DEVELOPING ANTHOCYANIN-BASED PRODUCTS · Tünde VATAI, vpisna številka • rezultat lastnega...

Transcript of DEVELOPING ANTHOCYANIN-BASED PRODUCTS · Tünde VATAI, vpisna številka • rezultat lastnega...

University of Maribor

Faculty of Chemistry and Chemical Engineering

DOCTORAL DISSERTATION

DEVELOPING ANTHOCYANIN-BASED PRODUCTS

by

TÜNDE VATAI

M. Sc. in Chemical Engineering

Menthor: Prof. Dr. Mojca Škerget (University of Maribor)

Co-menthor: Prof. Dr. Paolo Alessi (University of Trieste)

SUBCLEAN PROBIOMAT

Maribor, February 2009

UNIVERZA V MARIBORU

FAKULTETA ZA KEMIJO IN KEMIJSKO TEHNOLOGIJO

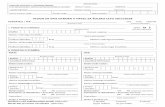

IZJAVA DOKTORSKEGA KANDIDATA

Podpisana Tünde VATAI, vpisna številka

• rezultat lastnega raziskovalnega dela,

95020485

izjavljam,

da je doktorska disertacija z naslovom

DEVELOPING ANTHOCYANIN-BASED PRODUCTS

• da so rezultati korektno navedeni in • da nisem kršil-a avtorskih pravic in intelektualne lastnine drugih.

Podpis doktorskege kandidatke:

Tünde VATAI

ACKNOWLEDGEMENTS

My thesis would not be complete without a word of thanks to those who made it

possible. A special thanks to Prof. Dr. Mojca Škerget, my supervisor and mentor, for

providing me invaluable scientific support, guidance and stimulations for my research. She

guided me patiently, supportively and helped me to carry through this work until the end. I

would like to thank not only the scientific support but as well for the private-life support.

Thank you for the attention, concerns and above all for the friendship!

A special word also to my co-supervisor: Prof. Dr. Paolo Alessi, who helped me

through the last year of the Ph. D., the most difficult year of the project. Thank you for the

guidance through the burocratic labyrinth and for not giving up, and for the scientific support

as well. I would like to express gratitude to Prof. Dr. Željko Knez, the „head” of the project for

the opportunity to do this project, for the support and guidance.

This research was financially supported through a European Community Marie Curie

Fellowship (Project MEST-CT-2004-007767). The European Commission DG Research–

Improving The Human Research Potential is gratefully acknowledged. I would like to thank

also to all the professors and students of the project „Suclean Probiomat” for the last 3 years.

Special thank to Prof. Maja Habulin for the coordination.

Special thank goes to Prof. Béla Simándi, who “introduced” me to the supercritical

fluids, guided me through the first steps of scientific research world and put his trust in me,

without who I would have never had the opportunity to participate in this project. Köszönöm

a tanácsokat és a támogatást!

There are so many people who contributed directly or indirectly to this thesis, until it

was successfully rounded up and I hope I am able to express here my dept gratitude to these

people as good as possible. During my work I had the opportunity to work at different

universities in different laboratories. It was a pleasure to participate in this project and get in

contact with so many precious people. Thank you all!

In the Laboratory for Separation Processes and Product Design (University of

Maribor) I have spent the most of the time. Thank you colleagues for the help, support,

advices and for the nice time we spent together. Najlepše hvala za vse!

The Bochum Ruhr University hosted me for 3 months. Thank you for all the support,

scientific discussions, and even more, friendship! The School of Chemistry in Nottingham

gave me an experience and opportunity to learn and explore new areas of my theme. Thank

you for the support in the lab and for the nice time in Nottingham!

The last year of the research I have spent in Trieste. The ups-and-downs of this year I would

not have resolved without the supportive atmosphere of DICAMP. Grazie!

5

A special thank for the Marie-Curie Fellows with whom I spent the project in Maribor

and Trieste. Thank you: Christian, Paul and Lucian; for not only being there as colleagues,

but as friends as well. I have learned many things from you, your support and advices helped

me to go through the difficulties of my research and your friendship helped me to survive the

most difficult days... Good luck for the future!

To all my friends: thank you for your support, even though the distance and different

circumstances sometimes made it difficult to keep in touch. You were always there for me

when I needed a good word or help. I am grateful for this project, because during these 3

years I have learnt a lot of other cultures (languages as well) and made many new friendships.

Without you all it would not have been the same! Köszönöm, Hvala, Danke, Grazie, Thank

you ….

Without my family I would not have been able to complete this thesis. Words cannot

express how grateful I am for all the support. You were always ready to help, supported me

through the difficulties, gave me the best advices, brought me up when I was down, not

letting me to give up. You were happy for my big and little successes as well, supported all my

decisions, honestly and unselfishly. Köszönöm.

Tünde VATAI

SUMMARY

Anthocyanins are group of polyphenols, responsible for the colours of yellow, orange,

red, pink and blue of most of the flowers and fruits. The major drawback of their use and

competitiveness compared to synthetic colorants is their colour instability, which may result

in degradation of colour during processing and storage. The overall goal of the Ph. D. work

was to develop a product, a natural colorant on anthocyanin base with adequate colour

stability, which can be an alternative replacement for synthetic colorants in food and drug

industry. Extraction of anthocyanins from grape marc, a by-product of the winery industry,

was investigated considering their potential use as natural colorants. The optimal

conventional extraction conditions were investigated with three different varieties of grape

marc native to Slovenia. For comparison, experiments with a fresh (non-by-product) material

–elder berry– were performed. The investigated operating parameters were: extraction

solvent, solvent concentration and temperature. Influence of the pH value of the extraction

media was investigated regarding the yield and degradation of anthocyanins. The stabilities

of the obtained extracts during storage were compared. Supercritical fluid extraction (SFE)

using carbon dioxide (CO2), was investigated for the pre-treatment of natural materials. Co-

pigments influence the stability and colour of the anthocyanins. Therefore, the obtained

extracts were analyzed on the content of some flavonoids.

The second major part of the Ph.D. work focused on product formulation and

stabilization of the anthocyanin extracts by using several high pressure techniques. Product

formulation with SCF techniques, namely Concentrated Powder Form (CPF™), Particles

from Gas Saturated Solution (PGSS™) and Supercritical Antisolvent Precipitation (SAS) were

carried out. Different anthocyanin-concentrates and carrier materials were tested. The

products were analyzed for their colour properties (Lightness, Hue angle and Chroma

values). The stability of the colour was monitored during prolonged storage.

Keywords: anthocyanins, natural colorants, extraction, SFE, carbon dioxide, product

formulation, PGSS™, CPF™, SAS, stability

UDK: 66.061-987:547.973 (043.3)

POVZETEK-RAZVOJ PRODUKTOV NA OSNOVI ANTOCIJANINOV

Antocianini so skupina polifenolov, ki so odgovorni za barvno raznolikost cvetov in

sadežev, od rumene, oranžne, rdeče, roza, do modre. V primerjavi s sintetičnimi barvili so

nestabilni, kar predstavlja glavni problem pri njihovi uporabi in se lahko pokaže kot

sprememba barve med procesiranjem in skladiščenjem. Glavni cilj doktorske disertacije je bil

razviti produkt, naravno barvilo na osnovi antocianinov, ki bo ustrezno stabilen in bo

predstavljal alternativo sintetičnim barvilom za uporabo v prehrambeni in farmacevtski

industriji.

Raziskovalno delo zajema študij ekstrakcije antocianinov iz grozdnih tropin, ki so

stranski produkt v proizvodnji vina in predstavljajo potencialni vir naravnih barvil. V

raziskavah smo uporabili tropine treh tradicionalnih sort rdečega grozdja, ki se pridelujejo v

Sloveniji. Za primerjavo so bili eksperimenti narejeni tudi z uporabo svežega materiala –

bezgovih jagod. Namen raziskav je bil določiti optimalne ekstrakcijske pogoje. Izvedla se je

študija vpliva naslednjih parametrov: vrste in koncentracije topila za ekstrakcijo ter

temperature. Študirali smo vpliv pH topila za ekstrakcijo na izkoristek in degradacijo

antocianinov. Opazovali smo stabilnost dobljenih ekstraktov med skladiščenjem. Raziskali

smo vpliv predobdelave naravnega materiala s superkritično ekstrakcijo s CO2. Poznano je,

da ko-pigmenti vplivajo na stabilnost in barvo antocianinov, zato smo v dobljenih ekstraktih

analizirali tudi vsebnost nekaterih flavonoidov.

