Curtain Wall Systems JamStud Introduction · Curtain Wall Connections p. 30 Curtain Wall Bridging...

Transcript of Curtain Wall Systems JamStud Introduction · Curtain Wall Connections p. 30 Curtain Wall Bridging...

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com

Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Jan 20111

Curtain Wall Systems JamStud® Introduction

Catalog Contents

JamStud® Nomenclature

JamStud® Background

JamStud® Value p. 2

Design Considerations p. 3-4

Section Properties p. 5-6

Jamb Design Example p. 7-8

Allowable Heights p. 9-16

Curtain Wall Connections p. 30

Curtain Wall Bridging p. 33-34

JamStud® is a revolutionary addition to the light gauge steel stud industry, producing significant economies in both design and installation when compared with conventional “C” Shaped studs. JamStud’s unique configuration delivers increased strength and stiffness, mini-mizing or eliminating the use of built-up jamb and header sections in a curtain wall assembly. Available in all common wall stud depths, JamStud streamlines the design and construction process. JamStud’s shape is easily differentiated from the typical c-shape, enabling the selection of the most optimal member sizes to fit project conditions. ASI’s complimentary Steel Smart System® 5.0 software (page 35) now includes the complete database of sections to quickly design both JamStud header and jamb members.

Benefits That Add Value:

Performance Improvements Increases load capacity over a standard “C-shaped” stud of the same thickness Reduces overall materials used (single “JS” from double or triple “C-Shape” common) Provides a flat surface for attachment of door or window frame (no additional track required) No welding or fastening built-up members togetherWeight Advantages Lighter weight results in easier handling Less weight results in shipping efficiencies

Engineering Advantages: Increased stiffness for deflection Simplified jamb and header design Increased load capacity enables selection of optimal thickness of curtain wall studs JamStud®

JamStud® Header/Sill Design p. 18

Header/Sill Allowable Spans p. 21-29

Header Design Example p. 19-20

OR

A Simple Choice

Copyright © 2009 The Steel Network Inc. All rights reserved. No part of this publication may be reproduced in whole or in part by any method without the prior written consent of The Steel Network, Inc.

Jan 2011Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com 2

Curtain Wall Systems JamStud® Value

14’ Wall Example: 600JS350-54mil JamStud® compared with (2) 600S162-43 and (1) 600T125-43 members. Refer to pages 7-8 for design methodology.

Assembly Comparison

A lighter jambwithout “built-up”materials or labor.

JamStud®

Solution Typical Built-Up Jambs

Jamb Member

Weight Per

Jamb (lbs)

No. of #10 Screws to Top

and Bottom Ends of Stud

No. of #10 Screws to

Attach Built-Up Jamb

(24” o.c.)

Total Number of

#10 Screws @ Each

Jamb

No. of #10 Screws to Stud & Jamb in Each

Two-Opening Assembly Above

Conclusion

600JS350-54, 50ksi

39.32

(To bottom track**)

None 2 8

JamStud® is as strong as the built-up column, but with 80% of the total weight and 26 fewer fasteners to install per jamb. Less materials

to handle and fewer fasteners translate to an increase in the rate of production.

(2) 600S162-43 + one 5’600T125-43

section*

50.44

(To bottom track**)

24* 28* 112**

The back-to-back jamb members require two #10 screws spaced vertically at 24” on center. Built-up jambs require 14 times the amount of screw fasteners for installation purposes as opposed to the JamStud® as-

sembly.

* A flat surface facing the opening is typically required for attachment of the window frame. A 5’ track section has been factored in the properties of the built-up jamb, adding 8 screws for each jamb in the screw total above.** Connection methods for supporting the header and sill, as well as wall bridging, vertical deflection, and jamb tie-downs are not factored in the number of screws to stud as they are similar in each assembly.

The Simple Choice to Increase Your Production

OR

JamStud® Built-Up Jamb

A built-up, multiplemember jamb with

a significant increasein the amount of screw

fasteners used.

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com

Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Jan 20113

Curtain Wall Systems Design Considerations

Tracing and verifying load paths through a structure is crucial to protect design liability. Loads need to migrate from the roof, through the wall and floor systems, and terminate in the foundation. JamStud® transfers out-of plane wind loads from the header and sill to the primary structural system with a single member, simplifying the verification process. Use of a VertiClip® to accommodate vertical deflection will connect the JamStud® web to the structure and provide a positive, verifiable connection path. The optional StiffClip® CL or AL at the base of the wall resists web crippling and delivers an effective load transfer element to the structure. The images below illustrate the simplicity in tracing a verifiable load path in a wall opening. Three examples are given. The example on the left shows slab-to-slab framing, in the middle is a diagram of bypass (balloon) framing, and to the right of that illustrates the loads at a sill and the bottom end of the JamStud®.

Load Paths

Slab to Slab Framing Bypass (Balloon) Framing Sill Framing

The largest arrows in each diagram indicate end reactions at the structure, with the medium-sized arrows signifying the reactions from the header and sill to JamStud®. The smallest arrows point to a uniform wind load. A web stiffener is sometimes required at the top and bottom of the stud and is dependent on the end reactions present. Use of VertiClip® SL at the top and either StiffClip® AL or StiffClip® CL at the bottom satisfy the web stiffener requirements (if needed).

Thermal ValueJamStud® provides an improvement in thermal considerations over built-up sections.

JamStud® reduces the amount of materials usedin the jamb, reducing the thermal bridge

as well as requiring less insulation.

The additional webs in a built-up sectionincreases the area of the thermal bridge. In

addition, insulation is required inside the cavityor cavities created in the built-up section.

(AirFlow)

(AirFlow)

Jan 2011Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com 4

Curtain Wall Systems Design Considerations

Each VertiClip® and DriftClip® is delivered to the installer with step bushings pre-installed for accurate fastener placement. Connection examples shown on this page represent possible application solutions. Connection use is dependant upon project load requirements. Solu-tions are found in The Steel Network’s Light Steel Framing Connection Catalog. Contact

TSN’s Technical Support Team at (888) 474-4876, or [email protected] for design recommendations.

Wall Bridging

Primary Structural DeflectionAll structures deflect vertically. To prevent non-axial-load-bearing studs from carrying the weight of the structure and to protect finishes, vertical deflection connections should be incorporated at the earliest possible moment of project design. The load-carrying capacity of a steel stud in bending is reduced significantly when adding an axial force propagated by the bending of a primary beam or slab. VertiClip® was developed to prevent the crushing effect on non-axial-load-bearing wall studs. Non-axial-load-bearing wall studs include exterior curtain wall and interior wall assemblies. When project conditions dictate, lateral drift and vertical deflection may be accommo-dated through utilization of TSN’s DriftClip® and DriftTrak® lines of connectors.

Finished walls frequently experience cracking, buckling, or crushing due to improper isolation of building movement. The movement of the primary building structure is largely accounted for in horizontal member live loading. In addition to live loads, wind, seismic forces, moisture content in materials, and temperature cycles all contribute to movement. The incorporation of vertical deflection connections during the working drawing phase will eliminate the liability of failures and added costs associated with wall system installation.

The VertiClip and DriftClip series of mechanical connectors is a complete solution for all vertical deflection configurations. Substantial effort has been made to standardize construction practices thus ensuring the positive connections of light steel framing components. VertiClip has undergone extensive field and independent laboratory testing to achieve a true slip connection solution that isolates all sec-ondary frame components from loads induced by vertical movement.

An ICC Evaluation Report for VertiClips (refer to ICC-ESR-1903) and DriftClips (refer to ICC-ESR-2049) at

www.icc-es.org or at www.steelnetwork.com

As axial compression and lateral wind loads are applied, wall studs react with weak axis buckling and torsional rotation. To offset these results, a form of bridging is incorporated into the wall system.

The allowable load capacity of steel studs is dependant upon the presence of securely-attached wall bridging systems at specific vertical intervals (48" or 60" o.c.).

Bridging is typically addressed with either a channel running through the stud punchouts securely fastened to each stud or by flat straps attached to each stud flange.

TSN provides the industry's most effective bridging methods in BridgeClip®, BridgeBar®, and BC600/800.

More bridging information is found on page 33 of this catalog.

Vertical Defl ection and Lateral Drift

Vertical Defl ection

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com

Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Jan 20115

Curtain Wall Systems JamStud® Section Properties

Material Properties: ASTM A1003/A1003M or ASTM A653/A653M, Grade 50 (340), 50ksi (340MPa) minimum yield strength, 65ksi (450 MPa)

minimum tensile strength, G-60 (Z180) hot-dipped galvanized coating.

X

X

Y Y

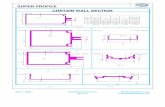

JamStud® Section Dimensions

JamStud® Section (All Studs 50ksi)

OverallDepth

FlangeWidth

ReturnLip 1

ReturnLip 2

InsideBend

Radius

DesignThick-ness

Unit Weight

D B d1 d2 R t(lbs/ft)

(in) (in) (in) (in) (in) (in)

350JS250-33 3.5 2.5 0.589 0.5 0.105 0.0346 1.20350JS250-43 3.5 2.5 0.610 0.5 0.105 0.0451 1.55350JS250-54 3.5 2.5 0.633 0.5 0.105 0.0566 1.94350JS250-68 3.5 2.5 0.663 0.5 0.105 0.0713 2.43350JS250-97 3.5 2.5 0.723 0.5 0.105 0.1017 3.44350JS350-68 3.5 3.5 0.663 0.5 0.105 0.0713 2.92350JS350-97 3.5 3.5 0.723 0.5 0.105 0.1017 4.13

350JS350-118 3.5 3.5 0.768 0.5 0.105 0.1240 5.00362JS250-33 3.625 2.5 0.589 0.5 0.105 0.0346 1.21362JS250-43 3.625 2.5 0.610 0.5 0.105 0.0451 1.57362JS250-54 3.625 2.5 0.633 0.5 0.105 0.0566 1.97362JS250-68 3.625 2.5 0.663 0.5 0.105 0.0713 2.46362JS250-97 3.625 2.5 0.723 0.5 0.105 0.1017 3.48362JS350-68 3.625 3.5 0.663 0.5 0.105 0.0713 2.95362JS350-97 3.625 3.5 0.723 0.5 0.105 0.1017 4.17

362JS350-118 3.625 3.5 0.768 0.5 0.105 0.1240 5.06400JS250-33 4 2.5 0.589 0.5 0.105 0.0346 1.25400JS250-43 4 2.5 0.610 0.5 0.105 0.0451 1.63400JS250-54 4 2.5 0.633 0.5 0.105 0.0566 2.04400JS250-68 4 2.5 0.663 0.5 0.105 0.0713 2.56400JS250-97 4 2.5 0.723 0.5 0.105 0.1017 3.61400JS350-68 4 3.5 0.663 0.5 0.105 0.0713 3.04400JS350-97 4 3.5 0.723 0.5 0.105 0.1017 4.30

400JS350-118 4 3.5 0.768 0.5 0.105 0.1240 5.22

JamStud® Section Dimensions

JamStud® Section (All Studs 50ksi)

OverallDepth

FlangeWidth

ReturnLip 1

ReturnLip 2

InsideBend

Radius

DesignThick-ness

Unit Weight

D B d1 d2 R t(lbs/ft)

(in) (in) (in) (in) (in) (in)

550JS250-33 5.5 2.5 0.589 0.5 0.105 0.0346 1.43550JS250-43 5.5 2.5 0.610 0.5 0.105 0.0451 1.86550JS250-54 5.5 2.5 0.633 0.5 0.105 0.0566 2.33550JS250-68 5.5 2.5 0.663 0.5 0.105 0.0713 2.92550JS250-97 5.5 2.5 0.723 0.5 0.105 0.1017 4.13550JS250-118 5.5 2.5 0.768 0.5 0.105 0.1240 5.00550JS350-68 5.5 3.5 0.663 0.5 0.105 0.0713 3.41550JS350-97 5.5 3.5 0.723 0.5 0.105 0.1017 4.82550JS350-118 5.5 3.5 0.768 0.5 0.105 0.1240 5.85600JS250-33 6 2.5 0.589 0.5 0.105 0.0346 1.49600JS250-43 6 2.5 0.610 0.5 0.105 0.0451 1.94600JS250-54 6 2.5 0.633 0.5 0.105 0.0566 2.42600JS250-68 6 2.5 0.663 0.5 0.105 0.0713 3.04600JS250-97 6 2.5 0.723 0.5 0.105 0.1017 4.30600JS250-118 6 2.5 0.768 0.5 0.105 0.1240 5.22600JS350-68 6 3.5 0.663 0.5 0.105 0.0713 3.53600JS350-97 6 3.5 0.723 0.5 0.105 0.1017 5.00600JS350-118 6 3.5 0.768 0.5 0.105 0.1240 6.06800JS250-43 8 2.5 0.610 0.5 0.105 0.0451 2.24800JS250-54 8 2.5 0.633 0.5 0.105 0.0566 2.81800JS250-68 8 2.5 0.663 0.5 0.105 0.0713 3.53800JS250-97 8 2.5 0.723 0.5 0.105 0.1017 5.00800JS250-118 8 2.5 0.768 0.5 0.105 0.1240 6.06800JS350-68 8 3.5 0.663 0.5 0.105 0.0713 4.01800JS350-97 8 3.5 0.723 0.5 0.105 0.1017 5.69800JS350-118 8 3.5 0.768 0.5 0.105 0.1240 6.90

Important Notes1. Section properties and capacities are calculated in accordance with AISI-NASPEC 2001 with 2004 Supplement2. Tabulated gross properties are based on the full, unreduced cross section of the stud away from punchouts.3. Effective section properties incorporate the strength increase from cold work of forming as applicable per AISI- NASPEC, Sec. A7.2. 4. Net effective section properties are calculated at a cross section through the punchout. 5. For deflection calculations, use the effective moment of inertia Ix & Iy, which are calculated at a stress 0.6 Fy (service load level).

y,

Jan 2011Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com 6

Curtain Wall Systems JamStud® Section PropertiesImportant Notes1. Section properties and capacities are calculated in accordance with AISI-NASPEC 2001 with 2004 Supplement2. Tabulated gross properties are based on the full, unreduced cross section of the stud away from punchouts.3. Effective section properties incorporate the strength increase from cold work of forming as applicable per AISI-NASPEC, Sec. A7.2. 4. Net effective section properties are calculated at a cross section through the punchout. 5. For deflection calculations, use the effective moment of inertia Ix & Iy, which are calculated at a stress 0.6 Fy (service load level).

