DESIGN APPLICATIONS Platinum Temperature … APPLICATIONS T5...

Transcript of DESIGN APPLICATIONS Platinum Temperature … APPLICATIONS T5...

![Page 1: DESIGN APPLICATIONS Platinum Temperature … APPLICATIONS T5 rendachaerialsasseblyasuppleenodesignnesuu [] C aterials & assebly Platinum Temperature Sensor Technology This article](https://reader034.fdocuments.net/reader034/viewer/2022051800/5abfee2c7f8b9a5a4e8b5f6c/html5/thumbnails/1.jpg)

D E S I G N A P P L I C A T I O N S

T5 Trend WaTch: MaTerials & asseMbly / a suppleMenT To design neWs AuGuST 2013 [www.designnews.com]

C

Materials & asseMbly

Platinum Temperature Sensor TechnologyThis article explores the inherent properties of platinum temperature sensors, the types of platinum RTD elements available, and typical applications.By BoB Gliniecki, HeraeuS SenSor TecHnoloGy uSa

Cars, trucks, appliances, climate control systems, industrial processes, and life science instruments all have in common the need for temperature measure-ment. Platinum resistance temperature detector (RTD) elements are specifically designed for the precise temperature measurements required by these, and dozens of other applications. This article explores the inherent properties of platinum temperature sen-sors, the types of platinum RTD elements available, and typical applications.

Platinum as a Temperature SensorA platinum RTD element is a thermal resistor — a resistor with a value that changes by a predictable amount in response to temperature changes. Plati-num RTD elements have a positive temperature coefficient (PTC), meaning the resistance increases with increasing temperature. A virtually linear change in resistance, coupled with intrinsic chemical and temperature resistance, makes platinum an ideal base material for temperature sensing. Used in tem-

Thin-flm platinum RTD elements with lead wires.

ES293946_DN1308_T5.pgs 08.01.2013 22:25 UBM blackyellowmagentacyan

![Page 2: DESIGN APPLICATIONS Platinum Temperature … APPLICATIONS T5 rendachaerialsasseblyasuppleenodesignnesuu [] C aterials & assebly Platinum Temperature Sensor Technology This article](https://reader034.fdocuments.net/reader034/viewer/2022051800/5abfee2c7f8b9a5a4e8b5f6c/html5/thumbnails/2.jpg)

MAKING THE CASEFor Solon, Ohio machine shop SRPM,

Inc, Sapa Aluminology™ means:

10% longer tool life

Improved consistency

Better chip control

Enhanced machining performance

More aggressive speeds

10% improved recovery

Better surface fi nish

Sapa ACC-U-LINE™ rod and bar product, available

from Sapa Premier Distributor Partners, is specially

engineered for high quality machining. Precision

machining company SRPM Inc. learned fi rsthand

the difference between Sapa ACC-U-BAR and

competitor product.

An ISO9001 certifi ed facility, SRPM produces

parts for everything from medical equipment to

aerospace components. Accuracy and consistency

are of the utmost importance, and they agree that

Sapa ACC-U-LINE rod and bar

products offer better performance in

their high speed multi-axis machining

centers. With Sapa product, SRPM can

achieve ultimate dimensional precision

and better chip control. This has resulted

in 10% longer tool life and a more profi table outcome for the

company. ACC-U-BAR allows SRPM to leverage more aggressive

cutting speeds and feeds.

ACC-U-LINE is a product of Sapa Aluminology™, which utilizes

Sapa’s Indirect Extrusion press technology reducing the frictional

heat generated during extrusion, resulting in rod, bar and hex

products that have more consistent grain structure, tighter

dimensions and higher mechanical properties. Our Application

Engineers and Metallurgists have the skill to create aluminum

product extrusions for any industry, and with locations around the

globe Sapa expertise in aluminum extrusion is truly unsurpassed.

It’s What’s Inside That Counts!