Drugi sklop raziskav v okviru doktorske disertacije zajema študij stabilizacije in

formulacije antocianinov z uporabo visokotlačnih tehnologij s superkritičnimi fluidi (SCF).

Raziskali smo naslednje SCF tehnike za formulacijo produkta: CPF™ (Concentrated Powder

Form; Koncentrirana praškasta oblika), PGSS™ (Particles from Gas Saturated Solution; Delci

iz raztopin nasičenih s plinom), SAS (Supercritical Antisolvent Precipitation; Prekristalizacija

z antitopilom). V raziskavah smo uporabili različne materiale na osnovi antocianinov

(ekstrakte, sokove in koncentrate) ter različne nosilce, ki so uporabni v prehrambeni

industriji. Izvedli smo analize barvnih lastnosti in stabilnosti barve med skladiščenjem

dobljenih praškastih produktov.

Ključne besede: ekstrakcija, superkritični ogljikov dioksid, formulacija produktov, PGSS™,

CPF™, SAS, naravna barvila, antocianini, stabilnost

UDK: 66.061-987:547.973 (043.3)

CONTENTS

Acknowledgements .................................................................................................................... 4

Summary .................................................................................................................................... 6

Povzetek ..................................................................................................................................... 7

Contents ..................................................................................................................................... 8

Index of Figures ......................................................................................................................... 11

Index of Tables .......................................................................................................................... 13

Symbols and Abbreviations ....................................................................................................... 15

Introduction .............................................................................................................................. 17

The Aims of the Thesis ............................................................................................................. 20

State of Art .................................................................................................................................21

1. Extraction Techniques ..................................................................................................21 1.1. Conventional Solid-Liquid Extraction ........................................................................ 22 1.2. Supercritical Fluid Extraction ..................................................................................... 22

2. Anthocyanins ................................................................................................................ 27 2.1. Stability of Anthocyanins ............................................................................................. 28 2.2. Extraction of Anthocyanins from Different Plant Materials ..................................... 33 2.3. Purification of Anthocyanin Extracts .......................................................................... 34 2.4. Analysis of Anthocyanins ............................................................................................. 34

2.4.1. Qualitative and Quantitative Analysis ........................................................................ 34 2.4.2. Colour Evaluation......................................................................................................... 37

3. Stabilization of the Anthocyanins ................................................................................ 39

4. Product Formulation with Supercritical Fluids ........................................................... 42 4.1. Concentrated Powder Form (CPF™) .......................................................................... 44 4.2. Particles from Gas Saturated Solutions (PGSS™) ...................................................... 46 4.3. Supercritical Antisolvent Precipitation (SAS) ............................................................ 48

Experimental Work .................................................................................................................. 52

5. Extraction ..................................................................................................................... 52

9

5.1. Materials ....................................................................................................................... 52 5.1.1. Plant materials ............................................................................................................. 52 5.1.2. Chemicals ...................................................................................................................... 52

5.2. Conventional Single-step Extractions ......................................................................... 53 5.3. Supercritical Fluid Extraction (SFE) with Carbon dioxide ........................................ 54

5.3.1. SFE without Co-solvent ............................................................................................... 54 5.3.2. SFE with Ethanol Co-solvent ....................................................................................... 55

5.4. Analytical Methods ...................................................................................................... 56 5.4.1. Determination of the Total Phenolic Compounds ...................................................... 56 5.4.2. Determination of Total Monomeric Anthocyanins .................................................... 56 5.4.3. Determination of Quercetin ......................................................................................... 57 5.4.4. Determination of Flavanols and trans-Resveratrol ................................................... 57

5.5. Results and Discussion ................................................................................................ 59 5.5.1. Conventional Extraction of Total Phenols and Anthocyanins ................................... 59 5.5.2. Supercritical Fluid Extraction of Total Phenols and Anthocyanins .......................... 64 5.5.3. Extraction of Co-Pigments ........................................................................................... 66

6. Separation and Purification of Individual Compounds ............................................... 68 6.1. Materials and Reagents................................................................................................ 68 6.2. Extraction ..................................................................................................................... 68 6.3. Column Chromatography ............................................................................................ 68 6.4. Analytical Methods ...................................................................................................... 69

6.4.1. Thin Layer Chromatography (TLC) ............................................................................ 69 6.4.2. UV/Visible Spectrophotometry ................................................................................... 69 6.4.3. High Performance Liquid Chromatography (HPLC) ................................................. 69 6.4.4. Mass Spectrometry (MS) ............................................................................................. 69

6.5. Results and Discussion ................................................................................................ 70 6.5.1. Analysis of the Un-purified Extracts ........................................................................... 70 6.5.2. Purification by Column Chromatography ................................................................... 70 6.5.3. Analysis of “Fresh Sample”: Grape Skin Extract (GS) ............................................... 71

6.6. Conclusions................................................................................................................... 71

7. Formulation with CPF™ .............................................................................................. 72 7.1. Materials and Methods ................................................................................................ 72 7.2. Experimental Apparatus and Procedure..................................................................... 72 7.3. Results and Discussion ................................................................................................ 73

8. Formulations with PGSS™ ........................................................................................... 77 8.1. Materials and Methods ................................................................................................ 77 8.2. Experimental Procedure and Apparatus..................................................................... 77

8.2.1. Laboratory Scale Experiments .................................................................................... 77 8.2.2. Pilot Scale Experiments ............................................................................................... 78

8.3. Results and Discussion ............................................................................................... 80

10

8.3.1. Elder Berry (EB) with Palm Fat .................................................................................. 80 8.3.2. Grape (NG) and Grape Marc (GM) extracts with Palm Fat ....................................... 83

9. Formulation with SAS .................................................................................................. 88 9.1. View cell experiments ................................................................................................. 88

9.1.1. Apparatus and Experimental Procedure.................................................................... 88 9.1.2. Results and Discussion ................................................................................................ 89

9.2. Supercritical Antisolvent Precipitation (SAS) ............................................................ 91 9.2.1. Materials and Apparatus.............................................................................................. 91 9.2.2. Scanning Electron Microscopy (SEM) ........................................................................ 92 9.2.3. Differential Scanning Calorimetry (DSC) ................................................................... 93

9.3. Experimental Procedure .............................................................................................. 93 9.4. Results and Discussion ................................................................................................ 93

9.4.1. PVP Precipitation from Ethanolic Solution ................................................................ 93 9.4.2. PVP Precipitation from Ethanol-Blackcurrant Mixture ............................................ 96

10. Stability Testing ...................................................................................................... 100 10.1. Degradation Indices of the Anthocyanins................................................................. 100 10.2. Changes in Lightness (L), Hue (H) and Chroma (C) ................................................ 101 10.3. Results and Discussion .............................................................................................. 102

10.3.1. Degradation Indices of the Obtained Extracts ......................................................... 102 10.3.2. Changes in the L, H and C values of Non-formulated Products .............................. 104 10.3.3. Changes in the L, H and C values of the Formulated Products ............................... 106

Conclusions and Future Prospects .......................................................................................... 114

Appendix ................................................................................................................................. 115

References .............................................................................................................................. 138

Biography ................................................................................................................................ 147

Bibliography ........................................................................................................................... 149

INDEX OF FIGURES

Figure 1: Carbon dioxide pressure vs. temperature phase diagram (left) and Carbon dioxide density vs.

pressure phase diagram (right). .................................................................................................................. 23

Figure 2: Schematic flow diagram of a basic SFE apparatus. .................................................................... 25

