DENTAL LEARNING No.4 Supp.pdfunit crowns milled using all-ceramic, zirconia, or lithium disilicate...

Transcript of DENTAL LEARNING No.4 Supp.pdfunit crowns milled using all-ceramic, zirconia, or lithium disilicate...

Knowledge for Clinical Practice

WWW.DENTALLEARNING.NET

A PEER-REVIEWED PUBLICATIONA PEER-REVIEWED PUBLICATION

DENTAL LEARNING

CE Course: CAD/CAM:Chairside Milling P. 2

CASE PRESENTATION:The Power and Simplicityof Digital Impressions P. 10

Same-Day Dentistry in the Big City P. 13

CASE PRESENTATION:Immediate Guided Implant Emergency Case Using CEREC P. 14

Embracing Technology for Growth P. 17

The Hidden Cost of Your Time P. 18

A 2017 GUIDE TO

CAD/CAM &CHAIRSIDE MILLING

Inside Earn

2 CE CreditsWritten for dentists, hygienists, and assistants

2 | DENTAL PRODUCT SHOP- PER www.dentalproductshop- per.com

LEARNING OBJECTIVES

The overall goal of this course is to provide information on CAD/CAM dentistry and the chairside milling of indirect restorations. After completing this course, participants will be able to:

1. Describe the key attributes of single-visit indirect restorative dentistry;

2. Review the process workflow options with CAD/CAM and chairside milling of restorations;

3. List potential advantages and disadvantages of chairside milling;

4. Describe the impact of CAD/CAM and chairside milling on offi ce effi ciency and patient satisfaction.

CAD/CAM technology has helped to transform the manner in which restorative treatment can be provided. In particular, the ability to provide patients with single-visit indirect restorations is appreciated by clinicians and patients. Chairside milling produces restorations that are at least as accurate as traditionally fabricated indirect restorations. Chairside milling also allows clinicians to optimize the process fl ow, reducing chairside time, increasing effi ciency, and saving patients additional visits. As with other procedures, each step must be accurately performed. Once the learning curve has been mastered, chairside milling represents an accurate method to provide patients with effi cient and esthetic restorative care.

ABSTRACT

Introduction

CAD/CAM has become mainstream and has changed

dentistry, particularly in the fi elds of restorative and implant

dentistry. Single-unit crowns are the most frequently

provided indirect restoration and, together with inlays and onlays,

were the fi rst to be provided using CAD/CAM technology. Since

then, bridges, veneers, post-and-cores, and implant abutments and

restorations have all been created using CAD/CAM dentistry.

Fabrication of a CAD/CAM restoration may occur in a laboratory

after sending the digital fi les through a secure internet portal, either

in a central location designated by the CAD/CAM system’s

manufacturer or in laboratories that are authorized by the

manufacturer. Such systems are “closed” systems. Increasingly,

systems are “open,” meaning that any laboratory with the

capability to use the software can fabricate the restoration using

virtual models and CAD/CAM milling, or by milling a model and

ABOUT THE AUTHORTarun Agarwal, DDSDr. Tarun Agarwal represents the next generation of leadership for the dental profession. As a respected speaker, author, and opinion leader, he is changing the way general dentists practice. His common sense approach to business,

dedication to clinical excellence, integration of technology and down-to-earth demeanor has made him a recognized educator. Dr. Agarwal received his dental degree from the University of Missouri at Kansas City and practices in Raleigh, North Carolina.

CAD/CAMChairside Milling

SPONSOR/PROVIDER: This is a Dental Learning, LLC continuing education activity. COMMERCIAL SUPPORTER: This course has been made possible through an unrestricted educational grant from HENRY SCHEIN. DESIGNATION STATEMENTS: Dental Learning, LLC is an ADA CERP recognized provider. ADA CERP is a service of the American Dental Association to assist dental professionals in identifying quality providers of continuing dental education. ADA CERP does not approve or endorse individual courses or instructors, nor does it imply acceptance of credit hours by boards of dentistry. Dental Learning, LLC designates this activity for 2 CE credits. Dental Learning, LLC is also designated as an Approved PACE Program Provider by the Academy of General Dentistry. The formal continuing education programs of this program provider are accepted by AGD for Fellowship, Mastership, and membership maintenance credit. Approval does not imply acceptance by a state or provincial board of dentistry or AGD endorsement. The current term of approval extends from 2/1/2016 - 1/31/2020. Provider ID: # 346890. Dental Learning, LLC is a Dental Board of California CE provider. The California Provider number is RP5062. This course meets the Dental Board of California’s requirements for 2 units of continuing education. EDUCATIONAL METHODS: This course is a self-instructional journal and web activity. Information shared in this course is based on current information and evidence. REGISTRATION: The cost of this CE course is $29.00 for 2 CE credits. PUBLICATION DATE: October 2017. EXPIRATION DATE: September 2020. REQUIREMENTS FOR SUCCESSFUL COMPLETION: To obtain 2 CE credits for this educational activity, participants must pay the required fee, review the material, complete the course evaluation and obtain a score of at least 70%. AUTHENTICITY STATEMENT: The images in this course have not been altered. SCIENTIFIC INTEGRITY STATEMENT: Information shared in this continuing education activity is developed from clinical research and represents the most current information available from evidence-based dentistry. KNOWN BENEFITS AND LIMITATIONS: Information in this continuing education activity is derived from data and information obtained from the reference section. EDUCATIONAL DISCLAIMER: Completing a single continuing education course does not provide enough information to result in the participant being an expert in the fi eld related to the course topic. It is a combination of many educational courses and clinical experience that allows the participant to develop skills and expertise. PROVIDER DISCLOSURE: Dental Learning does not have a leadership position or a commercial interest in any products that are mentioned in this article. No manufacturer or third party has had any input into the development of course content. CE PLANNER DISCLOSURE: The planner of this course, Joe Riley, does not have a leadership or commercial interest in any products or services discussed in this educational activity. He can be reached at [email protected]. TARGET AUDIENCE: This course was written for dentists, dental hygienists, and assistants, from novice to skilled. CANCELLATION/REFUND POLICY: Any participant who is not 100% satisfi ed with this course can request a full refund by contacting Dental Learning, LLC in writing or by calling 1-888-724-5230. Please direct all questions pertaining to Dental Learning, LLC or the administration of this course to [email protected]. Go Green, Go Online to www.dentallearning.net to take this course. © 2017

Integrated Media Solutions Inc./DentalLearning.net is an ADA CERP Recognized Provider. ADA CERP is a service of the American Dental Association to assist dental professionals in identifying quality providers of continuing dental education. ADA CERP does not approve or endorse individual courses or instructors, nor does it imply acceptance of credit hours by boards of dentistry. Concerns or complaints about a CE provider may be directed to the pro-vider or to ADA CERP at www.ada.org/cerp. Integrated Media Solutions Inc./DentalLearning.net designates this activity for 2 continuing education credits.

