DEAD LOAD DEFLECTION - okladot.state.ok.us · DEAD LOAD DEFLECTION TYPICAL DIAPHRAGM SPACING ......

Transcript of DEAD LOAD DEFLECTION - okladot.state.ok.us · DEAD LOAD DEFLECTION TYPICAL DIAPHRAGM SPACING ......

1999 SPECIFICATIONS

APPROVED BY BRIDGE ENGINEER:

01E

DATE:

OKLAHOMA DEPT. OF TRANSPORTATION

COUNTY BRIDGE STANDARD ( ENGLISH )

PCB4-2

K3 and H Bars

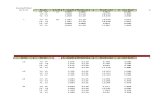

35’ SPAN 40’ SPAN 45’ SPAN 50’ SPAN

DESIGN DATA

12

7

K3

K4

DETAIL OF LIFTING EYE

PLAN

K2

K1

SPAN

"d"

C

C C

C

C

C

C

Diaphragm (Typ.)

C

C

8-S2 #4 @ 6" c/c (Bottom of Beam)

C

C

PLAN

C

ELEVATION - 0 SKEW ELEVATION - 30 SKEW

8-S4 #4 @ 6" c/c (Bottom of Beam)

@ 5" c/c

C

END VIEW

WITH REINFORCING

CENTERLINE SECTION

þÿ�(�1�2�-� ���"� �D�i

END VIEW

WITH REINFORCING

CENTERLINE SECTION

þÿ�(�1�4�-� ���"� �D�i

CENTERLINE SECTION

þÿ�(�2�2�-� ���"� �D�i

END VIEW

WITH REINFORCING

END VIEW

WITH REINFORCING

CENTERLINE SECTION

þÿ�(�1�8�-� ���"� �D�i

OPERATING

RATING

DEAD LOAD

DEFLECTION

TYPICAL DIAPHRAGM SPACING - 30 SKEW

(45’ AND 50’ SPANS ONLY)

DEAD LOAD DEFLECTION

DIAGRAM

End of K2 Bars End of K4 Bars

CL Brng.

NOTE:

@ 6" c/c

@ 6" c/c

@ 5" c/c

@ 6" c/c

@ 6" c/c

C

CL Brng.

(See End View and L Section)C(See End View and L Section)C

2" Dia. open hole for diaph.

rod. (45’ & 50’ Spans only)

"d" @ L Span

(See Table)

þÿ�D�r�a�p�e�d� �s�t�r�a�n�d�s�,� �K�1�,� �K�3�,� �a�n�d� �H� �b�a

of beam. Straight strands shall be cut flush with ends of beam.

K2 and K4 bars shall be set 2" clear from ends of beam.

C

at L BeamC

Dimensions along L BeamC

2" Dia. open hole for diaph.

rod. (45’ & 50’ Spans only)

End of

Beam

(placed as shown)

L1 BARS #4 x 3’-6"

3" Dia.

UL1 BARS #4 x 2’-1"

(L1 #4 bars in pairs & UL1 Bars #4)

(placed as shown)

(placed as shown)

(placed as shown)

(placed as shown)

(placed as shown)

(placed as shown) (placed as shown)

3"

9"

12

12

12

12

S1

S2

S1

S2

12

12

S3

S4

þÿ�1þÿ�1

S4

S3

þÿ�4

1’-4"

11"

þÿ�8

GENERAL NOTES

@ 6" c/c

@ 6" c/c

@ 6" c/c

@ 6" c/c

@ 6" c/c

@ 6" c/c

@ 6" c/c

@ 6" c/c

NOTE: 30 Rt. Fwd. Skew shown.

