Development of SPB LNG Fuel Tank for Ships. Section of Tank (2) Concept Design of SPB® LNG Fuel...

Transcript of Development of SPB LNG Fuel Tank for Ships. Section of Tank (2) Concept Design of SPB® LNG Fuel...

Structure Engineering Group

Gas Project Department

Offshore and Engineering Division

Gastech 2017

Development of SPB® LNG Fuel Tank

for Ships

Contents

(1)Introduction

(2)Concept Design of SPB® LNG Fuel Tank

(3)Development of the Simplified Vibration Calculation

(4)Development of High Manganese Steel

2

(1) Introduction

(1)-1 Emission Control Requirement

3

2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021

NOx Tier II Tier III (only ECA)SOx Global Cap 4.5% 3.5% 0.5%

ECA 1.0% 0.1%

ECA Coast of USA/Canada (from August)

Baltic Sea, North Sea Puerto Rico ,US Virgin Islands (Caribbean Sea)

CO2 EEDI Base △10% △20%

Source: Environmental Protection Agency (U.S.A.)

(1) Introduction

(1)-2 Use of LNG as Fuel

4

Advantage

- Emission Reduction

NOx: -80%

SOx: -100%

CO2: -25%

- LNG Price

Cheaper than Low Sulfur Fuel Oil

Disadvantage

- Increase Tank Space

Double in Fuel Volume

(= 1/2 density of heavy fuel oil)

Reduction of cargo volume

- Complexity of LNG fuel handling

- Undeveloped Infrastructure

Fuel Type SOx (g/kWh) NOx (g/kWh) CO2(g/kWh)

Heavy Fuel Oil 3.5% S 13 9-12 580-630

LNG 0 2 430-480

(1) Introduction

(1)-3 Feature of SPB® LNG Fuel Tank

SPB (Self-supporting, Prismatic-shape IMO type B)

In case of LNG fuel tank…..

5

Assumed Problem

Tank Space

LNG handling

(pressure and temperature)

Intermediate liquid level

(sloshing problem)

Damage

(accidental, fatigue etc.)

Solution

Flexible tank shape & volume

(Best space efficiency for any size & type of ships)

Easy operation and less maintenance

(Strong against outer / inner pressure)

Any level loading without sloshing

(Eliminate sloshing phenomenon by internal bulkhead)

Robust & Reliable tank system

(Proven by robust tank concept and experience)

Hull

Tank

Support

Insulation

6

(2) Concept Design of SPB® LNG Fuel Tank

(2)-1 Concept Design Study for Container Ship

Ship’s Principal Particular

Length: app. 330.0 ~ 400.0 m

Breadth: app. 45.0 ~ 65.0 m

Depth: app. 25.0 ~ 35.0 m

Container Loading Capacity 10,000 ~ 20,000 TEU

Sea Route: Far East to Europe

Range: app. 20,000 miles

LNG Fuel Tank

Capacity: 5,000 ~ 10,000 m3

L x B x D: app. 9.0~10.0m x 35.0~55.0m x 15.0~20.0m

Arrangement: In front of Engine Room

LNG Fuel

Tank SpaceEngine Room

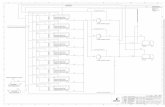

Trans. Section of Tank

(2) Concept Design of SPB® LNG Fuel Tank

(2)-2 Development of Cost-competitive Tank

14,000TEU container ship

Rationalization (optimization) of tank structure

- Reduction of tank weight

- Increasing of machinability and construction workability

Standardization of tank support construction

- Improvement of design and construction efficiency

(divided into three patterns by assumed reaction force)

FE modelling tool

- Efficiency and Speeding up of FE modelling

7

(2) Concept Design of SPB® LNG Fuel Tank

(2)-2 Development of Cost-competitive Tank

AfterBefore

10%reduction

8

14,000TEU container ship

Optimization Result of Longitudinal Girder Ring

Condition for Optimization

Target Structure Long. Girder Ring

Optimization Item Weight

Tank Material A5083-O

Tank Status Full

LNG Density 0.5 ton/m3

Vapor Pressure 0.07 MPa

Loading Condition - Static Heel Case

- Max. Trans. Acceleration Case

- Collision Case

ThicknessThin Thick

(2) Concept Design of SPB® LNG Fuel Tank

(2)-3 High Design Vapor Pressure Tank

9

Approval in Principle (AIP)

JMU received an AIP for the design

procedure for increasing design

vapor pressure SPB® tank up to

0.4 MPa (4.0 barG) from American

Bureau of Shipping in January 2017.

Diesel Engine

-Typical main engine for merchant ships

-Larger exciting force of vibration than turbine engine

Location

-Close to engine room

(3) Development of the Simplified Vibration Calculation

(3)-1 Background

10

Severer environment of vibration

comparing to LNG carrier, FLNG, etc.

LNG Fuel

Tank SpaceEngine Room

LNG Fuel

Tank SpaceEngine Room

(3) Development of the Simplified Vibration Calculation

(3)-2 Tank Vibration Assessment -Obtaining the Natural Frequency-

11

Conventional way

FEM: Time-consuming

Simplified method

Time can be saved.

Accuracy shall be verified.

𝑓 = 0.057𝜋2

𝑙2𝐸𝐼

𝜌𝐴

𝑓 =? ? ?SPB® fuel tank

(3) Development of the Simplified Vibration Calculation

(3)-3 Tank Vibration Assessment for Container Ships

12

Tank height is taller than that of other types of ship

(3) Development of the Simplified Vibration Calculation

(3)-4 Rigid Body Model (Step 1) and Elastic Body Model (Step 2)

13

Simplified methodFEM

Rigid + Elastic vibration

Step 1

Rigid body vibration

Step 2

Elastic body vibration

+

(3) Development of the Simplified Vibration Calculation

(3)-5 Coupling of Step 1 and Step 2 –Actual Phenomenon-

14

Simplified method

1

𝑓2 ≅1

𝑓12 +

1

𝑓22

𝑓: Natural frequency of the coupling mode𝑓1: Natural frequency of Step 1 mode𝑓2: Natural frequency of Step 2 mode

FEM

Rigid + Elastic vibration

(3) Development of the Simplified Vibration Calculation

(3)-6 Verification of the Accuracy

15

The Ratio of Natural Frequency (Simplified method vs FEM)

Filling level Longitudinal vibration Transverse vibration

Full 1.06 1.18

Empty 1.05 1.14

Enough accuracy for initial planning stage.

16

Effect of Higher Strength compared to other cryogenic materials

Yield Stress:

3 times as that of Aluminum

Plate Thickness : 60% of Aluminum

(Stiffener size can be reduced similarly)

Comparison with Aluminum

(4) Development of High Manganese Steel

(4)-1 Creation of New Material and Welding Material

To confirm Adequate Quality and Manufacturing Cost

- Creation of New Material and Welding Material

- Basic Test for Material Property

- Confirmation of Workmanship

(4)-2 Basic Test for Material Property

17

- Fatigue Strength Analysis

- Crack Propagation Analysis

- Leakage Quantities Estimation

SPB® Tank Design

・SN curve Data

・Fatigue Crack Growth Rate Curve Data

(4)-3 Confirmation of workmanship

- workability (cutting, bending etc.)

- welding

- corrosion resistance during construction

(4) Development of High Manganese Steel

Thank you for your kind attention.

More Information Available!! (Keyword: “jmu product spb”)

Homepage: http://www.jmuc.co.jp/en/products/spb_system/