Approved PACE Program Provider FAGD/MAGD Credit Approval does not imply acceptance by a state or provincial board of dentistry or AGD endorsement.2/1/2016 - 1/31/2020 Provider ID: # 346890AGD Subject Codes: 610, 784

Dental Learning, LLC is a Dental Board of California CE Provider. The California Provider # is RP5062. All of the information contained on this certi� cate is truthful and accurate. Completion of this course does not constitute authorization for the attendee to perform any services that he or she is not legally authorized to perform based on his or her license or permit type. This course meets the Dental Board of California’s requirements for 2 units of continuing education. CA course code is 02-5062-17020.

DENTALLEARNING.NET DENTAL LEARNING | 3

DENTAL LEARNING

then using a traditional technique to fabricate the restoration.

With digital impressions, a scan is taken of the clinical site,

adjacent teeth, and opposing arch, after which the scans are

transformed into images for immediate viewing on the screen. This

allows the clinician to check the preparation for any deficiencies on

a large screen and to immediately correct any deficient areas. From

there, the restoration can be designed and fabricated. In contrast,

with traditional impressions and a traditional technique, it may be

more difficult to spot marginal defects in the impression, and models

must be poured from these. Inherently, there are more opportunities

for errors with a traditional technique, from defects in impressions

or models to manual fabrication of the final restoration. Scanning

of traditional impressions is a third option—this does digitize the

information, allowing for CAD/CAM fabrication of the restoration;

however, it will also scan any impression errors. A CAD/CAM milling

unit may also be incorporated into the dental office, making it

possible to mill restorations chairside while the patient is in the office.

Chairside Milling In addition to the obvious advantage of being able to provide

single-visit indirect restorations that are esthetic and accurate,1

chairside milling reduces the time required for restorative care, does

not require delivery of a provisional restoration, and gives the dentist

complete control over the procedure and the process workflow.

A further advantage is the ease with which digital scanning and

chairside milling can be performed in challenging situations, such

as treating elderly patients with reduced cognition, or patients with

limited mobility or ability to tolerate long treatments.2 Conversely,

the cost of chairside-milling technology is a capital investment

not required if laboratory milling is performed, and there is a

learning curve associated with its adoption by the dental team and

optimization of process workflow, including delegation of tasks.1

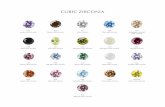

Block Options

Regardless of the type of restoration, CAD/CAM milling begins

with a CAD/CAM block and should end with an esthetic result even

for challenging cases. Options include zirconia-based, leucite-based,

and feldspar-based ceramics; lithium disilicate; and composite

blocks. All-ceramic CAD/CAM blocks offer strength and esthetics,

including a chameleon effect.3 The preparation design must take

into account the type of block being used, and provide the correct

preparation form and clearance for that material. CAD/CAM materials

blend well, allowing margins to be placed supragingivally or

perigingivally.

Accuracy and Longevity of CAD/CAM Restorations Several studies have determined that CAD/CAM restorations in

general have a marginal fit at least equivalent to those fabricated

using traditional impressions and laboratory techniques.4,5 In vivo and

in vitro studies have also assessed overall accuracy and fit of single-

unit crowns milled using all-ceramic, zirconia, or lithium disilicate

blocks, and found these to be acceptable and comparable to the

use of a traditional technique.6,7 Similarly, single-unit implant crowns

and abutments were clinically accurate in other studies.8,9 In one

recent review, the long-term survival rate for single-tooth indirect

restorations was similar following digital or traditional fabrication.10

A significant number of studies have been conducted on chairside-

milled restorations using ceramic and composite block materials. The

marginal and overall fit of chairside-milled restorations was found to

be at least as accurate as those fabricated using traditional methods;

the materials were also found to offer sufficient strength and fracture

resistance and clinically acceptable outcomes.11-16 In addition, the 5-

and 10-year survival rates for chairside milled restorations were found

to be 97% and 90%, respectively, in one review.17

Process Flow The process flow when providing patients with single-visit CAD/

CAM restorations can be simple. After scanning and verifying the

margins, interocclusal clearance, and proposed restoration design,

it’s simply a matter of waiting for the restoration to be milled,

any necessary staining and glazing or sintering, and trying in the

restoration and seating it. In cases where the shape of the teeth must

be duplicated, scans of the pre-existing teeth shapes can be made

Table 1. Chairside milling

POTENTIAL ADVANTAGES

Single-visit indirect restorations

No provisional phase

Efficiency

Esthetic results

Options to stain and glaze

Patient acceptance

Control of process

POTENTIAL DISADVANTAGES

Cost of acquisition

Learning curve

Difficulty delegating tasks

4 DENTAL LEARNING

and used as a virtual template for the restorations, provided the

intent is to have restorations with the same shape. This reduces the

likelihood of adjustments being needed or patient dissatisfaction.

Chairside milling also allows you to use a process fl ow that

optimizes the treatment schedule by performing other procedures

in the same visit as well as delivering the fi nal restoration without an

intermediate provisional phase (Figure 1). During the time of onset

of local anesthesia, scans of the opposing dentition can be made as

well as of the existing teeth at the site(s) if the same shape is desired,

and the shade can be selected. Later in the appointment, while

waiting for the restoration(s) to be chairside milled, and fi nished,

other treatment needs can be addressed in the same visit. Treatment

such as a direct composite restoration or endodontic therapy can

be completed, if appropriate, while the restoration is being milled.

This saves chairside time, maximizes effi ciency, and saves the patient

another visit.

Effi ciency (Speed)CAD/CAM imaging and chairside milling together save valuable

time by streamlining treatment and permitting delegation of

signifi cant portions of the process. In one study, digital scanning

alone saved dentists 55% of the time previously required to take a

traditional impression.18 Digital images are immediately available

for examination, such that any imperfect areas of a preparation can

be adjusted and rescanned if necessary, without the patient having

to return. Studies have shown that signifi cant time savings can be

achieved using CAD/CAM software and milling machines. In addition,

CAD/CAM software now has automated marking and evaluation of

margins, and uses digital articulating paper to rapidly determine the

occlusion and interdigitation of teeth in opposing arches. Full-color

images have also made it easier for us to view margins and other

aspects of the preparation. The case below shows use of CAD/CAM

and chairside milling for a single-unit esthetic anterior restoration.

