D

Click here to load reader

description

Transcript of D

October 19, 2007 10:58 00035

Biomedical Engineering: Applications, Basis and Communications, Vol. 19, No. 4 (2007) 269–277

DEVELOPMENT OF A PARALLEL SURGICAL ROBOTWITH AUTOMATIC BONE DRILLING CARRIAGE

FOR STEREOTACTIC NEUROSURGERY

Tzung-Cheng Tsai and Yeh-Liang Hsu∗Department of Mechanical Engineering, Yuan Ze University

Chung-Li, Taiwan, ROC∗[email protected]

Accepted 31 July 2007

ABSTRACTRobot-assisted surgery is an active interdisciplinary field. Conventional surgical robots are mostly serial archi-tectures, which have the advantages of large workspace, high dexterity and maneuverability. The disadvantagesare low stiffness and poor positioning accuracy compared to the parallel structure robots.

This paper presents the development of a parallel surgical robot for precise skull drilling in stereotacticneurosurgical operations. The dimensions of this robot are 35×35×45 cm3, and its weight is about 6 kg. Thissurgical robot has 6◦ of freedom. The feed carriage of the bone drilling device mounted the parallel surgicalrobot provides one additional translational degree of freedom. A master-slave microcontroller-based systemis designed for pose control. In applications for neurosurgical operation, the workspace is on the surface of askull located at one side of the robot. This work analyzed asymmetric workspace on the surface of a sphererepresenting the skull. A special socket joint design that enlarges the asymmetric workspace of the robot forabout 30% is also proposed.

This parallel surgical robot has been integrated with an automatic bone drilling carriage developed in ourprevious work to achieve completely automatic bone drilling.

Keywords: Robot-assisted surgery; Parallel robot; Stewart platform; Asymmetric workspace.

INTRODUCTION

In stereotactic neurosurgical operations, surgeons aremost concerned with improving the quality of surgicalprocedures, including accuracy, security, low morbidityand mortality. Surgeons often use a stereotactic framefixed on the patients’ head to set the precise loca-tion for intracranial lesions. However, the use of thiscumbersome frame in the operating room limits theinstrument’s access and has the detriment of phys-ical discomfort and mental stress for the patient.1,2

To overcome the drawbacks of the stereotactic frame,many neurosurgical robot systems have been developed.

Glauser et al.3 addressed conception and procedureof a robot dedicated to neurosurgical operations, andpointed out that if the tools are robotically operated,the surgeon is free to deal with other tasks during theintervention, thus saving operating time and improvingsafety. They mentioned that the drill must not pene-trate beyond 2 mm inside the skull to prevent injur-ing the dura. Bone drilling can be done anywhere ona 12×11 cm surface defined at the top of the head.Basically, the coordinate system of robot includes 5◦

of freedom for bone drilling. They also mentioned thatsurgeons presently work at a precision of about ±1mm.

∗Corresponding author: Professor Yeh-Liang Hsu, Department of Mechanical Engineering, Yuan Ze University, 135, Yuan-Tung Rd, Chung-Li, Taiwan.

269

October 19, 2007 10:58 00035

270 T.-C. Tsai & Y.-L. Hsu

They defined robot accuracy of ±0.1mm for the end-of-probe position.

Liu et al.2 developed a robot-assisted neurosurgerysystem that combines the visualization technology witha powerless 6-joint robot arm to realize frameless stereo-tactic neurosurgery. It provides surgeons with tools tomake the preoperative surgery plan and offers a navi-gator to direct the incisive site and the instrument ori-entation as well as the bore depth during surgery. Thewhole system is capable of accuracy less than 3mm infinding or returning to a preprogrammed target. Fol-lowing this development, Li et al.23 developed a medi-cal parallel robot applicable to chest compression in theprocess of cardiopulmonary resuscitation (CPR). It wasa three-prismatic-universal-universal (3-PUU) transla-tional parallel manipulator (TPM).