1 Iy and Mya are based on the web element in tension 2 Iy and Mya are based on the web element in compression

JamStud Section

(All 50 ksi)

Gross Properties (for Un-punched Sections) Effective Properties 50 ksi ("net" = Punched Sections) Effective Properties if limited to 33 ksi Strength

Area Ix Sx Rx Iy Ry Jx103 Cw Ro Xo m

bIx Sx

Sx (net)

MxaMxa (net)

VaVa

(net)Iy1 Mya1 Iy2 Mya2 Ix Mxa

Mxa (net)

(in2) (in4) (in3) (in) (in4) (in) (in4) (in6) (in) (in) (in) (in4) (in3) (in3)(kips-

in)(kips-

in)(lbs) (lbs) (in4)

(kips-in)

(in4)(kips-

in)(in4)

(kips-in)

(kips-in)

350JS250-33 0.351 0.734 0.419 1.445 0.329 0.967 0.140 1.206 3.025 -2.476 1.497 0.330 0.670 0.332 0.307 9.94 9.19 1145 527 0.329 7.98 0.267 5.90 0.700 7.03 6.68350JS250-43 0.456 0.945 0.540 1.439 0.424 0.964 0.309 1.565 3.017 -2.471 1.494 0.329 0.914 0.470 0.450 14.06 13.46 2141 747 0.424 10.67 0.372 8.56 0.945 9.94 9.70350JS250-54 0.571 1.171 0.669 1.432 0.526 0.960 0.609 1.953 3.008 -2.465 1.491 0.329 1.171 0.595 0.578 17.81 17.31 3371 925 0.526 13.68 0.490 11.80 1.171 12.87 12.66350JS250-68 0.715 1.450 0.829 1.424 0.653 0.955 1.212 2.443 2.996 -2.457 1.487 0.328 1.450 0.774 0.759 23.18 22.72 4208 900 0.653 17.58 0.643 16.28 1.450 18.04 17.79350JS250-97 1.010 1.999 1.142 1.406 0.904 0.946 3.483 3.431 2.972 -2.441 1.478 0.325 1.999 1.142 1.126 38.18 37.63 5886 850 0.904 24.45 0.904 27.63 1.999 25.60 25.24350JS350-68 0.858 1.870 1.068 1.476 1.471 1.309 1.454 5.401 3.980 -3.456 2.011 0.246 1.735 0.822 0.796 24.60 23.83 4208 900 1.471 29.02 1.449 25.62 1.849 18.07 17.66350JS350-97 1.214 2.586 1.478 1.460 2.050 1.300 4.184 7.627 3.958 -3.441 2.004 0.244 2.551 1.284 1.256 38.45 37.60 5886 850 2.050 40.60 2.050 43.35 2.586 30.61 30.16

350JS350-118 1.471 3.082 1.761 1.448 2.457 1.293 7.538 9.227 3.941 -3.430 1.998 0.243 3.082 1.675 1.649 50.15 49.38 7073 814 2.457 48.81 2.457 52.48 3.082 37.97 37.48362JS250-33 0.356 0.795 0.438 1.495 0.333 0.968 0.142 1.277 3.031 -2.453 1.487 0.345 0.727 0.348 0.320 10.42 9.59 1102 544 0.333 8.02 0.268 5.91 0.759 7.37 6.97362JS250-43 0.462 1.024 0.565 1.489 0.430 0.964 0.313 1.656 3.023 -2.447 1.484 0.344 0.991 0.492 0.470 14.73 14.06 2141 802 0.430 10.72 0.373 8.59 1.024 10.41 10.14362JS250-54 0.578 1.269 0.700 1.482 0.533 0.961 0.617 2.066 3.014 -2.442 1.481 0.344 1.269 0.623 0.604 18.65 18.09 3372 994 0.533 13.75 0.493 11.86 1.269 13.47 13.27362JS250-68 0.724 1.573 0.868 1.474 0.662 0.956 1.227 2.583 3.002 -2.434 1.477 0.342 1.573 0.810 0.795 24.26 23.80 4375 1007 0.662 17.67 0.647 16.40 1.573 18.89 18.65362JS250-97 1.023 2.169 1.197 1.456 0.916 0.946 3.527 3.625 2.977 -2.418 1.468 0.340 2.169 1.197 1.181 40.01 39.49 6124 954 0.916 24.58 0.916 26.16 2.169 26.83 26.48362JS350-68 0.867 2.023 1.116 1.528 1.491 1.311 1.469 5.715 3.977 -3.430 2.001 0.256 1.877 0.860 0.834 25.74 24.96 4375 1007 1.491 29.18 1.457 25.78 2.001 18.89 18.48362JS350-97 1.226 2.801 1.545 1.511 2.078 1.302 4.228 8.065 3.955 -3.415 1.994 0.254 2.762 1.342 1.314 40.19 39.35 6124 954 2.078 40.83 2.078 40.95 2.801 31.99 31.55

362JS350-118 1.486 3.340 1.843 1.499 2.491 1.295 7.617 9.753 3.938 -3.404 1.988 0.253 3.340 1.752 1.726 52.44 51.69 7363 917 2.491 49.09 2.491 53.57 3.340 39.72 39.24400JS250-33 0.369 0.995 0.497 1.643 0.346 0.969 0.147 1.506 3.055 -2.386 1.458 0.390 0.912 0.398 0.361 11.91 10.80 991 589 0.346 8.14 0.269 5.94 0.951 8.40 7.86400JS250-43 0.479 1.283 0.641 1.637 0.446 0.965 0.325 1.951 3.046 -2.381 1.455 0.389 1.242 0.561 0.530 16.80 15.87 2141 967 0.446 10.88 0.376 8.67 1.283 11.84 11.45400JS250-54 0.599 1.591 0.796 1.630 0.554 0.962 0.640 2.432 3.037 -2.375 1.452 0.388 1.591 0.709 0.683 21.23 20.44 3372 1201 0.554 13.94 0.498 12.01 1.591 15.30 15.05400JS250-68 0.751 1.975 0.987 1.622 0.688 0.957 1.273 3.038 3.025 -2.368 1.448 0.387 1.975 0.921 0.904 27.58 27.06 4876 1360 0.688 17.93 0.657 16.70 1.975 21.49 21.27400JS250-97 1.061 2.730 1.365 1.604 0.953 0.948 3.658 4.255 3.000 -2.352 1.440 0.386 2.730 1.364 1.350 45.60 45.12 6839 1299 0.953 24.95 0.953 27.14 2.730 30.60 30.29400JS350-68 0.894 2.525 1.263 1.681 1.547 1.316 1.514 6.736 3.976 -3.354 1.970 0.288 2.342 0.976 0.945 29.22 28.29 4876 1360 1.547 29.63 1.477 26.20 2.496 21.38 20.98400JS350-97 1.265 3.503 1.751 1.664 2.158 1.306 4.360 9.488 3.953 -3.339 1.963 0.286 3.452 1.521 1.493 45.54 44.71 6839 1299 2.158 41.47 2.158 42.22 3.503 36.21 35.79

400JS350-118 1.533 4.184 2.092 1.652 2.587 1.299 7.855 11.458 3.936 -3.328 1.958 0.285 4.184 1.986 1.962 59.45 58.73 8235 1256 2.587 49.87 2.587 56.85 4.184 45.04 44.60550JS250-33 0.421 2.063 0.750 2.215 0.390 0.962 0.168 2.703 3.239 -2.158 1.356 0.556 1.907 0.574 0.574 17.18 17.18 706 703 0.390 8.48 0.273 6.03 1.980 12.88 12.88550JS250-43 0.547 2.667 0.970 2.209 0.503 0.959 0.371 3.497 3.230 -2.153 1.353 0.556 2.589 0.860 0.860 25.75 25.75 1570 1193 0.503 11.34 0.383 8.86 2.667 18.02 18.02550JS250-54 0.684 3.317 1.206 2.202 0.625 0.956 0.730 4.352 3.221 -2.147 1.350 0.556 3.315 1.083 1.083 32.42 32.42 3117 1875 0.625 14.55 0.511 12.39 3.317 23.18 23.18550JS250-68 0.858 4.129 1.501 2.194 0.776 0.951 1.454 5.423 3.208 -2.139 1.345 0.555 4.129 1.400 1.400 41.93 41.93 5350 2534 0.776 18.71 0.680 17.47 4.129 32.68 32.68550JS250-97 1.214 5.747 2.090 2.176 1.077 0.942 4.184 7.559 3.183 -2.123 1.337 0.555 5.747 2.084 2.084 69.67 69.67 9700 3167 1.077 26.06 1.037 29.40 5.747 46.85 46.85

550JS250-118 1.471 6.881 2.502 2.163 1.285 0.935 7.538 9.058 3.163 -2.111 1.330 0.555 6.881 2.502 2.502 85.21 85.21 11723 3100 1.285 31.21 1.285 38.82 6.881 57.27 57.27550JS350-68 1.001 5.180 1.883 2.275 1.743 1.320 1.696 12.048 4.054 -3.084 1.858 0.421 4.808 1.479 1.479 44.29 44.29 5350 2534 1.743 31.04 1.527 27.26 5.113 32.11 32.11550JS350-97 1.417 7.228 2.629 2.259 2.434 1.311 4.886 16.898 4.029 -3.069 1.851 0.420 7.110 2.289 2.289 68.53 68.53 9700 3167 2.434 43.49 2.339 45.37 7.228 54.23 54.23

550JS350-118 1.719 8.673 3.154 2.246 2.921 1.304 8.809 20.344 4.012 -3.057 1.845 0.419 8.673 2.986 2.986 89.39 89.39 11723 3100 2.921 52.33 2.921 59.76 8.673 67.75 67.75600JS250-33 0.438 2.522 0.841 2.400 0.402 0.958 0.175 3.209 3.326 -2.094 1.325 0.604 2.336 0.628 0.628 18.81 18.81 644 644 0.402 8.57 0.274 6.05 2.422 14.23 14.23600JS250-43 0.569 3.261 1.087 2.394 0.519 0.955 0.386 4.150 3.317 -2.088 1.323 0.604 3.168 0.968 0.968 28.97 28.97 1432 1235 0.519 11.46 0.384 8.90 3.261 20.24 20.24600JS250-54 0.712 4.058 1.353 2.387 0.644 0.951 0.760 5.163 3.307 -2.082 1.319 0.604 4.056 1.217 1.217 36.45 36.45 2843 1942 0.644 14.70 0.513 12.48 4.058 26.01 26.01600JS250-68 0.894 5.055 1.685 2.378 0.801 0.947 1.514 6.431 3.295 -2.074 1.315 0.604 5.055 1.573 1.573 47.09 47.09 5350 2882 0.801 18.91 0.685 17.64 5.055 36.68 36.68600JS250-97 1.265 7.047 2.349 2.361 1.111 0.937 4.360 8.956 3.269 -2.058 1.306 0.604 7.047 2.342 2.342 78.29 78.29 10653 3964 1.111 26.34 1.048 29.89 7.047 52.66 52.66

600JS250-118 1.533 8.447 2.816 2.348 1.327 0.930 7.855 10.726 3.250 -2.045 1.300 0.604 8.447 2.816 2.816 95.89 95.89 12885 3889 1.327 31.56 1.310 39.70 8.447 64.46 64.46600JS350-68 1.036 6.309 2.103 2.467 1.799 1.318 1.756 14.285 4.106 -3.006 1.824 0.464 5.859 1.660 1.660 49.71 49.71 5350 2882 1.799 31.41 1.538 27.49 6.226 35.94 35.94600JS350-97 1.468 8.816 2.939 2.451 2.513 1.308 5.061 20.020 4.081 -2.990 1.817 0.463 8.669 2.563 2.563 76.74 76.74 10653 3964 2.513 44.02 2.365 46.04 8.816 60.62 60.62

600JS350-118 1.781 10.588 3.529 2.438 3.017 1.302 9.127 24.090 4.063 -2.978 1.811 0.463 10.588 3.341 3.341 100.03 100.03 12885 3889 3.017 52.97 2.971 60.99 10.588 75.80 75.80800JS250-43 0.659 6.378 1.595 3.110 0.572 0.931 0.447 7.513 3.746 -1.869 1.217 0.751 6.212 1.300 1.300 38.93 38.93 1060 1060 0.572 11.82 0.389 9.02 6.378 29.62 29.62800JS250-54 0.825 7.949 1.987 3.103 0.710 0.927 0.881 9.340 3.736 -1.862 1.214 0.752 7.942 1.779 1.779 53.27 53.27 2102 2102 0.710 15.16 0.521 12.70 7.949 38.26 38.26800JS250-68 1.036 9.923 2.481 3.095 0.883 0.923 1.756 11.624 3.724 -1.854 1.209 0.752 9.923 2.324 2.324 69.57 69.57 4219 3368 0.883 19.51 0.698 18.08 9.923 54.00 54.00800JS250-97 1.468 13.893 3.473 3.076 1.225 0.914 5.061 16.161 3.698 -1.838 1.200 0.753 13.893 3.459 3.459 115.65 115.65 10885 6032 1.225 27.19 1.079 31.18 13.893 77.87 77.87

800JS250-118 1.781 16.707 4.177 3.063 1.464 0.907 9.127 19.330 3.679 -1.825 1.193 0.754 16.707 4.177 4.177 142.24 142.24 16182 7301 1.464 32.59 1.359 42.05 16.707 95.61 95.61800JS350-68 1.179 12.165 3.041 3.212 1.990 1.299 1.998 25.787 4.413 -2.733 1.703 0.616 11.333 2.448 2.448 73.30 73.30 4219 3368 1.990 32.56 1.565 28.11 12.001 52.51 52.51800JS350-97 1.671 17.065 4.266 3.195 2.782 1.290 5.762 36.082 4.388 -2.717 1.695 0.617 16.771 3.750 3.750 112.28 112.28 10885 6032 2.782 45.66 2.432 47.85 17.065 88.10 88.10

800JS350-118 2.029 20.553 5.138 3.183 3.341 1.283 10.398 43.367 4.370 -2.705 1.689 0.617 20.553 4.870 4.870 145.80 145.80 16182 7301 3.341 54.97 3.083 64.28 20.553 110.33 110.33

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com

Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Jan 20117

Curtain Wall Systems Design Example

Designing JamStud®

1. Basis for Tables:

The JamStud® allowable heights tables in this catalog cover the following basic load combination for the Allowable Stress Design (ASD) Method (IBC2006 and ASCE 7-05):

D + WC&C (Strength determination)

WC&C is the Component and Cladding wind load. The Dead Load (D) acting on the stud is assumed minimumand therefore neglected in the tables.

