Determination of the intrinsic rate of ethane gas hydrate decomposition

Click here to load reader

-

Upload

matthew-clarke -

Category

Documents

-

view

220 -

download

2

Transcript of Determination of the intrinsic rate of ethane gas hydrate decomposition

*Corresponding author. Tel.: #1-403-2206695; fax: #1-403-282-3945.

E-mail address: [email protected] (P. R. Bishnoi).

Chemical Engineering Science 55 (2000) 4869}4883

Determination of the intrinsic rate of ethane gashydrate decomposition

Matthew Clarke, P. R. Bishnoi*Department of Chemical & Petroleum Engineering, University of Calgary, 2500 University Drive NW, Calgary, Alberta, Canada T2N 1N4

Received 22 December 1999; accepted 2 May 2000

Abstract

The kinetics of ethane hydrate decomposition was studied using an isothermal/isobaric semibatch stirred-tank reactor. Theexperimental set-up and procedure used was similar to that used by Kim, Bishnoi, Heidemann and Rizvi (1987), Chemical EngineeringScience, 42, (1645}1653) with one major modi"cation; the addition of an on-line particle size analyser. The experiments wereconducted at temperatures ranging from 274.15 to 281.15 K and at pressures between 5 and 11 bar. A new mathematical model isdeveloped to determine the rate constant of decomposition. The model accounts for the distribution of particle sizes in the hydratephase when determining the intrinsic rate constant of decomposition. The e!ect of the rate of stirring on the rate constant was alsoinvestigated to establish the regime where mass and heat transfer e!ects were negligible. The data were then obtained to determine theintrinsic rate constant. It was found that the activation energy for ethane hydrate decomposition is 104 kJ/mol and the intrinsic rateconstant of decomposition is 2.56]108 mol/m2 Pa s. ( 2000 Elsevier Science Ltd. All rights reserved.

Keywords: Gas hydrates; Kinetics; Crystallisation; Particulate; Population balance

1. Introduction

Gas hydrates constitute a class of solids in which smallmolecules occupy almost spherical holes in ice-like latti-ces made up of hydrogen-bonded water molecules. Thisclass of solids is known as clathrates. Technically speak-ing, clathrate compounds are characterised by the struc-tural combinations of two substances which remainassociated not through strong attractive forces, but be-cause strong mutual binding of the molecules of one sortmakes possible the "rm enclosure of the other. The hy-drate forming gases include light alkanes, carbon dioxide,hydrogen sulphide, nitrogen and oxygen. Gas hydratescan exist in one of the four structures: structure I andstructure II (Claussen, 1951; von Stackelberg & MuK ller,1954; Je!ery & McMullan, 1967), structure H (Ripmees-ter, Ratcli!e & Tse, 1998) and a new, as of yet unnamedstructure (Konstantin, Uchadin & Ripmeester, 1999).Ethane is known to form structure I hydrates.

Gas hydrates have signi"cant importance in the petro-leum industry. Traditionally, for the transportation of oil

and gas, the industry has designed pipelines to operateoutside hydrate forming conditions. This has been ac-complished by either adding traditional inhibitors suchas glycols and methanol or by dehydration of thegas/condensate #uids. One major task encountered bythe petroleum industry is to decompose a hydrate plugformed accidentally or otherwise. Having reliable dataon the intrinsic kinetics of gas hydrate decompositioncould allow for better predictions of the rates of de-composition in hydrate plugs.

On the other hand, in-situ hydrates found in perma-frost regions and under the ocean #oor represent a vast,untapped natural resource. In order to predict gas pro-duction rates from hydrate reservoirs, it is necessary to beable to account for the rate at which hydrates are decom-posing.

In view of the importance of gas hydrates to the petro-leum industry, the thermodynamics of hydrate formationhas been studied extensively. Experimental data on thethermodynamics of gas hydrate formation has been ob-tained for many systems and the computational methodsto predict gas hydrate formation conditions are wellestablished.

The "rst experimental observation of gas hydrates wasmade in 1811 by Sir Humphry Davis. Carson and Katz

0009-2509/00/$ - see front matter ( 2000 Elsevier Science Ltd. All rights reserved.PII: S 0 0 0 9 - 2 5 0 9 ( 0 0 ) 0 0 1 3 7 - 8

(1942) studied the four-phase equilibria of gas mixtures inthe presence of gas hydrates and of hydrocarbon-richliquids. The conditions of hydrate formation in liquidhydrocarbon/water systems was investigated by Ng andRobinson (1976). Holder, Corbin and Papadopoulos(1980) investigated the thermodynamics of gas hydratescontaining methane, argon and krypton. Experimentalequilibrium data for ethane hydrate formation in thepresence of single- and mixed-electrolyte solutions ofNaCl, KCl, CaCl

2and KBr were obtained by Englezos

and Bishnoi (1991). Dholabhai, Englezos, Kalogerakisand Bishnoi (1991) measured the equilibrium conditionsfor methane hydrate formation in mixed aqueous electro-lytes. Handa and Stupin (1992) experimentally deter-mined the conditions of methane and propane hydrateformation in 70 As silica gel pores. Dholabhai, Ka-logerakis and Bishnoi (1993a) measured the equilibriumconditions of propane hydrate formation in aqueouselectrolyte solutions. The conditions of structure H hy-drate formation has been studied extensively by Mehtaand Sloan (1993). Dholabhai, Kalogerakis and Bishnoi(1993b) measured the formation conditions of CO

2hy-

drates in aqueous electrolyte solutions. The equilibriumconditions of CO

2/CH

4mixtures in electrolyte solutions

was investigated by Dholabhai and Bishnoi (1994). Theequilibrium conditions of CO

2/CH

4mixtures in the

presence of electrolytes, methanol and ethylene glycolwas investigated by Dholabhai, Parent and Bishnoi(1997). Olsen, Majumdar and Bishnoi (1999) investigatedthe equilibrium conditions for mixtures of CO

2and N

2.