30 Lt. Fwd. Skew by opposite Hand.

bars in pairs & UL1 Bars #4)

2" 2

"

2" 2

"

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

SECTION THRU BEAM

HS 41

HS 41

HS 41

HS 45

þÿ�3�5�’� � � � � � �

þÿ�4�0�’� � � � � � �

þÿ�4�5�’� � � � � � �

þÿ�5�0�’� � � � � � �

Angle to Suit Lifting Beam

22’-1" (45’ Span) 24’-7" (50’ Span) þÿ�2�2�’�-�0 ��"� �(�4�5�’� �S�p�a�n�)� �

4’-6" (45’ Span) 5’-0" (50’ Span)

Beam Length = 44’-2" (45’ Span), 49’-2" (50’ Span)

4’-6" (45’ Span) 5’-0" (50’ Span)

þÿ�B�e�a�m� �L�e�n�g�t�h� �=� �4�4�’�-�0���"� �(�4�5�’

K3 BARS #4 x 8’-9"

K4 BARS #4 x 8’-3"

K1 BARS #4 x 8’-8"

K2 BARS #4 x 8’-3"

S3 BARS #4 x 2’-5"

S4 BARS #4 x 3’-8"

S1 BARS #4 x 2’-4"

S2 BARS #4 x 3’-6"

K3 BARS #4 x 8’-9"

K4 BARS #4 x 8’-3"

K1 BARS #4 x 8’-8"

þÿ�2

End of beam

End of Draped Strands, K1 and H Bars

8-S1 #4 @ 6" c/c (Top of Beam)

2"

End of beam3 spcs. @ 2" c/c=6" (L1 #4

2" L1 #4 Bars in Pairs & UL1 Bars #4 @ 12" c/c

þÿ�2

8-S1 #4

4-K2 #4

8-S2 #4

þÿ� �

End of beam

þÿ���"� �D�i�a�.� �P�r�e�t�e�

Hold Down Point

3’-6" (35’ Span) 4’-0" (40’ Span)

1’-

4"

Symm. about LRoughened Surface

17’-1" (35’ Span) 19’-7" (40’ Span)

Symm. about L

L Beam

End of Draped Strands,

8-S3 #4 @ 6" c/c (Top of Beam)

þÿ�2 L1 #4 Bars in Pairs & UL1 Bars #4 @ 12" c/c

2"

End of Beam @ L Beam

þÿ�2

þÿ�1�7�’�-�0 ��"� �(�3�5�’� �S�p�a�n�)� �

Symm. about L

L Beam

Symm. about LRoughened Surface

8-S3 #4

4-K4 #4

8-S4 #4

þÿ� � þÿ���"� �D�i�a�.� �P�r�e�t�e�

Hold Down Point

3’-6" (35’ Span) 4’-0" (40’ Span)

1’-

4"

þÿ�B�e�a�m� �L�e�n�g�t�h� �=� �3�4�’�-�0���"� �(�3�5�’

þÿ�8

10"

þÿ�4

1’-6"

þÿ�4

4’-0"

8"

4’-0"

3"

2’-8

"

4" 4"

4"

4"

1’-8

"2"

8-S2 or S4

8-S1 or S3

4"

4"

4" 4"

1" cl.

1" cl.

4"

4"

2"

1’-

8"

8-S1 or S3

8-S2 or S4

4"

4"

6"6"

1" cl.

1" cl.

4"

4"

8-S1 or S3

1’-

10

"

8-S2 or S4

6"

6"

8"8"

2"

1" cl.

1" cl.

4"

4"

1’-

10

"

8-S1 or S3

8-S2 or S4

8" 8"

2"

Beam Length = 34’-2" (35’ Span), 39’-2" (40’ Span)

End of beam at L Beam

Span Length

L Brng. L Brng.

1’-0"

3"3" 6"

6" 6"

1’-6"

6"

6"

1’-3

"

3’-

0"

6"

3"

Twisted Cable

4"

L Span

þÿ�5�’�

L Bridge

Intermediate

1’-

0"

1’-

0"

1’-

0"

1’-

0"

1" cl.