Figure 3: Structure of anthocyanidins. For substituens R1 and R2 see Table 4. ....................................... 28

Figure 4: Structural transformation of anthocyanins: flavylium cation (AH+), carbinol (B), chalcone (C)

and quinonoidal base (A) [Wrolstad, 2004]. ............................................................................................. 30

Figure 5: Equilibrium distribution of flavylium cation (AH+), quinoidal base (A), carbinol (B) and

chalcone (C) for malvidin-3-glycoside as a function of pH value [Mazza and Brouillard, 1987]. ........... 31

Figure 6: UV-Visible spectra of anthocyanins in pH 1.0 and 4.5 buffers and the structures of the

flavylium cation (A) and hemiketal/carbinol form (B); R=H or glycosidic substituents [Wrolstad et al.,

2005]. ........................................................................................................................................................... 36

Figure 7: Reaction of anthocyanin pigments with bisulphite to form colourless anthocyanin-sulfonic

acid adducts. ................................................................................................................................................. 37

Figure 8: The CIE L*a*b and L C H interpretations of visual colour. ....................................................... 38

Figure 9: Basic structure of the pigments derived from the acetaldehyde-mediated condensation

between anthocyanins and catechins. C* is an asymmetric carbon, which makes possible the existence

of diastereomer pigments. ........................................................................................................................... 39

Figure 10: Extraction plant material: elder berry and grape marc. .......................................................... 52

Figure 11: Supercritical extraction apparatus. ............................................................................................ 55

Figure 12: Extraction of Total phenols from different varieties of grape marc at 60°C with water and

acetone-, ethyl-acetate and ethanol-water mixtures. Grape marc varieties: RF refošk, CB cabernet, ME

merlot............................................................................................................................................................60

Figure 13: Extraction of Total anthocyanins from different varieties of grape marc at 60°C with water

and acetone-, ethyl-acetate and ethanol-water mixtures. Grape marc varieties: RF refošk, CB cabernet,

ME merlot. ....................................................................................................................................................60

Figure 14: Extraction of Total phenols from elder berry with acetone- and ethanol-water mixtures at

60 °C. Comparison of frozen and lyophilised extraction materials. ......................................................... 61

Figure 15: Extraction of Total anthocyanins from elder berry with acetone- and ethanol-water mixtures

at 60 °C. Comparison of frozen and lyophilised extraction materials. ..................................................... 62

12

Figure 16: Effect of the change in the pH value of extraction solvent (100% water) by extraction of

Total phenols (left) and Total anthocyanins (right) from Refošk (RF) grape marc ( at 60 °C). The pH 2

adjusted with phosphoric acid (phos) and pH 6 with sodium-hydroxide (NaOH). ................................. 63

Figure 17: Comparison of the single-step (conventional extraction, CE) and two-step (1st step:

supercritical fluid extraction, SFE; 2nd step: CE) extraction of Refošk (RF) grape marc: total phenols

(mg GA/g dry material) and total anthocyanins (mg/g dry material). ..................................................... 64

Figure 19: Comparison of the single-step (conventional extraction, CE) and two-step (1st step:

supercritical fluid extraction, SFE; 2nd step: CE) extraction of Elder berry (ELD): total phenols

(mg GA/g dry material) and total anthocyanins (mg/g dry material). ..................................................... 65

Figure 20: Extraction of t-resveratrol from Refošk (RF) grape marc with different solvents (ethanol,

ethyl-acetate and acetone) with different concentrations (in mixture with water) at temperatures of

20 °C and 60 °C. ........................................................................................................................................... 67

Figure 21: HPLC spectra of the of malvidin chloride standard solution................................................... 71

Figure 22: Flow scheme of the CPF™ apparatus. ...................................................................................... 73

Figure 23: SEM images of the obtained CPF™ products. Left: porous particle, right: agglomeration of

some particles. .............................................................................................................................................. 75

Figure 24: SEM spectra of CPF™ product. Four spectrum taken at different points of a samples. ....... 75

Figure 25: Laboratory scale apparatus for PGSS™ - batch mode. ............................................................ 78

Figure 26: Pilot plant for PGSS™ - continuous mode. .............................................................................. 79

Figure 27: Palm fat micronized by PGSS™ technology ............................................................................ 80

Figure 28: PGSS™ powders: grape marc extract with palm fat. Anthocyanin concentration increasing

from left to right. .......................................................................................................................................... 84

Figure 29: High pressure “view cell” apparatus. ....................................................................................... 88

Figure 30: SAS apparatus ............................................................................................................................ 92

Figure 31: The DSC curves of the original PVP, the PVP which was dried in oven prior the analyses and

PVP precipitated from ethanol (EtOH) solution by SAS. .......................................................................... 96

Figure 32: Process capacity diagram of CO2-EtOH-water system, resulting from SAS precipitation of

PVP from ethanol-BC solution, plotted as the water uptake capacity vs. fraction of the modifier in the

extractant. Equilibrium data plotted with blue diamonds [Durling et al., 2007] and experimental data

as red squares. .............................................................................................................................................. 97

13

Figure 33: Ternary phase diagram at 35 °C and 10 MPa. Black circles: literature data [Gilbert and

Paulaitis, 1986]. Red circles: experimental results. ................................................................................... 98

Figure 34: SEM pictures of a SAS precipitate of PVP from ethanol-BC mixture (5/95 ratio wt).

Magnifications of 250X and 900X, left and right pictures, respectively. ................................................. 98

Figure 35: The DSC curves of the PVP precipitated from BC/EtOH solution mixtures of 5/95 and

10/90 (wt) ratios. ......................................................................................................................................... 99

Figure 36: Monitoring the stability of obtained extracts. Total anthocyanins (mg/g dry material) vs

time (days). ................................................................................................................................................. 102

Figure 37: Lightness, Hue angle and Chroma values of the Refošk (RF) extracts obtained with acidified

and non-acidified solvents stored at dark and at light for 15 weeks. ...................................................... 105

Figure 38: Lightness, Hue angle and Chroma values of the CPF™ products stored at dark and at light

for 21 weeks. Concentration of Refošk (RF) extract in liquid: 10 wt % and 30 wt %. Comparison of

acidified (with citric acid to pH 1) and non-acidified extracts formulated with silica carrier. .............. 107

Figure 39: Colorimetric values of the PGSS™ - elder berry with palm fat - products stored for 56 weeks

at light-ambient temperature and dark-refrigerator. See sample codes in Appendix (XXII). .............. 109

Figure 40: Colorimetric values of the PGSS™ - grape marc/grape extracts with palm fat - products

stored for 65 weeks at light-ambient temperature and dark-refrigerator. See sample codes in Appendix

(XXII)........................................................................................................................................................... 111

Figure 41: Colorimetric values of the PGSS™ - grape marc extracts with palm fat - products stored for

65 weeks at light-ambient temperature and dark-refrigerator. See sample codes in Appendix (XXII).

...................................................................................................................................................................... 113

INDEX OF TABLES

Table 1: Comparison of some physical properties of a gas, fluid and liquid. ............................................ 23

Table 2: Critical properties of various solvents [Reid et al., 1987]. ........................................................... 24

Table 3: Anthocyanin content of some common fruits and vegetables [Giusti and Wrolstad, 2000]. ... 27

Table 4: Some of the most common anthocyanidins in the nature, their maximum absorption

wavelength (λmax) and visible colour. Substituents R1 and R2 refer to Fig. 3. ........................................... 28

Table 5: Comparison of the CPF™ and conventional techniques [Petermann et al., 2001]. .................. 45

14

Table 6: Summary of the performed single-step extractions. ................................................................... 53

Table 7: Summary of the performed two-step extractions. ....................................................................... 55

Table 8: CPF™ experiments with silica (Sipernat 22LS): pure carrier and the powderous products.