For the deflection determination, IBC 2003, IBC2006-Sec. 1604.3 and AISI-Wall Stud Design Standard 2004, Sec. B1 allow for a reduction factor of 0.7 on the Component and Cladding wind load (0.7WC&C).

The “JamStud® - Allowable Heights” tables are based on the following assumptions: 4-Way distribution of lateral wind pressure acting on the opening Opening height extends from the floor level to the bottom surface of the header Jamb member supports wind pressure from the opening, wind pressure from half of the distance to the adjacent

stud, and header reaction

The input for the tables includes the JamStud® section, opening width (ft.), opening height (ft.) design wind pressure (WC&C, psf), and specified deflection limit. The output from the tables reflects the allowable JamStud height (ft.-in.) and the controllingdesign factor, whether it is deflection or strength ("f" denotes strength, nothing denotes deflection). An “*” denotes critical web crippling at support of Jamb. The use of stiffening clips at supports typically eliminates the web crippling condition.

2. Design ExampleService (un-factored) Loads:

Wind Pressure (C&C) = 30 psf Wall Width = 6.0” Wall Height = 14.0 ft. Opening Width = 8.0 ft. Opening Height = 10.0 ft Stud Spacing = 16” o.c. Specified Deflection Limit = L/360

Bridging (Lateral Bracing) is recommended at a vertical spacing of 60” o.c. with both JamStud® flanges connected to the sheathing.

Typical Stud: 600S162-43

JamStud® Header

Jan 2011Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com 8

Curtain Wall Systems Design Example

Designing JamStud® Use the Table:Go to the "JamStud® - Allowable Heights" table with a 6.0 in. stud member, 30 psf wind load, L/360 deflection limit, 8.0 ft. opening width, and 10.0 ft opening height. Possible JamStud® selections from the table for 14.0 ft. height are 600JS250-97 (allowable height = 15’ 0”) and 600JS350-68 (allowable height = 14’ 2”). The alternative with typical 43mil “cee” studs results in a built-up section composed of (3) 600S162-43 capped by (2) 600T162-43.

Conclusion:The second JamStud® option, 600JS350-68, is a lighter section with less mil thickness. Use a 600JS350-68 (50ksi) (with design thick-ness = 0.0566” and Fy = 50 ksi). Allow 2 rows of bridging for the wall (including jamb stud) arranged so that the maximum spacing does not exceed 60 in. (5 ft.).

3. Extra Design ConsiderationsStrength determination in the "JamStud® - Allowable Heights" tables includes checks for bending and shear capacity values of the stud and a check for lateral end reaction of the stud for web crippling. If the tables indicate a critical web crippling (denoted with an “*”), you may use a clip at the top and bottom ends of the stud to eliminate the web crippling condition.

4. Design Comparison of Jamb Members

Design CaseTypical

Wall Stud

JamStud®

Solution Typical Built-Up Jamb

Section Shape Section** Shape

WC&C = 30 psfWall Width = 6.0”

Wall Height = 14.0’Opening Width = 6.0’

Opening Height = 10.0’Stud Spacing = 16” o.c.Deflection Limit = L/360

600S162-43 Single 600JS250-68*

(2) Studs 600S162-43*,attached at 24” o.c. max.vertically, capped with a closure Track 600T125-

43 for window frame attachment

WC&C = 20 psfWall Width = 3.625”Wall Height = 10.0’

Opening Width = 8.0’ Opening Height = 8.0’

Stud Spacing = 16” o.c.Deflection Limit = L/600

362S162-43 Single 362JS350-97

(3) Studs 362S162-43 + (1)middle Track 362T125-43,attached at 24” o.c. max.vertically, capped with a closure Track 362T125-

43 for window frame attachment

WC&C = 35 psfWall Width = 8.0”

Wall Height = 16.0’Opening Width = 4.0’

Opening Height = 10.0’Stud Spacing = 24” o.c.Deflection Limit = L/360

800S162-54 Single 800JS250-54*

(2) Studs 800S162-54,attached at 24” o.c. max.vertically, capped with a closure Track 800T125-

43 for window frame attachment

WC&C = 28 psfWall Width = 6.0”

Wall Height = 16.0’Opening Width = 12.0’ Opening Height = 12.0’ Stud Spacing = 16” o.c.Deflection Limit = L/360

600S162-54

Double 600JS350-68* attached at 24” o.c. max. vertically, capped with a closure Track 600T125-

43 for window frame attachment

(4) Studs 600S162-54 + (2)middle Tracks 600T125-54,

attached at 24” o.c. max.vertically, capped with a closure Track 600T125-

43 for window frame attachment

* Web crippling at the ends of the stud is not satisfied per AISI-Wall Stud Design Std. 2004 Sec. C4. Use VertiClip® SL and StiffClip® CL or AL at the top and the bottom ends of the stud, respectively, to eliminate web crippling, or refer to TSN’s Light Steel Framing Members Catalog for web crippling load tables.** The closure track for the window frame attachment was not considered as part of the design cross-section since it does not extend to the full height of the jamb.

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com

Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Jan 20119

Curtain Wall Systems JamStud® Allowable Heights

Important Notes1. No load factor for lateral wind pressure is used for strength determination as per ASD basic load combinations in ASCE 7-05 and IBC 2006.2. A load factor of 0.7 for lateral wind pressure is used for deflection determination as per IBC 2006, Sec. 1604.3 and AISI-Wall Stud Design Std. 2004, Sec. B1 (Except for 5 psf lateral pressure where 1.0 load factor is used).3. If wind reduction factor for deflection determination is not allowed by a specific building code, multiply table values not denoted by "f" by 85% to calculate the proper JS allowable height. Table values denoted by "f" are controlled by strength and should not be reduced.4. "f" denotes limiting wall height is controlled by strength. All other heights are controlled by deflection. 5. "*" denotes critical web crippling at support of Jamb based on AISI-Wall Stud Design Std. 2004 Sec. C4. Use of stiffening clips at supports eliminate the web crippling condition.6. Limiting heights are based on continuous support of each flange over the full length of the stud.7. Strength determination includes checks for bending and shear capacity values of the stud through punched section.8. Values for multi-span and load bearing conditions are available. Contact TSN's Technical Support Team for recommendations.

Jam

Stu

d

Me

mb

er

Op

en

ing

W

idth

(ft

)

Op

en

ing

H

eig

ht

(ft) Wind Pressure (PSF) And Deflection Limits

5 psf 15 psf 20 psf 25 psf 30 psf 40 psf

L/120 L/240 L/360 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600

36

2JS

25

0-3

3, 5

0ks

i 46 21' 7" 16' 4" 13' 11" 12' 4" 10' 7" 8' 11" 11' 0" f 9' 7" 8' 1" 9' 11" f * 8' 11" 7' 7" 9' 1" f * 8' 5" * 7' 1" 7' 11" f * 7' 8" * 6' 6" *8 20' 4" 15' 7" 13' 6" 11' 11" 10' 5" 8' 9" 10' 10" * 9' 5" 9' 9" f * 8' 9" * 8' 11" f * 8' 3" *

68 18' 2" 14' 1" 12' 3" 11' 0" 9' 8" 8' 4" * 9' 10" f * 8' 10" * 8' 11" f * 8' 4" * 8' 2" f *

10 17' 8" 13' 11" 12' 3" 11' 0" *

88 16' 7" f 13' 1" 11' 6" 10' 5" f * 9' 4" * 8' 2" * 9' 3" f * 8' 8" * 8' 6" f * 8' 2" * 8' 0" f *

10 16' 5" 13' 1" 11' 7" 10' 5" f *12 16' 4" 13' 1"

108 15' 1" f 12' 5" 11' 1" 10' 0" f * 9' 1" * 8' 1" * 9' 0" f * 8' 6" * 8' 5" f * 8' 1" * 8' 0" f *

10 15' 6" 12' 7" 11' 4" 10' 2" f *12 15' 7" 12' 9"

36

2JS

25

0-4

3, 5

0ks

i 46 24' 5" 18' 6" 15' 9" 13' 10" 11' 10" 9' 11" 12' 5" 10' 8" 9' 0" 11' 5" 9' 11" 8' 4" 10' 8" 9' 4" 7' 10" 9' 6" f 8' 5" 7' 2"8 23' 0" 17' 6" 15' 1" 13' 4" 11' 7" 9' 9" 12' 1" 10' 6" 8' 10" 11' 2" 9' 9" 8' 2" 10' 6" 9' 2" 9' 4" f * 8' 4" *

68 20' 6" 15' 9" 13' 7" 12' 2" 10' 8" 9' 1" 11' 1" 9' 9" 8' 4" 10' 4" 9' 1" 9' 8" f * 8' 7" * 8' 7" f *

10 19' 9" 15' 6" 13' 6" 12' 1" 10' 8" 11' 1" 10' 4" *

88 18' 9" 14' 7" 12' 8" 11' 5" 10' 2" 8' 10" 10' 6" 9' 4" 8' 2" * 9' 10" * 8' 10" * 9' 2" f * 8' 5" * 8' 3" f *

10 18' 3" 14' 5" 12' 9" 11' 6" 10' 3" 10' 7" *12 18' 1" 14' 5" 12' 9"

108 17' 6" 13' 9" 12' 1" 11' 0" 9' 10" 8' 8" 10' 2" * 9' 2" * 8' 2" * 9' 6" f * 8' 8" * 9' 0" f * 8' 4" * 8' 2" f *

10 17' 2" 13' 10" 12' 3" 11' 3" * 10' 1" * 10' 5" *12 17' 1" 13' 11" 12' 5"

36

2JS

25

0-5

4, 5

0ks

i 46 27' 0" 20' 5" 17' 4" 15' 2" 13' 0" 10' 10" 13' 7" 11' 8" 9' 9" 12' 6" 10' 10" 9' 1" 11' 8" 10' 2" 8' 6" 10' 7" 9' 2" 7' 9"8 25' 5" 19' 4" 16' 6" 14' 7" 12' 7" 10' 7" 13' 2" 11' 5" 9' 7" 12' 2" 10' 7" 8' 11" 11' 5" 9' 11" 8' 4" 10' 4" 9' 0"

68 22' 7" 17' 3" 14' 10" 13' 2" 11' 6" 9' 10" 12' 0" 10' 6" 9' 0" 11' 2" 9' 10" 8' 5" 10' 6" 9' 3" 8' 0" 9' 7" f 8' 6"

10 21' 8" 16' 10" 14' 8" 13' 1" 11' 6" 12' 0" 10' 6" 11' 2" 10' 6"

88 20' 8" 15' 11" 13' 9" 12' 4" 10' 11" 9' 5" 11' 3" 10' 0" 8' 9" 10' 7" 9' 5" 8' 3" 10' 0" 9' 0" 9' 1" f * 8' 4" *

10 19' 11" 15' 8" 13' 9" 12' 5" 11' 0" 11' 4" 10' 1" 10' 8" 10' 1" *12 19' 8" 15' 7" 13' 9" 12' 5"

108 19' 3" 14' 11" 13' 1" 11' 9" 10' 6" 9' 3" 10' 10" 9' 9" 8' 7" 10' 3" 9' 3" 8' 2" 9' 9" f * 8' 10"* 8' 10" f* 8' 3" *

10 18' 9" 14' 11" 13' 2" 12' 0" 10' 9" 11' 1" 10' 0" 10' 6" * 10' 0" f *12 18' 6" 14' 11" 13' 3" 12' 1"

36

2JS

25

0-6

8, 5

0ks

i 46 29' 6" 22' 3" 18' 11" 16' 6" 14' 1" 11' 8" 14' 9" 12' 8" 10' 6" 13' 7" 11' 8" 9' 9" 12' 8" 10' 11" 9' 2" 11' 5" 9' 10" 8' 4"8 27' 8" 21' 0" 17' 11" 15' 9" 13' 7" 11' 4" 14' 2" 12' 3" 10' 4" 13' 1" 11' 4" 9' 7" 12' 3" 10' 8" 9' 0" 11' 1" 9' 8" 8' 2"

68 24' 8" 18' 9" 16' 1" 14' 3" 12' 5" 10' 6" 12' 10" 11' 3" 9' 7" 11' 11" 10' 6" 9' 0" 11' 3" 9' 11" 8' 6" 10' 3" 9' 1"

10 23' 7" 18' 2" 15' 9" 14' 1" 12' 4" 10' 6" 12' 10" 11' 3" 11' 11" 10' 6" 11' 3" 10' 3"

88 22' 6" 17' 2" 14' 10" 13' 3" 11' 8" 10' 0" 12' 1" 10' 8" 9' 3" 11' 3" 10' 0" 8' 9" 10' 8" 9' 6" 8' 4" 9' 10" 8' 10"

10 21' 7" 16' 10" 14' 8" 13' 3" 11' 8" 10' 1" 12' 1" 10' 9" 11' 4" 10' 1" 10' 9"12 21' 2" 16' 9" 14' 8" 13' 3" 12' 2"

108 20' 11" 16' 1" 14' 0" 12' 7" 11' 2" 9' 9" 11' 6" 10' 4" 9' 1" 10' 10" 9' 9" 8' 7" 10' 4" 9' 3" 8' 3" 9' 7" 8' 8"

10 20' 2" 15' 11" 14' 0" 12' 9" 11' 5" 10' 0" 11' 9" 10' 7" 11' 1" 10' 0" 10' 7"12 19' 11" 15' 11" 14' 1" 12' 10"

Jan 2011Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com 10

Curtain Wall Systems JamStud® Allowable Heights

Important Notes1. No load factor for lateral wind pressure is used for strength determination as per ASD basic load combinations in ASCE 7-05 and IBC 2006.2. A load factor of 0.7 for lateral wind pressure is used for deflection determination as per IBC 2006, Sec. 1604.3 and AISI-Wall Stud Design Std. 2004, Sec. B1 (Except for 5 psf lateral pressure where 1.0 load factor is used).3. If wind reduction factor for deflection determination is not allowed by a specific building code, multiply table values not denoted by "f" by 85% to calculate the proper JS allowable height. Table values denoted by "f" are controlled by strength and should not be reduced.4. "f" denotes limiting wall height is controlled by strength. All other heights are controlled by deflection. 5. "*" denotes critical web crippling at support of Jamb based on AISI-Wall Stud Design Std. 2004 Sec. C4. Use of stiffening clips at supports eliminate the web crippling condition.6. Limiting heights are based on continuous support of each flange over the full length of the stud.7. Strength determination includes checks for bending and shear capacity values of the stud through punched section.8. Values for multi-span and load bearing conditions are available. Contact TSN's Technical Support Team for recommendations.