In recent years, more effort and attention has beengiven to the development of parallel structure robots.The basic reference for parallel mechanisms is theresearch by Stewart,4 called “Stewart platform.” Var-ious research issues on Stewart platform have beenaddressed in the literature; including its theory, con-struction, and investigation5–8; inverse and forwardkinematic analysis9,10; and workspace definition andanalysis.5,6,11–13

In the past decade, a significant amount of researchhas been done on developing the parallel robotfor different medical applications. Tanikawa et al.14

developed a parallel mechanism on a dexterous micro-manipulation system for use in assembling microma-chines, manipulating biological cells, and performingmicrosurgery. Brandt et al.15 developed a compactrobot “CRIGOS” for image-guided orthopedic surgery.Its modular system was comprised of a compact par-allel robot and a software system for planning surgicalinterventions and for supervision of the robotic device.

Merlet16,17 developed a micro robot called MIPSwith a parallel mechanical architecture having 3◦ offreedom (one for translation and two for orientation)that allows fine positioning of a surgical tool. The pur-pose of MIPS is to act as an active wrist at the tipof an endoscope, providing to the surgeon an accu-rate tool that may further offer a partial force-feedback.Shoham et al.18 developed a parallel manipulator calledthe MiniAture Robot for Surgical procedures (MARS),which was a 5 × 7 cm2 cylinder, weighing 200 g, andwith 6◦ of freedom. This robot can be used in a varietyof surgical procedures requiring precise positioning andorientation of a handheld surgical robot in the vicinityof a rigid bony structure.

Zimmerman et al.24,25 developed the Evolution 1precision robot (Universal Robot Systems Schwerin,

Germany) neurosurgical tool for precise steering ofinstruments with the cranium. The robot systemincluded seven actuated axes (serial robotic arm), auniversal instrument interface, a mobile preposition-ing system including a control computer rack, and atouch operated graphical user interface. It selected ahexapod robot or Stewart platform as the suitablekinematic structure for the operating robot. The sys-tem was used for neuronavigated endoscopic proce-dures for three patients. They addressed that the useof robotic technology for neuroendoscopic procedures isa major advance for controlled movement of the endo-scope within the cranium.

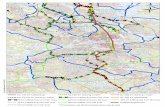

The authors previously developed a modular mecha-tronic system for automatic bone drilling in orthopedicsurgery.19,20 This system is an “add-on” device thatis compatible with commercially available DC motor-driven drills. As shown in Fig. 1, this system has threemodules: the control unit, the feed carriage, and thesupporting arm. The control unit consists of a controlbox and a PC. The control box supplies power to thedrill, and the feed carriage to feed forward in drillingoperation. At the same time, a fuzzy controller ana-lyzes the electric current consumed by the DC motorof the drill. When break-through is detected, the powerwill be cut and stop drilling in order to prevent exces-sive protrusion of the drill bit, then the feed carriagemoves backward to remove the drill from the bone. Inextensive drilling tests on real human skulls using dif-ferent feed rate, there were no unexpected failure, andthe overshoots of all tests were well less than 2mm.

The feed carriage is designed to be a hand tool forthe surgeon to hold with both hands to perform drillingoperations. The feed carriage can also be attached to a

Fig. 1 Modular mechatronic system for automatic bone drilling.

October 19, 2007 10:58 00035

Development of a Parallel Surgical Robot with Automatic Bone Drilling Carriage for Stereotactic Neurosurgery 271

supporting arm that has three joints providing 5◦ offreedom. The supporting arm is a passive device. Thesurgeon can manually move the feed carriage to a givenposition and angle, and tighten the joints by simplyturning a knob. These joints are held solid by hydraulicforce. The arm has an electric magnetic base, used toeliminate vibration and movement.

