Design of Experiments a short Introduction -...

Transcript of Design of Experiments a short Introduction -...

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

6M Meeting Turin

Seminar

Design of Experiments – a short Introduction

STZ Prozesskontrolle und Datenanalyse

Prof. Dipl. Phys. Waltraud Kessler

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Contents

Basic Statistics for Design of Experiments (DoE)

Sample Size, Power of a Design Analysis of Variance (ANOVA)

Screening Designs

Full Factorial Designs Fractional Factorial Designs

Designs for Response Surface Analysis or Optimization

Central Composite Designs (CCD) Optimization for Several Responses – Find the "Sweet Spot"

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Design of Experiments needs Statistics

We measure parts (very small) of a population (we run only some

experiments of the many possible ones)

Uncertainty: We measure the sample and describe the population

Questions that arise:

sample size - how many experiments do we really need?

extreme values - is this an outliers? Or is it an effect?

calculate mean, median - when are the different?

calculate standard deviation, interquartile range – what range is acceptable?

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Design of Experiments needs Statistics

By experiments you can measure the mean and standard

deviation of a sample.

This is used to estimate the true but unknown mean

and standard deviation of the underlying population.

„All models are wrong, some are helpful“ cit. G. Box

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Calculating Effects - Error of mean

1

1

2

2

n

xx

s

n

i

i 2ss Standard deviation: Variance:

The SEM quantifies the precision of the mean.

It is a measure of how accurately you estimate the true mean of the population.

A bigger n gives a more accurate estimation of the true population mean.

Standard error of the mean:

n

sSEM

degree of freedom

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Power of a Design is important

Δµ=µ-µ0 = 1

α=5%, n = 4

=20%

Power = 80%

φ φ

Question: What sample size n is necessary to measure

a mean 0 with a given accuracy of

Δµ=µ-µ0 = 1

α=5%, n = 9

=5%

Power = 95%

SEM = n

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Analysis of Variance (ANOVA)

Comparison of several means – find significant effects

Calculate the error and calculate the effects for experiments

One-way ANOVA

Changing only one factor

Two-way ANOVA

Changing two factors

Multi-way ANOVA

Changing several factors

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

DoE - Design of Experiments

General Factorial Designs

Find significant main effects and interactions

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Changing two factors

• Bioprocess for bioethanol conversion from cellulose

• Factor A: Time of treatment

• Factor B: Treatment

Response:

Conversion cellulose %

Significant effects:

Main effects:Treatment and Time

Non linear effect: Time

Interaction: Treatment*Time

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

DoE - Design of Experiments

Two level full factorial designs

Find significant main effects and interactions

Do the minimum number of experiments

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Two level full factorial designs

Task: Determine yield of a product depending on 3 factors: a) time b) temperature CPP (Critical Process Parameters) c) concentration Classical approach: One variable at a time (OVAT) - keep temperature and concentration constant, vary time - keep time and concentration constant, vary temperature - keep time and temperature constant, vary concentration Disadvantage: - Keep factors constant on which level? - You need many experiments. - You will not find interactions.

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Building a Full Factorial Design

Each factor is varied on 2 levels: low and high (-1 and +1)

Factors are varied independently of each other.

A:Time

C: Concentration

B: Temperature

B- low A+ high

B+ high

A- low

C- low

C+ high

2N experiments

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Few Experiments – many Effects

To investigate the influence of N factors

2N experiments have to be run

For 3 factors there are 7 possible effects:

Main effects: A, B, C

Two way interactions: AB, AC, BC

Three way interaction: ABC

• With only 8 experiments we can calculate all 7 effects.

• Additional experiments needed to determine the error.

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Do the Experiments in Random Order

The 2N-factorial design is the most simple

complete experimental design,

to examine the influence of N factors

and their interactions on a response.

Important:

Do whenever possible the runs in random order!

This avoids systematic errors to be regarded as effects.

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Graphical representation of regression equation

Main effects

AC interaction (Time*Concentration)

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Graphical Representation of Interactions

Lines are parallel

no interaction

Lines depart from parallelity

positive interaction

Lines depart from parallelity

negative interaction

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

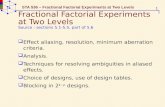

DoE - Design of Experiments

Screening Designs: Two-level Factorial Designs

Full Factorial Designs

Fractional Factorial Designs

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Fractional Factorial Designs with two levels

A

C

B

(- - -) (+ - -)

(+ + +)

Problem: • The number of factors to investigate is high • E.g. 5 factors requires 32 experiments • Too many experiments are necessary

Solution: • Only part of the experiments are run • E.g. for 5 factors only 16 experiments

Disadvantage: • It is not possible to calculate all interactions

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Fractional Factorials - Resolution

The detailed overview can be found in: Design Expert – Software for Experimental Design – www.statease.com

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Design Resolution The risk of misinterpretation because of the influence of confounding

on the factors depends on the degree of confounding. We speak of different resolution for the designs.

.

Work with resolution V (or higher) designs, if possible!