Jam

Stu

d

Me

mb

er

Op

en

ing

W

idth

(ft

)

Op

en

ing

H

eig

ht

(ft) Wind Pressure (PSF) And Deflection Limits

5 psf 15 psf 20 psf 25 psf 30 psf 40 psf

L/120 L/240 L/360 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600

36

2JS

25

0-9

7, 5

0ks

i 46 33' 7" 25' 4" 21' 6" 18' 9" 16' 0" 13' 2" 16' 9" 14' 4" 11' 10" 15' 4" 13' 2" 10' 11" 14' 4" 12' 3" 10' 3" 12' 10" 11' 1" 9' 3"

8 31' 7" 23' 10" 20' 4" 17' 10" 15' 4" 12' 9" 16' 0" 13' 9" 11' 6" 14' 9" 12' 9" 10' 8" 13' 9" 11' 11" 10' 0" 12' 5" 10' 10" 9' 1"

68 28' 2" 21' 3" 18' 1" 16' 0" 13' 10" 11' 7" 14' 5" 12' 6" 10' 7" 13' 4" 11' 7" 9' 11" 12' 6" 11' 0" 9' 4" 11' 5" 10' 0" 8' 7"

10 26' 9" 20' 5" 17' 8" 15' 8" 13' 8" 11' 7" 14' 3" 12' 6" 10' 7" 13' 3" 11' 7" 12' 6" 11' 0" 11' 5" 10' 0"

88 25' 9" 19' 5" 16' 8" 14' 9" 12' 10" 11' 0" 13' 5" 11' 9" 10' 1" 12' 5" 11' 0" 9' 6" 11' 9" 10' 5" 9' 0" 10' 9" 9' 7" 8' 5"

10 24' 6" 18' 10" 16' 4" 14' 8" 12' 11" 11' 1" 13' 4" 11' 10" 10' 2" 12' 6" 11' 1" 11' 10" 10' 6" 10' 10"

12 23' 9" 18' 7" 16' 3" 14' 7" 12' 11" 13' 5" 12' 6"

108 23' 10" 18' 1" 15' 7" 13' 11" 12' 3" 10' 7" 12' 8" 11' 3" 9' 10" 11' 10" 10' 7" 9' 3" 11' 3" 10' 1" 8' 11" 10' 5" 9' 4" 8' 4"

10 22' 10" 17' 9" 15' 6" 14' 0" 12' 5" 10' 10" 12' 10" 11' 6" 10' 1" 12' 1" 10' 10" 11' 6" 10' 4" 10' 8"

12 22' 3" 17' 7" 15' 6" 14' 1" 12' 6" 12' 11" 12' 2"

36

2JS

35

0-6

8, 5

0ks

i 46 31' 8" 23' 11" 20' 4" 17' 9" 15' 1" 12' 5" 15' 10" 13' 6" 11' 2" 14' 6" 12' 5" 10' 4" 13' 6" 11' 8" 9' 9" 12' 2" 10' 6" 8' 10"

8 29' 9" 22' 6" 19' 2" 16' 10" 14' 6" 12' 1" 15' 2" 13' 1" 10' 11" 14' 0" 12' 1" 10' 2" 13' 1" 11' 4" 9' 6" 11' 10" 10' 3" 8' 8"

68 26' 6" 20' 1" 17' 2" 15' 2" 13' 2" 11' 1" 13' 8" 11' 11" 10' 2" 12' 8" 11' 1" 9' 6" 11' 11" 10' 6" 8' 11" 10' 10" 9' 7" 8' "

10 25' 3" 19' 5" 16' 9" 14' 11" 13' 1" 11' 1" 13' 7" 11' 11" 10' 2" 12' 7" 11' 1" 11' 11" 10' 6" 10' 10"

88 24' 3" 18' 4" 15' 10" 14' 0" 12' 3" 10' 6" 12' 9" 11' 3" 9' 8" 11' 11" 10' 6" 9' 2" 11' 3" 10' 0" 8' 8" 10' 4" f 9' 3" 8' 1"

10 23' 1" 17' 11" 15' 7" 14' 0" 12' 4" 10' 7" 12' 9" 11' 4" 11' 11" 10' 7" 11' 4" 10' 1" 10' 4" f

12 22' 6" 17' 9" 15' 6" 14' 0" 12' 4" 12' 10" 12' 0"

108 22' 6" 17' 2" 14' 10" 13' 3" 11' 9" 10' 2" 12' 2" 10' 10" 9' 5" 11' 4" 10' 2" 8' 11" 10' 10" 9' 8" 8' 7" 9' 11" f 9' 1" 8' 1"

10 21' 7" 16' 10" 14' 10" 13' 5" 11' 11" 10' 5" 12' 4" 11' 1" 11' 7" 10' 5" 11' 1" 10' 0" 10' 1" f *

12 21' 2" 16' 10" 14' 10" 13' 6" 12' 0" 12' 5"

36

2JS

35

0-9

7, 5

0ks

i 46 37' 0" 28' 0" 23' 9" 20' 8" 17' 7" 14' 5" 18' 5" 15' 9" 12' 11" 16' 11" 14' 5" 11' 11" 15' 9" 13' 5" 11' 2" 14' 1" 12' 1" 10' 1"

8 34' 10" 26' 3" 22' 4" 19' 7" 16' 9" 13' 10" 17' 6" 15' 0" 12' 6" 16' 1" 13' 10" 11' 7" 15' 0" 13' 0" 10' 10" 13' 7" 11' 9" 9' 10"

68 31' 2" 23' 5" 19' 11" 17' 6" 15' 0" 12' 7" 15' 8" 13' 7" 11' 5" 14' 6" 12' 7" 10' 8" 13' 7" 11' 10" 10' 1" 12' 4" 10' 10" 9' 3"

10 29' 6" 22' 5" 19' 3" 17' 1" 14' 10" 12' 7" 15' 5" 13' 6" 11' 5" 14' 4" 12' 7" 10' 8" 13' 6" 11' 10" 10' 1" 12' 3" 10' 10"

88 28' 5" 21' 5" 18' 3" 16' 1" 13' 11" 11' 10" 14' 6" 12' 8" 10' 10" 13' 6" 11' 10" 10' 2" 12' 8" 11' 2" 9' 8" 11' 7" 10' 3" 8' 11"

10 26' 11" 20' 7" 17' 9" 15' 10" 13' 11" 11' 10" 14' 5" 12' 8" 10' 11" 13' 5" 11' 10" 10' 3" 12' 8" 11' 3" 11' 8" 10' 4"

12 26' 0" 20' 3" 17' 7" 15' 9" 13' 11" 14' 5" 12' 9" 13' 5" 12' 9"

108 26' 5" 19' 11" 17' 1" 15' 1" 13' 2" 11' 4" 13' 9" 12' 1" 10' 5" 12' 9" 11' 4" 9' 10" 12' 1" 10' 9" 9' 5" 11' 1" 9' 11" 8' 9"

10 25' 1" 19' 3" 16' 9" 15' 1" 13' 4" 11' 7" 13' 9" 12' 3" 10' 9" 12' 11" 11' 7" 10' 2" 12' 3" 11' 0" 10' 9" f 10' 3"

12 24' 4" 19' 1" 16' 9" 15' 1" 13' 5" 13' 10" 12' 4" 13' 0" 12' 4"

36

2JS

35

0-1

18

, 50

ksi

46 39' 11" 30' 2" 25' 7" 22' 4" 19' 0" 15' 6" 19' 11" 16' 11" 13' 10" 18' 2" 15' 6" 12' 9" 16' 11" 14' 5" 11' 11" 15' 1" 12' 11" 10' 9"

8 37' 7" 28' 5" 24' 1" 21' 1" 18' 0" 14' 10" 18' 10" 16' 2" 13' 5" 17' 3" 14' 10" 12' 4" 16' 2" 13' 11" 11' 7" 14' 6" 12' 7" 10' 6"

68 33' 9" 25' 3" 21' 5" 18' 9" 16' 1" 13' 5" 16' 10" 14' 6" 12' 2" 15' 6" 13' 5" 11' 4" 14' 6" 12' 7" 10' 8" 13' 2" 11' 6" 9' 9"

10 31' 11" 24' 2" 20' 8" 18' 3" 15' 10" 13' 4" 16' 6" 14' 4" 12' 2" 15' 3" 13' 4" 11' 4" 14' 4" 12' 7" 10' 8" 13' 1" 11' 6"

88 30' 10" 23' 1" 19' 8" 17' 3" 14' 11" 12' 7" 15' 6" 13' 6" 11' 6" 14' 4" 12' 7" 10' 9" 13' 6" 11' 10" 10' 2" 12' 4" 10' 10" 9' 5"

10 29' 1" 22' 1" 19' 0" 16' 11" 14' 9" 12' 7" 15' 4" 13' 6" 11' 6" 14' 3" 12' 7" 10' 10" 13' 6" 11' 11" 10' 3" 10' 9" f 10' 9" f

12 28' 0" 21' 7" 18' 9" 16' 9" 14' 9" 12' 7" 15' 4" 13' 6" 14' 3" 12' 7" 13' 6" 12' 4"

108 28' 7" 21' 5" 18' 4" 16' 2" 14' 1" 11' 11" 14' 7" 12' 10" 11' 0" 13' 7" 11' 11" 10' 4" 12' 10" 11' 4" 9' 10" 10' 4" f 10' 4" f 9' 2"

10 27' 0" 20' 8" 17' 11" 16' 0" 14' 1" 12' 2" 14' 7" 12' 11" 11' 3" 13' 8" 12' 2" 10' 7" 12' 11" 11' 7" 10' 2" 10' 9" f 10' 9" f

12 26' 1" 20' 4" 17' 9" 16' 0" 14' 2" 12' 3" 14' 8" 13' 0" 13' 9" 12' 3" 12' 9" f 12' 0"

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com

Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Jan 201111

Curtain Wall Systems JamStud® Allowable Heights

Important Notes1. No load factor for lateral wind pressure is used for strength determination as per ASD basic load combinations in ASCE 7-05 and IBC 2006.2. A load factor of 0.7 for lateral wind pressure is used for deflection determination as per IBC 2006, Sec. 1604.3 and AISI-Wall Stud Design Std. 2004, Sec. B1 (Except for 5 psf lateral pressure where 1.0 load factor is used).3. If wind reduction factor for deflection determination is not allowed by a specific building code, multiply table values not denoted by "f" by 85% to calculate the proper JS allowable height. Table values denoted by "f" are controlled by strength and should not be reduced.4. "f" denotes limiting wall height is controlled by strength. All other heights are controlled by deflection. 5. "*" denotes critical web crippling at support of Jamb based on AISI-Wall Stud Design Std. 2004 Sec. C4. Use of stiffening clips at supports eliminate the web crippling condition.6. Limiting heights are based on continuous support of each flange over the full length of the stud.7. Strength determination includes checks for bending and shear capacity values of the stud through punched section.8. Values for multi-span and load bearing conditions are available. Contact TSN's Technical Support Team for recommendations.

