Detailed Design Review - EDGEedge.rit.edu/edge/P08025/public/Detailed Design Review.pdfProject Carna...

Transcript of Detailed Design Review - EDGEedge.rit.edu/edge/P08025/public/Detailed Design Review.pdfProject Carna...

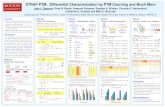

Project Carna Detailed Design Review

Team Carna [P08025]

View Project Summary

WEBSITE

REV-2

Customer Needs List

Specifications

CARNA System Diagram

DAQ

Data

Storage

Power

PlantHealth

Monitor

LUI

Tank

Control

Sensors/

Actuators

Mock Circulation

Loop

Control

Sensors/

Actuators

Data Storage

Charger & Batteries& DC-DC converters

10 Pump Test Modules

Data

StorageLUI

Data Management Centers

Tank System and Modular Loop – Rev1

Modular Loop Sensor and Control Brick

Tank System and Modular Loop – Rev2

Tank System and Modular Loop – Rev3

Pressure Needed at inlet of loop to obtain max pressure at inlet of LVAD

24

30

36

42

48

54

60

66

72

78

84

90

96

0 1 2 3 4 5 6 7 8 9 10

Flow rate (L/min)

Pre

ssu

re L

oss +

Pre

ssu

re a

t L

VA

D in

let

(in

H2O

)

Tw o Tank -- 3/4" tubing w ith 1" globe valve Inline Pump -- 1/2" tubing w ith 1" globe valve

Comparison of Two Tank vs. Inline Pump Design

�What is needed?

� Flow control at the inlet and outlet of LVAD

�What are the specifications?

� Inlet: -20 to 50 mmhg (-0.39 to 0.97 psi)

� Outlet: 0 to 150 mmhg (0 to 2.9 psi)

�What is the proposed solution?

� Integrate a globe valve before and after the

LVAD, to be controlled by a modulating

electric actuator

Flow/Pressure Control

Globe Valve Overview

� Best Suited Control: Linear and Equal percentage

� Recommended Uses:1. Throttling service/flow regulation2. Frequent operation

� Applications: Liquids, vapors, gases, corrosive substances, slurries

� Advantages: Disadvantages:1. Efficient throttling 1. High pressure drop2. Accurate flow control 2. More expensive 3. Available in multiple than other valves

portshttp://www.cheresources.com/valvezz.shtml

Globe Valve Selection

� Johnson Controls

VG7243NT 1” globe

valve

� Bronze with Stainless

Steel trim

�Compatible with saline environment

� Factory coupled with

modulating electric

actuator

Electric Actuator

� Johnson Controls VA-7152 electric valve actuator

� Proportional control

�An electronic controller provides the proportional input signal

�This signal is compared to the actual valve position via the internal feedback potentiometer

� Failsafe open

Heat Transfer of Tank

Tank Template [Excel]

MCUPhone on

A Chip

Health N

etw

ork

Function:

Communicate with

main subsystems. Get

health status. Periodically

ship data to the Server

for long-term storage. The

ability to voice-call/sms and

email through cellular

network.

Cellular Network

Health Monitor

FUTURE WORK

Fault Tolerant Switching

Create requested output voltages

main power

auxiliary power

A.T.S.(AutomaticTransition Switch)

Quality Surge Suppression

Energy Storage 1

Energy Storage 2Create requested output voltages

Manuel by-pass

Manuel by-pass

V1A

V1B

V10A

V10B

Off the shelf UPS

VAC,1

VAC,2

Power Plant (Single Fault Tolerant Switch) – Rev1

FUTURE WORK

AutoTransfer

Switch

SurgeSuppression

DCPower

Supply

BatteryBackup

Module

UPS

UPS

Batteries

RedundancyModule

DCPower

Supply

BatteryBackup

Module

Batteries

RedundancyModule

DC

AC1

AC2

Main

Aux

Power Plant – Off the Shelf Industrial Supply Concept – Rev2

FUTURE WORK

Data Management Center – Rev 1

DAQ 1

DAQ 2

Contro

l Netw

ork

RS

232

LUI

WEB Server

SFTP

SMTP

SSHRedundant Storage Array

Internal Network

Switch

10/100/1000 Base-T

DMC

Health Network RS232

Who is Master DAQ ?

Organize Data

Send M

aste

r Data

Only

??

Firewall

World-Access

Loop and Tank

Parameters

Accessible

From LUI

RAID-1

Storage

Parallel

Ethernet

Switch

Data Management Center – Rev2

MySql Database

Fire

wall

Serv

ices

PTM #2

PT

M

Com

m.

RAID-1

Storage

MySql Database

Fire

wall

Serv

ices

PT

M

Com

m.