Main effects

confounded with

2-factor interactions confounded with

Resolution III - Designs 2-factor interaction main effects

Resolution IV - Designs 3-factor interaction 2-factor interaction

Resolution V - Designs 4-factor interaction 3-factor interaction

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Example for 26-2 Fractional Design

Tablets are coated with an insoluble film in a fluid bed dryer The influence of 6 process parameters on drug release is investigated

Factor Name Units Low Actual High Actual A Inlet air quantity m3/h 110 130 B Atomisation pressure bar 0.60 1.30 C Amount film polymer mg/cm2 1.00 2.00 D Inlet air Temp. °C 45 60 E Spray rate g/Min 6 13 F Drying time min 3 6

Response variable: Drug release after 2 h

Full design: 64 runs Fractional design 16 runs + 3 center points (Resolution IV)

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Effects for 26-2 Fractional Design

All possible effects are: 6 main effects 15 two-way interactions. As resolution is IV, many 2-way interactions are confounded. Significant effects: C BC could also be AE or DF CF could also be BD All others are not significant, Because of hierarchy add B and F!

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Interpreting the Results

Drug release 2 h

The factors A, D, E and their interactions are not in the model.

Factor Estimate

Intercept 40.52

B-Atomisation pressure 0.054

C-Amount film polymer -3.21

F-Drying time 0.044

BC -1.02

CF -0.73

Actual Factor Settings

A: Inlet air quantity = 110

D: Inlet air temperature = 45

E: Spray rate = 6

F: Drying time = 3

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Response Surface Designs for

Optimization

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Next Step: Regression

Models with Main Effects and Interactions

A

B

y

- Linear dependence on factor A and B

y = b0 + b1A + b2B

0

B

A

y

- Add the interaction AB

y = b0 + b1A + b2B + b12AB

0

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Response Surface Modeling (RSM) Designs Ex

pec

ted

Res

po

nse

y

It is possible to fit nonlinear (quadratic) response surfaces with these models.

A minimum of 3 design points (levels) per factor is required.

Factor A = Factor B = Time (min)

Add squared terms

y = b0 + b1A + b2B

+ b12AB

+ b11A2 + b22B

2

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Response Surface Designs for Optimization

3 Level Factorial Designs

Central Composite Designs

Several responses: Finding "Sweet spots"

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

3 Level Full Factorial Designs

Factor levels are given in transformed coordinate system (-1, 0, +1)

The center point has the coordinate (0, 0, .., 0)

The distances -1 to 0 and 0 to +1 are the same.

Easy to set up, but for more than 2 factors no more efficient.

The number of experiments increases very fast: 2 Factors 9 experiments 3 Factors 27 experiments 4 Factors 81 experiments

Factor A

Fact

or

B

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Central Composite Designs – for 2 Factors

We add experiments to the existing design of the screening phase.

Cube points from + starpoints + centre points = Central Composite design

factorial design (α-Points, axial points) + centre points

+ centre points

= Faktor A

Faktor B

Faktor B

Faktor A

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Central Composite Designs for 3 Factors

For the ideal CC design all points are on a sphere around the center points.

Number of factors Number of experiments

2 9

3 15

4 25

5 43

Minimum number of experiments

Add at least 3 more center points 5 levels on each factor

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Face Centered CC Design for 3 Factors

• The starpoints are on the cube.

• No extreme settings

• Easier to handle

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Three Responses Find Design Space

Yield Model: A + B + AB+ A2 + B2

Viscosity Model: A + B + A2 +B2

Molecular weight Model: A + B + AB

Targets for responses: Yield > 78 % Viscosity between 62 and 68 mPas Molecular weight 3400 (g/mol)

A: Time A: Time A: Time

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Working Areas for Individual Responses

Contour plots of possible working areas

Which settings are valid for all responses?

Yield Viscosity Molecular Weight

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Optimizing Several Responses

Settings in yellow area fullfill all

requirements

→ Consider uncertainties

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Design Space und Control Space

The yellow area fulfills all demands for

all three responses This is the

Design Space

The light yellow area shows the working area

where all responses fulfill the demands with

95% probability This is the

Control Space

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Knowledge Space, Design Space, Control Space

1. The design defines the Knowledge Space

2. The responses define the Design Space

3. The uncertainties (confidence intervals) define the Control Space.

The control space will be used for production. Within control space

are the factor settings for normal operation.

Knowledge Space (Factor Space)

Control Space Normal Operation

Design Space

M06 Meeting Turin, Italy 14-15 June, 2017

Design of Experiments – a short introduction

Screening Designs vs. Response Surface Methods

Factorial Designs (Full or Fractional Designs)

Designs for Response Surface Methods

During screening emphasis is on identifying factor effects and their possible interactions. Questions: What are the important design factors? Are there interactions involved?

The goal is optimization of one or several responses. Emphasis is on the fitted surface. Questions: How well does the surface represent the true behavior? Which working area complies with all specified response values?

![Photochemical-mediated solid-state [2+2]-cycloaddition ...Photochemistry experiments S4 3.1 Single crystal XRD experiments S4 3.2 Two-photon irradiation experiments S8 3.3 Powder XRD](https://static.fdocuments.net/doc/165x107/5ed92bd66714ca7f47694756/photochemical-mediated-solid-state-22-cycloaddition-photochemistry-experiments.jpg)