Mahadev and Bishnoi (1999) obtained experimental datafor the equilibrium conditions of hydrogen sulphide hy-drates in the presence of electrolytes and methanol.A comprehensive compilation of the experimental datareported in the literature is made by Sloan (1997).

van der Waals and Platteeuw (1959) used statisticalthermodynamics to derive a model to predict the incipi-ent hydrate formation conditions. Parrish and Prausnitz(1972) substituted the Kihara Potential model for theLennard Jones potential model, in the work of van derWaals and Platteeuw, and predicted the formation con-ditions of hydrates from gas mixtures. Holder and John(1983) use a modi"ed Langmuir constant that accountsfor aspherical interactions between gas molecules and thehydrate lattice. Englezos and Bishnoi (1988) combined themodel of van der Waals and Platteeuw with the model ofPitzer to predict the formation conditions of gas hydratesin aqueous electrolyte solutions. Bishnoi, Gupta, Englezosand Kalogerakis (1989) developed a computational pro-cedure to perform multi-phase #ash calculations for sys-tems that contain hydrates. Tse and Bishnoi (1993)presented a methodology for predicting the incipientequilibrium for carbon dioxide gas hydrates in the pres-ence of electrolytes such as NaCl, KCl and CaCl

2.

Clarke, Pooladi-Darvish and Bishnoi (1999) modelledthe conditions for hydrate formation in porous media.

Vysniauskus and Bishnoi (1983) pioneered kineticstudies of gas hydrate formation above the ice point.Isothermal, isobaric experiments were carried out ina semi batch stirred tank reactor, using methane andethane. Englezos, Dholabhai, Kalogerakis and Bishnoi(1987) developed a model for hydrate growth, based ontwo-"lm theory and crystallisation theory. Kalogerakis,Jamaluddin and Dholabhai (1993) examined the e!ect ofanionic, cationic and non-ionic surfactants on the kinet-ics of hydrate formation. Chun and Lee (1996) reportedthe kinetics of CO

2hydrate formation and Malegoankar,

Dholabhai and Bishnoi (1997) studied the hydrate forma-tion kinetics of CH

4and CO

2.

While the kinetics of hydrate formation has beenstudied for a few systems, relatively little attention hasbeen paid to gas hydrate decomposition. Ullerich, Selimand Sloan (1987) described the decomposition of a syn-thetic core of methane hydrate as a moving boundaryheat transfer problem. Kim, Bishnoi, Heidemann andRizvi (1987) developed a model for the intrinsic rate ofgas hydrate decomposition and determined the rate con-stant from experimental data for methane. Their experi-mental work consisted of measuring the amount ofmethane collected during the hydrate decomposition,while maintaining a constant temperature and pressurein a semi-batch stirred-tank reactor. In order to deter-mine the intrinsic rate constant in their model, the initialparticle size was estimated from settling times and Stokeslaw and it was assumed that all particles had the samediameter before decomposition. Jamaluddin et al. (1989)combined heat transfer with intrinsic kinetics to simulatethe decomposition of a core of methane hydrate. Khair-khah, Pooladi-Darvish, Bishnoi and Collet (1999) dis-cussed a three-mechanism model (two-phase #uid #ow,kinetics of dissociation and heat transfer) for the perfor-mance prediction of gas production from hydrate reser-voirs. Masuda, Fujinaga, Naganawa, Fujuta andHayashi (1999) presented a numerical model for predic-ting the #ow behaviour of gas and water with hydratedissociation in a porous media and the results wereveri"ed with results from methane gas}hydrate dissocia-tion in berea sandstone cores.

In the current study, the experimental procedure ofKim et al. (1987) is modi"ed to include an on-line particlesize analyser. A new mathematical model, which canaccount for the initial particle size distribution, is de-veloped and used to determine the intrinsic rate constantand activation energy for ethane hydrate decomposition.

2. Experimental apparatus and procedure

2.1. Apparatus

The experimental apparatus of Kim et al. (1987) wasmodi"ed to include an on-line particle size analyser.

4870 M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883

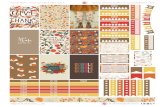

Fig. 1. Schematic of experimental apparatus.

Preliminary details regarding the experimental appar-atus and procedure have been given by Clarke andBishnoi (1999). Fig. 1 shows a simpli"ed schematic of theexperimental apparatus. The current set-up consists of anisothermal, isobaric semi-batch stirred-tank reactor,a gas supply reservoir for hydrate formation, a collectionreservoir for decomposition and a Galai PSA 2010 par-ticle size analyser.

The slurry of hydrates is circulated through a high-pressure micro#ow cell in the analyser by means of a Gil-son 303 reciprocating pump at the rate of 25 ml/min. Thehigh-pressure micro#ow cell was originally designed tostudy asphaltene precipitation (Nielsen, Svrcek & Meh-rotra, 1994). The slurry, as it #ows out of the reactor andthrough the circuit, would gain heat from the ambientcausing the hydrates to decompose. To prevent the ther-mal decomposition of hydrates, the entire circuit is chil-led by circulating cooling glycol from the reactor baththrough a concentric tube cooling arrangement. The hy-drate}water slurry #ows through the inner tube and thecooling glycol through the outer tube.