Extract concentrations in the liquid and solvent conditions. .................................................................... 74

Table 9: Comparison of the initial colorimetric values of three CPF™ products (formulated with silica

carrier), and two commercial colorants. ..................................................................................................... 76

Table 10: Powderous products of PGSS™ micronization: Elder berry concentrate with palm fat. ........ 81

Table 11: Morphology and particle size of three different PGSS™ products: anthocyanin concentrates

with palm fat by 5, 20 and 42 wt % liquid/carrier ratios. .......................................................................... 82

Table 12: The CIE colour properties of some PGSS™ samples: Elder berry. ........................................... 83

Table 13: Morphology and particle size of four different PGSS™ products: concentrated wine with

palm fat of 5 and 29 wt % liquid/carrier ratios and grape marc extract with palm fat of 5 and 37 wt %

liquid/carrier ratios. GPR: Gas-to-product ratio (w/w). ........................................................................... 85

Table 14: Colorimetric values (L, H and C) of some PGSS™ formulated products. Liquid: grape marc

(GM) and commercial grape (NG) extract in 50 wt % ethanol-water or in water. ................................... 86

Table 15: Comparison of the visual colour of four PGSS™ samples: acidified solution samples of 39 and

49 wt% liquid/carrier ratios and non-acidified samples of 40 and 48 wt% liquid/carrier ratios. .......... 87

Table 16: Morphology and particle size observed by SEM of the original PVP and PVP precipitated by

SAS from ethanol solution with different conditions. ............................................................................... 94

Table 17: Tg of PVP K-25 measured by inverse gas chromatography (IGC) technique [Kikic et al., 2003]

....................................................................................................................................................................... 95

Table 18: Comparison of degradation indices (colour density, % polymeric colour, browning and

degradation index) in different grape marc extracts obtained with 50 % ethanol at 60 °C - with non-

acidified solvent (NA), with solvent pH value adjusted to 1 (A) and addition of natural antioxidant (X)

to the solvent -: initial values and values after 55 days storage (stored at -16 °C). ................................ 103

SYMBOLS AND ABBREVIATIONS

A Absorbance

A Acidified solvent

A Quinoidal form

A420nm Absorbance at 420 nm

A520nm Absorbance at 520 nm

A700nm Absorbance at 700 nm

AH+ Flavylium cation

aH+ Hydroxonium ion activity

Aλvis-max Absorbance at maximum

visible wavelength

B Carbinol (pseudo)base

BAW n-butanol/acetic acid/water

BC black currant

BI Browning Index

C Carbon atom

C Chalcone

C Chroma or saturation

CB Cabernet

CE Conventional extraction

CH3COONa Sodium acetate

CIE International Commission on

Illumination

CO2 Carbon dioxide

CPF™ Concentrated Powder Form

Cy-3-gly Cyanidin-3-glycoside

DF Dilution factor

DI Degradation Index

DSC Differential Scanning Calorimetry

ELD Elder berry

EtOH Ethanol

FD&C Food, Drug & Cosmetics

GA Gallic acid

GAS Gas Anti Solvent process

GM Grape marc

GPR Gas-to-product ratio

GS Grape skin extract

H Hue angle

H2PO4 Phosphoric acid

HCl Hydrochloric acid

HPLC High Performance Liquid

Chromatography

IGC Inverse Gas Chromatography

IR Infra-red

K2S2O5 Potassium metabisulphite

KA Proton transfer equilibrium constant

KCl Potassium chloride

KH Hydration constant

KT Ring-chain tautomeric constant

L Lightness

l path length

ME Merlot

mextract extract weight

MS Mass Spectrometry

MW Molecular weight

NA Non-acidified solvent

Na2CO3 Sodium carbonate

NaOH Sodium hydroxide

NG Nor-grape extract

NMR Nuclear Magnetic Resonance

O Oxigen atom

PEG Polyethyleneglycol

PGSS™ Particles From Gas Saturated Solutions

phos Phosphoric acid

PPO Polyphenoloxidases

PVP Polyvynilpirrolidone

RESS Rapid Expansion of Supercritical

Solutions

RF Refošk

SAS Supercritical Anti Solvent process

SC Supercritical

scCO2 Supercritical carbon dioxide

SCF(s) Supercritical Fluid(s)

SEM Scanning Electron Microscope

SFE Supercritical Fluid Extraction

Si Silicon atom

SO2 Sulphur dioxide

16

TA Total anthocyanins

Tg Glass transition temperature

TLC Thin Layer Chromatography

UV/VIS UV/Visible

V06 Pilot scale extract from 2006

V07 Pilot scale extract from 2007

X Solvent with natural antioxidant

ε Molar absorptivity

λEM Emission wavelength

λEX Excitation wavelength

λmax Maximum absorption wavelength

λvis-max Maximum visible absorption

wavelength

INTRODUCTION

Anthocyanins are natural pigments, which are responsible for the orange, red, blue,

violet colours of some fruits and flowers. Beside the attractive colour their positive health

effects are also significant [Kong et al., 2003]. The use of anthocyanin extracts as natural

colorants has been reviewed by several authors [Bridle and Timberlake, 1997; Francis, 1989;

Markakis, 1982; Mazza and Miniati, 1993]. The limitation in the use of anthocyanins as

natural food colorants is their colour instability. The major degradation factors of the

anthocyanins are the temperature, the presence of oxygen and light, co-pigmentation, metal

ions, enzymes, the pH value, etc. [Jackman et al., 1987]. Acylation, glycosylation and

condensation with different flavonoids improves the stability of the anthocyanins [Mazza and

Brouillard, 1987].

Recent researches have been focused on finding new plant sources of anthocyanins,

where they can be found in more stable form [Cevallos-Casals and Cisneros-Zevallos, 2004;

Giusti and Wrolstad, 2003; Malien-Aubert et al., 2001; Pazmińo-Durán et al., 2001].

Economically, the best potential sources of anthocyanins are those, which are by-

products in the manufacture or plant materials with high availability. The winery by-product,

grape marc (also known as grape pomace) provides a raw material, which is rich in

polyphenols identified also in grapes and wine. These phenols are mainly anthocyanins,

flavonols and phenolic acids [Amico et al., 2004; Monagas et al., 2006; Ruberto et al., 2007].

Several authors reported antiradical and antioxidant activity of the grape marc extracts,

suggesting the winery by-product for production of natural antioxidants. Regarding the

extraction of antioxidants, the influence of process and extraction parameters were

investigated [Lapornik et al., 2005; Spigno and De Faveri, 2007]; different grape cultivars

[Ruberto et al., 2007], components of grape marc [Pinelo et al., 2005] and vinification

methods [Gomez-Plaza et al., 2006] were also compared. Spigno & De Faveri (2007) gave a

short review on the extraction of grape marc, remarking the lack of systematic approaches to

optimise the extractions.

It was found that most of the above mentioned literature is focused mainly on the

extraction of polyphenols and antioxidants, while the anthocyanins are mentioned as

additional compounds [Gomez-Plaza et al., 2006; Lapornik et al., 2005; Malien-Aubert et al.,

2001; Negro et al., 2003; Ruberto et al., 2007]. The aim of the present work was to

investigate the extraction of anthocyanins from grape marc considering their potential use as

natural colorants. The optimal conventional extraction conditions were investigated with

three different varieties of grape marc native to Slovenia. For comparison, experiments were

performed with a fresh (non-by-product) material. Elder berry was chosen since it is rich in

anthocyanins and has a long history of use as food colorant and as traditional medicine, as

18

well. The investigated operating parameters were: extraction solvent, solvent concentration

and temperature. Further, according to literature [Mazza and Brouillard, 1987] at the pH

values below 2 the anthocyanins exist in the flavylium cation form, i.e. in most coloured form,

therefore different solvent pH values were also compared. The stabilities of the obtained

extracts during storage were compared. Furthermore, the stabilization of extracts, obtained

by the addition of a commercial natural antioxidant, was investigated.