Case 1The patient in this case was a 35-year-old female who

arrived with a fractured upper left canine. The patient was not

experiencing any pain. After a clinical evaluation including a

periapical radiograph and discussion with the patient, it was

determined that the tooth was nonvital and would require root

canal treatment if it were to be saved and crowned. Although

the crown on the adjacent bicuspid was white, and the anterior

composites were discolored with areas of microleakage, the

patient declined to have these treated at this time. Together with

the patient, we therefore decided that the best option was to

perform same-day root canal therapy and fabricate a chairside-

milled crown for same-day placement (Figures 2, 3). Our patient

had experienced moderate levels of caries and had recurrent

caries in the tooth being treated. Of relevance, one of the benefi ts

CAD/CAM Chairside Milling

Localanesthesiaandwaitfor

onsetPre-treatmentscansand

shadeselection

Chairsidemilling

Preparation,softtissue

management

Otherpatienttreatmentifrequired,

simultaneouswithchairsidemilling

Single-visitappointment

made

Preparationscan,adjacent

teeth

Single-visittreatmentcompleted

Figure 1—Process fl ow. Figure 2—Initial presentation

DENTALLEARNING.NET DENTAL LEARNING | 5

DENTAL LEARNING

shown for CAD/CAM restorations has been a potential decrease

in recurrent caries believed to be a result of the excellent marginal

fit of these restorations.19

We first performed the root canal therapy and removed dental

caries before placing a fiber post cemented with a self-adhesive

resin composite luting agent and creating a resin composite

buildup around this (Figure 4). The preparation and margins were

then finalized. Given the patient’s low lip line and smile line,

together with the availability of esthetic restorative materials,

a perigingival margin was created. This would provide the best

biocompatibility with the gingival architecture (Figure 5).

My assistant then placed gingival retraction cord and took

a scan of the preparation and surrounding dentition, as well as

the opposing arch. After this, the digital images were reviewed

to check the margins and the scans overall. Subsequently, the

full-color software provided an image of the proposed restoration

for us to check on the screen (Figure 6). The shade had been

determined using natural northern light. With current CAD/CAM

systems, shade selection for each tooth can be automated or

determined by the software, providing a reliable comparison

point with assessing the shade(s) you have selected. This has

two advantages—it saves time, and it removes subjectivity in

shade selection, thereby reducing the likelihood of errors in shade

selection. After the proposed restoration was accepted, it was

milled while the patient waited in the office.

We verified the fit of the milled crown, then stained it where

required for customization and glazed the crown. Historically, one

of the drawbacks of CAD/CAM restorations milled chairside was

the time required to stain and glaze a chairside-milled restoration.

Compact technology has been introduced that significantly

speeds up the stain and glaze process. The crown was cemented

using a self-etch resin composite luting agent. After seating the

crown, we waited until the cement had reached the gel phase, Figure 4—Fiber post and composite build-up

Figure 3—Periapical radiograph

Figure 5—Completed preparation

Figure 6—Digital full color image with proposed crown form

6 DENTAL LEARNING

making it possible to easily peel away the excess cement using an

explorer before final curing (Figures 7-8).

Case 2. Implant Placement and RestorationIn the case shown here, the patient had fractured the root of an

endodontically treated upper right molar. It was determined that the

tooth was hopeless and would need to be extracted. The patient

opted for immediate implant placement. After scans were taken, the

surgical guide was created for optimal positioning of the immediate

implant, and the implant was provisionalized. After osseointegration,

the patient returned for the final indirect restorations. A scan body

was placed over the implant-abutment complex, and the area was

scanned using CAD/CAM software (Figure 9). Subsequently, we were

able to view the proposed restoration design, which was then milled

chairside before being placed and screw-retained (Figures 10-12).

This procedure was streamlined with chairside milling.

Patient BenefitsFor patients, chairside CAD/CAM restorations offer significant

benefits. One-visit restorations are possible, with same-

day preparation and placement of indirect restorations. The

convenience and experience of digitally scanned, chairside-milled

restorations result in high levels of patient satisfaction. Overall,

patients have been found to prefer digital scans, which are less

unpleasant and less likely to induce gagging than traditional

impressions.20,21 Patients have also indicated a preference for

single-visit indirect restorations.22 In addition, the chairside-milled

restoration looks lifelike and natural.

CAD/CAM Chairside Milling

Figure 8—Final restoration

Figure 10—Proposed implant restoration

Figure 7—Removal of excess cement during the gel phase

Figure 9—Preparing the site for CAD/CAM scanning

DENTALLEARNING.NET DENTAL LEARNING | 7

DENTAL LEARNING

Conclusions Digital impressions can be taken and restorations created that

rival traditional techniques for form and esthetics. Of course, care

must be taken to ensure that the digital scans are accurate and

that preparation and milling procedures are properly executed.

Once the learning curve has been mastered, chairside milling

provides an easy and efficient method to provide restorative care.

The process workflow with chairside milling can be streamlined

and efficient dentistry provided. Chairside time is optimized,

accurate and esthetic restorations can be provided, and patient

satisfaction is excellent.

References1 Santos GC, Jr., Santos MJ, Jr., Rizkalla AS, et al. Overview of CEREC CAD/CAM

chairside system. Gen Dent. 2013;61(1):36-40.

2 Van Zeghbroeck L. CAD/CAM treatment for the elderly - a case report. Gerodontology. 2012;29(2):e1176-9.

3 Baroudi K, Ibraheem SN. Assessment of Chair-side Computer-Aided Design and Computer-Aided Manufacturing Restorations: A Review of the Literature. J Int Oral Health. 2015;7(4):96-104.

4 Hirayama H, Chang YC. Fit of zirconia copings generated from a digital impression technique and a conventional impression technique. Tufts University of Dental Medicine master’s thesis.

5 Sorensen JA, Sorensen PN, Mizuro K. Marginal fidelity of crowns made with optical versus conventional impressions. IADR Abstract #1599. April 2009.

6 Berrendero S, Salido MP, Valverde A, et al. Influence of conventional and digital intraoral impressions on the fit of CAD/CAM-fabricated all-ceramic crowns. Clin Oral Investigations. 2016 Jan. [Epub ahead of print].

7 Abdel-Azim T, Rogers K, Elathamna E, et al. Comparison of the marginal fit of lithium disilicate crowns fabricated with CAD/CAM technology by using conventional impressions and two intraoral digital scanners. J Prosthet Dent. 2015;114(4):554-9.

8 Cooper LF, Stanford C, Feine J, McGuire M. Prospective assessment of CAD/CAM zirconia abutment and lithium disilicate crown restorations: 2.4 year results. J Prosthet Dent. 2016;116:33-9.

9 Nejatidanesh F, Shakibamehr AH, Savabi O. Comparison of marginal and internal adaptation of CAD/CAM and conventional cement retained implant-supported single crowns. Implant Dent. 2016;25:103-8.

10 Wittneben JG, Wright RF, Weber HP, Gallucci GO. A systematic review of the clinical performance of CAD/CAM single-tooth restorations. Int J Prosthodont. 2009;22:466-47.