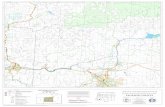

Based on the development of the modular mecha-tronic system for automatic bone drilling, this paperpresents a parallel surgical robot system that uses aStewart platform to replace the passive supporting armof the automatic bone drilling device. The laboratoryprototype is shown in Fig. 2. The dimensions of thisrobot are 35×35×45cm3, and its weight is about 6 kg.The feed carriage of the bone drilling device, which hasone translational degree of freedom, is mounted directlyon the parallel surgical robot.

Section 2 of this paper describes the geometry of theparallel surgical robot, and Sec. 3 describes the designof pose controller of the robot. The functions of thepose controller is also verified. Section 4 investigatesthe asymmetric workspace on the surface of a sphererepresenting the skull. A special socket joint designwhich enlarges the asymmetric workspace of the robotfor about 30% is also proposed.

GEOMETRY OF THE PARALLELSURGICAL ROBOT

The geometry of this parallel surgical robot, illustratedin Fig. 3, is composed of a fixed base, a movable plat-form, and six variable length actuators connecting thefixed base and the movable platform. This is a 6◦ offreedom universal-prismatic-spherical mechanism, andthere is an additional translational degree of freedom atthe automatic bone drilling carriage mounting on theend-effecter of parallel surgical robot. The fixed base

Drill

Simulated skullFeed carriage

Pose controller

Parallel robot

Drill

Simulated skullFeed carriage

Pose controller

Parallel robot

Fig. 2 Parallel surgical robot.

Fig. 3 Schematic diagram of parallel surgical robot.

coordinate system {B} is placed at the base center Ob

with the Z-axis perpendicular to the base plane. Themovable platform coordinate system {P} is located atthe center Op of the moving platform. P1 to P6 (balljoints) and B1 to B6 (universal joints) are the jointpairs attached to the movable platform and the fixedbase. D1D2 represents the feed carriage. D1 is the drilltip of the feed carriage. The link lengths are denoted asL1 to L6.

Figure 4 shows the geometry of the movable platformand the fixed base. The SSM (Symmetric SimplifiedManipulator) geometry21 is used for the joints layout.The positions of the joints are arranged symmetricallyon the fixed base, on a radius Rb circle. The x-axis of{B} bisects the angle B1ObB6. Table 1 lists the actualdimensions. The minimum and maximum value of thelink length of the linear actuators used in the robot aredenoted by lmin and lmax. The rotational angle of a balljoint λ is defined as the angle between the z-axis of themovable platform attached to its socket and the vectoralong the link connected to the joints. The maximumangle of ball joints λmax used in this work is 25◦. Themaximum feed depth f of the feed carriage is 60mm.

DESIGN OF POSE CONTROLLER

In neurosurgery, the surgeon defines a given pose (x,y, z, ψ, θ, φ) for the drill, in which (x, y, z) is the3D position of tip of drill, and (ψ, θ, φ) representsyaw, pitch, roll angles that determine the drilling direc-tion. A set of valid drill pose for the feed carriage canbe obtained after checking the link length and jointangle constraints.22 Using inverse kinematics analysis,

October 19, 2007 10:58 00035

272 T.-C. Tsai & Y.-L. Hsu

(A) movable platform

(B) fixed base

Fig. 4 Geometry of the movable platform and the fixed base.

the pose of movable platform can be expressed by a3 × 3 orientation matrix R and a translation vector qwhich define {P} with respect to {B}. Vectors li con-necting bi (coordinate of the i-th universal joint) to pi

(coordinate of the i-th ball joints) expressed in {B}, aregiven by:

li = Rpi + q − bi (1)

Finally, the link lengths of linear actuators aregiven by:

Li = ‖Rpi + q − bi‖ (2)

Fig. 5 Structure of the pose controller.

Figure 5 shows the structure of the pose controllerof the parallel surgical robot. The PC-based, high-levelcontroller processes the inverse kinematics analysis toobtain the desired lengths of the linear actuators. Thelow-level controller consisting of seven microcontrollerscarries out the fuzzy control algorithm to extend orretract the six linear actuators to the desired lengths. Inthis master-slave structure, the master microcontrolleris used to process commands of actuator lengths fromthe host computer and communicate with each slavemicrocontroller in turn. Inter-integrated circuit (I2C) isused as the communication interface between the micro-controllers. The 8-bit microcontroller PIC is used in thisresearch, with CPU, memory, oscillator, watchdog, andI/O incorporated within the same chip.