It was observed before, that pre-treatment with non-polar solvents (e.g. hexane)

improves the extraction of polyphenols from grape [Gonzalez-Paramas et al., 2006; Pomar et

al., 2005; Ruberto et al., 2007; Spigno and De Faveri, 2007]. In the present work

supercritical fluid extraction (SFE) using carbon dioxide (CO2), was applied for the pre-

treatment of natural materials. SFE with CO2 is a particularly suitable isolation method for

natural materials [Reverchon and De Marco, 2006] and gives an alternative to replace the

non-polar organic solvents. Extractions with supercritical CO2 (scCO2) result in solvent-free

products and avoid deteriorating reactions, due to low process temperatures. The CO2 is

readily available, relatively cheap and accepted as a solvent in the food industry. Two-step

extraction, combining SFE and conventional extraction, was investigated in the present work.

During first extraction step scCO2 (with or without ethanol co-solvent) was applied to remove

the non-polar components from the extracting material. During the subsequent second-step,

conventional extraction of the residual material was performed at optimal operating

parameters, which were investigated in single-step extraction experiments.

Co-pigments influence the stability and colour of the anthocyanins. Weak complexes

are formed with tannins, flavonoids, proteins and polysaccharides [Gonzalez-Paramas et al.,

2006; Jackman and Smith, 1996]. Some of these compounds enhance the colour of

anthocyanins. The complexes also tend to be more stable during process and storage

[Escribano-Bailon et al., 2001]. Therefore, the obtained extracts were analyzed on the content

of some flavonoids. Flavonoids exhibit numerous biological and pharmacological effects,

including anti-oxidant, anti-carcinogenic, anti-inflammatory, cardio protective, bacteriostatic

effects etc. [Havsteen, 2002]. Among them catechins and quercetin, which is considered as

one of the key compounds, are known to posses high anti-oxidative and free radical

scavenging capacity. In addition, extraction of t-resveratrol, which is an interesting

compound due to its pharmacological activity [Gurbuz et al., 2007; Monagas et al., 2006; Sun

and Temelli, 2006] was investigated.

Formulation of product in powderous form (using carrier) is one of ways of

stabilization of anthocyanins [Jackman et al., 1987], which also facilitates their easier

incorporation into foods. However, the conventional technologies often use high

temperatures, high amount of organic solvents and long processing time, helping the

degradation of the anthocyanins. Hence, novel technologies, which also have lower

19

environmental impact, will have important role in the future food industry. Particle

formation using supercritical fluids (SCFs) is one of the new technologies, which has been

intensively researched and improved in the recent years [Jung and Perrut, 2001].

Applications for many fields have been developed and it is likely that these technologies will

gain their position in the industry [Weidner et al., 2003]. The interest in SCF (supercritical

fluid) product formulation for food industry has increased as well, due to its advantages

compared to conventional technologies [Brunner, 2005]. The overall goal of this work was to

develop an anthocyanin based natural colorant suitable for applications in food industry.

Product formulation with SCF techniques, namely Concentrated Powder Form (CPF™),

Particles from Gas Saturated Solutions (PGSS™) and Supercritical Antisolvent Precipitation

(SAS) were carried out. Different anthocyanin-concentrates and carrier materials were

tested. The products were analyzed for their colour properties (Lightness, Hue angle and

Chroma values). The stability of the colour was monitored during prolonged storage

(light/dark and ambient temperature/refrigerator).

The 3-years Ph. D. research work – in the frame of the Marie-Curie programme

(project “Suclean Probiomat”) – was carried out at different universities in different

laboratories. The extraction of the anthocyanins from different plant materials was

investigated in the first 1.5 years at the University of Maribor. The formulation with high

pressure technique Concentrated Powder Form using dense carbon dioxide for formulation

and stabilization of anthocyanin extracts was investigated at the Ruhr University of

Bochum. Extract of grape marc was sprayed on different carrier materials in order to

investigate the possible stabilization with CPF™. Another high-pressure technology –

Particles from Gas Saturated Solution – was applied for the formulation of the anthocyanin-

concentrates. The experiments were performed in laboratory (University of Maribor) and

pilot scale (Ruhr University of Bochum) as well. At the University of Trieste

supercritical antisolvent precipitation of anthocyanins was investigated. The precipitation

was achieved from water concentrate with PVP co-precipitate. The phase equilibrium of the

systems: anthocyanin-concentrate (BC) with carbon dioxide, BC-modifier-CO2, PVP-

modifier-CO2 and PVP-BC-modifier-CO2 were investigated in high pressure view cell prior to

the SAS experiments. The stability of the anthocyanin extracts and formulated products were

measured at the University of Maribor. Degradation indices (browning index,

degradation index, polymeric colour and colour density) were measured for different extract

samples. The formulated products were measured for their colour properties Lightness, Hue

Angle and Saturation and the results were compared to the non-formulated products. The

colour was measured using the method of CIEL (International Commission on Illumination,

Vienna), based on uniform colour spaces (CIELAB) which enables objective measurement

and characterization of colour properties. One part of the obtained formulated product was

20

stored in dark in refrigerator and the other part at light at room temperature. The stability of

the CPF™ powder was monitored during storage. The results were compared with the pure

extract (not CPF™ formulated) stored at same conditions. The experiments of separation and

purification of individual compounds of anthocyanins were performed at the University of

Nottingham. Different separation and purification methods were applied in order to obtain

the principal individual anthocyanins.

THE AIMS OF THE THESIS

The aim of the Ph. D. work was to optimize the extraction of the anthocyanin

pigments from the by-product grape marc. Beside the conventional technologies, novel

technologies, which have less environmental impact, were aimed to use. Since the

anthocyanin pigments are prone to degradation, methods which avoid the degradation were

selected. The formulation with supercritical fluids has never been studied for anthocyanins in

such form. The possible formulation was therefore aimed to investigate using diverse SCF

technologies, such as CPF™, PGSS™ and SAS. The overall goal of was to develop a product, a

natural colorant on anthocyanin base, with adequate colour stability, which can be an

alternative replacement for synthetic colorants in food and drug industry.

21

STATE OF ART

1. EXTRACTION TECHNIQUES

Extraction by definition is a method for separating the constituents of a mixture

utilizing preferential solubility of one or more components in a second phase [Fonyó and

Fábry, 1998]. The goal is to withdraw an active agent or a waste substance from a solid or

liquid mixture with a liquid solvent. The added solvent must be immiscible or only partially

miscible with the solid or the liquid. By intensive contact the active agent transfers from the

solid or liquid mixture (raffinate) into the solvent (extract) [Gamse, 2002]. The two phases

are then separated either by gravity or centrifugal forces. To obtain the active agent in pure

form and to recover the solvent, further separation processes are necessary (evaporation,

crystallization, liquid-liquid extraction, rectification or re-extraction) [Hunek, 1992].

Depending on the phases the extraction is classified into two types:

Solid – liquid extraction

Liquid – liquid extraction

The extraction is a widely used process; the main areas are metallurgical,

pharmaceutical, petroleum, vegetable oil and sugar industries. It is used for extracting active

compounds from plant materials, as well as for cleaning of waste water to separate solved

compounds.

The main requirements for the extraction solvents are the followings:

high selectivity (only the active agent has to be extracted),

high capacity (in order too minimize the amount of necessary solvent),

high difference in density (easier separation),

optimal surface tension,

low vapour pressure at operating temperature (to prevent loss of solvent during

extraction),

low viscosity (low pressure drop and good heat and mass transfer),

low miscibility (important for further regeneration of the solvent),

chemical and thermal stability,

adequate flame temperature (25 °C higher than operating temperature),

non corrosive, no/low toxicity,

low price and

easy recovery.

22

After obtaining the targeted compounds in pure form regeneration of the solvent is

necessary. In many cases the regeneration step is the most cost intensive part of the whole

process. The most common methods are rectification, evaporation, crystallisation and further

extraction.

1.1. CONVENTIONAL SOLID-LIQUID EXTRACTION

The principle of the solid-liquid extraction is that the soluble compounds of a solid

matter (active agent in an inert matrix) are extracted by a solvent. The extract is present in

the extraction material either as in solid or liquid form. It can be included in cells, as well as

fine dispersion in the solid matter like caffeine in coffee [Gamse, 2002]. For a successful and

economic process the followings should be considerated:

The extraction materials should be grinded, milled or similar, before the extraction,

in this way the extraction time (and cost) is reduced.