11 Magne P, Schlichting LH, Maia HP, Baratieri LN. In vitro fatigue resistance of CAD/CAM composite resin and ceramic posterior occlusal veneers. J Prosthet Dent. 2010;104(3):149-57.

12 Vichi A, Sedda M, Del Siena F, et al. Flexural resistance of Cerec CAD/CAM system ceramic blocks. Part 1: Chairside materials. Am J Dent. 2013;26(5):255-9.

13 Batson ER, Cooper LF, Duqum I, Mendonça G. Clinical outcomes of three different crown systems with CAD/CAM technology. J Prosthet Dent. 2014;112(4):770-7.

14 Almeida de Silva JS, Erdelt K, Edelhoff D, et al. Marginal and internal fit of four-unit zirconia fixed dental prostheses based on digital and conventional impression techniques. Clin Oral Investig. 2014;18:515-23.

15 Keul C, Stawarczyk B, Erdelt KJ, et al. Fit of 4-unit FDPs made of zirconia and Co-Cr-alloy after chairside and labside digitalization - a laboratory study. Dent Mater. 2014;30(4):400-7.

16 Tidehag P, Ottosson K, Sjögren G. Accuracy of ceramic restorations made using an in-office optical scanning technique: an in vitro study. Oper Dent. 2014;39(3):308-16.

17 Fasbinder DJ. Clinical performance of chairside CAD/CAM restorations. J Am Dent Assoc. 2006;137:22S-31.

18 Joda T, Lenherr P, Dedem P, et al. Time efficiency, difficulty, and operator’s preference comparing digital and conventional implant impressions: A randomized controlled trial. Clin Oral Implants Res 2016.

19 Mjör IA, Davis ME, Abu-Hanna A. CAD/CAM restorations and secondary caries: a literature review with illustrations. Dent Update. 2008 Mar;35(2):118-20.

20 Gjelvold B, Chrcanovic BR, Korduner EK, et al. Intraoral digital impression technique compared to conventional impression technique: A randomized clinical trial. J Prosthodont. 2016;25(4):282-7.

21 Yuzbasioglu E, Kurt H, Turunc R, Bilir H. Comparison of digital and conventional impression techniques: evaluation of patients’ perception, treatment comfort, effectiveness and clinical outcomes. BMC Oral Health. 2014;14:10.

22 Christensen GJ. In-office CAD/CAM milling of restorations: the future? J Am Dent Assoc. 2008;139(1):83-5.

Figure 11—Final restoration and post-placement radiograph

Figure 12—Final screw-retained implant crown

8 DENTAL LEARNING

1. __________________ are the most frequently provided indirect restorations. a. Three-unit bridgesb. Single-unit crownsc. Veneersd. Inlays

2. Digital impressions are transformed into images for immediate viewing on the screen, allowing the clinician to check the preparation on a large screen and to immediately __________________ .a. adjust the software imageb. ask the laboratory to adjust any

deficient areasc. correct any deficient areas d. make an extra appointment for the patient

3. Scanning of traditional impression allows adjustment of any impression errors.a. Trueb. False

4. Chairside milling __________________ . a. can be advantageous when treating

elderly patientsb. reduces the time required for

restorative carec. gives the dentist complete control

over the processd. all of the above

5. Studies have found the accuracy and fit of single-unit crowns milled using __________________ blocks to be acceptable. a. zirconia b. all-ceramic c. lithium disilicate d. all of the above

6. In one review, the 10-year survival rate for chairside-milled restorations was __________________.a. 80%b. 85%c. 90%d. 95%

7. As one of the steps for chairside milling and provision of single-visit restorations, scans of the pre-existing teeth shapes can be made and used to create a __________________.a. provisional restorationb. virtual tray for the scanc. digital template to duplicate the shape

of the teethd. mouth guard

8. Chairside milling makes it possible to perform other procedures while the restoration is being milled. a. Trueb. False

9. In one study, digital scanning saved dentists __________________ of the time previously required to take a traditional impression. a. 25%b. 35%c. 45%d. 55%

10. Digital articulating paper __________________. a. does not yet existb. must be blue for accuracyc. allows rapid determination of the

occlusiond. b and c

11. One of the potential disadvantages of CAD/CAM and chairside milling is the __________________.a. learning curve required after adopting

this technologyb. resistance from patientsc. need for remakesd. none of the above

12. When performing CAD/CAM restorations, the preparation design must take into account the __________________.a. form and clearance required for the

block material being usedb. shade requiredc. patient’s aged. time required

13. The marginal fit of CAD/CAM restorations in general, compared to traditional restorations, is __________________.a. usually almost equivalentb. at least equivalentc. always inferiord. always superior

14. CAD/CAM software now offers automated marking and evaluation of margins.a. Trueb. False

15. A potential decrease in recurrent caries with CAD/CAM restorations is believed to be due to __________________.a. patients’ resulting motivation to flossb. their excellent marginal fit c. their internal fitd. the materials used

16. Having software that can assess the shades of teeth adjacent to the preparation can __________________.a. save timeb. help provide verification of the shade

you have selectedc. remove all possibility of needing to do

any staining or glazing d. a and b

17. Compact technology has been introduced that significantly speeds up the in-office stain and glaze process.a. Trueb. False

18. The ability to remove excess cement during a gel phase makes it __________________.a. impossible to leave any behindb. easy to peel away before the final curec. more radiopaqued. easier to dissolve any residual cement

afterward

19. Patient preference and satisfaction with single-visit milled restorations is good due to the __________________ compared to provision of a traditional restoration.a. needle-free experienceb. the overall convenience, experience,

and reduced likelihood of gaggingc. lack of taste associated with scanning d. ease of adjusting the occlusion after

seating

20. The process workflow with chairside milling allows for __________________.a. optimized chairside timeb. accurate restorations, provided steps

in the process are properly followedc. esthetic restorationsd. all of the above

CEQuizTo complete this quiz online and immediately download your CE verification document, visit www.dentallearning.net/CCM-ce, then log in to your account (or register to create an account). Upon completion and passing of the exam, you can immediately download your CE verification document. We accept Visa, MasterCard, Discover, and American Express.