The temperature and pressure control system was thesame as that used in the studies of Englezos et al. (1987)and later by Malegoankar et al. (1997). Di!erential pres-sure transducers were used to measure the pressure in thereactor and in the supply and collection reservoirs.Type-T thermocouples were used to measure the temper-ature in the reactor and in the reservoirs. The temper-atures and pressures were recorded using a National-Instruments AT-MIO-16X data acquisition card.A data-acquisition program was written to interface withthe card and to calculate the number of moles of the gasin the hydrate phase at any time during the experiment.

The Trebble}Bishnoi equation of state (Trebble& Bishnoi, 1987, 1988) was used for all thermodynamiccalculations.

2.2. Procedure

The procedure for a typical experiment is similar tothat followed by Kim et al. (1987). The major change inthe procedure is due to the particle analyser. Essentially,the experiment can be divided into three stages: hydrateformation, stabilisation and hydrate decomposition.

2.2.1. Hydrate formationThe hydrate formation procedure is almost identical

to that used by Englezos et al. (1987) and later byMalegoankar et al. (1997). Prior to beginning the experi-ment, the reactor is thoroughly cleaned using doubledistilled/de-ionised water and the entire system is #ushedwith the experimental gas. Also, prior to the formationexperiment, the volume of the supply reservoir and of thecollection reservoir are determined from the Ruska pumpexperiment (Englezos et al., 1987) and, if necessary, thelaser on the particle size analyser is aligned. A syringe isused to charge the reactor with 310 ml of double-distil-led/de-ionised water.

As soon as the water is in thermal equilibrium with thereactor, it is charged with the experimental gas to a pres-sure that is higher than the three-phase equilibrium pres-sure at the experimental temperature, point A in Fig. 2, inorder to form hydrates. Once the temperatures in thereservoirs and the reactors have stabilised, the data ac-quisition program is started. Once the data acquisitionprogram has determined the moles of gas initially in the

M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883 4871

Fig. 2. Experimental process path.

Fig. 3. Schematic of mechanism for hydrate decomposition.

system, the stirrer is started. The number of moles con-sumed at any time during the formation experiment issimply the number of moles of hydrate former initially inthe gas phase minus the present value. The appearanceof hydrates, often referred to as the turbidity point, ismarked by a sudden change in the transparency of thesolution.

2.2.2. StabilisationOnce the formation has proceeded for a suitable length

of time, the supply gas #ow to the reactor is terminated.The reactor is then depressurised to a pressure of about0.5 bar above the three-phase equilibrium pressure,point B in Fig. 2. This is accomplished by transferring thegas to the collection reservoir R3, thus keeping the sys-tem closed during the experiment. At this point, theparticle size distribution of the circulating slurry is mea-sured. Since the system pressure is nearly equal to theequilibrium pressure, the driving force for hydrategrowth will be negligible.

2.2.3. Hydrate decompositionOnce the particle size distribution has been measured,

the #ow of hydrates to the particle size analyser is termin-ated, to isolate the sampling loop, and the decompositionis initiated by further depressurising the reactor to a pres-sure below the three-phase equilibrium pressure. The gasproduced due to the decomposition is collected in reser-voir R3 and the temperature and pressure in the reservoirand in the reactor are recorded. During the entire experi-ment, the mass is well stirred. At any time during thedecomposition stage of the experiment, the number ofmoles remaining in the hydrate phase is

n(t)"no!m(t)#m(0) (1)

The terms n(t) and noactually account for the moles of

gas in the hydrate plus that in the liquid phase. However,since the liquid phase is saturated, the number of moles inthe liquid phase does not change during the experiment.

3. Development of a new mathematical model

The envisioned process of a decomposing hydrateparticle is shown schematically in Fig. 3. As the hydratedecomposes, a cloud of gas surrounds the hydrate par-ticle. This cloud of gas prevents hydrate particles fromagglomerating or breaking during decomposition. Also,since the hydrate particle is completely surrounded bythe gas phase, and the liquid phase is saturated with thegas, it is not necessary to account for liquid side resist-ance to mass transfer when describing hydrate decompo-sition kinetics.

Hence, the overall driving force for gas hydrate de-composition is the di!erence between the fugacity of thehydrate former at the surface of the hydrate particle andthe fugacity of the hydrate former in the cloud of gas. Thefugacity at the surface of the particle is the equilibriumfugacity of the gas at the hydrate surface temperature.Also, the fugacity of the hydrate former in the gas cloudis the same as that in the bulk gas. Kim et al. (1987)proposed a two-step mechanism for gas hydrate de-composition consisting of the following steps:

1. Destruction of the clathrate host lattice at the surfaceof a particle.

2. Desorption of the guest molecule from the surface.

With these assumptions, Kim et al. (1987) wrote the rateof disappearance per particle as

Adn

dtBp

"!KdA

p( f

%2!f V

g), (2)

1

Kd

"

1

kr

#

1

km

. (2a)

The term kris the reaction rate constant (steps 1 and 2)

and the term km

is the mass transfer coe$cient. Masstransfer e!ects arise as a result of the temperature di!er-ence between the hydrate surface and the gas cloudsurrounding the hydrate particle and are dependentupon the rate of heat transfer as well as upon the degree

4872 M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883

of mixing. Good mixing of the reacting mass can elimin-ate the temperature di!erence. Thus, 1/k

mbecomes negli-

gible.The particle surface area for a non-spherical particle

can be written as

Ap"/

s¸2"

nt

¸2. (3)

The sphericity, t, is de"ned as `the ratio of the surfacearea of a sphere having the same volume as the particle tothe apparent estimated surface area of the particlea(Mullin, 1997). Mathematically, the sphericity can bewritten as

t"

p

/sA6/

vp B

2@3. (4)

In the model of Kim et al. (1987), the particle surfacearea was obtained by measuring the settling time andapplying Stoke's law to obtain an average particle dia-meter. In the present study, the total surface area isobtained from the measured hydrate particle size distri-bution.