Each linear actuator is controlled by a motor driverthat receives control signals from a slave microcon-troller. A displacement transducer with a resolutionof 0.05% (linearity) is attached to each link. A fuzzycontrol algorithm is implemented in the microcon-troller. In many tests with the laboratory prototype,the maximum positioning error for each linear actuatoris less than 0.3mm.

Table 1. Dimensions of the Parallel Surgical Robot.

Rb Rp αb αp lmin lmax λmax D1D2 D2Op f

150mm 100 mm 12◦ 48◦ 333.97mm 483.97mm 25◦ 150 mm 100mm 60mm

October 19, 2007 10:58 00035

Development of a Parallel Surgical Robot with Automatic Bone Drilling Carriage for Stereotactic Neurosurgery 273

A simple experiment was designed to verify the func-tions of the pose controller and the accuracy of the lab-oratory prototype of the parallel surgical robot. In theexperiment, the tip of the drill is moved to nine differ-ent target points, three points in each axis, as listed inTable 2. A 3D digitizer, which is a four-joint passiveserial mechanism, was used to obtain the actual coor-dinates achieved by the tip of the drill. The positionaccuracy of the 3D digitizer itself is 0.23mm. Table 2shows the errors of displacement for the drill tip in eachaxis. The position errors of the target points in x and y

coordinates are significantly larger than that in z coor-dinates. In our observation, the backlash of the jointsin our laboratory prototype causes greater errors in x

and y-axes.The accuracy of orientation of the movable platform

is also examined. Positions of three specified points onthe movable platform are used to calculate the yaw andpitch angle of the movable platform. Table 3 shows theerror in orientation in 16 different target poses.

These experiments verify that the pose controllercan achieve the desired pose correctly, though thelaboratory prototype of the parallel surgical robot obvi-ously needs better engineering work to reduce the back-lash of the joints, so that the accuracy in both positionand orientation can be further improved.

ANALYSIS OF ASYMMETRICWORKSPACE

It is well known that the major drawback of par-allel robots is their more restricted workspace thanserial robots. The workspace analyses of parallel robotshave been widely studied over the past decade. Manyresearchers5,6,11–13 have presented effective algorithmsto determine the various workspaces, which are sym-metric in nature. In our application of skull bonedrilling, the desired workspace is on one side ofthe parallel surgical robot. In particular, the desiredworkspace is on the surface of the skull. Therefore

Table 2. Errors of Displacement for the Drill Tip in Each Axis.

Absolute Errors (mm)

Index Target Points x y z

1 [0, 0, 20] 1.17 0.14 −0.022 [0, 0, 40] −0.95 −0.42 0.273 [0, 0, 60] −1.58 0.22 −0.134 [20, 0, 0] 1.61 0.56 0.195 [40, 0, 0] 0.26 0.10 0.506 [60, 0, 0] 0.74 0.37 0.287 [0, 20, 0] 1.66 −0.89 −0.208 [0, 40, 0] −1.28 1.07 −0.139 [0, 60, 0] 0.10 −0.10 −0.33

Max. error 1.66 1.07 0.50

Table 3. Errors in Orientation for the Movable Platform.