CAD/CAM Chairside Milling

DENTALLEARNING.NET DENTAL LEARNING | 9

CAD/CAM Chairside MillingCE ANSWER FORM (E-mail address required for processing)

Please direct all questions pertaining to Dental Learning, LLC or the administration of this course to [email protected]. COURSE EVALUATION and PARTICIPANT FEEDBACK: We encourage participant feedback pertaining to all courses. Please be sure to complete the evaluation included with the course. INSTRUCTIONS: All questions have only one answer. Participants will receive confirmation of passing by receipt of a verification certificate. Verification certificates will be processed within two weeks after submitting a completed examination. EDUCATIONAL DISCLAIMER: The content in this course is derived from current information and research-based evidence. Any opinions of efficacy or perceived value of any products mentioned in this course and expressed herein are those of the author(s) of the course and do not necessarily reflect those of Dental Learning. Completing a single continuing education course does not provide enough information to make the participant an expert in the field related to the course topic. It is a combination of many educational courses and clinical experience that allows the participant to develop skills and expertise. COURSE CREDITS/COST: All participants scoring at least 70% on the examination will receive a CE verification certificate. Dental Learning, LLC is an ADA CERP recognized provider. Dental Learning, LLC is also designated as an Approved PACE Program Provider by the Academy of General Dentistry. The formal continuing education programs of this program provider are accepted by AGD for Fellowship, Mastership, and membership maintenance credit. Please contact Dental Learning, LLC for current terms of acceptance. Participants are urged to contact their state dental boards for continuing education requirements. Dental Learning, LLC is a California Provider. The California Provider number is RP5062. The cost for courses ranges from $19.00 to $90.00. RECORD KEEPING: Dental Learning, LLC maintains records of your successful completion of any exam. Please contact our offices for a copy of your continuing education credits report. This report, which will list all credits earned to date, will be generated and mailed to you within five business days of request. Dental Learning, LLC maintains verification records for a minimum of seven years. CANCELLATION/REFUND POLICY: Any participant who is not 100% satisfied with this course can request a full refund by contacting Dental Learning, LLC in writing or by calling 1-888-724-5230. Go Green, Go Online to www.dentallearning.net to take this course. © 2017

PLEASE PHOTOCOPY ANSWER SHEET FOR ADDITIONAL PARTICIPANTS.

1. A B C D

2. A B C D

3. A B C D

4. A B C D

5. A B C D

6. A B C D

7. A B C D

8. A B C D

9. A B C D

10. A B C D

11. A B C D

12. A B C D

13. A B C D

14. A B C D

15. A B C D

16. A B C D

17. A B C D

18. A B C D

19. A B C D

20. A B C D

21. A B C D

22. A B C D

23. A B C D

24. A B C D

25. A B C D

26. A B C D

27. A B C D

28. A B C D

29. A B C D

30. A B C D

QUIZ ANSWERSFill in the circle of the appropriate answer that corresponds to the question on previous pages.

EDUCATIONAL OBJECTIVES1. Describe the key attributes of single-visit indirect restorative dentistry;

2. Review the process workflow options with CAD/CAM and chairside milling of restorations;

3. List potential advantages and disadvantages of chairside milling;

4. Describe the impact of CAD/CAM and chairside milling on office efficiency and patient satisfaction.

If you have any questions, please email Dental Learning at [email protected] or call 888-724-5230.

COURSE SUBMISSION: 1. Read the entire course.

2. Complete this entire answer sheet in either pen or pencil.

3. Mark only one answer for each question.

4. Mail or fax answer form.

For immediate results:1. Read the entire course.

2. Go to: www.dentallearning.net/CCM-ce.

3. Log in to your account or register to create an account.

4. Complete course and submit for grading to receive your CE verification certificate.

A score of 70% will earn your credits.

Dental Learning, LLC500 Craig Road, First Floor, Manalapan, NJ 07726ALL FIELDS MARKED WITH AN ASTERISK (*) ARE REQUIRED

*If paying by credit card, please note:MasterCard | Visa | AmEx | Discover

*Name ______________________________________________*Address______________________________________________*Account Number ______________________________________________*Expiration Date *CVC# ___________________________ _________________

The charge will appear as: Dental Learning, LLC.

If paying by check, make check payable to: Dental Learning, LLC.

AGD Codes: 610, 784

Price: $29 CE Credits: 2Save time and the environment by taking this course online.

COURSE EVALUATIONPlease evaluate this course using a scale of 3 to 1, where 3 is excellent and 1 is poor.

1. Clarity of objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2 1

2. Usefulness of content . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2 1

3. Benefit to your clinical practice . . . . . . . . . . . . . . . . . . . . 3 2 1

4. Usefulness of the references . . . . . . . . . . . . . . . . . . . . . . 3 2 1

5. Quality of written presentation . . . . . . . . . . . . . . . . . . . . 3 2 1

6. Quality of illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2 1

7. Clarity of quiz questions . . . . . . . . . . . . . . . . . . . . . . . . . 3 2 1

8. Relevance of quiz questions . . . . . . . . . . . . . . . . . . . . . . 3 2 1

9. Rate your overall satisfaction with this course . . . . . . . . 3 2 1

10. Did this lesson achieve its educational objectives? Yes No

11. Are there any other topics you would like to see presented in the future? __________________________________________________________________________

SPECIAL CODE __________________________

*Name: Title: Specialty:

*Address: NPI No.

*City: *State: *Zip: AGD Identification No.

*E-mail:

*Telephone: License Renewal Date:

10 DENTAL LEARNING

CASE PRESENTATION

The Power and Simplicity of Digital ImpressionsBy Walter Renne, DMD, Tony Mennito, DMD, and Tyler Parrish

WALTERRENNE, DMD

Dr. Renne is an associate professor

in the Department of Oral Rehabilitation

and Restorative Dentistry in the

College of Dental Medicine at the

University of South Carolina.

TONYMENNITO, DMD

Dr. Mennito is an associate professor

in the Department of Oral Rehabilitation

and Restorative Dentistry in the

College of Dental Medicine at the

University of South Carolina.

TYLER PARRISH

A fourth-year dental student in the

College of Dental Medicine at the

University of South Carolina, Tyler Parrish

treatment planned and co-authored this

case.

NEW PRODUCTS | PRODUCT SPOTLIGHT | TRIED & TRUE CLINICAL PRACTICEPRODUCT

focus

Digital technology is constantly improving the effi ciency with which we carry out patient treatment. The speed and accuracy of intra-

oral digital impression systems is perhaps the area in which this improvement has been most signifi cant. Upgrades to both hardware and software allow for not only more expedient treatment, but also for more predictable clinical results. The coupling of powerful planning tools within the Planmeca Romexis software with the speed, accuracy, and ease of use of the Planmeca Emerald scanner offers many advan-tages to both the patient and practitioner.

The option of a single-visit smile can be very at-tractive for patients due to minimal interruption of their everyday lives. The temporary stage can often be problematic and frustrating for both patient and clinician. The potential for skipping this step can be attractive to both parties but does require more extensive planning leading up to execution of the treatment plan. The Planmeca Romexis smile design software provides a simple tool that allows the patient and dentist an opportunity to try out different shade options, smile designs, and tooth shapes, ensuring that a common vision is shared for fi nal prosthetic design. The software also allows you to export your smile design into the CAD software to ensure that it is replicated in the fi nal design or wax-up. Printing of the resulting model can be used to mock up or temporize the patient if required.