A global rate of disappearance can be obtained byintegrating Eq. (2) over all particle sizes present:

Ry(t)"!

p

tK

d( f

%2!f V

g)P

=

0

¸2u(¸, t) d¸, (5)

Ry(t)"!

pt

Kd( f

%2!f V

g)k

2(t), (6)

k2(t)"P

=

0

¸2u(¸, t) d¸. (7)

A material balance on the reacting mass volume gives

dn

dt"P

V

Ry(t) d<"R

y(t)<. (8)

Equations (6) and (8) can be combined to give

dn

dt"R

y(t)<"!

p

t<K

d( f

%2!f V

g)k2 (t), (9)

Pn(t)

n0

dn"(n(t)!n0)

"!

p

t<K

d( f

%2!f V

g)P

t

0

k2(t) dt. (10)

The second moment can be obtained from the popula-tion balance. By assuming that there is no breakage oragglomeration, the population balance can be written as

LuLt

#

LL¸

(Gu)"0. (11)

It is not always necessary to solve Eq. (11) for the entireparticle size distribution. Often, it is su$cient to just lookat part of the distribution. This greatly simpli"es the

mathematical formulation. Eq. (11) can be transformedinto a set of ordinary di!erential equations by usinga moment transformation. Eq. (11) is multiplied by¸j and integrated with respect to ¸ from zero to in"nity:

P=

0

Lu

Lt¸jd¸#P

=

0

LL¸

(Gu)¸j d¸"0. (12)

Eq. (12) can be integrated term by term as follows:

P=

0

Lu

Lt¸j d¸"

d

dt AP=

0

u¸j d¸B"dk

jdt

, (13)

kj"P

=

0

u¸j d¸. (14)

The second term in Eq. (12) is integrated by parts. Thederivative term only applies to the product Gu. Also,when integrating Eq. (12), it must be noted that the valueof the particle density function is zero at size equals zeroand size equals in"nity, and that the linear growth rate isassumed to be independent of size. Therefore,

P=

0

LL¸

(Gu)¸j d¸"GCu¸jD=0!jP

=

0

¸j~1u d¸D"!jGk

j~1. (15)

After performing the moment transformations, Eq. (11)becomes

dkj

dt"jGk

j~1. (16)

The value of j that is chosen depends on what informa-tion is required. For example, if it is the volume ofparticles that is important, j is chosen as 3. This wouldgive four di!erential equations. Setting j equal to in"nitywould give the entire distribution.

For the case of hydrate decomposition, the secondmoment of the particle size distribution is needed. Thesecond moment may be obtained from Eq. (16) by writingthe terms for j"0, 2. This gives the following set ofordinary di!erential equations:dk

0dt

"0, k0(0)"ko

0,

dk1

dt"Gk

0, k

1(0)"ko

1,

dk2

dt"2Gk

1, k

2(0)"ko

2.

(17)

The solution to the above set of di!erential equationshas been given by Clarke and Bishnoi (1999). The solu-tion to the moment equations are

Ck0

k1

k2D"ko

0 C1

tG

t2G2D#ko1 C

0

1

2GtD#ko2 C

0

0

1D. (18)

M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883 4873

The expression for the second moment can be com-bined with Eq. (10) to give

n(t)"no!

p

tK

d<( f

%2!f V

g)(13

ko0G2t3

#ko1Gt2#ko

2t). (19)

The linear growth rate is obtained from

Adn

Hdt B

p

"!KdA

p( f

%2!f V

g), (2)

Ap"/

s¸2, (3)

<p"/

V¸3, (20)

nH"

o<p

M"

o/V¸3

M. (21)

Eqs. (3) and (21) are substituted into Eq. (2) to give

o/V

M Ad¸3

dt Bp

"!Kd/s¸2( f

%2!f V

g), (22)

3o/V¸2

M Ad¸

dt Bp

"!Kd/

s¸2( f

%2!f V

g), (23)

Ad¸

dt Bp

"G"!

KdM( f

%2!f V

g)

3o/

s/v

. (24)

The ratio of the shape factors can be written in terms ofsphericity by using Eq. (4):

/s

/v

"

nt/

vA6/

vn B

2@3. (25)

When combined with Eq. (24) the linear growth ratebecomes

G"!

KdM( f

%2!f V

g)

3ons

/vt A

6/v

n B2@3

. (26)

The negative sign in Eq. (26) is due to the fact that theparticle is shrinking.

Eqs. (26) and (19) completely describe the intrinsic rateof decomposition of gas hydrates of any arbitrary shape,as long as the surface area is known.

If it is assumed that all particles have the same initialdiameters, the new model reduces to the model of Kimet al. (1987).