1" cl. þÿ�4

þÿ�2�’�

10"

5"

10"

2-K1 #4

4-K2 #4 2-H #4

2-K1 #4 2-H #4

Sole LP

with studs (see

Std. PCB10-2)

2-K3 #4

4-K4 #4 2-H #4

2-K3 #4 2-H #4

2-K1 or K3 #4

L1 #4 in pairs

4-K

2 o

r K

4

UL1 #4

2-H #4

UL1 #4

2-H #4

2-K1 or K3 #4

L1 #4 in pairs

4-K

2 o

r K

4

#4 @

5"

c/c

=1’-3"

#4 @

5"

c/c

=1’-3"

UL1 #4

2-H #4

2-K1 or K3 #4

4-K

2 o

r K

4

#4 @

5"

c/c

=1’-3"

L1 #4 in pairs

UL1 #4

2-H #4

2-K1 or K3 #4

L1 #4 in pairs

4-K

2 o

r K

4

#4 @

5"

c/c

=1

’-3

"

P.C. BEAM ELEVATIONS AND SECTIONSTYPE II, 32’-9" RDY.

CB-17E

PRESTRESSED CONCRETE BEAMS:

þÿ� � �C�H�A�M�F�E�R� �R�E�Q�U�I�R�E�M�E�N�T�:� � �C�h�a�m�f�e�r� �a�l�l� �

otherwise noted.

FORMS & PALLETS: All beams shall be cast in concrete floored pallets and metal forms.

FINISH: Top of beams to be rough floated. At approximately the time of initial set, entire

top of beam shall be scrubbed transversely with coarse wire brush to remove all laitance and to

produce a roughened surface for bonding slab.

CONCRETE: Concrete for beams shall have a min. 6,000 p.s.i. strength at 28 days.

CEMENT: Type I or III Portland Cement may be used for the Prestressed Concrete Beams.

CYLINDER STRENGTH: At transfer of the tensioning load, the cylinder strength of the

concrete shall be at least 4,500 p.s.i.

HANDLING: In the handling of the beams, they must be maintained in an upright position at

all times and must be picked up from the lifting eye provided at the beam ends. Disregard of

this requirement may lead to collapse of the member.

SPECIFICATIONS FOR STEEL STRANDS: Type 270 K, 7-wire, uncoated, low relaxation

steel strand shall conform to the requirements of AASHTO M203 (ASTM A-416) and

Supplement I.

STRAND: All strands shall be the size and type as shown on the Plans. Initial load per strand

shall be 75% of the breaking strength of the strand for low relaxation strand.

TREATMENT OF CUT STRANDS: All non-draped pretensioning strands shall be cut off

flush with the end of the beam. All cut off strands that will be exposed are to be coated with two

coats of an approved zinc rich paint (minimum 6 mils). Painting to be done by fabricator.

SHOP DRAWINGS: The Contractor shall have his Prestressed Concrete Beam

Fabricator furnish the Bridge Engineer, for his approval, two sets of checked shop

drawings. Shop drawings shall show the casting length center to center of

bearings, and the calculated prestress shortening. One copy shall be returned to

the fabricator with any desired corrections indicated. The fabricator shall then

furnish the Bridge Engineer with as many, generally seven, corrected copies of the

shop drawings as may be required for approval and distribution. The approval

of the shop drawings in no way relieves the Contractor or his fabricator of the

responsibility for mistakes on the shop drawings.

þÿ�T�h�e� �P�r�e�s�t�r�e�s�s�e�d� �C�o�n�c�r�e�t�e� �B�e�a�m�s� �m�a�y� �b�e�

strands rather than the "Draped" strands shown. The New Design and Structural

þÿ�C�a�l�c�u�l�a�t�i�o�n�s� �f�o�r� �"�D�e�b�o�n�d�e�d�"� �a�n�d� �o�r� �"� �s�

a Professional Engineer registered in the State of Oklahoma and submitted to

the Bridge Engineer for approval.

If "Debonded" Strands are used the "U" bars shall extend on additional 4 feet,

toward the middle of the span, just past the point of debonding.

L End Diaphragm

L End Diaphragm

LOADING: HS 20-44

CONCRETE: f’c =6,000 psi

f’ci =4,500 psi

30^

1

1

þÿ�3� �s�p�c�s�.� �@� �2

Revise Bar Spacing 3-23-01