An extraction solvent with high selectivity is preferable.

The extraction temperature: higher temperatures ease the extraction; however with

heat-sensitive compounds careful optimization is necessary.

Counter current extraction plants are preferred, because of higher concentration of

the extract.

The separation of the solvent from solution extract as well as from extraction residual

has to be achieved economically.

A total solid-liquid extraction process includes: (1) the preparation of the extraction

material, (2) separation and recovery of the solvent from extract and (3) separation and

recovery of solvent from extraction residual.

1.2. SUPERCRITICAL FLUID EXTRACTION

By definition, a supercritical fluid is a substance above both its critical temperature

and pressure (Fig. 1-left). At the critical point, the densities of the equilibrium liquid phase

and the saturated vapour phases become equal, resulting in the formation of a single

supercritical phase. This can be observed in the density-pressure phase diagram for carbon

dioxide, as shown in Fig. 1 (right), where the critical point is located at 31.1 °C (304.1 K) and

7.38 MPa (73.8 bar). With increasing temperature, the liquid-vapour density gap decreases,

up to the critical temperature, at which the discontinuity disappears [Simándi and Sawinsky,

1996].

23

. Figure 1: Carbon dioxide pressure vs. temperature phase diagram (left) and Carbon dioxide

density vs. pressure phase diagram (right).

Supercritical fluids can be regarded as “hybrid solvents” with properties between

those of gases and liquids, i.e. a solvents with a low viscosity, high diffusion rates and no

surface tension. The density of a supercritical fluid is comparable to the density of liquids but

the viscosity of the fluid is like those of a gas and the diffusion coefficient is one to two orders

higher than of a liquid [Gamse, 2002]. Table 1 gives a comparison of some physically

properties of a liquid, gas and fluid.

Table 1: Comparison of some physical properties of a gas, fluid and liquid.

Density Diffusion coefficient Viscosity (kg/l) (cm2/s) (g/cm∙s)

Gas 10-3 10-1 10-4 Fluid 0.3-0.9 10-3-10-4 10-4-10-3 Liquid 1 10-5 10-2

A further advantage of supercritical fluids is that the solubility of the compounds can

be influenced by variation of pressure and temperature, which both have different influences

on the solubility. An increase in the pressure results in higher solubility, due to the increase

in density. An increase in the temperature has two influences: (1) the density of the fluid

decreases and (2) the vapour pressure of the substance to be solved increases. Depending on

which effect is more dominant, the increase in temperature can result in an increase, as well

24

as in a decrease of solubility. Normally, for pressures twice higher as the critical pressure, an

increase in temperature results also in an increase in solubility. The critical properties for

some components, which are commonly used as supercritical fluids, are shown in Table 2.

Table 2: Critical properties of various solvents [Reid et al., 1987].

Solvent Molecular weight Crit. temperature Crit. pressure Crit. density (g/mol) (K) (MPa) (g/cm³) Carbon dioxide (CO2) 44.01 304.1 7.38 0.469 Water (H2O) 18.02 647.3 22.12 0.348 Methane (CH4) 16.04 190.4 4.60 0.162 Ethane (C2H6) 30.07 305.3 4.87 0.203 Propane (C3H8) 44.09 369.8 4.25 0.217 Ethylene (C2H4) 28.05 282.4 5.04 0.215 Propylene (C3H6) 42.08 364.9 4.60 0.232 Methanol (CH3OH) 32.04 512.6 8.09 0.272 Ethanol (C2H5OH) 46.07 513.9 6.14 0.276

In food processing, supercritical carbon dioxide has been the most successful, due to

its relatively simple handling and favourable solvent properties. It has low critical

parameters; critical pressure of 7.38 MPa and critical temperature of 31.1 °C, which enables

operating at mild temperature. In addition, the CO2 is environment safe, accepted as a

solvent in the food industry, readily available and relatively cheap. One of the most important

properties of supercritical fluids is that their solvating properties are a complex function of

their pressure and temperature. Raw materials containing CO2-soluble products can be

selectively extracted or selectively precipitated to obtain ultra-pure products. In the

beginning, the SFE was performed at higher pressures (>30 MPa), this way substances with

high affinity to scCO2 were extracted. The higher pressure was applied to increase the solvent

power of the SCF. Later on, it was found out, that extractions at lower pressure show greater

selectivity. Therefore, the optimization of the solvent power and selectivity is one of the

things which should be always considered prior SFE [Reverchon and De Marco, 2006].

The basic SFE plant (Fig. 2) consists of an extraction vessel, where the raw material is

charged. The liquefied CO2 is heated and enters the extraction vessel from the bottom. SCF at

the exit of the extractor flows through a depressurization valve to a separator in which, due to

the lower pressure, the extracts are released from the gaseous medium and collected. In order

to fractionate the obtained extract more separators can be added. The fractions of different

composition are separated by setting different temperatures and pressures in the separators

[Simandi et al., 1998].

25

Figure 2: Schematic flow diagram of a basic SFE apparatus.

The further variations on SFE are:

Multistage extraction, where the pressure and/or temperature are varied in each

process step. This is used in the case that compounds with similar properties have to

be extracted or separated. It is achieved by changing the solvent power with pressure

and temperature [Reverchon, 1997].

Addition of a liquid co-solvent to increase the extraction of polar compounds. ScCO2

extracts non-polar compounds, thus to increase the affinity towards more polar

compounds co-solvent, usually ethanol, is added. However, the disadvantages of this

modification are that, by increasing the solvent power, the selectivity decreases and

the extract will be collected together with the liquid solvent.

The advantages of supercritical fluid extraction compared to conventional extraction

techniques are:

By varying the process parameters (pressure, temperature), the power/selectivity of

the SCF can be influenced.

Provides an alternative to replace toxic organic solvents.

Enables extraction of compounds more similar to their natural form, since there is no

thermal stress.

Compounds which are not possible to extract by conventional methods can be

obtained by SFE.

The extraction/fractionation solvent can be easily and completely removed.

26

The main disadvantages of SFE are the higher investments costs compared to

conventional extraction techniques. However, to invest in the simplest SFE (extractor and

separator) plant is relatively cheap and allows simple scaling up to larger scale [Reverchon

and De Marco, 2006]. The decaffeination of tea and coffee or hop extraction, already gained

their place in the industry. The tendency shows that the interest in SFE products increases,

due to their high added value. Legal limitations of solvent residues and solvents which can be

used for food-, drug-, and cosmetic industry support this process to become more economical

[Marr and Gamse, 2000]. Different papers deal with design of high pressure plants and cost

calculations [Lack et al., 2001; Luetge and Schuetz, 2007]. Thus, the SFE technology is

becoming a potential for future applications in food industries and attracts higher interest

from the side of investors. SFE reviews have been done by many authors, in general and from

selected aspects, as well: [Brunner, 2005; Kerrola, 1995; Lang and Wai, 2001; Meireles,

2003; Moyler, 1993; Reverchon, 1997; Reverchon and De Marco, 2006; Rosa and Meireles,

2005; Turner et al., 2002].

27

2. ANTHOCYANINS

Anthocyanins comprise a diverse group of water soluble pigments responsible for

orange, red, purple and blue colours of many fruits, vegetables, flowers, leaves, roots and

other plant storage organs. Some of the sources with their pigment content are listed in

Table 3. Besides the colour attributes, their several pharmacological properties are reported.

Health benefits associated with anthocyanin extracts include enhancement of sight

acuteness, antioxidant capacity, treatment of various blood circulation disorders resulting

from capillary fragility, vaso-protective and anti-inflammatory properties, inhibition of

platelet aggregation, maintenance of normal vascular permeability, controlling diabetes, anti-

neoplastic and chemo-protective agents, radiation-protective agents, and possibly others due

to their diverse action on various enzymes and metabolic processes [Giusti and Wrolstad,

2003; Kong et al., 2003].