3.1. Determination of the rate constant

The rate constant, Kd, can be determined by using

a least-squares analysis on Eq. (19) along with the experi-mental data. It is important to note that the only un-known in Eq. (19) is the rate constant. The least squaresproblem can be set up by de"ning an objective function

as follows:

g"+An(t)D%91

!Cno!nt

Kd<( f

%2!f V

g)A

1

3ko0G2t3

#ko1Gt2#ko

2tBDB

2

"+(n(t)D%91

![no!K

da(t)])2, (27)

where

a(t)"p

t<( f

%2!f V

g)(13ko0G2t3#ko

1Gt2#ko

2t). (28)

The rate constant is chosen to minimise the function g,in Eq. (27). This occurs where the derivative of the func-tion g with respect to K

dis zero,

dg

dKd

"0"2+(n(t)D%91

![no!K

da(t)])a(t). (29)

This can be rearranged to give

+(a(t)n(t)D%91

![a(t)no!K

da2(t)])"0, (30)

Kd"

+a(t)no!+a(t)n(t)D

%91+a2(t)

. (31)

4. Results and discussion

4.1. Validation of the particle size analyser

Preliminary experiments were conducted in order totest the reliability of the on-line particle size analyser.These experiments consisted of circulating Latex micro-spheres, of a known diameter, through the sampling loopand measuring the size distribution with the particle sizeanalyser. The microspheres were known to be almostmonodisperse, with a mean diameter of 22.40 lm. Theresults from the particle size analyser, as seen in Fig. 4,show a very narrow size distribution. The average dia-meter was determined to 22.38 lm. This shows thatthe modi"ed #ow cell is capable of producing accuratereadings.

4.2. Mass balance

Fig. 5 shows the data for a typical experiment, includ-ing dissolution, formation, stabilisation and decomposi-tion. During the dissolution stage, ethane is beingabsorbed into water. At approximately 1500 s, there is anabrupt change in the slope of the curve. This correspondsto the appearance of hydrate nuclei. After the hydrateshave been allowed to grow for a su$cient time, thesupply gas is stopped and the pressure in the reactor isreduced to a pressure about 0.5 bar above the three-phase equilibrium pressure. This occurs at approximately

4874 M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883

Fig. 4. Particle size analysis of 22.40 lm calibration spheres.

Fig. 5. Moles of ethane consumed during formation and remaining in the hydrate phase during decomposition.

3000 s in Fig. 5. During the stabilisation phase, it isassumed that because the pressure is very close to equi-librium, the size of the hydrate particles stays constant.At this point, the size distribution of the hydrate particles

is measured. The size distribution for a typical sample isshown in Fig. 6. The moles of hydrate former remainingin the hydrate phase at this point gives n

o. At t"3500 s

in Fig. 5, the decomposition process is initiated by further

M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883 4875

Fig. 6. Particle size histogram for ethane hydrates.

reducing the pressure to a value below the three-phaseequilibrium pressure.

The data from the decomposition section of the experi-ment, along with Eq. (31), are used to calculate K

d.

A commercial software package called Table Curve (Jan-del Scienti"c, 1994) was used to solve Eq. (31).

4.3. Extrapolation of the particle size distribution

The Galai particle size analyser hardware has been setto measure particles in the range 5}600 mm. It was ob-served from the experimental data that the particle sizeswere always below 600 mm. Therefore, it was necessaryto extrapolate the particle size distribution into the range2r

c(D(5 lm, where r

cis the critical radius of a hy-

drate nuclei (Englezos et al., 1987). For the experimentshown in Figs. 5 and 6, the number distribution function,u, is obtained from the cumulative oversize number dis-tribution function and is seen in Fig. 7. The cumulativelog-normal oversize number distribution function,Eq. (32) was "tted to the data:

y"a#b

2 C1#erfA!(c!x)

J2d BD, (32)

where a, b, c and d are adjustable parameters and aredetermined by using Table Curve (Jandel Scienti"c,1994). From the above function, the number distribution

is given by

u"!

dy

dx. (33)

From Eq. (33), the number area and volume distribu-tions below 5 lm can be determined as follows:

N"Px2

x1

u(x) dx, (34)

A"pPx2

x1

u(x)x2 dx, (35)

<"p6 P

x2

x1

u(x)x3 dx. (36)

From the analysis of the cumulative oversize numberdistribution, it can be shown that particles below5 mm constitute 23.43% of the number distribution,2.27% of the area distribution and 0.10% of the volumedistribution.

Once the complete particle size distribution is known,it is possible to calculate the number of moles of ethane inthe hydrate phase, n

o. The value of n

othat is calculated

from the data acquisition should be the same as the valuethat is calculated from the particle size analysis. For theexperiment shown in Fig. 5, n

ois found to be 7.463]

10~3 mol from the temperature and pressure measure-ments and 7.201]10~3 mol from the particle size analy-sis. This is a di!erence of about 4%. This di!erencemay be attributed to the non-sphericity of the particles

4876 M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883

Fig. 7. Cumulative number density oversize plot for ethane hydrates.

and to uncertainties in extrapolating the particle sizedistribution.

4.4. Elimination of heat and mass transfer ewects

In order to establish that heat and mass transfer resist-ances around the particles were not signi"cant, experi-ments were conducted at various stirring rates. Fig. 8shows that the rate constant is virtually unchanged ingoing from 300 to 500 rpm. It is only below 300 rpm thatthe rate constant changes. This implies that heat andmass transfer resistances start to become signi"cant atlower agitation rates, or that 1/k

m, from Eq. (2a), becomes

large. Thus, subsequent experiments were conducted at400 rpm, where the measured global rate is actually theintrinsic rate.

In particulate systems, it may not be possible to elimin-ate mass transfer resistances for extremely small particles.Thus, it is necessary to establish that these small par-ticles do not contribute greatly to the experimentalobservations.

For an agitated vessel, the Sherwood number can becalculated from the FroK ssling correlation,

Sh"2#0.6Re1@2 Sc1@3, (37)

Sh"k¸

DAB

, (38)

Re"u¸

l, (39)

Sc"l

DAB

. (40)

The case of Sh"2 corresponds to the situation of di!u-sion away from a sphere in a stagnant #uid. This iscomplete mass transfer control.