Node 1

Node 2

Heartbeat

Heartbeat

PTM #4

PTM #1

PTM #7

PTM #3

PTM #8

PTM #10

PTM #5

PTM #6

PTM #9

Internet

LUI

LUI

Touch

Screen

Display

Pump Test Module Version 1.0 (Redundant DAQ and Multiplexing)

� Two computers with each having a DAQ card recording data (signals

from CARNA).

� Information is then passed into the DMC (Data Management Center)

through Ethernet.

100BaseT Internal Network

DAQ 1(PC)

DAQ 2(PC)

Breakout Box Breakout Box

Multiplexer Multiplexer

Data ManagementCenter

Health Monitor

Health

Network

System Signals Line from [Wet] CARNA and Pumps

Control N

etwork

Health

Network

LUI

CARNA [Dry]: Parallel redundant PCs

Pump Test Module - Conflicts with v 1.0

� Very expensive in purchasing two DAQ cards for dual PCs

� Repetitive tasks are done in recording data, the two PCs and the DMC

all recording data.

� Electrical design will be more complicated and more time intensive.

� The added complexity of having all the multiplexing and two PCs did not

seem robust or cost effective.

Pump Test Module Revision 2.0 (One Micro-controller)

� Pump Test Module (PTM) has one micro-controller (with an Ethernet

daughterboard connected to it - for network access) attached to a pump

controller

� Handles the signals coming from CARNA and distributes the data

between the DAQ Controller and Main Controller

� Pseudo Double-fault tolerance achieved by a daisy chain configuration.

Each PTM watches two pumps.

Pump 1 Loop 1

Pump 2 Loop 2

Pump 3 Loop 3

Pump 4 Loop 4

Pump 5 Loop 5

Pump 6 Loop 6

Pump 7 Loop 7

Pump 8 Loop 8

Pump 9 Loop 9

Pump 10 Loop 10

PTM 1

PTM 2

PTM 3

PTM 4

PTM 5

PTM 6

PTM 7

PTM 8

PTM 9

PTM 10

Single Fault Tolerance

If one PTM unit fails, ALL pump

signals are still measured.

If 2 non-adjacent PTM units fail,

ALL pump signals are still

measured.

Pseudo Double Fault Tolerance

Pump Test Module - Conflicts with v 2.0

� Amount of data moving from between the DAQ Controller and Main

Controller (294 Kb/sec) is large, using a 8-bit bus

� PIC 24 micro-controllers can execute around 40 million instructions per

second.

� Large amount of data will cause bottleneck traffic with only one micro-

controller, this will cause the micro-controller to spend most of its time

moving the data.*

� 136 instructions executed within a micro-controller is too much, since it

also have to handle all or their other individual tasks.

4000000 instructions per second

294000 bytes per second=136 instructions per second

*

Pump Test Module Revision 3.0 (Using two micro-controllers)

� By increasing the data bus to 16-bits, the number of transfers can be cut

in 2.

� Instead of using a parallel interface, SPI (serial peripheral interface) bus

can be used.

� Using a daisy chain SPI configuration with the other PTMs will allow the

first slave output being connected to the second slave input, etc.

Pump Test Module Revision 3.0

� Two micro-controllers will handle 42 analog inputs.

� The PTM micro-controllers (2) must:

� Sample 28 inputs at 5kHz

� Sample 14 inputs at 500Hz

� Organize the data into blocks

� Transfer the data to Flash (temporary storage)

� Control the Ethernet controller

� Control the flow loop actuators

� One micro-controller would do the analog-to-digital conversion and store

the data in its RAM in a large FIFO buffer.

� The other micro-controller would handle all other tasks, and read the

data from the first micro-controller.

Pump Test Module Revision 3.0 - Overall Layout

Pump Test Module - Overall Sampled Signals

Pump Test Module - Conflicts with v 3.0

� SPI modules do have several disadvantages:

� No in-band addressing; out-of-band chip select signals are

required on shared buses

� No hardware flow control

� No slave acknowledgement, the master could be talking to

nothing and not know it.

� Once the data is in the Main Controller, it has to be buffered, sent to

the flash chip (temporary storage), and sent out through the Ethernet.

� Multiple instruction cycles are needed to perform the data transfers.

Pump Test Module Revision 4.0 (Redundant PTM modules)

� Use of NI PCI-6225 card, replaces the two micro-controllers

� In addition, PTM needs a PC in order to:

� Receive data from the DAQ

� Receive control messages from the DMC

� Store the data locally

� Send the data to the DMC through Ethernet

� Communicate with the Health Monitor

Specifications of NI PCI 6225

� 80 Analog Inputs; 16 Bit resolution

� 2 Analog output; 16 Bit resolution

� Analog Output Range; +/- 10V

� 24 Digital I/O Lines

� 8 Correlated (clocked) I/O's, 1 Mhz

Pump Test Module Revision 4.0

� Role of the PCI-6225 DAQ

� Sample 26 critical signals

� Sample 16 critical signals, 14 at 5Khz, and 2 at 500Hz

� Buffer Data and store locally on Shuttle PC

� Send buffered data to the Data Management Center through Ethernet

Analog

In

Eth

ern

et

Data to DMC

Pump Test Module Rev 4.0

1

32

…..

