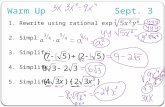

Warm up Simplify: Rewrite and Simplify: a) b). Homework Review.

Cyclor - Simplify wastewater treatment in a compact system

-

Upload

degremont -

Category

Technology

-

view

524 -

download

1

Transcript of Cyclor - Simplify wastewater treatment in a compact system

Cyclor™ACTIVATED SLUDGE BY SEQUENCING BATCH REACTOR

URBAN

WASTEWATER

SIMPLIFY WASTEWATER TREATMENT IN A COMPACT SYSTEM

P-PPT-ER-004-EN-1004

Urban

Wastewater

2

CONTENTS

• Description: the Cyclor™ as part of the treatment system

• Operating principle

• The component parts of the Cyclor™ :

– The patented scoop

– Aeration

– The selector

• The advantages of the Cyclor™

• A few references

• Case study: Issoire, 63, France

• Case study: Sallanches, 73, France

• Case study: Güstrow, Germany

Cyclor™

3

Cyclor™: A CONVENTIONAL TREATMENT WITHIN ONE SINGLE STRUCTURE

INTERMITTENT OPERATION

Biological tank Clarifier

Biological treatment using prolonged aeration in sequential stages:

the Cyclor™

+

CONTINUOUS OPERATION

Urban

Wastewater

4

Treatment stages

SEPARATED IN TIMEnot in space

INTERMITTENT OPERATION

OPERATING PRINCIPLE (1/3)

Cyclor™

Urban

Wastewater

5

The various possible configurations–Cycle duration (4 hours 20 minutes, 6 hours 30 minutes)–Number of cells –Aeration sequencing

Cyclor™

OPERATING PRINCIPLE (2/3)

Nitrification and/or denitrification Denitrification DenitrificationSludge extraction

Cycle duration

AerationAnoxia Anoxia

Time

feed | reaction

Reaction - Feed Decantation65 min

Drainage65 min

MaxLevel

Level

MinimumLevel

Aeration Anoxia Aeration

Urban

Wastewater

6

EXEMPLE DE CYCLE - 4 CELLULES, 4H20

Cyclor™ AN EXAMPLE OF A 4-CELL CYCLE OVER 4 HOURS 20 MINUTES

OPERATING PRINCIPLE (3/3)

Anoxia

Settling65 min

Drainage65 min

HighLevel

Aeration

LowLevel

Fill130 min

Time

Cell 1

Cell 2

Cell 3

Cell 4

7

Cyclor™ - ITS MAIN COMPONENT PARTS

Cyclor™ engineeringThe Cyclor™Biological Reactor

Cell Reactor + selector

• Circular• Rectangular

ScoopTreated water collection system

• Available in 4 sizes

Aeration system

• Floor• Aeration/•Mixer Combination

Treated water collection system

Raw water

Cells

TreatedWater

Urban

Wastewater

8

• A circular weir protected by a scum baffle

• A double locked scoop� Pneumatic locking by injecting air, thus preventing treated water contamination� Hydraulic locking using an automatic valve on the scoop discharge

Fill/Aeration + Decantation

The treated water valve closes

Air is injected → Creating an air blanket

A floating, sealed weir

Drainage

The treated water valve opens

The air blanket is eliminated

The weir is submerged and drainage is controlled

ITS COMPONENT PARTS –

THE PATENTED SCOOP

Cyclor™ ���� The Cyclor™ scoop:

Controlled Drainage

Urban

Wastewater

9

Issoire

Jougne

Pithiviers

Bonnière

Aeration through the floor over the entire surface area of the structure

Use of other aeration systems: OKI type mechanical mixing, INVENT for separating aeration and mixing

Option whereby aeration and mixing are separate

ITS COMPONENT PARTS – AERATION

Cyclor™ ���� Aeration: several

possible systems

Urban

Wastewater

10

A plug flow zone equipped with vertical baffles

•Improved sludge settling capacity by encouraging flocculation to the detriment of filamentous bacteria(High F/M ratio zone)

•Optimized denitrification and biological dephosphatation reactions(Predominant anoxic and anaerobic condition)

Cyclor™���� Perfectly controlled biological

treatment

ITS COMPONENT PARTS –

THE SELECTOR

To be established for each individual case

11

THE Cyclor™ MODULAR OPERATION

– AN EXAMPLE

• Problem caused by a fault• Maintenance required

Transition to Fault mode

in the Programmable Logic Controller

• Cripple mode operation:

100% of the flow accepted 100% of the

time

In the case of a configuration comprising fewer than 2 Cyclor™ cells, a buffer tank will be required for storing part of the flow

Urban

Wastewater

12

THE ADVANTAGES OF THE Cyclor™

Cyclor™ • Compact: eliminates the clarifier(s); Footprint reduced by up to 40% compared with a conventional suspended growth system