The appropriate velocity to use in Eq. (39) is the slipvelocity. The slip velocity is usually assumed to be thefree-fall velocity of the particle (Mullin, 1997). Accordingto Mullin (1997) the free fall velocity can be estimated bythe following equations:

ut"0.153g0.71¸1.14Do0.71o~0.29

sg~0.43,

J4g¸*o/3os,

¸4500 lm,

¸'500 lm.

(41)

Eqs. (37)}(41) show that for ethane hydrate, the Sher-wood number approaches 2 as the particle diameterapproaches 56 nm. It was found, however, that the con-tribution of the particles with diameter less than or equalto 56 nm to the total number of moles of ethane in thehydrate phase is negligible.

4.5. Reproducibility of results

The reproducibility of the results was established byconducting the experiment under the same conditionsand comparing the results from each run. Three runswere done at a temperature of 275.75 K, a pressure of5.87 bar and a stirring rate of 400 rpm. From the three

M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883 4877

Fig. 8. E!ect of agitation rate on the rate constant for ethane hydrate decomposition.

experiments, it was found that the rate constants were5.32]10~12, 5.20]10~12 and 5.35]10~12 mol/m2 Pa s.This variation in the values of the rate constant wasconsidered acceptable and indicates that the experi-mental procedure yielded precise results.

4.6. Results for all experiments

Figs. 9}12 show the experimental results for the de-composition stage of the experiment at four di!erenttemperatures. Table 1 summarises the rate constants forethane at each of the conditions. Because heat and masstransfer resistances have been eliminated, the global rateconstant, from Eq. (2a), is equal to the intrinsic rateconstant. As expected, the rate constant increases withtemperature.

4.7. Temperature dependence of the intrinsic rate constant

Fig. 13 shows a plot of ln Kd

vs 1/¹. The plot showsa good linear "t, suggesting the following Arrhenius-typeequation for K

d:

Kd"Ko

dexpA!

*E

R¹B. (42)

From Fig. 13, it is seen that the rate constant increaseswith temperature and that the activation energy is posit-ive. A plot of ln K

dvs 1/¹ was used to calculate

ln (Kod)"19.36$2.63

or

Kod"2.56]108 mol/m2 Pa s

*E

R"12511.39 K$727.4 K

or

*E"104 kJ/mol.

Since hydrate decomposition is endothermic, it shouldbe expected that the activation energy is at least as largeas the heat of formation (Smith, 1981). The heat of forma-tion is approximately 80 kJ/mol. A linear Arrhenius plotis further evidence that heat and mass transfer resistanceshave been eliminated.

4.8. Intrinsic versus global kinetics

The pre-exponential term, Kod, is an intrinsic rate con-

stant and is independent of the pressure, temperature,particle geometry and process geometry. The intrinsicrate of reaction refers only to the rate at which onechemical species is converted into another. It is com-pletely independent of physical processes such as heat,mass and momentum transfer. What is measured in thelaboratory is the global rate of reaction, which is the rateassociated with the bulk temperature and pressure.However, the construction and operating conditions oflaboratory reactors can be chosen to reduce the di!erences

4878 M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883

Fig. 9. Moles of ethane remaining in the hydrate phase at 1.0 C and 4.87 bar.

Fig. 10. Moles of ethane remaining in the hydrate phase at 2.6 C and 7.88 bar.

between the global and the intrinsic rates so that theintrinsic rate constant can be extracted from the experi-mental data. These di!erences can be completely elimi-

nated only if the concentration of a reactant or product isthe same in all points of a reacting mass and if theconcentrations can change only due to reaction.

M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883 4879

Fig. 11. Moles of ethane remaining in the hydrate phase at 6.0 C and 7.88 bar.

Fig. 12. Moles of ethane remaining in the hydrate phase at 7.5 C and 10.87 bar.

4880 M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883

Table 1Rate constants for Ethane Hydrate Decomposition

¹(K) Formation pressure (bar) Decomposition pressure (bar) K$

(mol/m2 Pa s)

274.15 6.87 4.87 3.65436E-12274.15 6.87 4.87 3.69074E-12275.75 8.37 5.87 5.32831E-12275.75 8.37 5.87 5.20260E-12275.75 8.37 5.87 5.35292E-12279.15 12.87 9.12 9.18665E-12280.65 14.87 10.87 1.13846E-11

Fig. 13. Arrhenius plot for ethane hydrate decomposition.

In the current experiments, the heat transfer e!ects areeliminated by immersing the equipment in a constanttemperature bath and by conducting experiments close tothe equilibrium pressure. The mass transfer e!ects areeliminated by agitating the solution. Thus, by eliminatingthe mass and heat transfer e!ects, it is possible to isolatethe intrinsic kinetics of gas hydrate decomposition.

4.9. Applications

The intrinsic rate equations obtained from laboratorydata can be combined with the equations for heat, massand momentum transfer to obtain global rate equationsthat are useful for design and simulation. For example, theintrinsic kinetic equation can be combined with the energybalance to describe the decomposition of a synthetic coreof gas hydrate (Jamaluddin et al., 1989). Other applica-tions include, but are not limited to, modelling the de-composition of a pipeline plug and prediction of theproduction from hydrate reservoirs.