NI - USB6225

USB> 1 GHz

uProcessor

RS232

1 GB RAM

> 80 GB Harddrive

US

B 2

.0

Small PC

RS232

Digital

I/O

MUX select

Health Monitor

Flow Loop Control Flow Loop

Filters and Power Amplifiers

Messages to & from DMC

4

Analog

Out

16

:1 M

UX

16

:1 M

UX

…..

1+1-

2+2-

42+42-

Instrumentation Amps

Hub

DMC Node 1

DMC Node 2

Pump 1 Loop 1

Pump 2 Loop 2

Handshake

Handshake

Re-circulating RAM Buffer

Pump / Loop Analysis

In-Control

Thin Data

Out-of-Control

MySql – RAID-1

Handshake

Re-circulating RAM Buffer

Pump / Loop Analysis

In-Control

Thin Data

Out-of-Control

MySql – RAID-1

All Data

All Data

NI DAQmx

NI DAQmx

RAID

Buff

er

Label

LabelValve

Control

Schedule

PTM

TCP/IP

HANDSHAKE HANDSHAKE

HANDSHAKE

Ready?

Ready?

Data Compression

De-Compression

Send

If not ready,

Record Who and When

If r

ead

y Pass to the buffer

ReceiveF

lags to

Health

Monito

r

Split Handshake

Ready?

De-Compression

Pass to the buffer

Receive

Fla

gs to

Health

Monito

r

SPLIT HANDSHAKE

Ready?

Node Specific

If not ready, wait…

Buffer Data from RAID

If ready, then catch up

and return to shared

Handshaking.

PTM

PTM

DMC

DMC

LVADR2-Simulator

(Microcontroller or

PC NI/Labview) DA

C A

rra

y

HE 1

HE 2

HE 3

HE 4

HE 5

HE 6

HE 7

HE 8

CARNA

Differenced HE 1

Differenced HE 2

Differenced HE 3

Differenced HE 4

5VGRND

AMB 1

AMB 2

Motor Speed

AMB 1

AMB 2

Motor Speed

Digital Signals Analog Voltages

Pump Simulator

LVAD simulator

� Simulates LVAD Signals (Provided by LVAD-R2 Controller)

�8 Hall Effect sensors, to characterize the displacements of the

Impellers overtime

�AMB currents: active magnetic bearing are to correct the

position of the impeller, LVAD outputs 2 signals

�Motor current, voltage related to the current consumed in a 3

phase, brushless DC motor

�Power consumption

Overview

LVAD simulator

� Waveforms generated by National Instruments card

NI6052-E or NI6221, those cards can both produce 2 outputs with an

aggregate sampling rate of above 360kS/sec.

� The LVAD simulator will simulate normal functioning of the LVAD-R2 and

Controller and to simulate failures

� The LVAD simulator will also help test and validate the functioning of the

DMC and PTM.

� Testing the sampling and recording capacities of our system

� Testing the abilities to recognize and to treat failures so that the DMC

can thin, or not, the data

Overview

NI DAQ card(4 analog out)

Voltage divider

Resistors about 10k8 HE sensor signals

Input Current

AMB current

Motor current

•Simulate: 8 HE sensors generating 8 signals in the real LVAD, we simulate only one , divide its

voltage to distinguish between the 8 signals

•AMB currents simulated by one signal

simulate

•Motor current, voltage related to the current consumed in a 3 phase, brushless DC motor, simu

•Power consumption (Input Current at a fixed voltage?

LVAD simulator

Play a set of recorded data

Simulate data

Provided by

Customer

choose

Set1 Set2 Set3…

choose

Normal functionni

ng

Cases of failure..

User interface

menus

LVAD simulator

Failures to simulate:

� HE sensor signal going out of range. Statistical calculations based on the available sets of data can highlight an amplitude range beyond which LVAD is malfunctioning

�HE frequency too high. The typical frequency should not exceed 500Hz, for the HE sensor signal

�Inconsistent motor current : The motor current should not be stuck to a value, but instead of

oscillating periodically.

Those cases of failures will be discussed later while specifying what kind of failures DMC will be

sensitive to. The DMC will decide to thin to data, ie to store less data when there is no obvious

problem is the pump. Based on what criteria it uses, other cases of failure will be generated by the LVAD simulator.

Some more complex cases might require more outputs dedicated to one type of signal. For

example, the slamming of the impeller against the shaft, extreme case, would require more than 1

HE output to be simulated. Our software will allow the assignment of several outputs of the NI DAQ card to one type of signal (HE, AMB current, motor current…) to simulate complex cases.

LVAD simulator