Points Target Poses (x, y, z, Yaw, Pitch) (Yaw and Pitch) Yaw(◦) Pitch(◦)

1

(+40, +40, +50, +5◦, 0◦) (5.13◦, 0.43◦) 0.13◦ 0.43◦(+40, +40, +50, −5◦, 0◦) (−5.02◦, 0.30◦) 0.02◦ 0.30◦(+40, +40, +50, 0◦, +5◦) (0.40◦, 4.90◦) 0.40◦ −0.10◦(+40, +40, +50, 0◦, −5◦) (0.07◦, −5.48◦) 0.07◦ 0.48◦

2

(−40, +40, +50, +5◦, 0◦) (4.87◦, 0.31◦) −0.13◦ 0.31◦(−40, +40, +50, −5◦, 0◦) (−5.31◦, 0.19◦) 0.31◦ 0.19◦(−40, +40, +50, 0◦, +5◦) (0.29◦, 4.79◦) 0.29◦ −0.21◦(−40, +40, +50, 0◦, −5◦) (0.06◦, −5.13◦) 0.06◦ 0.13◦

3

(−40, −40, +50, +5◦, 0◦) (4.40◦, 0.15◦) −0.60◦ 0.15◦(−40, −40, +50, −5◦, 0◦) (−5.14◦, 0.15◦) 0.14◦ 0.15◦(−40, −40, +50, 0◦, +5◦) (0.29◦, 4.67◦) 0.29◦ −0.33◦(−40, −40, +50, 0◦, −5◦) (0.44◦, −5.16◦) 0.44◦ 0.16◦

4

(40, −40, +50, +5◦, 0◦) (4.75◦, 0.34◦) −0.25◦ 0.34◦(40, −40, +50, −5◦, 0◦) (−5.13◦, 0.64◦) 0.13◦ 0.64◦(40, −40, +50, 0◦, +5◦) (0.46◦, 4.57◦) 0.46◦ −0.43◦

(−40, −40, +50, 0◦, −5◦) (0.27◦, −5.59◦) 0.27◦ 0.59◦

October 19, 2007 10:58 00035

274 T.-C. Tsai & Y.-L. Hsu

we hope to investigate how to enlarge the asymmet-ric workspace on the surface of a sphere representingthe skull.

The relative positions of the skull and the robot obvi-ously have significant influence on the workspace. Theconstant orientation workspace is analyzed based on theinterval analysis approach to find the possible locationsthe tip of the drill can reach while the moveable plat-form maintains a fixed orientation, ψ = θ = φ = 0◦,as shown in Fig. 6. This asymmetric workspace pro-vides the range of proper position of the skull. Thetip of drill can approximately reach within the rangeof −30mm∼−280mm in the x-axis, ±140mm in they-axis, and 420mm∼580mm in the z-axis.

Then a simulated skull represented by a sphere withradius of 75mm is used, as shown in Fig. 7. S denotesthe desired drilling point. β is the angle between thefeed direction D1D2 and the z-axis of movable plat-form. It is very important that the tip of the drill D1

reaches S, and the feed direction D1D2 coincides withthe normal vector at S. A 180 × 180 mesh is put onthe sphere. The step size of the mesh projected on thesphere simulating the skull is about 2.18mm2. Kine-matics analysis described in the previous section is usedto check the number of grid points on the sphere thatcan be reached by the tip of the drill with the feeddirection D1D2 coinciding with its normal vector. Thelocation of the center of the simulated skull influences

Fig. 6 Workspace of the tip of drill relative to parallel surgical robot.

October 19, 2007 10:58 00035

Development of a Parallel Surgical Robot with Automatic Bone Drilling Carriage for Stereotactic Neurosurgery 275

Fig. 7 Simulated skull localization.

the number of reachable points. The maximum numberof reachable points is 393 when the center of simulatedskull is at (−300, 0, 440).

In practical applications, the ball joint’s motion isrestricted by the physical construction of the joint,especially by the maximum ball joint angle λmax. λmax

of the ball joints used in this work is 25◦, but initialangles of all ball joints are approximately 15◦ while allsix links are fully retracted. There is only 10◦ in thepositive direction of rotation, which greatly restricts

Fig. 8 Simulation results of different limitations of ball joint angles.

the workspace. This is especially true for links P2 andP5 as shown in Fig. 8, because the P2 and P5 balljoints restrict the tip of the drill from reaching a widerworkspace (the simulated skull) located on the negativex-axis.