ACC-U-LINE Core Competitor’s Core

BETTER BARMAKES A DIFFERENCE

800-233-3165 | www.sapagroup.com/NA

ES294185_DN1308_T6_FP.pgs 08.01.2013 23:25 UBM blackyellowmagentacyan

![Page 3: DESIGN APPLICATIONS Platinum Temperature … APPLICATIONS T5 rendachaerialsasseblyasuppleenodesignnesuu [] C aterials & assebly Platinum Temperature Sensor Technology This article](https://reader034.fdocuments.net/reader034/viewer/2022051800/5abfee2c7f8b9a5a4e8b5f6c/html5/thumbnails/3.jpg)

360° Metal-to-

Metal Contact

Pre-assembled embedded

O-ring seals in asymmetrical

groove – Patent No. 3,175,454

Seals liquids & gases to

20,000psi internal/external

Self-sealing screw, bolt, nut &

rivet versions

Temperature range from -160°F to

+500°F (-106°C to +260°C)

Tested to UL Standard 50,

Types 1-13

Optional threadlocking

Self-sealing washers seal

to 100psi. Metric & inch.

Made in U.S.A.

C®

USUL Recognized

800.498.9034www.apmselfsealingfasteners.com

View Video

WHEN JUST FASTENING ISN’T ENOUGH®

BETTER FASTENER

SEALING

WITHOUT

CHEMISTRY

Seal and fasten in one step with a reusable,self-sealing fastener. No liquid adhesive/sealants…no worries about waste disposal or respiratory safety.

T7 Trend WaTch: MaTerials & asseMbly / a suppleMenT To design neWs AuGuST 2013 [www.designnews.com]

Structural Adhesive Resists High Temperatures

www.masterbond.com

+DFNHQVDFN1-86$ììPDLQŴPDVWHUERQGFRP

Master Bond Supreme 45HTQToughened, quartz filled epoxy

Serviceable from -60ºF to 450ºF

Superior durability and chemical resistance

High compressive strength

Materials & asseMbly

perature sensing since the early 1900s, platinum has a long history of use in precision temperature measurement applications.

The elemental properties of platinum contribute to several characteristics ben-eficial to temperature sensing.

High Precision: Strict controls on platinum RTD element manufacturing processes and raw materials minimize deviations from the ideal resistance vs. temperature response, resulting in high sensor precision.

High Signal Resolution: A relatively high (approximately 3900ppm) change in resistance vs. temperature provides good signal resolution. Choosing an element resistance higher than the stan-dard Pt100 (100Ω), such as Pt1000 (1000Ω), Pt2000 (2000Ω), or Pt10k (10000Ω), further enhances resolution by increasing the ohms/°C response to temperature variation.

Wide Operating Temperature Range: Platinum RTD elements are available for operation within the tem-perature range of -196C to 1000C.

Long-term Stability: The typical

long-term drift of thin-film platinum RTD elements is 0.04 percent maxi-mum after 1,000 hours at 500C.

Interchangeability and Standard-ization: The IEC 60751 specification

SMD elements.

ES295740_DN1308_T7.pgs 08.05.2013 21:46 UBM blackyellowmagentacyan

![Page 4: DESIGN APPLICATIONS Platinum Temperature … APPLICATIONS T5 rendachaerialsasseblyasuppleenodesignnesuu [] C aterials & assebly Platinum Temperature Sensor Technology This article](https://reader034.fdocuments.net/reader034/viewer/2022051800/5abfee2c7f8b9a5a4e8b5f6c/html5/thumbnails/4.jpg)

Meet the world’s most dynamic composites players and develop your business faster

DESlGN & PROCESS EFFlClENCY

AUTOMOTlVE

State of honor

Country of honor

CALlFORNlA

CANADA

` TRADE SHOW & DEMO ZONE

` l.C.S. / CONFERENCES

` BUSlNESS MEETlNGS

` COMPOSITES TOUR

` lNNOVATION AWARDS & SHOWCASE

` TECHNlCAL SALES PRESENTATlONS

` JOB CENTER

The No1 Composites Network in the World

Boston Convention & Exhibition Center

Get your free access badge online at: http://www.jeccomposites.com/badgesjam

[www.designnews.com] AuGuST 2013 Trend WaTch: MaTerials & asseMbly / a suppleMenT To design neWs T8

defines the requirements, tolerance classes, and resistance vs. temperature function for platinum RTD thermom-eters made with a platinum element hav-ing a temperature coefficient of 3.851 x 10-³ °C-¹, commonly expressed as “TC3851,” “TC3850,” or “3850ppm.” The defined tolerance classes allow for interchangeability between two elements of the same resistance value. Other available temperature coefficients include 3750ppm, 3770ppm, and 3916ppm.