Table 3: Anthocyanin content of some common fruits and vegetables [Giusti and Wrolstad,

2000].

Source Pigment content

mg/100 g fresh weight Reference

Apples 10 [Mazza and Miniati, 1993] Bilberries 300-320 [Mazza and Miniati, 1993] Blackberries 83-326 [Mazza and Miniati, 1993] Black currants 130-400 [Timberlake, 1988] Blueberries 25-495 [Mazza and Miniati, 1993] Red cabbage 25 [Timberlake, 1988] Black chokeberries 560 [Kraemer-Schafhalter et al., 1996] Cherries 4-450 [Kraemer-Schafhalter et al., 1996] Cranberries 60-200 [Timberlake, 1988] Elder berries 450 [Kraemer-Schafhalter et al., 1996] Grapes 6-600 [Mazza and Miniati, 1993] Kiwi 100 [Kraemer-Schafhalter et al., 1996] Red onions 7-21 [Mazza and Miniati, 1993] Plums 2-25 [Timberlake, 1988] Red radishes 11-60 [Giusti et al., 1998] Black raspberries 300-400 [Timberlake, 1988] Red raspberries 20-60 [Mazza and Miniati, 1993] Strawberries 15-35 [Timberlake, 1988]

The anthocyanins are part of the flavonoid group and they are glycosides of

anthocyanidins [Timberlake, 1980]. The major anthocyanidins and their structure are shown

in Fig. 3 and the Table 4 together with the most common substituents; the wavelength

maxima and visible colour of the individual anthocyanidin. As seen in the Table 4, the

increasing hydroxylation or methoxylation of the aglycone shifts the colour to more bluish.

The anthocyanins contain sugars and acylated sugars. The main monosides are glucose,

28

galactose, rhamnose and arabinose. The most frequent biosides are rutinose, sambubiose,

lathyrose and sophorose. The triosides which occur can be linear or branched chain. The

main acylating groups are the phenolic acids, p-coumaric, caffeic and ferulic acid. The

position 3 is always occupied by a sugar (acylated or not), and the further sugars may appear

in the positions 5, 7, 3´ and 4´. Most of the fruits contain 3-glycosides and the most common

is the 3,5-diglycosilation.

Figure 3: Structure of anthocyanidins. For substituens R1 and R2 see Table 4.

Table 4: Some of the most common anthocyanidins in the nature, their maximum absorption

wavelength (λmax) and visible colour. Substituents R1 and R2 refer to Fig. 3.

Aglycon R1 R2 λmax (nm) Colour Pelargonidin H H 494 orange Cyanidin OH H 506 orange-red Peonidin OMe H 506 orange-red Delphinidin OH OH 508 red Petunidin OMe OH 508 red Malvidin OMe OMe 510 bluish-red

2.1. STABILITY OF ANTHOCYANINS

Anthocyanins may degrade in different degradation mechanisms to results in soluble

colourless and/or brown coloured and insoluble products [Francis, 1989; Giusti and

Wrolstad, 2003; Malien-Aubert et al., 2001]. Degradation may occur during

extraction/purification and normal food processing and storage. The major factors

29

influencing anthocyanin stability are the pH value, temperature, presence of oxygen and

light, but enzymatic degradation and interactions with other components (e.g. ascorbic acid,

metal ions, sugars, co-pigments) are important as well [Bridle and Timberlake, 1997; Francis,

1989; Jackman et al., 1987; Mazza and Brouillard, 1987; Timberlake, 1980]. Storage

conditions may have an effect also [Morais et al., 2002].

The high reactivity of the aglycone (anthocyanidin) is mainly responsible for the

various structural modifications of anthocyanins in acidic media. Anthocyanidins are

generally unstable and less soluble in aqueous media than anthocyanins, thus glycosylation is

assumed to confer stability and solubility to the pigment molecule. Loss of the glycosyl

moiety is usually followed by rapid decomposition of the aglycone. The presence of hydroxyl

groups has different effects, for example C-3 position OH group destabilizes, while C-4 and

C-5 stabilizes the coloured form [Iacobucci and Sweeny, 1983]. Attempts to improve stability

by methylation of free phenolic hydroxyl groups have been found to reduce stability. The

presence of either a 4´-OH or a 7-OH in the molecule significantly stabilizes the pigment

while methylation of these hydroxyls decreases it [Mazza and Brouillard, 1987]. Stability of

anthocyanin colour and structure is influenced also by presence of acyl groups, which are

linked to the sugar moieties of the pigment molecule [Jackman and Smith, 1996; Malien-

Aubert et al., 2001]. Pigments containing two or more acyl groups display excellent colour

stability throughout the entire pH range [Cevallos-Casals and Cisneros-Zevallos, 2004; Giusti

and Wrolstad, 2003]. The main acylating groups are phenolic acids: p-coumaric, caffeic,

ferulic or sinapic acid; but may be also p-hydroxybenzoic, malonic or acetic acid [Giusti et al.,

1999a].

The structural transformations (Fig. 4) of anthocyanins are fundamental to their

colour stability. At pH values below 2, the anthocyanin exists primarily in the form of the red

flavylium cation (AH+) [Mazza and Brouillard, 1987]. As the pH is increased a rapid proton

loss occurs to afford the blue quinoidal form A. On standing, a further reaction occurs, that is

hydration of the flavylium cation to give the colourless carbinol (pseudo)base B. These in turn

can, at an even slower rate equilibrate to the open chalcone form C, which is also colourless.

The relative amounts of cation, quinoidal forms (A), carbinol (B) and chalcone (C) at

equilibrium vary with both pH and the structure of the anthocyanin [Iacobucci and Sweeny,

1983; Jackman and Smith, 1996; Jackman et al., 1987a].

30

Figure 4: Structural transformation of anthocyanins: flavylium cation (AH+), carbinol (B),

chalcone (C) and quinonoidal base (A) [Wrolstad, 2004].

The equilibrium distribution of the four structures of malvidin-3-glycoside with the

pH value is shown in Fig. 5. At very low pH values the AH+ is the dominant form. With

increasing pH its concentration and the colour of the anthocyanin is decreased and its

hydrates to the colourless carbinol. The equilibrium between these two forms is characterised

by the pKH value, which is 2.6 for malvidin-3-glycoside. At this pH there is only small

formation of the colourless chalcone and quinoidal base (A), but with increasing pH, the

amount of B, C and A forms increase at the expense of the red cationic form (AH+). The

equilibrium between the cation and quinoidal base is at pKA of 4.25 (for malvidin-3-

glycoside). Above pH of 5 only small amount of a colour is present in the form of quinoidal

base [Timberlake, 1980]. The colour of anthocyanin-containing solutions and the relative

concentration of each of the coloured (AH+, A) and colourless (B, C) species at the

equilibrium are dependent on the values of the equilibrium constants controlling the acid-

base or proton transfer (KA), hydration (KH) and ring-chain tautomeric (KT) reactions [Mazza

and Brouillard, 1987], where

Ka = ([A]/[AH+]) aH+

31

Kh = (([B] + [C])/[AH+]) aH+

KT = [C]/[B]

and aH+ is the hydroxonium ion or proton activity (pH = - log aH+).

Figure 5: Equilibrium distribution of flavylium cation (AH+), quinoidal base (A), carbinol (B)

and chalcone (C) for malvidin-3-glycoside as a function of pH value [Mazza and Brouillard,

1987].

The stability is also markedly influenced by temperature [Cevallos-Casals and

Cisneros-Zevallos, 2004; Giusti and Wrolstad, 2003; Gomez-Plaza et al., 2006; Morais et al.,

2002]. In general, structural features that lead to increased pH-stability (i.e. methoxylation,

glycosylation, acylation) also lead to increased thermal stability [Jackman and Smith, 1996].

The mechanism of anthocyanin degradation is temperature dependent and usually follows

first-order kinetics [Giusti and Wrolstad, 2003; Tseng et al., 2006]. The concentration of

polymeric pigments increases with temperature and storage time [Brouillard et al., 2003].