• Easy to set up : the architectural integration of the process for low visibility integrated plants design

• Controlled bulking

• Good quality of treated water

• Optimized sludge decantation

• Good operating modularity

• Simple to operate: automatically controlled cycles, simple interface for optimized aeration management

• Low maintenance: no pumping, except in the case of stacked cells

• Loading fluctuation factor ranging from 1 to 4 maximum over a week

13

AMONG THE Cyclor™ REFERENCES (1/2)

PLANT NAME COUNTRYCONTRACT

DATE

COMPLETION

DATEPE

FLOWRATE

in m3/d

NUMBER OF

CELLS

Etar de Pegões Portugal Sept 07 Mar 09 <100

Etar de Gradil Portugal Oct 07 Feb 09 <100

Atuogia Portugal Nov 07 35,000 6,650 4

Castiglion Fibocchi Italy 9,000 3,024 2

Buccine Italy 4,000 900 2

Arezzo, Monte San Savino& Marciano della Chiana

Italy 4,000 900 2

Zambujeira Portugal 25,000 4,750 4

Afonsoeiro Portugal 48,000 11,500 4

Alcochete Portugal 27,750 8,350 4

Etar de Seixalinho Portugal 48,000 14,400 4

Birs Switzerland 150,000 5

Saarwellingen Germany 15,000

Baiyun China 80,000 40,000 4

Gok Reung Korea 3,800 1,600 3

14

PLANT NAME COUNTRYCONTRACT

DATE

COMPLETION

DATEPE

FLOWRATE

in m3/d

NUMBER OF

CELLS

Vallée du Carol France Apr 07 Jun 08 5,800 1

Le Harve, 76 France Apr 07 Dec 09 415,000 8

Les Abrets, 38 France Apr 07 <200

Airvault, 79 France July 07 Sep 08 4,200 2

Severac le château, 12 France Sep 07 Sep 08 5,500 2

Val d’Ambin, 73 France Nov 07 July 08 10,000 2

Montélimar, 26 France Nov 07 Nov 10 90,000

Annot, 04 France Nov 07

Beauvoir sur mer, 85 France Nov 07 <500

Sallanches, 73 France Oct 07 53,000 15,950 4

Noel Cerneaux, 25 France In service 1,200

Noves, 13 France In service 4,000

St Gildas des bois, 22 France In service 3,700 1,300 2

Super Lioran, 15 France In service 7,000 1,500 2

AMONG THE Cyclor™ REFERENCES (2/2)

15

34 000 p.e. wastewater treatment plantIssoireCommissioned February 2008

General principle

•Bar screening

•Pre-treatment(Grit-Grease Remover)

•Cycllllor™ 4 circular Cycllllor™ cells (1800 m3 ,

25 m2 selector) 4 hour 20 minute cycle

•GDD + Centrifugation

STATEMENT – 6 MONTHS

Raw water average(mg/L)

Treated water average(mg/L)

Standard(mg/L)

S.Solids

260 6 (97%) 20 (90%)

COD 560 32 (92%) 75 (90%)

BOD5350 9 (97 %) 90 (90%)

NGL 70 10 ( 84% ) 15 (70%)

Ptot8 2 ( 81%) 2 (85%)

CASE STUDY:ISSOIRE (63), FRANCE

16

53 000 p.e. wastewater treatment plantSallanchesCommissioned October 2007

General Principle

•Bar screening•Pre-treatment (Grit-Grease remover)

•Primary decantation (2 Densadeg 2D 1300 m3/hour)

• Cycllllor™ 4 circular Cycllllor™ cells (500 m3 + 42 m2 selector)4 hour 20 minute cycle

•GDD + Digestion + Centrifugation

Raw water average(mg/L)

Treated water average(mg/L)

Standard (mg/L)

S.Solids

294 19 (93%) 35 (et 90%)

COD 590 42 (93%) 125 (75%)

BOD5 254 14 (94%) 25 (82%)

NGL 47 11 (74%)

Ptot 9 4

CASE STUDY:SALANCHES (73), FRANCE

STATEMENT – 8 MONTHS

17

DESIGN: 60 000 p.e.Qd=9750 m3d, Qpp=1360 m3/hourCommissioned : 2001

Cycllllor™ 4 semi circular cells

4 hour 20 minute cycle

• Cyclazur scoop (7.5 m)

•Cell: 900 m2 ; Hmin: 4.24 m, Hmax : 5.5

•84 m2 (Qr=86m3/hour) selector

•Grav. Thickener + Centrifugation

STATEMENT – 2001-2002 THEN 2005-2006

Raw water average(mg/L)

Treated water average(mg/L)

Standard (mg/L)

S.Solids

430 4 (98%)

COD 860 30 (96%) 90

BOD5415 5 (99%) 10

NTK 56 3 ( 93%)

Ptot14 0.4 (97%) 1

CASE STUDY:GÜSTROW, GERMANY