Linearity: The resistance vs. tempera-ture relationship for a platinum RTD element can be described by the follow-ing polynomial:

Rt = R₀(1+at+bt2)where R₀ is the resistance at 0C, t is

temperature t, a and b are experimen-tally derived constants, and Rt is the resistance at temperature t.

The value for b is so small that for

most applications a linear relationship between temperature and resistance may be assumed. The linearity simpli-fies signal processing, and minimizes measurement error.

Platinum RTD Sensor Manufacturing ProcessTwo major types of platinum RTD temperature sensors are available: thin-film (including surface-mount device, or SMD) and wirewound sensors. As the respective names imply, thin-film elements are manufactured via thin-film photolithography, while wire-wound sensors are constructed from a precision-wound platinum wire.

Thin-Film Elements

Thin-film platinum RTD elements are manufactured via a process similar to processes used by the semiconduc-tor industry. A thin-film platinum layer is deposited on a specially pre-

pared aluminum oxide substrate. The platinum layer is then structured using photolithography techniques, a protec-tive glass layer is added, the resistance value is calibrated via laser trimming, and, finally, lead wires and a protective glass-ceramic seal is added. By varying the materials and processes, thin-film elements for both cryogenic and high-temperature (>1000C) operation are possible.

SMD RTD Elements

The manufacturing process for SMD RTD elements shares most of the steps of the thin-film manufacturing process. But instead of connection lead wires, the SMD element has soldering pads for electrical contact.

Wirewound Elements

Two major types of wirewound platinum RTD elements are available: ceramic wirewound and glass wire-wound. Glass wirewound elements,

ES293949_DN1308_T8.pgs 08.01.2013 22:25 UBM blackyellowmagentacyan

![Page 5: DESIGN APPLICATIONS Platinum Temperature … APPLICATIONS T5 rendachaerialsasseblyasuppleenodesignnesuu [] C aterials & assebly Platinum Temperature Sensor Technology This article](https://reader034.fdocuments.net/reader034/viewer/2022051800/5abfee2c7f8b9a5a4e8b5f6c/html5/thumbnails/5.jpg)

T9 Trend WaTch: MaTerials & asseMbly / a suppleMenT To design neWs AuGuST 2013 [www.designnews.com]

Materials & asseMbly

which are constructed from a precision platinum coil wound on a glass mandrel and sealed with glass, are a small fraction of the wire-wound elements produced.

Ceramic wirewound ele-ments are constructed using two primary methods:

Mandrel-wound: Man-drel-wound elements are constructed by winding a coil of platinum wire around a ceramic mandrel, and sealing with a ceramic coating.

Bore-hole construction: In the more widely used bore-hole construction, a preci-sion wound platinum wire coil, with connection leads attached, is inserted into pre-cisely dimensioned holes in a ceramic cylinder.

The mandrel-wound construction offers better resistance to vibration vs. bore-hole constructed wirewound ele-ments. The bore-hole design, however, allows for tight accuracy over a very wide temperature range, and minimal hysteresis, compared to mandrel-wound types.

Thin-Film vs. Wirewound—What RTD Element Should Be used?With the development of the wire-wound element in the early 1900s, and the ceramic insulated wirewound element in the 1950s, wirewound ele-ments were the RTD sensor of choice for much of the 20th century. After the thin-film platinum RTD element was developed in the 1970s, gradually, thin-film elements were selected over wirewound elements for a majority of applications. The solid-state construc-tion of the thin-film element provides excellent shock and vibration resistance and miniaturization. Coupled with lower cost (compared to a wirewound element) and good stability, the thin-film element delivers a balance of per-formance and economy. In the recent past, the lower maximum temperature rating of thin-film elements required the use of wirewound elements in some applications that were otherwise suitable for thin-film elements. The development of thin-film elements with maximum temperature ratings of 750C, 850C, and 1,000C, enables the use of thin-film elements in applica-tions formerly reserved for wirewound elements.