Jam

Stu

d

Me

mb

er

Op

en

ing

W

idth

(ft

)

Op

en

ing

H

eig

ht

(ft) Wind Pressure (PSF) And Deflection Limits

5 psf 15 psf 20 psf 25 psf 30 psf 40 psf

L/120 L/240 L/360 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600

40

0JS

25

0-3

3, 5

0ks

i 46 23' 8" 17' 11" 15' 3" 13' 5" 11' 6" 9' 7" 11' 7" f * 10' 5" 8' 9" 10' 5" f * 9' 7" * 8' 1" 9' 8" f * 9' 1" * 7' 8" * 8' 5" f * 8' 3" * 7' 0" *

8 22' 3" 17' 0" 14' 7" 12' 11" * 11' 3" 9' 5" 11' 7" f * 10' 2" * 8' 7" 10' 4" f * 9' 5" * 8' 0" * 9' 5" f * 8' 11" * 8' 2" f * 8' 1" *

68 19' 10" 15' 3" 13' 3" 11' 10" f * 10' 5" 8' 11" 10' 4" f * 9' 6" * 8' 2" * 9' 4" f * 8' 11" * 8' 8" f * 8' 5" *

10 19' 2" 15' 0" 13' 2" 11' 10" f * 10' 5" * 10' 4" f *

88 17' 8" f 14' 2" 12' 4" 10' 11" f * 9' 11" * 8' 8" * 9' 9" f * 9' 2" * 8' 0" * 8' 11" f * 8' 8" * 8' 4" f * 8' 3" *

10 17' 8" f 14' 1" 12' 5" 11' 0" f * 10' 0" *

12 17' 7" 14' 1" 12' 5"

108 16' 0" f 13' 4" 11' 10" 10' 5" f * 9' 8" * 8' 6" * 9' 5" f * 9' 0" * 8' 0" * 8' 9" f * 8' 6" * 8' 3" f * 8' 2" *

10 16' 4" f 13' 6" 12' 0" 10' 8" f *

12 16' 8" 13' 7" 12' 1"

40

0JS

25

0-5

4, 5

0ks

i 46 29' 7" 22' 4" 19' 0" 16' 7" 14' 2" 11' 9" 14' 10" 12' 9" 10' 7" 13' 7" 11' 9" 9' 9" 12' 9" 11' 0" 9' 2" 11' 4" f 9' 11" 8' 4"

8 27' 10" 21' 1" 18' 0" 15' 10" 13' 8" 11' 5" 14' 3" 12' 4" 10' 4" 13' 2" 11' 5" 9' 7" 12' 4" 10' 9" 9' 0" 11' 2" 9' 9" 8' 2"

68 24' 9" 18' 10" 16' 1" 14' 3" 12' 5" 10' 6" 12' 11" 11' 4" 9' 8" 12' 0" 10' 6" 9' 0" 11' 4" 9' 11" 8' 6" 10' 1" f 9' 1"

10 23' 8" 18' 3" 15' 10" 14' 2" 12' 5" 10' 6" 12' 10" 11' 4" 12' 0" 10' 6" 11' 4" 10' 1" f *

88 22' 8" 17' 3" 14' 11" 13' 3" 11' 8" 10' 0" 12' 1" 10' 8" 9' 3" 11' 4" 10' 0" 8' 9" 10' 8" f 9' 6" 8' 4" 9' 6" f * 8' 10" *

10 21' 8" 16' 11" 14' 9" 13' 3" 11' 9" 10' 1" 12' 2" 10' 9" 11' 4" 10' 1" 10' 9" f *

12 21' 3" 16' 9" 14' 9" 13' 3" 12' 2"

108 21' 0" 16' 2" 14' 1" 12' 7" 11' 2" 9' 9" 11' 7" 10' 4" 9' 1" 10' 10" f 9' 9" 8' 7" 10' 2" f * 9' 4" * 8' 3" * 9' 3" f * 8' 8" *

10 20' 4" 16' 0" 14' 1" 12' 9" 11' 5" 10' 0" 11' 9" 10' 7" 11' 1" * 10' 0" * 10' 5" f *

12 20' 0" 16' 0" 14' 2" 12' 10"

40

0JS

25

0-9

7, 5

0ks

i 46 36' 10" 27' 10" 23' 7" 20' 7" 17' 6" 14' 4" 18' 4" 15' 8" 12' 10" 16' 10" 14' 4" 11' 10" 15' 8" 13' 5" 11' 1" 14' 0" 12' 0" 10' 0"

8 34' 8" 26' 2" 22' 3" 19' 6" 16' 8" 13' 10" 17' 5" 15' 0" 12' 6" 16' 0" 13' 10" 11' 6" 15' 0" 12' 11" 10' 10" 13' 6" 11' 8" 9' 10"

68 31' 0" 23' 3" 19' 10" 17' 5" 15' 0" 12' 7" 15' 8" 13' 6" 11' 5" 14' 5" 12' 7" 10' 7" 13' 6" 11' 10" 10' 0" 12' 3" 10' 9" 9' 2"

10 29' 5" 22' 4" 19' 2" 17' 0" 14' 9" 12' 6" 15' 5" 13' 5" 11' 5" 14' 3" 12' 6" 10' 8" 13' 5" 11' 10" 10' 1" 12' 3" 10' 9"

88 28' 4" 21' 3" 18' 2" 16' 0" 13' 11" 11' 9" 14' 6" 12' 8" 10' 10" 13' 5" 11' 9" 10' 1" 12' 8" 11' 2" 9' 7" 11' 7" 10' 3" 8' 11"

10 26' 10" 20' 6" 17' 8" 15' 9" 13' 10" 11' 10" 14' 4" 12' 8" 10' 11" 13' 5" 11' 10" 10' 2" 12' 8" 11' 3" 11' 7" 10' 4"

12 25' 11" 20' 2" 17' 7" 15' 9" 13' 10" 14' 4" 12' 8" 13' 5" 12' 8"

108 26' 3" 19' 10" 17' 0" 15' 1" 13' 2" 11' 3" 13' 8" 12' 0" 10' 5" 12' 9" 11' 3" 9' 10" 12' 0" 10' 9" 9' 5" 11' 1" 9' 11" 8' 9"

10 24' 11" 19' 2" 16' 8" 15' 0" 13' 3" 11' 6" 13' 9" 12' 3" 10' 8" 12' 10" 11' 6" 10' 1" 12' 3" 11' 0" 11' 4" 10' 2"

12 24' 2" 19' 0" 16' 8" 15' 0" 13' 4" 13' 10" 12' 4" 13' 0" 12' 4"

40

0JS

35

0-6

8, 5

0ks

i 46 34' 7" 26' 2" 22' 2" 19' 5" 16' 6" 13' 6" 17' 3" 14' 9" 12' 2" 15' 10" 13' 6" 11' 2" 14' 9" 12' 7" 10' 6" 13' 2" 11' 4" 9' 6"

8 32' 7" 24' 7" 20' 11" 18' 4" 15' 9" 13' 1" 16' 5" 14' 2" 11' 10" 15' 2" 13' 1" 10' 11" 14' 2" 12' 3" 10' 3" 12' 9" 11' 1" 9' 4"

68 29' 1" 21' 11" 18' 8" 16' 5" 14' 2" 11' 11" 14' 9" 12' 10" 10' 10" 13' 8" 11' 11" 10' 2" 12' 10" 11' 3" 9' 7" 11' 8" 10' 3" 8' 9"

10 27' 7" 21' 1" 18' 2" 16' 1" 14' 1" 11' 11" 14' 7" 12' 9" 10' 10" 13' 7" 11' 11" 10' 2" 12' 9" 11' 3" 11' 8" 10' 3"

88 26' 7" 20' 0" 17' 2" 15' 2" 13' 2" 11' 3" 13' 9" 12' 0" 10' 4" 12' 9" 11' 3" 9' 8" 12' 0" 10' 8" 9' 3" 10' 10" f 9' 10" 8' 7"

10 25' 3" 19' 4" 16' 9" 15' 0" 13' 2" 11' 4" 13' 8" 12' 1" 10' 5" 12' 9" 11' 4" 12' 1" 10' 9" 10' 11" f

12 24' 5" 19' 1" 16' 8" 15' 0" 13' 3" 13' 8" 12' 1" 12' 10" 12' 1"

108 24' 8" 18' 8" 16' 1" 14' 3" 12' 6" 10' 10" 13' 0" 11' 6" 10' 0" 12' 2" f 10' 10" 9' 5" 11' 5" f 10' 3" 9' 0" 10' 4" f 9' 7" 8' 6"

10 23' 6" 18' 2" 15' 11" 14' 4" 12' 8" 11' 1" 13' 2" 11' 9" 10' 3" 12' 4" 11' 1" 11' 9" 10' 7" 10' 7" f *

12 22' 11" 18' 1" 15' 11" 14' 4" 12' 10" 13' 3" 12' 5"

Jan 2011Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com 12

Curtain Wall Systems JamStud® Allowable Heights

Important Notes1. No load factor for lateral wind pressure is used for strength determination as per ASD basic load combinations in ASCE 7-05 and IBC 2006.2. A load factor of 0.7 for lateral wind pressure is used for deflection determination as per IBC 2006, Sec. 1604.3 and AISI-Wall Stud Design Std. 2004, Sec. B1 (Except for 5 psf lateral pressure where 1.0 load factor is used).3. If wind reduction factor for deflection determination is not allowed by a specific building code, multiply table values not denoted by "f" by 85% to calculate the proper JS allowable height. Table values denoted by "f" are controlled by strength and should not be reduced.4. "f" denotes limiting wall height is controlled by strength. All other heights are controlled by deflection. 5. "*" denotes critical web crippling at support of Jamb based on AISI-Wall Stud Design Std. 2004 Sec. C4. Use of stiffening clips at supports eliminate the web crippling condition.6. Limiting heights are based on continuous support of each flange over the full length of the stud.7. Strength determination includes checks for bending and shear capacity values of the stud through punched section.8. Values for multi-span and load bearing conditions are available. Contact TSN's Technical Support Team for recommendations.

Jam

Stu

d

Me

mb

er

Op

en

ing

W

idth

(ft

)

Op

en

ing

H

eig

ht

(ft) Wind Pressure (PSF) And Deflection Limits

5 psf 15 psf 20 psf 25 psf 30 psf 40 psf

L/120 L/240 L/360 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600

40

0JS

35

0-1

18

, 50

ksi

46 43' 8" 33' 1" 28' 1" 24' 6" 20' 9" 16' 11" 21' 10" 18' 6" 15' 2" 19' 11" 16' 11" 13' 11" 18' 6" 15' 9" 13' 0" 16' 6" 14' 1" 11' 8"

8 41' 2" 31' 1" 26' 5" 23' 1" 19' 8" 16' 2" 20' 7" 17' 7" 14' 6" 18' 10" 16' 2" 13' 5" 17' 7" 15' 1" 12' 7" 15' 9" 13' 7" 11' 4"

68 37' 1" 27' 9" 23' 6" 20' 6" 17' 6" 14' 6" 18' 4" 15' 9" 13' 2" 16' 10" 14' 6" 12' 2" 15' 9" 13' 8" 11' 6" 14' 2" 12' 4" 10' 6"

10 35' 0" 26' 5" 22' 6" 19' 10" 17' 1" 14' 4" 17' 10" 15' 6" 13' 1" 16' 6" 14' 4" 12' 2" 15' 6" 13' 6" 11' 6" 14' 1" 12' 4" 10' 6"

88 33' 11" 25' 4" 21' 6" 18' 10" 16' 2" 13' 6" 16' 10" 14' 7" 12' 4" 15' 6" 13' 6" 11' 6" 14' 7" 12' 9" 10' 10" 13' 3" 11' 7" 10' 0"

10 31' 11" 24' 1" 20' 8" 18' 3" 15' 11" 13' 6" 16' 6" 14' 6" 12' 4" 15' 4" 13' 6" 11' 7" 14' 6" 12' 9" 10' 11" 13' 2" 11' 8" 10' 1"

12 30' 8" 23' 5" 20' 3" 18' 1" 15' 10" 13' 6" 16' 5" 14' 6" 12' 4" 15' 4" 13' 6" 14' 6" 12' 9" 13' 3"

108 31' 6" 23' 6" 20' 0" 17' 7" 15' 2" 12' 10" 15' 10" 13' 9" 11' 9" 14' 7" 12' 10" 11' 0" 13' 9" 12' 1" 10' 6" 12' 7" 11' 2" 9' 9"

10 29' 8" 22' 6" 19' 4" 17' 3" 15' 1" 12' 11" 15' 8" 13' 10" 11' 11" 14' 7" 12' 11" 11' 3" 13' 10" 12' 4" 10' 9" 12' 9" 11' 5" 10' 0"

12 28' 6" 22' 0" 19' 1" 17' 2" 15' 2" 13' 1" 15' 8" 13' 11" 12' 0" 14' 8" 13' 1" 13' 11" 12' 5" 12' 9" f

60

0JS

25

0-3

3, 5

0ks

i 46 34' 7" 26' 2" 22' 2" 18' 7" f * 16' 6" * 13' 6" * 15' 6" f * 14' 9" * 12' 2" * 13' 7" f * 13' 6" * 11' 2" * 12' 3" f * 12' 3" f* 10' 6" * 10' 5" f * 10' 5" f * 9' 6" *

8 32' 6" 24' 7" 20' 11" 17' 7" f * 15' 9" * 13' 1" * 15' 1" f * 14' 2" * 11' 10"* 13' 6" f * 13' 1" * 10' 11"* 12' 5" f * 12' 3" * 10' 3" * 10' 10" f * 10' 10" f* 9' 4" *

68 28' 10"f* 21' 10" 18' 8" 14' 9" f * 14' 2" * 11' 11"* 12' 10" f * 12' 10"f* 10' 10"* 11' 7" f * 11' 7" f* 10' 1" * 10' 8" f * 10' 8" f* 9' 7" * 9' 2" f * 9' 2" f * 8' 9" *

10 26' 11" f 21' 0" 18' 1" 15' 3" f * 14' 0" * 11' 11"* 13' 5" f * 12' 9" * 10' 10"* 12' 1" f * 11' 11" * 10' 2" * 11' 1" f * 11' 1" f*

88 24' 4" f * 20' 0" 17' 1" 13' 1" f * 13' 1" f* 11' 3" * 11' 6" f * 11' 6" f * 10' 4" * 10' 5" f * 10' 5" f* 9' 8" * 9' 5" f * 9' 5" f * 9' 3" * 8' 0" f * 8' 0" f * 8' 0" f*

10 23' 3" f 19' 4" 16' 9" 13' 10" f* 13' 2" * 11' 4" * 12' 4" f * 12' 1" * 10' 5" * 11' 2" f * 11' 2" f* 10' 0" f * 10' 0" f*

12 22' 11" f 19' 1" 16' 8" 14' 0" f * 13' 2" * 12' 4" f * 12' 1" *

108 21' 6" f * 18' 8" 16' 0" 12' 0" f * 12' 0" f* 10' 9" * 10' 6" f * 10' 6" f * 10' 0" * 9' 4" f * 9' 4" f * 9' 4" f * 8' 0" f * 8' 0" f * 8' 0" f * 8' 0" f * 8' 0" f * 8' 0" f*

10 20' 10" f 18' 2" 15' 10" 12' 10" f* 12' 8" * 11' 1" * 11' 4" f * 11' 4" f * 10' 3" * 10' 0" f * 10' 0" f* 10' 0" f * 10' 0" f*

12 20' 11" f 18' 1" 15' 11" 13' 3" f * 12' 9" *

60

0JS

25

0-4

3, 5

0ks

i 46 39' 1" 29' 7" 25' 1" 21' 11" * 18' 7" 15' 2" 19' 6" * 16' 7" 13' 7" 17' 10" f * 15' 2" * 12' 6" 15' 11" f * 14' 2" * 11' 8" * 13' 5" f * 12' 8" * 10' 7"*

8 36' 10" 27' 9" 23' 7" 20' 8" * 17' 8" 14' 7" 18' 5" * 15' 10" * 13' 2" 16' 11" f * 14' 7" * 12' 2" * 15' 5" f * 13' 8" * 11' 5" * 13' 5" f * 12' 4" * 10' 4"*