Case in PointA patient presents with the chief complaint, “I do

not like my smile” (Figure 1). She was given several options, including comprehensive orthodontic therapy as the best and most conservative option.

After detailed discussion of the various treatment options, the patient decided she wanted ceramic restorations and esthetic crown lengthening.

The fi rst step in the treatment planning process is to determine feasibility of restorative work. Quality full-face smile and retracted intraoral photographs are taken, along with a high-quality intraoral digital impression. With input from the pa-tient, the smile is designed using the Smile Design software (DSD) software (Planmeca Romexis) inte-grated with the Planmeca Emerald scanner (Figure 2). Next, the DSD is integrated into the Planmeca PlanCAD Easy* design software for virtual waxing of the case. This virtual wax-up will be 3D-printed for patient approval as well as to communicate to the periodontist the location of the proposed fi nal veneers to aid in the esthetic crown lengthening surgery. This surgery was performed to ensure that the proposed fi nal restorations would not en-croach on the biologic width (Figure 3).

After healing for 10 weeks, the patient returns for same-day preparation, milling, and delivery of 5 units of cingulum preservation crowns and minimal prep veneers. The original digital wax-up that was 3D-printed and used to guide the crown-lengthening surgery is scanned into the Planmeca PlanCAD Easy software using the Planmeca Emerald scanner. This wax-up can also serve as a template to make a sili-cone matrix for provisional restorations in the event that the patient did not like her fi nal milled restora-tions. After preparation and isolation, fi nal impres-sions are made by scanning the preparation arch, opposing arch, and digital bite (Figures 4, 5). The software color-codes clearance to ensure proper material thickness will be achieved (Figure 6).

High-quality digital color models are made and margins are marked using intuitive software tools. Restorations are quickly designed, replicating the diag-nostic digital wax-up that was approved by the patient (Figure 7). The restorations were sent for milling using the Planmeca

PlanMill 40. These e.max MT restorations were then custom characterized, glazed, and fi red to achieve a more natural ap-pearance. After patient approval, the fi nal e.max restorations were treated with Monobond etch and prime (Ivoclar Viva-dent) for 1 minute and bonded in place

using Optibond XTR adhesive (Kerr Re-storatives) and Variolink Esthetic (Ivoclar Vivadent) cement (Figures 8, 9).

*Available in the United States, Planmeca PlanCAD software performs the same functions as Planmeca PlanCAD Easy, which is offered internationally.

Figure 1—Preoperative photo

Figures 4, 5—After preparation and isolation, fi nal impressions are made by scanning the preparation arch, opposing arch, and digital bite.

Figure 7—Restorations designs replicate the diagnostic digital wax-up.

Figure 2—The smile is designed using Planmeca Romexis Smile Design software with scans from the Planmeca Emerald scanner.

Figures 8, 9—The patient’s new smile is revealed in the retracted and fi nal smile photos.

Figure 3—Esthetic crown-lengthening surgery ensures that the fi nal restorations would not encroach on the biologic width.

Figure 6—The software color-codes clearance to ensure proper material thickness will be achieved.

DENTALLEARNING.NET DENTAL LEARNING | 11

Practice Same-Day DentistryPlanmeca FIT with Planmeca Emerald. - The Complete Solution

The Planmeca Emerald™ and Planmeca PlanMill® 40 S are quite the pairing with efficient design options, brilliant colored scans, easy-to-use software and premium unrivaled support options — all while saving you the extra fees and your patients' time. When you have the Planmeca FIT™ Open CAD/CAM system you’ll be able to perform highly advanced, powder-free restorations, including same-day crowns, inlays, onlays, bridges and veneers with the speed and confidence you demand.

Call 855-262-9694 for a demonstration today.

I love being able to do one-visit dentistry. It’s a good fi t for my kind of patients. I practice in New York City, where we have a lot of transient

people. It could be someone who just fl ew in for a vacation, or someone who might be working in town temporarily. We are located close to the United Nations building and have handled some emergencies. People were happy with the results, so we’re now on their list if a diplomat is having trouble with a tooth. Regardless of what city or area you’re in, people will fi nd you online or by word of mouth if you can provide same-day dentistry.

The most common cases I see are as simple as a broken tooth, such as a missing whole or partial cusp, which would warrant a crown. With transient patients, you can put them in temporaries, but they’re unlikely to go see their home dentist for the permanent restoration anytime soon. They’re often too busy, or they’ve traveled to another country where the temporary broke and they saw yet an-other new dentist. The beautiful thing about using CAD/CAM technology is we’re able to provide them with a fi nal restoration right then and there, usually within 2 hours.

I’m a really hands-on person and enjoy using the Planmeca FIT system. I use e.max because its psi is 360, whereas a normal PFM is only 100 psi. The sys-tem also works with zirconia, but we fi nd it can wear on opposing natural teeth. I personally think e.max is as strong as needed but much more beautiful than zirconia. I create inlays with IPS Empress, which doesn’t need to be fi red. You can just mill it and

bond it right into place, usually in less than 2 hours. The Planmeca FIT system is my go-to for all

indirect restorations unless I need a bridge that is longer than 33 mm. The quality and strength of the milled restorations are excellent. What I really love about creating the crowns here in the offi ce is having the ability to stain and glaze them to match patients’ other teeth. Foreign dentists have sent me emails to say they were impressed with the results. One man who was so happy with the color match we achieved became our patient when he returned to New York.

Same-day dentistry is great for any patient be-cause they don’t have to leave work multiple times. If patients have to take off work, they would rather take just one day. That’s the beauty of the technolo-gy. It’s nice when I have a preplanned reason to use this technology, but it’s great for all our patients that I am able to do things “on the fl y.”

Same-Day Dentistry in the Big City

FREDERICK STANGE, DDSAfter graduating

with honors in fi ne arts from Stony

Brook University, Dr. Stange continued his education at his alma

mater and earned his doctorate from

the Stony Brook University School

of Dental Medicine. In his midtown

Manhattan dental practice, Dr. Stange combines the skills he learned as a fi ne

art major with his vast knowledge of

cosmetic dentistry to give patients a smile

they can be proud to show off. Dr.

Stange has taught undergraduate

dental students and conducted oral

biology lectures, been an instructor

for oral diagnostics, and was involved

in research on Arm & Hammer’s

Complete Care. He is also dedicated to continuing his own

dental education.

Frederick Stange, DDS, has been providing same-day dentistry for about 4 years in his busy Manhattan practice. He’s found that most patients, whether they are out-of-towners or patients he’s been treating for years, appreciate his ability to diagnose, treatment plan, and provide fi nal restorations within 2 hours or less.

PRODUCT EVALUATION | Q&A | FROM THE PODIUM | EARLY ADOPTERS WHY I USE...