For new applications, a wirewound element may be chosen over a thin-film element if superior stability, higher power capability, resistance to self-heating, and high accuracy over a wider temperature range is required. In addi-tion, several older applications were de-veloped and qualified with wirewound elements. The potential cost savings realized by switching to a thin-film element are far outweighed by the cost of requalification with a thin-film element.

Ceramic wirewound platinum RTD elements.

TOWER

Manufacturing Corporation25 Reservoir Ave, Providence, RI 02907

401-467-7550 fax 401-461-2710www.towermfg.com

Design for SAFETY with a TOWER

GFCI• Our GFCI’s provide electrical

shock protection for a wide range of industrial products

• We design Ground Fault Circuit Interrupters so you can easily build them into your production line, and.

• We also offer 15 and 20 amp GFCI cord sets in lengths of 1 ft. to 100 ft.

We customize to meet your specs. Our Asian plant keeps you competitive. Our US headquarters assures quick, dependable service.

For more information [email protected].

ES293945_DN1308_T9.pgs 08.01.2013 22:25 UBM blackyellowmagentacyan

![Page 6: DESIGN APPLICATIONS Platinum Temperature … APPLICATIONS T5 rendachaerialsasseblyasuppleenodesignnesuu [] C aterials & assebly Platinum Temperature Sensor Technology This article](https://reader034.fdocuments.net/reader034/viewer/2022051800/5abfee2c7f8b9a5a4e8b5f6c/html5/thumbnails/6.jpg)

Others say they’re FAST...

Proto Labs’ entire operation is optimized to deliver quick-turn CNC

machined and injection molded parts in as fast as one business day.

We manufacture parts every day for thousands of customers, many of

whom come to us at the last minute with dozens of designs they need

to test ASAP. Since 1999, we’ve produced tens of thousands of molds,

and shipped tens of millions of parts to our customers all over the world.

Sure, it’s our technology that allows us to make your parts faster

than anyone else. We back it up with large-scale global manufacturing

facilities with hundreds of CNC machines and injection molding presses

on three separate continents.

Whether your project calls for a few machined parts or thousands of

molded parts from 50 dif erent designs—we have the scale to meet your

needs. Every time!

But do they have the

to deliver?SCALE

ISO 9001:2008 Certifi e • ITAR Registere

Call 877.479.3680

or visit www.protolabs.com

Puzzled by

resin choices?

Request your FREE Resin

Puzzle — nine of the most

common thermoplastics used

in injection molding. Visit

www.protolabs.com/parts to request your design aid.

Enter code DN13B.

Check out our virtual tour!

© 2013 Proto Labs, Inc

Visa/Mastercard Accepted

ES294740_DN1308_T10_FP.pgs 08.02.2013 05:38 UBM blackyellowmagentacyan

![Page 7: DESIGN APPLICATIONS Platinum Temperature … APPLICATIONS T5 rendachaerialsasseblyasuppleenodesignnesuu [] C aterials & assebly Platinum Temperature Sensor Technology This article](https://reader034.fdocuments.net/reader034/viewer/2022051800/5abfee2c7f8b9a5a4e8b5f6c/html5/thumbnails/7.jpg)

[www.designnews.com]www.masterbond.com

Bond Porous and

Non-Porous Surfaces

Adhesive/Sealant EP21 Epoxy System

ì Forgiving one to one mix ratio

ì Outstanding physical strength properties

ì Chemically resistant

ì Superior durability

Hackensack, NJ 07601 USA

+1.201.343.8983

versatility by design

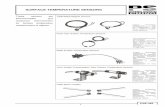

Typical Platinum RTD Element PackagesTypical platinum RTD element packages include thin-film, SMD, and wirewound types. Each package is suitable for specific applications and operating conditions.

Thin-film platinum RTD ele-ments with lead wires feature:

• Low cost

• High stability

• High vibration resistance

• Small size

• Fast response time

• Solderability and weldability

• Wide choice of sizes

• Wide choice of resistance values:

Pt100, Pt200, Pt500, Pt1k, Pt2k, Pt10k, and others

• Temperature capability from

-196C to 1,000C

SMD elements feature:• Pick-and-place compatibility

• 1206, 0805, and 0603 packages

• Small size

• Fast response time

• Wide choice of resistance values:

Pt100, Pt1k, and Pt10k• Typical operating temperature

range from -50C to 150C

Ceramic wirewound platinum RTD elements feature:

• Very high stability

• Wide variety of sizes

• Operating temperature range

from -200C to 850C• Availability in resistance values

up to 500Ω

Platinum RTD Element Areas of ApplicationTransportation: Increasingly

stringent environmental regulations for all vehicles, and in particular, diesel-powered vehicles, have led to the development of unique tech-nologies for emission reduction. Platinum thin-film elements with high-temperature capability are used to measure temperature in a variety

Oven applications for thin-flm platinum RTD elements.