68 33' 0" 24' 9" 21' 0" 18' 5" * 15' 10" 13' 2" 16' 1" f * 14' 3" * 12' 0" 14' 5" f * 13' 2" * 11' 2" 13' 3" f * 12' 5" * 10' 6" * 11' 9" f * 11' 3" * 9' 7" *

10 31' 3" 23' 8" 20' 3" 17' 11" * 15' 7" 13' 1" 16' 2" * 14' 1" * 11' 11" 14' 10" f * 13' 1" * 11' 2" * 13' 7" f * 12' 4" * 10' 6" * 11' 10" f * 11' 3" *

88 30' 2" 22' 7" 19' 3" 16' 6" f * 14' 7" 12' 4" 14' 3" f * 13' 3" * 11' 3" 12' 11" f * 12' 4" * 10' 7" * 12' 0" f * 11' 8" * 10' 0" * 10' 9" f * 10' 8" * 9' 3" *

10 28' 6" 21' 8" 18' 8" 16' 7" * 14' 6" 12' 4" 14' 11" f * 13' 3" * 11' 4" * 13' 6" f * 12' 4" * 10' 8" * 12' 6" f * 11' 9" * 10' 1" * 11' 0" f * 10' 9" *

12 27' 5" 21' 3" 18' 5" 16' 6" * 14' 6" * 12' 5" * 15' 0" f * 13' 3" * 13' 6" f * 12' 5" * 12' 6" f *

108 27' 11" 21' 0" 17' 11" 14' 11" f* 13' 10"* 11' 9" 13' 1" f * 12' 7" * 10' 10"* 11' 11" f * 11' 9" * 10' 2" * 11' 1" f * 11' 1" f* 9' 9" * 10' 1" f * 10' 1" f * 9' 1" *

10 26' 6" 20' 3" 17' 7" 15' 5" f * 13' 10"* 12' 0" * 13' 11" f * 12' 9" * 11' 1" * 12' 10" f * 12' 0" * 10' 6" * 11' 11" f * 11' 5" * 10' 0" * 10' 8" f * 10' 7" *

12 25' 7" 20' 0" 17' 6" 15' 9" * 13' 11" * 12' 1" * 14' 1" f * 12' 10" * 12' 10" f * 12' 1" *

60

0JS

25

0-5

4, 5

0ks

i 46 43' 1" 32' 8" 27' 9" 24' 2" 20' 6" 16' 9" 21' 6" 18' 3" 14' 11" 19' 8" 16' 9" 13' 9" 18' 3" * 15' 7" 12' 10" 15' 5" f * 13' 11" * 11' 6"

8 40' 8" 30' 8" 26' 1" 22' 9" 19' 5" 16' 0" 20' 4" 17' 4" 14' 4" 18' 8" 16' 0" 13' 3" 17' 4" * 14' 11" 12' 5" 15' 0" f * 13' 5" * 11' 3"

68 36' 7" 27' 5" 23' 2" 20' 3" 17' 4" 14' 4" 18' 2" 15' 7" 13' 0" 16' 2" f * 14' 4" 12' 1" 14'10" f* 13' 6" 11' 4" 13' 1" f * 12' 3" * 10' 5"

10 34' 7" 26' 1" 22' 3" 19' 7" 16' 11" 14' 3" 17' 8" 15' 4" 12' 11" 16' 4" * 14' 3" 12' 1" 15' 2" f * 13' 5" 11' 4" 13' 2" f * 12' 2" * 10'5"*

88 33' 6" 25' 0" 21' 2" 18' 7" 16' 0" 13' 4" 16' 1" f 14' 5" 12' 2" 14' 5" f * 13' 4" 11' 4" 13' 4" f * 12' 7" * 10' 9" 11' 11" f * 11' 6" * 9' 11"

10 31' 7" 23' 10" 20' 5" 18' 1" 15' 9" 13' 4" 16' 4" 14' 4" 12' 3" 15' 0" f * 13' 4" 11' 5" 13'10" f* 12' 7" * 10'10"* 12' 2" f * 11' 7" * 10'0"*

12 30' 3" 23' 2" 20' 1" 17' 11" 15' 8" 13' 4" 16' 3" 14' 4" 12' 3" * 15' 0" f * 13' 4" * 13'10" f* 12' 8" * 12' 2" f *

108 31' 1" 23' 3" 19' 9" 16' 10" f 15' 0" 12' 8" 14' 7" f 13' 7" 11' 8" 13' 3" f * 12' 8" 10' 11" 12' 4" f * 12' 0" * 10' 5" * 11' 2" f * 11' 0" * 9' 8" *

10 29' 3" 22' 3" 19' 2" 17' 0" f 14' 11" 12' 10" 15' 3" f 13' 8" 11' 10" 14' 0" f * 12'10"* 11' 2" * 13' 1" f * 12' 2" * 10' 8" * 11' 8" f * 11' 3" *

12 28' 2" 21' 9" 18' 11" 17' 0" 15' 0" 12' 11" 15' 6" * 13' 9" * 14' 2" f * 12'11"* 13' 1" f * 12' 3" *

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com

Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Jan 201113

Curtain Wall Systems JamStud® Allowable Heights

Important Notes1. No load factor for lateral wind pressure is used for strength determination as per ASD basic load combinations in ASCE 7-05 and IBC 2006.2. A load factor of 0.7 for lateral wind pressure is used for deflection determination as per IBC 2006, Sec. 1604.3 and AISI-Wall Stud Design Std. 2004, Sec. B1 (Except for 5 psf lateral pressure where 1.0 load factor is used).3. If wind reduction factor for deflection determination is not allowed by a specific building code, multiply table values not denoted by "f" by 85% to calculate the proper JS allowable height. Table values denoted by "f" are controlled by strength and should not be reduced.4. "f" denotes limiting wall height is controlled by strength. All other heights are controlled by deflection. 5. "*" denotes critical web crippling at support of Jamb based on AISI-Wall Stud Design Std. 2004 Sec. C4. Use of stiffening clips at supports eliminate the web crippling condition.6. Limiting heights are based on continuous support of each flange over the full length of the stud.7. Strength determination includes checks for bending and shear capacity values of the stud through punched section.8. Values for multi-span and load bearing conditions are available. Contact TSN's Technical Support Team for recommendations.

Jam

Stu

d

Me

mb

er

Op

en

ing

W

idth

(ft

)

Op

en

ing

H

eig

ht

(ft) Wind Pressure (PSF) And Deflection Limits

5 psf 15 psf 20 psf 25 psf 30 psf 40 psf

L/120 L/240 L/360 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600

60

0JS

25

0-6

8, 5

0ks

i 46 47' 0" 35' 8" 30' 4" 26' 5" 22' 5" 18' 3" 23' 6" 20' 0" 16' 4" 21' 6" 18' 3" 14'11" 20' 0" 17' 0" 13' 11" 17' 10" 15' 2" 12' 6"

8 44' 5" 33' 7" 28' 6" 24' 10" 21' 2" 17' 4" 22' 2" 18' 11" 15' 7" 20' 4" 17' 4" 14' 4" 18' 11" 16' 2" 13' 5" 16' 11" 14' 7" 12' 2"

68 40' 1" 30' 0" 25' 5" 22' 2" 18' 10" 15' 7" 19' 9" 16' 11" 14' 0" 18' 1" 15' 7" 13' 0" 16' 10" f 14' 7" 12' 3" 14' 7" f 13' 2" 11' 2"

10 37' 11" 28' 6" 24' 3" 21' 3" 18' 4" 15' 4" 19' 1" 16' 6" 13' 11" 17' 8" 15' 4" 12'11" 16' 6" 14' 5" 12' 2" 14' 11" f 13' 1" 11' 2"

88 36' 9" 27' 5" 23' 2" 20' 3" 17' 4" 14' 5" 18' 1" 15' 7" 13' 1" 16' 4" f 14' 5" 12' 2" 14' 11" f 13' 6" 11' 6" 13' 2" f 12' 4" 10' 7"

10 34' 7" 26' 0" 22' 2" 19' 7" 16' 11" 14' 4" 17' 8" 15' 5" 13' 1" 16' 4" 14' 4" 12' 3" 15' 5" 13' 6" 11' 7" 13' 7" f * 12' 4" 10' 8" *

12 33' 1" 25' 2" 21' 8" 19' 3" 16' 10" 14' 4" 17' 6" 15' 4" 13' 1" 16' 3" 14' 4" 12' 3" 15' 4" 13' 6" 13' 7" f * 12' 5" *

108 34' 2" 25' 5" 21' 6" 18' 10" 16' 3" 13' 7" 16' 7" f 14' 8" 12' 5" 14' 10" f 13' 7" 11' 7" 13' 8" f 12' 10" 11' 0" 12' 3" f 11' 9" 10' 2"

10 32' 1" 24' 2" 20' 9" 18' 4" 16' 0" 13' 8" 16' 8" 14' 8" 12' 7" 15' 5" f 13' 8" 11'10" 14' 5" f 13' 0" 11' 3" 12' 11" f * 12' 0" * 10' 6" *

12 30' 8" 23' 6" 20' 5" 18' 3" 16' 0" 13' 9" 16' 7" 14' 8" 12' 8" 15' 6" 13' 9" 14' 7" f * 13' 1" * 12' 11" f * 12' 1" *

60

0JS

25

0-9

7, 5

0ks

i 46 53' 7" 40' 9" 34' 8" 30' 3" 25' 8" 20' 11" 26' 11" 22' 10" 18' 7" 24' 7" 20' 11" 17' 0" 22' 10" 19' 5" 15' 10" 20' 4" 17' 4" 14' 2"

8 50' 9" 38' 5" 32' 7" 28' 5" 24' 2" 19' 9" 25' 4" 21' 6" 17' 8" 23' 2" 19' 9" 16' 3" 21' 6" 18' 5" 15' 2" 19' 3" 16' 6" 13' 8"

68 46' 1" 34' 6" 29' 1" 25' 4" 21' 6" 17' 7" 22' 6" 19' 2" 15' 10" 20' 7" 17' 7" 14' 7" 19' 2" 16' 5" 13' 8" 17' 2" 14' 10" 12' 5"

10 43' 6" 32' 7" 27' 8" 24' 2" 20' 8" 17' 2" 21' 8" 18' 7" 15' 7" 19' 11" 17' 2" 14' 5" 18' 7" 16' 1" 13' 7" 16' 10" 14' 7" 12' 4"

88 42' 4" 31' 6" 26' 7" 23' 2" 19' 8" 16' 2" 20' 7" 17' 7" 14' 8" 18' 11" 16' 2" 13' 7" 17' 7" 15' 2" 12' 9" 15' 10" 13' 9" 11' 8"

10 39' 10" 29' 9" 25' 3" 22' 2" 19' 0" 15' 11" 19' 11" 17' 2" 14' 6" 18' 4" 15' 11" 13' 6" 17' 2" 15' 0" 12' 9" 15' 7" 13' 8" 11' 9"

12 37' 11" 28' 7" 24' 6" 21' 8" 18' 10" 15' 11" 19' 7" 17' 1" 14' 6" 18' 2" 15' 11" 13' 6" 17' 1" 15' 0" 12' 10" 15' 7" 13' 9"

108 39' 5" 29' 3" 24' 8" 21' 6" 18' 4" 15' 3" 19' 2" 16' 6" 13' 10" 17' 7" 15' 3" 12'10" 16' 6" 14' 4" 12' 2" 14' 11" 13' 0" 11' 2"

10 36' 11" 27' 8" 23' 6" 20' 8" 17' 11" 15' 2" 18' 8" 16' 3" 13' 10" 17' 3" 15' 2" 13' 0" 16' 3" 14' 4" 12' 4" 14' 10" 13' 2" 11' 5"

12 35' 2" 26' 8" 22' 11" 20' 4" 17' 9" 15' 2" 18' 6" 16' 3" 13' 11" 17' 2" 15' 2" 13' 1" 16' 3" 14' 5" 12' 5" 14' 11" 13' 3"

60

0JS

25

0-1

18

, 50

ksi

46 57' 5" 43' 9" 37' 3" 32' 7" 27' 8" 22' 6" 29' 0" 24' 7" 20' 0" 26' 6" 22' 6" 18' 3" 24' 7" 20' 10" 17' 0" 21' 11" 18' 7" 15' 2"

8 54' 7" 41' 4" 35' 1" 30' 7" 26' 0" 21' 2" 27' 3" 23' 2" 18' 11" 24' 11" 21' 2" 17' 4" 23' 2" 19' 9" 16' 3" 20' 8" 17' 8" 14' 7"

68 49' 8" 37' 2" 31' 5" 27' 4" 23' 1" 18' 10" 24' 3" 20' 7" 16' 11" 22' 2" 18' 10" 15' 7" 20' 7" 17' 7" 14' 7" 18' 5" 15' 10" 13' 2"

10 46' 11" 35' 2" 29' 9" 26' 0" 22' 2" 18' 4" 23' 2" 19' 11" 16' 7" 21' 3" 18' 4" 15' 4" 19' 11" 17' 2" 14' 5" 17' 11" 15' 7" 13' 1"

88 45' 9" 34' 1" 28' 8" 24' 11" 21' 2" 17' 4" 22' 2" 18' 10" 15' 7" 20' 3" 17' 4" 14' 5" 18' 10" 16' 2" 13' 7" 16' 11" 14' 7" 12' 4"

10 43' 0" 32' 1" 27' 2" 23' 9" 20' 4" 16' 11" 21' 3" 18' 4" 15' 5" 19' 7" 16' 11" 14' 4" 18' 4" 15' 11" 13' 6" 16' 7" 14' 6" 12' 4"

12 40' 11" 30' 9" 26' 3" 23' 1" 20' 0" 16' 10" 20' 10" 18' 2" 15' 4" 19' 4" 16' 10" 14' 4" 18' 2" 15' 11" 13' 6" 16' 6" 14' 6" 12' 5"

108 42' 8" 31' 7" 26' 7" 23' 2" 19' 8" 16' 3" 20' 7" 17' 7" 14' 8" 18' 11" 16' 3" 13' 7" 17' 7" 15' 3" 12' 10" 15' 10" 13' 10" 11' 9"