Such pigments contribute to the colouration of grapes and red wines and their presence

protect the anthocyanins in these products.

Oxygen may cause degradation of anthocyanins by direct oxidation mechanism

and/or by indirect oxidation where oxidized constituents of the medium react with the

anthocyanins [Jackman et al., 1987]. Ascorbic acid and oxygen act synergistically in

32

anthocyanin degradation [Francis, 1989]. Anthocyanins are generally unstable when exposed

to UV or visible light or other sources of ionizing radiation [Cevallos-Casals and Cisneros-

Zevallos, 2004; Gomez-Plaza et al., 2006]. Light causes an increase in the rates at which

anthocyanins undergo thermal degradation. The enzymes, endogenous in many plant tissues,

which cause anthocyanin degradation and subsequent loss of colour are generally named

anthocyanases, but based on their activity two distinct groups have been identified [Jackman

and Smith, 1996]. The glycosidases, which hydrolyse the glycosidic bonds of anthocyanins,

yield free sugar and aglycone, resulting in the spontaneous degradation via the colourless

chalcone. The polyphenoloxidases (PPO) act on anthocyanins in the presence of o-diphenols

via coupled oxidation mechanism.

In acidic media anthocyanins occur as the flavylium cation, which itself exists in six

resonance species, the positive charge being delocalized over the entire heterocyclic structure

[Jackman and Smith, 1996]. Non- or mono acylated anthocyanins are particularly prone to

nucleophilic attack at positions C-2 and C-4, which generally yields in colourless species.

Nucleophilic attack by water occurs at C-2 position yielding the colourless

carbinol/hemiacetal. The C-4 position is less favourable for attack by water. This position is

more likely to be attacked by amino acids and carbon nucleophiles such as catechin, phenol,

phloroglucinol, etc. Anthocyanins are rapidly decolourized by the addition of SO2, an

antiseptic agent used extensively in the wine industry to control microbial growth. The

bleaching reaction is reversible and pH dependent; a covalent adduct at the C-2 or C-4

positions of the flavylium ring is formed [Timberlake, 1980]. Acetaldehyde and other

aldehydes cause loss of colour of anthocyanins through electrophilic attack. Anthocyanidin

3,5-diglycosides are less prone to electrophilic attack than 3-glycosides [Jackman and Smith,

1996].

The high sugar concentrations have protective effect on anthocyanins, probably by

lowering water activity. Above threshold level (100 ppm), sugars and their degradation

products accelerate the degradation of anthocyanins [Cevallos-Casals and Cisneros-Zevallos,

2004; Jackman and Smith, 1996]. The sugar degradation compounds react with the

anthocyanins leading to formation of colourless or complex brown coloured products

[Malien-Aubert et al., 2001]. Oxygen enhances the degradative effects of all sugars and sugar

derivatives.

Anthocyanins form weak complexes with alkaloids, proteins, tannins, other

flavonoids, organic acids, nucleic acids, polysaccharides and metal ions through so called

intermolecular co-pigmentation [Dimitric Markovic et al., 2005; Gonzalez-Paramas et al.,

2006; Mazza and Brouillard, 1987]. Intramolecular co-pigmentation is called, when the

anthocyanin molecule is acylated. Co-pigmentation causes a bathochromic shift from red to

blue and increases the tinctorial power [Giusti et al., 1999a]. As the concentration of

33

anthocyanin is increased the pigment molecules associate with each other [Timberlake,

1980], thus reducing the potential to complex with a co-pigment. Polymeric flavonoids and

anthocyanins play important role in the colouration of grapes and red wines [Brouillard et al.,

2003]. During aging the monomeric anthocyanins are replaced by the more stable polymeric

pigments. Such components are less pH-sensitive and more resistant to discolouration.

Complexation may also occur with different metals: iron, tin, aluminium, copper and various

others [Jackman et al., 1987a]. These metal chelates and salts normally cause a bathochromic

displacement from red to stable blue and violet colours.

2.2. EXTRACTION OF ANTHOCYANINS FROM DIFFERENT PLANT MATERIALS

In most fruits and vegetables the anthocyanin pigments are located in cells near the

surface or exterior [Francis, 1982]. The most commonly used extraction solvent is methanol

or ethanol [Metivier et al., 1980; Ortega-Regules et al., 2006; Pinelo et al., 2005], many times

in mixture with water [Lapornik et al., 2005; Negro et al., 2003; Vidal et al., 2004; Wu and

Prior, 2005]. The solubility of anthocyanins, which have polar character, is the highest in

methanol, a little lower in ethanol and the lowest in water, but differences are not big, so for

food industry usage ethanol is more adequate solvent. Extraction procedures involve the use

of acidic solvents which denature the membranes of cell tissue and simultaneously dissolve

the pigments [Amico et al., 2004; Heredia et al., 1998; Monagas et al., 2006; Revilla et al.,

1998; Revilla et al., 1999; Ruberto et al., 2007]. Acidification serves to maintain a low pH

value, thus providing a favourable medium for the formation of flavylium form [Iacobucci

and Sweeny, 1983; Jackman et al., 1987b; Timberlake, 1980]. In some cases the obtained

concentrate is further extracted with hexane, ether, or ethyl acetate to remove lipid material

and unwanted polyphenols [Fuleki and Francis, 1968]. The acid tends to stabilize

anthocyanins, but it may also change the native form of the pigment in the tissue by breaking

associations with metals, co-pigments etc. Losses of labile acyl and sugar residues may occur

after acidified extraction during subsequent concentration and recrystallization [Adams,

1972; Jackman et al., 1987a]. To minimize the decomposition of acylated pigments lower acid

concentration was suggested [Revilla et al., 1998]. In some cases weaker organic acids have

been utilized in the extraction solvents [Cacace and Mazza, 2003; Wu and Prior, 2005].

Extraction with ethanolic, or aqueous SO2 or bisulphite solutions is also favourable because it

increases the pigment yield and concentrates of higher purity, colour intensity and pigment

stability are obtained than with pure solvent [Gomez-Plaza et al., 2006; Jackman et al.,

1987b].

The increase of the extraction temperature increases the rate of extraction and

reduces the extraction time by increasing the diffusivity [Cacace and Mazza, 2003; Turker

34

and Erdogdu, 2006]. However, anthocyanins are not heat stable, thus temperature of the

extracting medium cannot be increased indefinitely to maximize the process. The increased

extraction time increased the anthocyanin yield up to 12 h after which a decrease, probably

due to degradation, was observed [Lapornik et al., 2005].

2.3. PURIFICATION OF ANTHOCYANIN EXTRACTS

Purification and separation has been carried out primarily by chromatographic

techniques [Jackman et al., 1987b]. The selection of chromatographic solvents depends on

the nature of the crude anthocyanin sample. For purification of larger quantities column

chromatography with different loadings were reported [Amico et al., 2004; Giusti et al.,

1999a; Gomez-Miguez et al., 2006; Gomez-Plaza et al., 2006; Kammerer et al., 2005; Longo

and Vasapollo, 2006; Pomar et al., 2005]. Anthocyanins may also be purified and

concentrated by membrane filtration, which separates proteins and higher molecular weight

carbohydrates from smaller molecules (sugars, phenolics, anthocyanins etc.). However,

aggregation of some polymerized anthocyanins may cause them to be retained by the

membrane [Jackman and Smith, 1996]. Rapid and most efficient separation of complex

mixtures is achieved with reversed-phase high-performance liquid chromatography (HPLC).

The technique is non-destructive; the separated peaks are readily collected for subsequent

analysis. With appropriate selection of eluent, column type and length, flow rate and

temperature, HPLC can be used to separate the anthocyanins without the need for

preliminary purification of extracts [García-Beneytez et al., 2002; Kallithraka et al., 2005;

Kuskoski et al., 2003; Ortega-Regules et al., 2006; Ruberto et al., 2007].

2.4. ANALYSIS OF ANTHOCYANINS

2.4.1. QUALITATIVE AND QUANTITATIVE ANALYSIS