ES293950_DN1308_T11.pgs 08.01.2013 22:25 UBM blackyellowmagentacyan

![Page 8: DESIGN APPLICATIONS Platinum Temperature … APPLICATIONS T5 rendachaerialsasseblyasuppleenodesignnesuu [] C aterials & assebly Platinum Temperature Sensor Technology This article](https://reader034.fdocuments.net/reader034/viewer/2022051800/5abfee2c7f8b9a5a4e8b5f6c/html5/thumbnails/8.jpg)

[www.designnews.com]

See us at Booth #1451

Chicago Design & Manufacturing Midwest Show

of locations in the exhaust sys-tem, including the EGR (ex-haust gas recirculation) system, exhaust pipe, catalyst bed, and diesel particulate filter (DPF). Lower-temperature automo-tive applications for platinum thin-film elements include oil temperature, oil quality, and intake mass air flow sensors.

Appliances: Thin-film plati-num RTD elements are used in several appliance applica-tions, glass-ceramic cooktops, electronic oven controls, and pyrolysis (burn-off ) control in self-cleaning ovens.

Electronics: Interconnects, such as copper conductors, and other components, such as sensors, increase in resistance in response to increasing temperature. In order to maintain the accuracy of high-precision circuits, it is necessary to compensate for this increase in resistance. Pick-and-place mountable SOT223, TO-92, and SMD package RTD elements are used to provide precise circuit temperature compensation. In addition to tempera-ture compensation, board-mountable RTD elements are also used for precise temperature control in energy manage-ment systems.

Process Technology: Chemical and petrochemical processes require a precision temperature sensor that is re-sistant to thermal shock, pressure, and other stresses associated with complex, large-scale chemical processing. Both thin-film and wirewound platinum RTD elements with temperature rat-ings of 600C and 850C are available to meet the needs of the process industry.

Life Sciences: In addition to sen-sitivity to a specific parameter, many in vitro diagnostics, such as personal blood glucose meters, are temperature-sensitive. As a result, temperature com-pensation is often required to maintain the accuracy of the measurement. Platinum RTD elements are used for precision temperature compensation.

An extension of platinum thin-film temperature sensing technology is the multi-sensor platform chip (MSP)

concept. Fabricated using thin-film platinum structuring techniques, in addition to containing a temperature sensor, the multifunction chip may also include a heater, capacitive inter-digitated electrode structure, and other active sensing layers, including pH

and 02 sensors. This chip provides the foundation for precision gas or mul-tiple parameter sensor systems, includ-ing chemical sensors, and cell vitality sensors

Versatility of PlatinumThe key properties of temperature and chemical resistance, and ease of fabri-cation make platinum an ideal choice for precision temperature sensing in both typical and harsh environments. A wide variety of styles and configura-tions provide the designer with a wide selection of sensors. A linear response to temperature, standardized response curves, and simple connection meth-ods make platinum sensors easy to use. In response to market demand, platinum RTD sensor manufacturers continue to advance the technology with higher-temperature ratings and thin-film sensors with multiple func-tion capability.Bob Gliniecki is the product manager at Heraeus Sensor Technology USA. To see the full version of this articles, go to http://bit.ly/132wKa1.

Multi-sensor platform chip.

ES293948_DN1308_T12.pgs 08.01.2013 22:25 UBM blackyellowmagentacyan

![DESIGN APPLICATIONS Platinum Temperature Sensor Technology · DESIGN APPLICATIONS T5 rendachaerialsasseblyasuppleenodesignnesuu [] C aterials & assebly Platinum Temperature Sensor](https://static.fdocuments.net/doc/165x107/5d5bb62388c9931f7e8b6727/design-applications-platinum-temperature-sensor-technology-design-applications.jpg)