DENTALLEARNING.NET DENTAL LEARNING | 13

peerto

peer

A recent single-vist crown on No. 3 stands in contrast to the PFM crown placed on No. 30 many years earlier.

14 DENTAL LEARNING

CASE PRESENTATION

Immediate Guided Implant Emergency Case Using CEREC By Yao-Lin Tang, DDS

YAO-LIN TANG, DDS

Dr. Tang’s formative years were spent

on the island nation of his birth,

Taiwan, where he received his

Bachelor of Science in Dental Surgery.

He later ventured to California to receive his Doctor of Dental

Surgery degree from University of

the Pacifi c School of Dentistry, and began

his fi rst practice in 1995. Dr. Tang has

over 20 years of practical knowledge

in cosmetic and general dentistry.

He has served as a professional

mentor for several organizations in CAD/CAM

restorations and digital radiography—

technology at the forefront of his practice in San

Mateo, CA.

NEW PRODUCTS | PRODUCT SPOTLIGHT | TRIED & TRUE CLINICAL PRACTICEPRODUCT

focus

A n emergency patient was referred with a broken tooth No. 9 (Figures 1, 2). The tooth had previously been treated with a

root canal and crown, but the tooth had fractured. Because the patient lives about an hour and a half from my offi ce, I decided to do an immediate implant with guided surgery. The Orthophos XG 3D CBCT unit and the CEREC Omni can (both Dentsply Sirona) were used to capture an intraoral scan of her upper arch. Next the restoration for tooth No. 9 was designed using CEREC software. An SSI fi le was exported and imported into the Galaxis CBCT software, merging both fi les. This data was used to determine the best angulation for the implant, the appropriate implant crown position, and the bone condition (Figure 3).

The patient’s buccal plate is very thin. The ridge is very limited, and it would be very challenging to attempt to do an immediate implant procedure on this patient without the accuracy of a surgi-cal guide. CEREC software was used to design a CEREC Guide 2, which was then milled with the CEREC MC XL milling machine (Figures 4A, 4B). This process takes about 30 to 40 minutes.

Tooth No. 9 was extracted atraumatically with a Benex Extractor (Benex Dent), preserving all the bone. After placing the CEREC Guide 2, the oste-otomy was performed through the surgical guide. Next, the 3.3 mm x 12 mm implant was placed, a bone graft was added, and a cover screw was used to enhance healing. In order to maintain the gingival papilla, I used the CEREC to make a tem-

porary cantilever bridge with an ovate contact on tooth No. 9 out of CERASMART (GC America). The temporary restoration was cemented using tooth No. 10 (which also needs a crown) as the abut-ment for the cantilever bridge. Although this was a temporary, I make temporaries with CEREC just like a permanent restoration, and I custom stain and glaze both temporary and fi nal restorations (Figures 5A, 5B).

The patient returned after 2 weeks for a postop check, at which point the site was healing very well. When the patient returned again in 4 months, I exposed the implant, and the CEREC was used to mill a VITA ENAMIC IS custom abutment (VITA North America) to train the gingival tissue for the fi nal restorations (Figures 6A, 6B). The patient returned in another 2 weeks for the fi nal restora-tion. I used the CEREC and VITA ENAMIC IS as the abutment material for tooth No. 9 and for both fi nal crowns (Figure 7).

Figure 1—An emergency appointment with a broken tooth No. 9. It had previously been treated with a root canal and a crown, and had fractured.

Figure 2—Preoperative x-ray

Figure 4B—CEREC Guide 2 used during surgery, shown with the Dentsply Sirona key and a guided drill

Figure 6A—Planning for ENAMIC custom healing abutment, placed to help improve gingival form

Figure 3—Ideal implant placement planned with CEREC and Galaxis software for restora-tions on teeth Nos. 9 and 10

Figure 5A—Stained and glazed CERASMART temporary restoration milled on the CEREC MC XL milling machine

Figure 6B—Healing abutment in place

Figure 4A—Designing the CEREC Guide 2 using the digital impression

Figure 5B—Temporary restorations at the 2-week recall appointment. The tissues were healing nicely.

Figure 7—Final restorations

15 DENTAL LEARNING

ConclusionI have been milling crowns with CEREC

for many years, but now that everything is digital, we make all our implant crowns

and surgical guides in-house as well. The whole procedure is “model-less,” as we don’t take any impressions. Since I started using CBCT, I use only guided

surgery for implant cases. I don’t do free-hand surgery any more. Thanks to digital dentistry and CEREC, I can provide my patients with better service.

PRODUCT EVALUATION | Q&A FROM THE PODIUM EARLY ADOPTERS | WHY I USE

F rom the beginning, I was very impressed with the quality of CEREC restorations. I thought the ability to save time and offer my patients same-

visit dentistry for crowns would be a differentiator in my practice. I purchased the system and my journey began. I soon realized that using CEREC isn’t just about the digital impression system and making the restoration. CEREC technology has also allowed us to have access to the latest, strongest, most esthetic materials for our patients.

Offering same-visit dentistry to my patients has also helped my practice grow. I began using CEREC effectively, and it became a key part of my business model as I expanded my practice. The whole process can be completed in a single visit. When the restora-tion is milling, you can use that time to interact with the patient, which allows me to create trust with the patient, raise their dental IQ , and build my practice through referrals. Beyond CAD/CAM, I purchased a Dentsply Sirona CBCT unit, the Orthophos XG 3D, for diagnosing purposes. Proper diagnosis is key because if you can’t diagnose correctly, you can’t seat prop-erly. CBCT allowed me to look for pathologies and do implant planning, nerve localization for wisdom teeth, extractions, orthodontics, and periodontics.

What’s most interesting with Dentsply Sirona is that the digital impression we take can be merged with cone beam volume, which is great because it allows us to do implant planning almost in reverse. We decide where the fi nal restoration will go in the patient’s

mouth virtually, we merge that volume with CBCT, and we place that volume where the implant will be placed. What’s special is that this allows us to fabricate a surgical guide that can be made in your offi ce milling chamber. When one uses a surgical guide for implant placement, it’s very precise and allows the procedure to be done in a much shorter period of time.

My advice to other dentists is to accept the fact that technology is our greatest aid. Twenty or 25 years ago, no one had cell phones, but today we wonder how we operated without them. We have to accept the fact that things do evolve for the better and keep an open mind. We need to look at the possibilities, speak to others, do our research, and consider how it can benefi t our patients and us.

DENTALLEARNING.NET DENTAL LEARNING | 17

Find out why Bobby Chagger, DDS, believes that CAD/CAM and CBCT technologies:• Have made a daily impact in his offi ce and enabled his practice to grow• Have helped him place implants with greater accuracy and effi ciency

BOBBYCHAGGER, DDS

Dr. Bobby Chagger obtained a DDS from University of Toronto

in 1996. He later graduated from the Misch International

Implant Institute and studied advanced functional esthet-

ics from the Las Vegas Institute for Advanced Dental

Studies. Dr. Chagger is a CEREC educator,

CEREC software beta tester, and

travels across North America, Asia, and

Europe to work with companies to

understand how new technology is chang-

ing possibilities in dentistry. He has

published articles on CEREC technology

and now trains other dentists in both

basic and advanced dentistry using

CEREC 3D.