5. Conclusion

An experimental procedure for the determination of theintrinsic kinetics of gas hydrate decomposition is present-ed and a new model for the determination of the intrinsickinetics of gas hydrate decomposition is developed. Thenew experimental technique utilises an on-line particle sizeanalyser. The mathematical model is based on the work ofKim et al. (1987) and crystallisation theory. The intrinsicrate of ethane hydrate decomposition is calculated fromexperimental data. It is found that the rate constant ofethane hydrate decomposition increases with temperatureand that it follows an Arrhenius relationship.

Notation

Ap

surface area of a particle, m2

DAB

di!usivity of species A in B, m2/sfeq

equilibrium fugacity, Pa

M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883 4881

f Vg

fugacity of the hydrate former in the gasphase, Pa

g acceleration due to gravity, m/s2G linear growth rate, m/sk mass transfer coe$cient, m/skm

mass transfer coe$cient mol/m2 Pa sK

ddecomposition rate constant, mol/m2 Pa s

Kod

intrinsic decomposition rate constant,mol/m2 Pa s

¸ characteristic length, mm(t) number of moles of hydrate former in the gas

phase at time t, molM molecular mass, kg/moln(t) Number of moles remaining in the hydrate

phase during decomposition, molno

Number of moles in the hydrate phase at thestart of decomposition, mol

P pressure, Parc

critical radius of a hydrate nuclei, mR universal gas constant, 8.314 J/mol KR

y(t) global rate of reactions, mol/m3 s

Re reynolds numberSc

Schmidt numberSh Sherwood numbert time, s¹ temperature Ku velocity, m/sut

terminal velocity, m/s< volume of reacting mass, m3

<p

volume of a particle, m3

z compressibility

Greek Letters

*E Activation energy, J/mol*o Density di!erence between the solid and

liquid, kg/m3

/v

Volume shape factor/s

Surface area shape factoru Particle density function, m~4

g Viscosity, Pa skm

mth moment of the particle size distribution,m//m3

l Kinematic viscosity, m2/so Density, kg/m3

os

Density of the solid, kg/m3

t Sphericity

Acknowledgements

Funding for this work was provided by ShellE & P Houston and by the Natural Sciences and ResearchCouncil of Canada (NSERC).

References

Bishnoi, P. R., Gupta, A. K., Englezos, P., & Kalogerakis, N. (1989).Multiphase equilibrium #ash calculations for systems containing gashydrates. Fluid Phase Equilibria, 53, 97}107.

Carson, D. B., & Katz, D. M. (1942). Gas hydrates. ¹rans. Am. Inst. Min.Metall. Pet. Eng. 146, 150}162.

Chun, M. K., & Lee, H. (1996). Kinetics of formation of carbon dioxideclathrate hydrates. Korean Journal of Chemical Engineering, 13(6),620}626.

Clarke, M. A., & Bishnoi, P. R. (1999). Determination of the intrinsickinetics of gas hydrate decomposition kinetics using particle sizeanalysis. Presented at the 3rd international conference on gas hydrates,Salt Lake City, Utah, July 18}22.

Clarke, M. A., Pooladi-Darvish, M., & Bishnoi, P. R. (1999). A method topredict equilibrium conditions of gas hydrate formation inporous media. Industrial Engineering Chemistry Research, 38,2485}2490.

Claussen, W. F. (1951). A second water structure for inert gas hydrates.Journal of Chemical Physics, 19, 1425}1432.

Dholabhai, P. D., Englezos, P., Kalogerakis, N., & Bishnoi, P. R. (1991).Equilibrium conditions for methane hydrate formation in aqueousmixed electrolyte solutions. Canadian Journal of Chemical Engineer-ing, 69, 800}805.

Dholabhai, P. D., Kalogerakis, N., & Bishnoi, P. R. (1993a). Experi-mental study on propane hydrate equilibrium conditions in aqueouselectrolyte solutions. Fluid Phase Equilibria, 83, 455}462.

Dholabhai, P. D., Kalogerakis, N., & Bishnoi, P. R. (1993b). Equilibriumconditions for carbon dioxide hydrate formation in aqueous electrolytesystems. Journal of Chemical Engineering Data, 38, 650}654.

Dholabhai, P. D., & Bishnoi, P. R. (1994). Hydrate equilibrium condi-tions in aqueous electrolyte solutions: Mixtures of methane andcarbon dioxide. Journal of Chemical and Engineering Data, 39,191}194.

Dholabhai, P. D., Parent, J. S., & Bishnoi, P. R. (1997). Equilibriumconditions of hydrate formation from binary mixtures of methaneand carbon dioxide in the presence of electrolytes. methanol andethylene glycol. Fluid Phase Equilibria, 141, 235}246.

Englezos, P., & Bishnoi, P. R. (1991). Experimental study on theequilibrium ethane hydrate formation conditions in aqueous elec-trolyte solutions. Industrial and Engineering Chemistry Research, 30,1655}1659.

Englezos, P., & Bishnoi, P. R. (1988). Prediction of gas hydrate forma-tion conditions in aqueous electrolyte solutions. A.I.Ch.E. Journal,34, 1718}1721.

Englezos, P., Dholabhai, P., Kalogerakis, N., & Bishnoi, P. R. (1987).Kinetics of formation of methane and ethane gas hydrates. ChemicalEngineering Science, 42, 2647}2658.

Handa, Y. P., & Stupin, D. (1992). Thermodynamic properties anddissociation characteristics of methane and propane hydrates in70-As -radius silica gel pores. Journal of Physical Chemistry, 96,8599}8603.

Holder, G. D., Corbin, G., & Papadopoulos, K. D. (1980). Thermodyn-amic and molecular properties of gas hydrates containing methane,argon and krypton. Industrial and Engineering Chemistry, Funda-mentals, 19, 282}286.

