light work. The planingmill building measured 68 ft. by 180 ft. andhad a track extending through its entirelength. Lumber was stored to the south ofthe planing mill in an area served by a 5-toncrane. North of the planing mill, on theopposite side of the craneway, was thetruck shop. In the north end of the facilitywas the "bad order" car receiving yard witha capacity of more than 300 cars.

The stores department building wasconstructed at a central location relative tothe main locomotive shop and the round-house. A 100-ft. craneway ran along theeast side of the building, separating thisbuilding from the main shop. The storesdepartment, occupying three-stories plusbasement and measuring 62 ft. by 162 ft.,was designed to serve as the mechanicalstorehouse for the entire northern divisionand as stationary storehouse for the wholerailroad. A portion of the second story was

II

The newall-welded boiler and frame of D&H Class E-6a 2-8-0 No. 1219being reassembled in one of the erecting bays of the locomotive shopat Colonie in May of 1937. The 1219 was built by the AmericanLocomotive Company in Schenectady in 1918. (Col-Iection of theauthors)

divided into offices for the superintendentof shops and his staff, as well as an appren-tice instruction room. (At that time, theD&H had a complete system of instructionfor apprentices consisting of an elementarycourse in arithmetic, drawing and othercourses which were compulsory.)

An electric elevator with 3,000 lbs. ca-pacity moved materials within the build-ing, while the overhead crane on the lOO-ft.craneway running between the store~-~building and the main shop was available 1<-, _mo e materials on platforms on the eastand south side of the building. Loadingplatforms surrounded the building, withtracks running parallel to and in close prox-imity to all of these. An industrial trackconnected the main shop with the storesbuilding.

The power house, which was locatedjust south of the roundhouse, was an L-shaped building 156 ft. by 121 ft. with aboiler room 41 ft. wide and an engine andpump room 80 ft. wide. While the principalelectric power source for Colonie was theDelaware & Hudson's Mechanicville steampower station, built principally for thecompany's electric lines, a 350 kilowattDC reciprocating steam generating set wasincluded in the Colonie power house. Theelectric power from Mechanicville wasdelivered as 40-cycle, 11,OOO-voltAC cur-rent and transformed into 240-volt AC. Amotor-generator set also converted ACpower to 240 volts DC for operating someof the machinery such as the overheadcranes. There was also a steam powered aircompressor with a capacity of 2,000 cu. ftper min., as well as an electric motor drivair compressor of 2,000 cfm capacity.

Heat for the Colonie facility was sup-

January 1991 NEWSLETTER OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S. THE CALL BOARD 13

'{

plied by six large boilers in the powerhouse which burned birds-eye coal underforced drafts provided by two 8 ft. fans. A!oncrete smoke stack was 210 ft. high and

ft. in diameter. All of the buildings withthe exception of the stores building, theroundhouse and the truck shop, were heatedby indirect radiation, i.e. the heating coilsand motor driven fans were located in theclerestory bays of the buildings andductwork conveyed the hot air down to thefloor levels. The roundhouse, truck shopand stores building were all heated by di-rect radiation.

The Delaware & Hudson's Colonie fa-cility was the result ofD&H President L. F.Loree's desire to have the most modemfacility possible. Loree, a civil engineer bytraining, was said to have played a directrole in planning the new facility, which wasundoubtedly "state-of-the-art" for the time.

References"Watervliet Terminal, Delaware & HudsonCo.," in Railway Engineering and Mainte-nance of Way, December 1912."Construction Features of the WatervlietShops of the Delaware & Hudson Com-pany," in Cassiers Magazine: An Engi-neering Monthly, May 1912.

Delaware & Hudson Class E-5 2-8-0 No. 1056 in the Colonie roundhouseon May 22, 1917. Note the smoke jacks in the upper right of thephotograph, as well as the pits between the tracks. The Colonieroundhouse had 30 stalls and was built with a 90-ft. turntable.(Collection of the authors)

The heavy machine shop bay on west side of the D&H Colonie locomotive shop in about 1925. (D&HCollection, New York State Library)

.•.

Delaware & Hudson Class E-5 2-8-0 No. 1056 sitting on the track leading intothe locomotive shop at Colonie on May 21,1917, with the foundry building inthe background. The 1056 was built by the American Locomotive Companyin Schenectady in 1912.