To further increase the workspace on the sphere,Fig. 9 shows a special-designed offsetting socket, inwhich the ball joints can be installed along a specificdirection. Using the offsetting socket for P2 and P5 balljoints compensates the ball joint angle from 0◦ ∼ 25◦

to 15◦∼ 40◦. Figure 10 shows the effect of using thisoffsetting socket for the P2 and P5 ball joints. Whenthe center of the simulated skull is at (−300, 0, 440),the number of reachable points increases from 393 to452 using the offsetting socket for P2 and P5 ball joints.The maximum number of reachable grid points is 512,when the center of simulated skull is at (−240, 0, 450).This offsetting socket design enlarges the asymmetricworkspace by approximately 30%. The area of these 512grid points on the sphere is approximately 70×35 mm2.

DISCUSSION AND CONCLUSION

This paper presents the development of a parallel surgi-cal robot for precise skull drilling in stereotactic neuro-surgical operations. We chose a parallel structure robotfor this work due to its advantages in size, weight,low cost, and safety. A master-slave microcontroller-based system is designed for pose control. The majordrawback of parallel robots is their more restrictedworkspace than serial robots. In the applications for

October 19, 2007 10:58 00035

276 T.-C. Tsai & Y.-L. Hsu

Fig. 9 The different of assembly of ball joints.

neurosurgical operation, the workspace is on the sur-face of a skull located at one side of the robot. Thisasymmetric workspace on the surface of a sphere repre-senting the skull is analyzed and a special socket jointdesign which enlarges the asymmetric workspace of therobot for about 30% is also proposed.

Fig. 10 Comparison of different assembly ball joint angle for P2 and P5.

This parallel surgical robot has been integrated withthe automatic bone drilling carriage developed in ourprevious work to achieve completely automatic bonedrilling. The linear actuators of the parallel robotextend to move the tip of the drill to the desired pose.The feed carriage of the drill begins to feed forward tostart drilling operation. The drill should always be nor-mal to the surface of the skull for sensing the electriccurrent consumed by the DC motor of the drill. Theelectric current has a direct relation with the cuttingtorque on the drilled. When break-through is detected,the drill stops, and the feed carriage moves backward toremove the drill from the bone. Finally, the linear actu-ators of the parallel robot retract fully and the robotreturns to its original position, awaiting commands forthe next drilling.

Important aspect of this work is to integrate parallelsurgical robot with an automatic bone drilling carriagedeveloped in our previous work to achieve completely

October 19, 2007 10:58 00035

Development of a Parallel Surgical Robot with Automatic Bone Drilling Carriage for Stereotactic Neurosurgery 277

automatic bone drilling. The functions of the pose con-troller and the accuracy of the laboratory prototype ofthe parallel surgical robot were verified. This labora-tory prototype of the parallel surgical robot obviouslyneeds better engineering work to reduce the backlashof the joints, so that the accuracy in both position andorientation can meet the required precision.

ACKNOWLEDGMENT

The authors wish to thank Dr. Shih-Tseng Lee, Chair-man of Department of Neurosurgery, Chang-GungMemory Hospital and Chang-Gung University, for hisvaluable input throughout this research.

REFERENCES

1. Hemler PF, Koumrian T, Adler J, Guthrie B, A threedimensional guidance system for frameless stereotacticneurosurgery, Computer-Based Medical Systems, ProcFifth Ann IEEE Symp 14–17:309–314, 1992.

2. Da Liu, Tianmiao Wang, Zigang Wang, Zesheng Tang,Zengmin Tian, Jixiang Du, Quanjun Zhao, Study onrobot-assisted minimally invasive neurosurgery and itsclinical application, Robot Autom 2001 Proc 2001 ICRAIEEE Int Conf 2:2008–2013, 2001.

3. Glauser D, Flury P, Villotte N, Burckhardt CW,Conception of a Robot Dedicated to NeurosurgicalOperations, Adv. Robot. 1991. ‘Robots in UnstructuredEnviron’ 91 ICRA, Fifth Int Conf 1:899–904, 1991.