Holder, G. D., & John, V. T. (1983). Thermodynamics of multi-component hydrate forming mixtures. Fluid Phase Equilibria, 14,353}361.

Jamalludin, A. K. M., Kalogerakis, N., & Bishnoi, P. R. (1989). Model-ling of decomposition of a synthetic core of methane gas hydrate bycoupling intrinsic kinetics with heat transfer rates. Can. J. Chem.Eng., 67, 948}955.

Jandel Scienti"c. Table Curve, 1994.Je!ery, G. A., & McMullan, R. K. (1967). The clathrate hydrates.

Progress in Inorganic Chemistry, 8, 45}51.

4882 M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883

Kalogerakis, N., Jamaluddin, A. K. M., & Dholabhai, P. D. (1993).E!ect of surfactants on hydrate formation kinetics. In Proceedingsof the 1993 SPE international symposium on oilxeld chemistry, March2}5, 1989, New Orleans, LA, USA, (p. 375). Richardson, TX: SPE.

Khairkhah, D., Pooladi-Darvish, M., Bishnoi, P. R., & Collet, T. S.(1999). In Production potential of the Malik xeld Scientixc results fromJAPEX/JNOC/GSC Malik 2L-38 Gas Hydrate Research Well, McKen-zie Delta, Northwest Territories, Canada (p. 377). Canada: Cana-dian Geological Survey.

Kim, H. C., Bishnoi, P. R., Heidemann, R. A., & Rizvi, S. S. H. (1987).Kinetics of methane hydrate decomposition. Chemical EngineeringScience, 42, 1645}1653.

Konstantin, A., Uchadin, K. A., & Ripmeester, J. A. (1999). A complexclathrate hydrate structure showing bimodal guest hydration.Nature, 397, 420}423.

Mahadev, K. N., & Bishnoi, P. R. (1999). Equilibrium conditions for thehydrogen sul"de hydrate formation in the presence of electrolytesand methanol. Canadian Journal of Chemical Engineering, 77,718}722.

Malegoankar, M. B., Dholabhai, P. D., & Bishnoi, P. R. (1997). Kineticsof carbon dioxide and methane hydrate formation. Canadian Jour-nal of Chemical Engineering, 75, 1090}1096.

Masuda, Y., Fujinaga, Y., Naganawa, S., Fujita, K., & Hayashi, Y.(1999). Modelling and experimental studies on dissociation of meth-ane gas hydrates in Berea sandstone cores. Presented at the 3rdInternational conference on gas hydrates. Salt Lake City, Utah. July18}22.

Mehta, A. P., & Sloan, E. D. (1993). Structure H hydrate phase equilib-ria of methane#liquid hydrocarbon mixtures. Journal of ChemicalEngineering Data, 38, 580}585.

Mullin, J. (1997). Crystallization (3rd ed.). London: Butterworth-Heinemann.

Ng, H. J., & Robinson, D. B. (1976). The measurement and prediction ofhydrate formation in liquid hydrocarbon}Water System. Industrialand Engineering Chemistry Research, 15, 293}298.

Nielsen, B., Svrcek, W., & Mehrotra, A. K. (1994). E!ect of temperatureand pressure on asphaltene particle size distributions in crude oilsdiluted with n-pentane. Industrial and Engineering Chemistry Re-search, 33, 1324}1328.

Olsen, M. B., Majumdar, A., & Bishnoi, P. R. (1999). Experimentalstudies on hydrate equilibria-carbon dioxide and its systems. Inter-national Journal for the Society of Materials Engineering and Re-sources, 7, 23}27.

Parrish, W. R., & Prausnitz, J. M. (1972). Dissociation pressures of gashydrates formed by gas mixtures. Industrial and Engineering Chem-istry, Research, 11, 26}35.

Ripmeester, J. A., Ratcli!e, C. I., & Tse, J. S. (1998). The nuclearmagnetic resonance of 129Xe trapped in clathrates and some othersolids. Journal of the Chemical Society, Farraday Transactions, 84,3731}3738.

Sloan, E. D. (1997). Clathrate hydrates of natural gases (2nd ed.). NewYork: Marcel Dekker.

Trebble, M. A., & Bishnoi, P. R. (1987). Development of a new four-parameter equation of state. Fluid Phase Equilibria, 35, 1}18.

Trebble, M. A., & Bishnoi, P. R. (1988). Extension of the trebble}Bishnoiequation of state to mixtures. Fluid Phase Equilibria, 40, 1}21.

Tse, C. W., & Bishnoi, P. R. (1993). Prediction of carbon dioxide gashydrate formation conditions in aqueous electrolyte solutions.Canadian Journal of Chemical Engineering, 72, 119}124.

Ullerich, J. W., Selim, M. S., & Sloan, E. D. (1987). Theory and measure-ment of hydrate dissociation. A.I.Ch.E. Journal, 33, 747}752.

Van der Waals, J. M., & Platteeuw. J. C. (1959). Clathrate solutions.Adv. Chem. Phys., 2, 1}21.

von Stackelberg, M., & MuK ller, H. R. (1954). Feste Gas Hydrate II.Zeitschrift fuer Elektrochem, 58, 25}31.

Vysniauskus, A., & Bishnoi, P. R. (1983). A kinetic study ofmethane hydrate formation. Chemical Engineering Science, 38,1061}1072.

Vysniauskus, A. & Bishnoi, P. R. (1985). Kinetics of ethane hydrateformation. Chem. Eng. Sci., 40, 299}310.

M. Clarke, P. R. Bishnoi / Chemical Engineering Science 55 (2000) 4869}4883 4883