10 39' 11" 29' 9" 25' 3" 22' 2" 19' 1" 16' 1" 19' 11" 17' 3" 14' 8" 18' 5" 16' 1" 13' 8" 17' 3" 15' 2" 13' 0" 15' 9" 13' 10" 12' 0"

12 37' 11" 28' 7" 24' 6" 21' 8" 18' 11" 16' 0" 19' 8" 17' 2" 14' 9" 18' 3" 16' 0" 13' 9" 17' 2" 15' 2" 13' 1" 15' 9" 13' 11" 12' 1"

60

0JS

35

0-6

8, 5

0ks

i 46 49' 10" 37' 10" 32' 2" 28' 1" 23' 10" 19' 5" 25' 0" 21' 2" 17' 3" 22' 10" 19' 5" 15'10" 21' 2" 18' 0" 14' 9" 18' 10" f 16' 1" 13' 2"

8 47' 2" 35' 8" 30' 3" 26' 5" 22' 5" 18' 4" 23' 6" 20' 0" 16' 5" 21' 6" 18' 4" 15' 2" 20' 0" 17' 1" 14' 2" 17' 8" f 15' 4" 12' 9"

68 42' 8" 31' 11" 27' 0" 23' 6" 20' 0" 16' 5" 20' 11" 17' 10" 14' 9" 19' 2" 16' 5" 13' 8" 17' 4" f 15' 4" 12' 10" 15' 0" f 13' 10" 11' 8"

10 40' 4" 30' 3" 25' 8" 22' 6" 19' 4" 16' 1" 20' 2" 17' 5" 14' 7" 18' 7" 16' 1" 13' 7" 17' 5" 15' 2" 12' 9" 15' 4" f 13' 9" 11' 8"

88 39' 2" 29' 2" 24' 7" 21' 6" 18' 4" 15' 2" 19' 0" f 16' 5" 13' 9" 16' 10" f 15' 2" 12' 9" 15' 4" f 14' 3" 12' 0" 13' 6" f 12' 11" 11' 0"

10 36' 10" 27' 7" 23' 6" 20' 8" 17' 10" 15' 0" 18' 7" 16' 2" 13' 8" 17' 0" f 15' 0" 12' 9" 15' 10" f 14' 2" 12' 1" 13' 11" f * 12' 11" 11' 1"

12 35' 2" 26' 8" 22' 10" 20' 3" 17' 8" 15' 0" 18' 5" 16' 1" 13' 8" 17' 1" 15' 0" 12'10" 15' 11" f 14' 2" 12' 1" 13' 11" f * 12'11"*

108 36' 5" 27' 1" 22' 10" 20' 0" 17' 1" 14' 3" 17' 1" f 15' 5" 13' 0" 15' 3" f 14' 3" 12' 2" 14' 0" f 13' 5" 11' 6" 12' 6" f 12' 4" 10' 7"

10 34' 2" 25' 8" 21' 11" 19' 4" 16' 10" 14' 4" 17' 3" f 15' 4" 13' 2" 15' 9" f 14' 4" 12' 4" 14' 9" f 13' 7" 11' 9" 13' 2" f * 12' 6" * 10' 10"*

12 32' 7" 24' 10" 21' 5" 19' 2" 16' 9" 14' 4" 17' 5" 15' 4" 13' 3" 16' 2" f 14' 4" 12'5" * 14' 11" f * 13' 8" * 13' 3" f * 12' 7" *

Jan 2011Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com 14

Curtain Wall Systems JamStud® Allowable Heights

Important Notes1. No load factor for lateral wind pressure is used for strength determination as per ASD basic load combinations in ASCE 7-05 and IBC 2006.2. A load factor of 0.7 for lateral wind pressure is used for deflection determination as per IBC 2006, Sec. 1604.3 and AISI-Wall Stud Design Std. 2004, Sec. B1 (Except for 5 psf lateral pressure where 1.0 load factor is used).3. If wind reduction factor for deflection determination is not allowed by a specific building code, multiply table values not denoted by "f" by 85% to calculate the proper JS allowable height. Table values denoted by "f" are controlled by strength and should not be reduced.4. "f" denotes limiting wall height is controlled by strength. All other heights are controlled by deflection. 5. "*" denotes critical web crippling at support of Jamb based on AISI-Wall Stud Design Std. 2004 Sec. C4. Use of stiffening clips at supports eliminate the web crippling condition.6. Limiting heights are based on continuous support of each flange over the full length of the stud.7. Strength determination includes checks for bending and shear capacity values of the stud through punched section.8. Values for multi-span and load bearing conditions are available. Contact TSN's Technical Support Team for recommendations.

Jam

Stu

d

Me

mb

er

Op

en

ing

W

idth

(ft

)O

pe

nin

g

He

igh

t (f

t) Wind Pressure (PSF) And Deflection Limits5 psf 15 psf 20 psf 25 psf 30 psf 40 psf

L/120 L/240 L/360 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600

60

0JS

35

0-9

7, 5

0ks

i 46 58' 0" 44' 3" 37' 8" 32' 11" 27' 11" 22' 8" 29' 3" 24' 10" 20' 3" 26' 9" 22' 8" 18' 6" 24' 10" 21' 1" 17' 2" 22' 1" 18' 9" 15' 4"

8 55' 2" 41' 9" 35' 5" 30' 11" 26' 3" 21' 5" 27' 6" 23' 5" 19' 1" 25' 2" 21' 5" 17' 6" 23' 5" 19' 11" 16' 4" 20' 10" 17' 10" 14' 9"

68 50' 2" 37' 7" 31' 9" 27' 7" 23' 4" 19' 1" 24' 6" 20' 10" 17' 1" 22' 5" 19' 1" 15' 9" 20' 10" 17' 9" 14' 9" 18' 7" 15' 11" 13' 4"

10 47' 6" 35' 6" 30' 1" 26' 3" 22' 5" 18' 6" 23' 5" 20' 1" 16' 8" 21' 6" 18' 6" 15' 6" 20' 1" 17' 4" 14' 6" 18' 1" 15' 8" 13' 3"

88 46' 3" 34' 5" 29' 0" 25' 2" 21' 4" 17' 6" 22' 5" 19' 1" 15' 9" 20' 6" 17' 6" 14' 7" 19' 1" 16' 4" 13' 8" 16' 6" f 14' 9" 12' 5"

10 43' 6" 32' 5" 27' 5" 24' 0" 20' 7" 17' 1" 21' 6" 18' 6" 15' 6" 19' 9" 17' 1" 14' 5" 18' 6" 16' 1" 13' 7" 16' 9" f 14' 7" 12' 6"

12 41' 4" 31' 1" 26' 6" 23' 4" 20' 2" 17' 0" 21' 0" 18' 4" 15' 6" 19' 6" 17' 0" 14' 5" 18' 4" 16' 0" 13' 8" 16' 8" 14' 7" 12' 6"

108 43' 1" 31'11" 26'11" 23' 5" 19' 10" 16' 5" 20' 10" 17' 9" 14' 10" 19' 1" 16' 5" 13' 9" 17' 4" f 15' 4" 12' 11" 15' 0" f 13' 11" 11' 10"

10 40' 4" 30' 1" 25' 6" 22' 4" 19' 3" 16' 2" 20' 1" 17' 5" 14' 9" 18' 7" 16' 2" 13' 10" 17' 5" 15' 3" 13' 1" 15' 7" f 14' 0" 12' 1"

12 38' 4" 28'11" 24' 9" 21' 11" 19' 0" 16' 2" 19' 10" 17' 4" 14' 10" 18' 5" 16' 2" 13' 11" 17' 4" 15' 4" 13' 2" 15' 10" 14' 1" 12' 2"

60

0JS

35

0-1

18

, 50

ksi

46 62' 8" 47' 10" 40' 9" 35' 8" 30' 3" 24' 7" 31' 9" 26' 11" 21' 11" 29' 0" 24' 7" 20' 0" 26' 11" 22' 10" 18' 7" 24' 0" 20' 4" 16' 7"

8 59' 8" 45' 3" 38' 5" 33' 6" 28' 5" 23' 2" 29' 10" 25' 4" 20' 8" 27' 3" 23' 2" 18' 11" 25' 4" 21' 7" 17' 8" 22' 7" 19' 3" 15' 10"

68 54' 6" 40' 11" 34' 6" 30' 0" 25' 4" 20' 7" 26' 7" 22' 7" 18' 5" 24' 3" 20' 7" 16' 11" 22' 7" 19' 2" 15' 10" 20' 1" 17' 2" 14' 3"

10 51' 7" 38' 7" 32' 8" 28' 5" 24' 2" 19' 11" 25' 4" 21' 8" 17' 11" 23' 3" 19' 11" 16' 7" 21' 8" 18' 7" 15' 7" 19' 5" 16' 10" 14' 1"

88 50' 5" 37' 6" 31' 7" 27' 5" 23' 2" 18' 11" 24' 4" 20' 7" 16' 11" 22' 2" 18' 11" 15' 7" 20' 7" 17' 7" 14' 8" 18' 5" 15' 10" 13' 3"

10 47' 4" 35' 3" 29' 9" 26' 0" 22' 2" 18' 4" 23' 2" 19' 11" 16' 7" 21' 3" 18' 4" 15' 5" 19' 11" 17' 3" 14' 6" 17' 11" 15' 7" 13' 3"

12 45' 0" 33' 8" 28' 8" 25' 2" 21' 8" 18' 2" 22' 7" 19' 7" 16' 6" 20' 10" 18' 2" 15' 4" 19' 7" 17' 1" 14' 6" 17' 9" 15' 7" 13' 3"

108 47' 0" 34' 10" 29' 3" 25' 5" 21' 6" 17' 8" 22' 7" 19' 2" 15' 10" 20' 7" 17' 8" 14' 8" 19' 2" 16' 6" 13' 10" 17' 2" f 14' 11" 12' 7"

10 44' 0" 32' 8" 27' 8" 24' 2" 20' 8" 17' 3" 21' 8" 18' 8" 15' 9" 19' 11" 17' 3" 14' 8" 18' 8" 16' 3" 13' 10" 16' 11" 14' 10" 12' 9"

12 41' 9" 31' 3" 26' 8" 23' 6" 20' 4" 17' 3" 21' 3" 18' 6" 15' 9" 19' 8" 17' 3" 14' 9" 18' 6" 16' 3" 13' 11" 16' 10" 14' 11" 12' 10"

80

0JS

25

0-4

3, 5

0ks

i 46 51' 0" 38' 9" 32' 11" 28' 9" * 24' 5" * 19' 10" 24'10" f * 21' 9" * 17' 8" * 21' 3" f * 19' 10" * 16' 2" * 18' 9" f * 18' 5" * 15' 1" * 15' 9" f * 15' 9" f * 13' 6" *

8 48' 3" 36' 6" 31' 0" 27' 0" * 22' 11" * 18' 9" 22'11" f * 20' 6" * 16' 10" * 20' 0" f * 18' 9" * 15' 6" * 17'10" f * 17' 6" * 14' 6" * 15' 2" f * 15' 2" f * 13' 1" *

68 43' 8" 32' 8" 27' 8" 22' 4" f * 20' 5" * 16' 9" * 18' 9" f * 18' 3" * 15' 1" * 16' 5" f * 16' 5" f * 13'11" * 14' 0" f * 14' 10"f* 13' 1" * 12' 9" f * 12' 9" f * 11' 11" *

10 41' 3" 31' 0" 26' 3" 21' 6" f * 19' 9" * 16' 5" * 18' 5" f * 17' 9" * 14' 11" * 16' 6" f * 16' 5" * 13'10" * 15' 2" f * 15' 2" f * 13' 0" * 13' 4" f * 13' 4" f * 11' 11" *

88 40' 2" * 29' 11" 25' 3" 19' 3" f * 18' 9" * 15' 6" * 16' 3" f * 16' 3" f * 14' 0" * 14' 4" f * 14' 4" f * 13' 0" * 13' 0" f * 13' 0" f * 12' 3" * 11' 3" f * 11' 3" f * 11'3" f *

10 37' 1" f * 28' 3" 24' 0" 18'10" f * 18' 2" * 15' 3" * 16' 4" f * 16' 4" f * 13' 11" * 14' 9" f * 14' 9" f * 13' 0" * 13' 7" f * 13' 7" f * 12' 4" * 11' 9" f * 11' 9" f * 11' 4" *

12 34' 10" f 27' 3" 23' 4" 19' 2" f * 18' 0" * 15' 3" * 17' 0" f * 16' 5" * 13' 11" * 15' 6" f * 15' 3" * 13' 0" * 14' 3" f * 14' 3" f * 12' 4" * 12' 0" f * 12' 0" f *

108 35' 2" f * 27' 9" 23' 5" 17' 2" f * 17'2" f * 14' 7" * 14' 7" f * 14' 7" f * 13' 3" * 12'11" f * 12'11"f * 12' 4" * 11' 9" f * 11' 9" f * 11' 8" * 9' 11" f * 9' 11" f * 9'11" f *

10 32' 3" f * 26' 3" 22' 5" 17' 1" f * 17'1" f * 14' 7" * 14'11" f * 14'11" f * 13' 4" * 13' 6" f * 13' 6" f * 12' 6" * 12' 4" f * 12' 4" f * 11' 11" * 10' 0" f * 10' 0" f * 10'0" f *

12 30' 10" f 25' 5" 21' 11" 17' 8" f * 17' 1" * 14' 7" * 15' 9" f * 15' 8" * 13' 5" * 14' 4" f * 14' 4" f * 12' 8" * 12'11" f * 12'11" f* 12' 0" *

80

0JS

25

0-5

4, 5

0ks

i 46 56' 1" 42' 9" 36' 4" 31' 9" * 26' 11" 21' 11" 28' 3" * 24' 0" 19' 6" 25' 10" * 21' 11" * 17' 10" 23'10" f * 20' 4" * 16' 7" * 19' 6" f * 18' 2" * 14'10" *

8 53' 3" 40' 4" 34' 3" 29' 10" 25' 4" 20' 8" 26' 7" * 22' 7" * 18' 6" 24' 3" * 20' 8" * 17' 0" 21' 9" f * 19' 3" * 15'10" * 18' 3" f * 17' 3" * 14' 3" *