4. Stewart D, A platform with six degrees of freedom, ProcInst Mech Engrs 1(5):371–386, 1965.

5. Fichter EF, A stewart platform-based manipulator:General theory and practical construction, The Int JRobot Res 5(2):157–182, 1986.

6. Merlet, J-P, Parallel Robots, Kluwer Academic Publish-ers, 2000.

7. Yang DCH, Lee TW, Feasibility study of a plat-form type of robotic manipulators from a kinematicsviewpoint, J Mech Transmissions, and Autom Design106(2):191–198, 1984.

8. Tsai L-W, Robot Analysis: The Mechanics of Serial andParallel Manipulators, John Willey & Sons Inc, 1999.

9. Nanua P, Waldron KJ, Murthy V, Direct kinematicsolution of a Stewart platform, Robot Autom IEEETrans 6(4):438–444, 1990.

10. Liu K, Fitzgerald JM, Lewis FL, Kinematic analysisof a Stewart platform manipulator, Indust Electr IEEETrans 40(2):282–293, 1993.

11. Gosselin C, Determination of the workspace of 6-DOF parallel manipulators, J Mech Transmissions, andAutom Design 112(3):331–336, 1990.

12. Gosselin C, Martin Jean, Determination of the work-space of planar parallel manipulators with joint limits,Robot Auto Syst 17:129–138, 1996.

13. Oren Masory, Jian Wang, Workspace evaluation ofStewart platforms, Adv Robot 9(4):443–461, 1995.

14. Tamio Tanikawa, Tatsuo Arai, Development of a micro-manipulation system having a two-fingered micro-hand,IEEE Trans Robot Auto 15(1):152–162, 1999.

15. Brandt G, Zimolong A, Carrat L, Merloz P, StaudteH-W, Lavallee S, Radermacher K, Rau G, CRIGOS:A compact robot for image-guided orthopedic surgery,Inform Technol Biomed IEEE Trans 3(4):252–260,1999.

16. Merlet, J-P, Micro parallel robot MIPS for medicalapplications, Emerging Technology Factory Automa-tion 2001. Proc 2001 8th IEEE Int Conf 2:611–619,2001.

17. Merlet, J-P, Optimal design for the micro parallel robotMIPS, Robotics and Automation 2002. Proc ICRA’ 02,IEEE Int Conf 2:1149–1154, 2002.

18. Shoham M, Burman M, Zehavi E, Joskowicz L, BatkilinEK, Yigal S, Bone-mounted miniature robot for surgi-cal procedures: Concept and clinical applications, IEEETrans Robot Autom 19(5):893–901, 2003.

19. Hsu YL, Lee ST, Lin HW, Development of a modu-lar mechatronic system for automatic bone drilling inorthopedic surgery, Biomed Eng Appl Basis, and Com-mun 13(4):168–174, 2001.

20. Hsu et al., Automatic Bone Drilling Apparatus forSurgery Operation, United States Patent 6,336,931,2002.

21. Merlet, J-P, Determination of 6D workspaces of Gough-Type parallel manipulator and comparison betweendifferent geometries, Int J Robot Res 18(9):902–916,1999.

22. Masory Oren, Jiahua Yan, Measurement of poserepeatability of Stewart platform, J Robot Syst 12(12):821–832, 1995.

23. Li Y, Xu Q, Design and Development of a Medical Par-allel Robot for Cardiopulmonary Resuscitation, Mecha-tronics, IEEE/ASME Trans 12(3):265–273, 2007.

24. Zimmermann M, Krishnan R, Raabe A, Seifert V,Robot-assisted navigated neuroendoscopy, Neuro-surgery 51(6):1446–1451, 2002.

25. Zimmermann M, Krishnan R, Raabe A, Seifert V,Robot-assisted navigated endoscopic ventriculostomy:Implementation of a new technology and first clinicalresults, Acta Neurochir 146(7):697–704, 2004.