EmbracingTechnologyfor Growth GROW YOUR PRACTICE BY HAVING YOURTEAM TRAINED TO USE THE LATEST TOOLSFOR DIGITAL DENTISTRY

peerto

peer

4 STEPS IN A SINGLE VISIT1 Scan: Use the CEREC scanner to take digital

impressions. The entire intraoral cavity, including the maxilla and mandible, can be scanned.

2 Design: The CEREC software generates restora-tion proposals and can connect with Invisalign or other laboratories. The data can also be merged with the CBCT volume for implant planning.

3 Produce: The CEREC grinding and milling unit allows for in-offi ce fabrication of restorations.

4 Sinter & Glaze: Full-contour zirconia restorations are sintered and glazed chairside in the compact CEREC SpeedFire.

W e dentists have to start understanding that our time is the most valuable and expensive asset we have. We tend

to believe that personnel, materials, and supplies are expensive—but when you boil it down, it’s really a matter of time itself being the best return on investment (ROI) in terms of our productivity. This concept should be applied to patients as well; ultimately, we have to value their time more than anything. The average patient takes about 3 hours off work for a dental appointment, so the more times they have to do that, the less productive they are, too.

So many of the intangible things that we just accept as the traditional way of doing dentistry are eliminated with chairside digital dentistry. For example, in the traditional model, patients must return to have indirect restorations placed. The cost of the time involved—from the assistant to the front-offi ce person, setting up an appointment, and then rescheduling if the patient cancels—adds up fast. These are unrealizable costs. When comparing direct costs of single-visit dentistry vs. two-visit restorations, materials come to mind—impression material, provisional material, temporary cement, all with their guns and tips. These things add up. And don’t forget the cost of ordering and maintain-ing the inventory.

It’s easier to focus on the tangible ROI when a res-toration is fabricated in-house. Using Dentsply Sirona’s CEREC system, the average time for an appointment with me is between 60 and 90 minutes for a single tooth restoration. Typically, my assistant takes our pre-liminary digital impression, which includes the bite and the opposing. Prepping the tooth varies in time, de-pending on the case. After isolation, I take a fi nal digital impression. Depending on state law, the dentist can then walk away and move on to other things, such as another patient. A well-trained assistant can do the de-sign and start the milling process, which usually takes 8 to 14 minutes. It takes 5 to 8 minutes to design the restoration, including processing. While the machine is milling the crown, the assistant is free to do other things. When the milling is fi nished, the assistant makes sure it fi ts and polishes it or puts it into an oven, which takes 5 to 16 minutes. At that point, the dentist comes back to deliver it, which can take 5 to 10 minutes when you’re bonding it in. Much of the process can be dele-gated to an assistant, saving the dentist time.

A good example of understanding the value of time is when something needs a remake or adjustments, we don’t have to start the process over again—we can immediately correct it right in the offi ce. For example, if the color is not right, I can literally just click “mill” again and have a different color restoration ready to go, which is a tremendous advantage.

I like knowing that I’m saving myself and all parties involved time and money, while having the satisfaction of creating indirect restorations myself.

The Hidden Costof Your TimeWHEN IT COMES TO THE ROI OF INDIRECTRESTORATIONS, CONSIDER BOTH THE TANGIBLE AND INTANGIBLE COSTS

TARUNAGARWAL, DDS

Dr. Agarwal is a full-time practicing

general dentist who deals with the same issues we all face—overhead, diffi cult patients, ups and downs of private

practice, and team management. Despite

being contracted with insurance, he’s managed to build a successful practice that is focused on

clinical excellence, customer service,

and allowing patients to choose optimal

dentistry. Dedicated to continuing

education, he has studied with many

leaders in the fi eld of dentistry but readily

admits his best learning has come

from the “school of hard knocks.”

Dr. Tarun Agarwal uses a CAD/CAM system to make indirect restorations in-house. He’s found that it saves him, his team, and—just as importantly—his patients time. For Dr. Agarwal, one of the intangible hidden costs of traditional dentistry was just that … time … and he doesn’t miss those days at all.

peerto

peerDENTAL LEARNING

18 DENTAL LEARNING

TANGIBLE COSTS OF INDIRECT CROWNS

Lab Chairside$90-$150 $25-$352–3 visits 1 visit (60–90 min)

1 Is attracting more patients important to your practice?

2 Wouldyourpatientsbenefitfromspendinglesstimeinthe chair?

3 ArePPOsaffectingyourbottomline?

4 Do you need assistance choosing technology solutions?

CEREC Equipment & Blocks now

available through Henry Schein!

Attracting and keeping patients is more important than ever. With Henry Schein

as your trusted advisor and our expanded portfolio of CAD/CAM solutions, your

patients can enjoy an enhanced treatment experience while spending less time

in the dental chair.

You can rely on us to help you seamlessly integrate the right

technology into every step of your workflow with the service

and support needed to improve efficiency and productivity.

Let your Henry Schein Digital Technology Specialist address the specific challenges of your practice—today!

For a demonstration or more information, contact your local Henry Schein Sales Consultant or call 855.801.1124

Expanded Solutions for CAD/CAM Dentistry

For more information contact your local Henry Schein Consultant or call 800-890-8153

Digital solutionsfor happier patientsIntegrating digital technology into every step of your clinical workflow.

Henry Schein ConnectDental,

Henry Schein’s platform for digital dentistry,

combines a wide choice of digital technology

solutions with all the knowledge, service,

and support needed to help practitioners

navigate the rapidly changing world of

digital dentistry.

Helping dentists make patients’ lives better!

As your trusted advisor, you can rely on us to help you

make the technology choices that meet the unique

needs of your practice or laboratory. With Henry Schein

ConnectDental, you get the right technology — seamlessly

integrated into your practice and ongoing support to

continuously operate efficiently and successfully.

• Enhancing the patient experience

• Delivering predictable, quality dentistry

• Improving your efficiency and productivity

Patient Experience Ad_8.5x10.75.indd 1 9/21/17 10:26 AM

![Phase equilibria in the subsystem barium disilicate - … · Phase Equilibria in the Subsystem Barium Disilicate ... cation [8] polymorphism in barium disilicate was an nounced. T](https://static.fdocuments.net/doc/165x107/5b5b4ac67f8b9a302a8da3fa/phase-equilibria-in-the-subsystem-barium-disilicate-phase-equilibria-in-the.jpg)