68 48' 5" 36' 3" 30' 7" 26' 7" * 22' 7" 18' 5" 22'11" f * 20' 1" * 16' 6" 19'11" f * 18' 5" * 15' 3" 17'11" f * 17' 2" * 14' 3" * 15' 4" f * 15' 4" f * 12'11" *

10 45' 9" 34' 3" 29' 0" 25' 4" * 21' 8" 17' 11" 21'11" f * 19' 5" * 16' 2" 19' 6" f * 17' 11" * 15' 0" 17'10" f * 16' 10" * 14' 1" * 15' 9" f * 15' 3" * 12'10" *

88 44' 7" 33' 2" 27' 11" 23' 7" f * 20' 7" 16' 11" 19' 8" f * 18' 5" * 15' 3" 17' 4" f * 16' 11" * 14' 1" * 15' 8" f * 15' 8" f * 13' 3" * 13' 7" f * 13' 7" f * 12' 1" *

10 41' 11" 31' 3" 26' 6" 22' 6" f * 19' 11" 16' 7" 19' 4" f * 17' 11" * 15' 1" 17' 4" f * 16' 7" * 14' 0" * 16' 0" f * 15' 7" * 13' 3" * 14' 3" f * 14' 3" f * 12' 2" *

12 39' 10" 30' 0" 25' 7" 22' 4" f * 19' 7" 16' 6" 19' 8" f * 17' 9" * 15' 1" 17'11" f * 16' 6" * 14' 1" * 16' 5" f * 15' 7" * 13' 3" * 14' 5" f * 14' 3" * 12' 2" *

108 41' 6" 30' 9" 25' 11" 20'10" f * 19' 2" * 15' 10" 17' 7" f * 17' 3" * 14' 4" 15' 7" f * 15' 7" f * 13' 4" * 14' 2" f * 14' 2" f * 12' 7" * 12' 5" f * 12' 5" f * 11' 7" *

10 38' 10" 29' 0" 24' 8" 20' 3" f * 18' 8" * 15' 9" 17' 7" f * 16' 11" * 14' 5" 15'11" f * 15' 9" * 13' 5" * 14' 9" f * 14' 9" f * 12' 9" * 13' 4" f * 13' 4" f * 11' 9" *

12 36' 11" 27' 11" 23' 11" 20' 5" f * 18' 6" 15' 9" 18' 2" f * 16' 10" * 14' 5" * 16' 8" f * 15' 9" * 13' 6" * 15' 5" f * 14' 11" * 12'10" * 13' 7" f * 13' 7" f *

Toll Free Nationwide Phone (888) 474-4876www.steelnetwork.com

Raleigh, NC : Phone (919) 845-1025Las Vegas, NV : Phone (702) 643-4330

Jan 201115

Curtain Wall Systems JamStud® Allowable Heights

Important Notes1. No load factor for lateral wind pressure is used for strength determination as per ASD basic load combinations in ASCE 7-05 and IBC 2006.2. A load factor of 0.7 for lateral wind pressure is used for deflection determination as per IBC 2006, Sec. 1604.3 and AISI-Wall Stud Design Std. 2004, Sec. B1 (Except for 5 psf lateral pressure where 1.0 load factor is used).3. If wind reduction factor for deflection determination is not allowed by a specific building code, multiply table values not denoted by "f" by 85% to calculate the proper JS allowable height. Table values denoted by "f" are controlled by strength and should not be reduced.4. "f" denotes limiting wall height is controlled by strength. All other heights are controlled by deflection. 5. "*" denotes critical web crippling at support of Jamb based on AISI-Wall Stud Design Std. 2004 Sec. C4. Use of stiffening clips at supports eliminate the web crippling condition.6. Limiting heights are based on continuous support of each flange over the full length of the stud.7. Strength determination includes checks for bending and shear capacity values of the stud through punched section.8. Values for multi-span and load bearing conditions are available. Contact TSN's Technical Support Team for recommendations.

Jam

Stu

d

Me

mb

er

Op

en

ing

W

idth

(ft

)

Op

en

ing

H

eig

ht

(ft) Wind Pressure (PSF) And Deflection Limits

5 psf 15 psf 20 psf 25 psf 30 psf 40 psf

L/120 L/240 L/360 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600 L/240 L/360 L/600

80

0JS

25

0-6

8, 5

0ks

i 46 61' 2" 46' 8" 39' 9" 34' 9" 29' 6" 24' 0" 30' 11" 26' 3" 21' 4" 28' 3" 24' 0" 19' 6" 26' 3" * 22' 3" 18' 2" 23' 4" * 19' 10" * 16' 2"

8 58' 2" 44' 1" 37' 5" 32' 8" 27' 9" 22' 7" 29' 1" 24' 8" 20' 2" 26' 7" 22' 7" 18' 6" 24' 8" * 21' 0" 17' 3" 21' 6" f * 18' 9" * 15' 6"

68 53' 1" 39' 9" 33' 7" 29' 2" 24' 8" 20' 1" 25' 11" 22' 0" 18' 0" 23' 8" f * 20' 1" 16' 6" 21' 1" f * 18' 9" 15' 5" 17' 9" f * 16' 9" * 13' 11"

10 50' 3" 37' 7" 31' 9" 27' 9" 23' 7" 19' 5" 24' 8" 21' 1" 17' 6" 22' 7" f 19' 5" 16' 2" 20' 5" f * 18' 2" 15' 3" 17' 9" f * 16' 5" * 13' 10"

88 49' 0" 36' 6" 30' 8" 26' 8" 22' 7" 18' 5" 23' 5" f 20' 1" 16' 6" 20' 4" f * 18' 5" 15' 3" 18' 3" f * 17' 2" * 14' 4" 15' 8" f * 15' 6" * 13' 0"

10 46' 1" 34' 4" 29' 0" 25' 4" 21' 7" 17' 11" 22' 4" f 19' 5" 16' 3" 19' 10" f * 17' 11" 15' 1" 18' 2" f * 16' 10" 14' 3" 16' 1" f * 15' 3" * 13' 0" *

12 43' 9" 32' 10" 27' 11" 24' 6" 21' 2" 17' 9" 22' 1" 19' 2" 16' 2" 20' 2" f * 17' 9" 15' 1" 18' 8" f * 16' 9" 14' 3" 16' 3" f * 15' 3" * 13' 0" *

108 45' 9" 33' 10" 28' 6" 24' 9" 20' 11" 17' 3" 20' 8" f 18' 9" 15' 6" 18' 1" f * 17' 3" 14' 4" 16' 5" f * 16' 1" * 13' 6" 14' 3" f * 14' 3" f * 12' 4" *

10 42' 9" 31' 10" 26' 11" 23' 7" f 20' 3" 16' 11" 20' 1" f 18' 3" 15' 5" 18' 1" f * 16' 11" 14' 4" 16' 8" f * 15' 11" * 13' 7" 14' 11" f * 14' 7" * 12' 6" *

12 40' 7" 30' 6" 26' 0" 22' 11" 19' 11" 16' 10" 20' 5" f 18' 1" 15' 5" 18' 8" f * 16' 10" 14' 5" 17' 4" f * 15' 11" * 13' 8" * 15' 3" f * 14' 7" * 12' 7" *

80

0JS

25

0-9

7, 5

0ks

i 46 69' 7" 53' 3" 45' 5" 39' 9" 33' 9" 27' 6" 35' 5" 30' 1" 24' 5" 32' 5" 27' 6" 22' 4" 30' 1" 25' 6" 20' 9" 26' 9" 22' 9" 18' 6"

8 66' 5" 50' 6" 42' 11" 37' 5" 31' 9" 25' 10" 33' 4" 28' 3" 23' 0" 30' 5" 25' 10" 21' 1" 28' 3" 24' 0" 19' 7" 25' 2" 21' 5" 17' 7"

68 61' 0" 45' 9" 38' 8" 33' 7" 28' 4" 23' 0" 29' 9" 25' 2" 20' 6" 27' 2" 23' 0" 18' 9" 25' 2" 21' 4" 17' 6" 22' 5" 19' 1" 15' 9"

10 57' 10" 43' 3" 36' 6" 31' 9" 26' 11" 22' 1" 28' 3" 24' 1" 19' 9" 25' 10" 22' 1" 18' 3" 24' 1" 20' 7" 17' 1" 21' 6" 18' 6" 15' 6"

88 56' 7" 42' 1" 35' 5" 30' 8" 25' 11" 21' 0" 27' 2" 23' 0" 18' 9" 24' 9" 21' 0" 17' 3" 23' 0" 19' 7" 16' 1" 20' 6" 17' 6" 14' 7"

10 53' 2" 39' 7" 33' 4" 29' 0" 24' 7" 20' 3" 25' 10" 22' 0" 18' 3" 23' 7" 20' 3" 16' 11" 22' 0" 18' 11" 15' 10" 19' 9" 17' 1" 14' 5"

12 50' 6" 37' 8" 31' 11" 27' 11" 23' 11" 19' 11" 25' 0" 21' 6" 18' 1" 23' 0" 19' 11" 16' 9" 21' 6" 18' 9" 15' 10" 19' 6" 17' 0" 14' 5"

108 52' 11" 39' 2" 32' 11" 28' 6" 24' 0" 19' 7" 25' 3" 21' 4" 17' 6" 23' 0" 19' 7" 16' 2" 21' 4" 18' 3" 15' 2" 18' 7" f 16' 5" 13' 9"

10 49' 6" 36' 8" 30' 11" 26' 11" 22' 11" 19' 0" 24' 0" 20' 7" 17' 2" 22' 0" 19' 0" 16' 0" 20' 7" 17' 10" 15' 1" 18' 5" f 16' 2" 13' 10"

12 46' 10" 34' 11" 29' 8" 26' 0" 22' 5" 18' 10" 23' 4" 20' 3" 17' 2" 21' 7" 18' 10" 16' 0" 20' 3" 17' 9" 15' 1" 18' 5" 16' 2" 13' 11"

80

0JS

25

0-1

18

, 50

ksi

46 74' 7" 57' 2" 48' 10" 42' 9" 36' 5" 29' 7" 38' 2" 32' 5" 26' 4" 34' 10" 29' 7" 24' 1" 32' 5" 27' 6" 22' 4" 28' 10" 24' 6" 19' 11"

8 71' 5" 54' 4" 46' 3" 40' 4" 34' 3" 27' 10" 35' 11" 30' 6" 24' 9" 32' 10" 27' 10" 22' 8" 30' 6" 25' 10" 21' 1" 27' 1" 23' 0" 18' 10"

68 65' 9" 49' 5" 41' 9" 36' 3" 30' 7" 24' 9" 32' 2" 27' 2" 22' 1" 29' 4" 24' 9" 20' 2" 27' 2" 23' 0" 18' 10" 24' 2" 20' 6" 16' 10"

10 62' 5" 46' 9" 39' 5" 34' 4" 29' 0" 23' 8" 30' 6" 25' 10" 21' 2" 27' 10" 23' 8" 19' 6" 25' 10" 22' 1" 18' 3" 23' 1" 19' 10" 16' 6"

88 61' 2" 45' 7" 38' 4" 33' 2" 28' 0" 22' 8" 29' 5" 24' 10" 20' 2" 26' 9" 22' 8" 18' 6" 24' 10" 21' 0" 17' 3" 22' 1" 18' 9" 15' 6"

10 57' 6" 42' 9" 36' 0" 31' 3" 26' 6" 21' 8" 27' 10" 23' 8" 19' 6" 25' 5" 21' 8" 18' 0" 23' 8" 20' 3" 16' 11" 21' 2" 18' 3" 15' 4"

12 54' 8" 40' 9" 34' 5" 30' 0" 25' 8" 21' 3" 26' 10" 23' 0" 19' 3" 24' 8" 21' 3" 17' 10" 23' 0" 19' 11" 16' 9" 20' 9" 18' 1" 15' 4"

108 57' 3" 42' 5" 35' 7" 30' 10" 25' 11" 21' 0" 27' 3" 23' 0" 18' 10" 24' 10" 21' 0" 17' 3" 23' 0" 19' 7" 16' 2" 20' 6" 17' 6" 14' 7"

10 53' 7" 39' 8" 33' 5" 29' 0" 24' 8" 20' 4" 25' 10" 22' 1" 18' 4" 23' 8" 20' 4" 17' 0" 22' 1" 19' 0" 16' 0" 19' 10" 17' 2" 14' 7"

12 50' 9" 37' 9" 31' 11" 27' 11" 23' 11" 20' 0" 25' 0" 21' 7" 18' 2" 23' 0" 20' 0" 16' 11" 21' 7" 18' 10" 16' 0" 19' 7" 17' 2" 14' 8"

80

0JS

35

0-6

8, 5

0ks

i 46 64' 4" 49' 2" 41' 11" 36' 8" 31' 1" 25' 4" 32' 8" 27' 8" 22' 6" 29' 10" * 25' 4" 20' 7" 27' 8" * 23' 6" 19' 1" 24' 8" * 20' 11" * 17' 1"

8 61' 4" 46' 6" 39' 6" 34' 6" 29' 3" 23' 10" 30' 8" 26' 0" 21' 3" 28' 0" 23' 10" 19' 5" 26' 0" * 22' 2" 18' 1" 22' 3" f * 19' 9" * 16' 3"

68 56' 1" 42' 1" 35' 6" 30' 10" 26' 1" 21' 2" 27' 4" 23' 2" 18' 11" 24' 6" f * 21' 2" 17' 4" 21' 9" f * 19' 9" * 16' 3" 18' 4" f * 17' 8" * 14' 7"

10 53' 1" 39' 9" 33' 7" 29' 3" 24' 10" 20' 5" 26' 0" 22' 3" 18' 4" 23' 3" f * 20' 5" 17' 0" 21' 0" f * 19' 1" 15' 11" 18' 2" f * 17' 3" * 14' 5"

88 51' 11" 38' 7" 32' 6" 28' 2" 23' 10" 19' 5" 24'2" f * 21' 2" 17' 4" 21' 0" f * 19' 5" 16' 0" 18'10" f * 18' 1" * 15' 0" 16' 1" f * 16'1" f * 13' 7" *