Crosby Shackles

-

Upload

anjar-darundriya -

Category

Documents

-

view

351 -

download

9

description

Transcript of Crosby Shackles

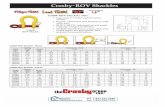

Crosby Alloy Screw Pin Shackles Page 062G-209A Crosby Alloy Screw Pin Shackles G-209-A Screw pin anchor shackles meet the performance requirements of Federal Specification RR-C-271D Type IVA, Grade B, Class 2, except for those provisions required of the contractor. For additional information, see page 349.l Capacities 2 thru 21 metric tons. l Forged Alloy Steel - Quenched and Tempered, with alloy pins. l Working Load Limit permanently shown on every shackle. l Hot Dip Galvanized.l Crosby products meet or exceed all the requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, Crosby products meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B20.26. l Shackles can be furnished proof tested with certificates to designated standards, such as ABS, DNV, Lloyds, or other certification. Charges for proof testing and certification available when requested at time of order.Nominal Size (in.)Working Load Limit (t)*G-209-A Stock No.Weight Each (lbs.)Dimensions (in.)Tolerance+/ -A B C D E F G H L M P C A3/8 2 1017450 .31 .66 .44 1.44 .38 1.03 .91 1.78 2.49 .25 2.03 .38 .13 .067/16 2-2/3 1017472 .38 .75 .50 1.69 .44 1.16 1.06 2.03 2.91 .31 2.38 .44 .13 .061/2 3-1/3 1017494 .63 .81 .63 1.88 .50 1.31 1.19 2.31 3.28 .38 2.69 .50 .13 .065/8 5 1017516 1.38 1.06 .75 2.38 .63 1.69 1.50 2.94 4.19 .44 3.34 .69 .13 .063/4 7 1017538 2.25 1.25 .88 2.81 .75 2.00 1.81 3.50 4.97 .50 3.97 .81 .25 .067/8 9-1/2 1017560 3.61 1.44 1.00 3.31 .88 2.28 2.09 4.03 5.83 .50 4.50 .97 .25 .061 12-1/2 1017582 5.32 1.69 1.13 3.75 1.00 2.69 2.38 4.69 6.56 .56 5.07 1.06 .25 .061-1/8 15 1017604 7.25 1.81 1.25 4.25 1.16 2.91 2.69 5.16 7.47 .63 5.59 1.25 .25 .061-1/4 18 1017626 9.88 2.03 1.38 4.69 1.29 3.25 3.00 5.75 8.25 .69 6.16 1.38 .25 .061-3/8 21 1017648 13.25 2.25 1.50 5.25 1.42 3.63 3.31 6.38 9.16 .75 6.84 1.50 .25 .13* Maximum Proof Load is 2 times the Working Load Limit (metric tons) and 2.2 times the Working Load Limit (short tons).Minimum Ultimate Strength is 4.5 times the Working Load Limit (metric tons), and 5 times the Working Load Limit. (for short tons) For Working Load Limit reduction due to side loading applications, see page 68..Copyright 2005 The Crosby Group, Inc. All Rights Reserved 19/10/2005Crosby Round Pin Shackles Page 060 ROUND PINANCHOR SHACKLES l Capacities 1/2 thru 35 metric tons. l Forged - Quenched and Tempered, with alloy pin.l Working Load Limit permanently shown on every shackle. l Hot Dip galvanized or Self-Colored. l Fatigue Rated.l Shackles can be furnished proof tested with certificates to designated standards, such as ABS, DNV, Lloyds, or other certification. Charged for proof testing and certification available when requested at the time of order.l Shackles are Quenched and Tempered and can meet DNV impact requirements of 42 joules at -20 degress C. l Look for the Red Pin... the mark of genuine Crosby quality. ROUND PINCHAIN SHACKLES G-213S-213 G-215S-215 Round pin achor shackles meet the performance requirements of Federal Specification RR-C-271D Type IVA, Grade A, Class1, except for those provisions required of the contractor. For additional information, see page 349Round pin chain shackle meets the performance requirements of Federal Specifications RR-C271D Type IVB, Grade A, Class 1, except for those provisions required of the contractors. For additional information, see page 349. NominalSize (in.) Working Load Limit (t)* Stock No.Weight Each (lbs.)Dimensions (in.) Tolerance +/- G-213S-213ABCDEFGHNPCA 1/41/21018017 1018026 .13.47 .31 1.13.25 .78 .61 1.28 1.84 1.34 .25 .06 .065/163/41018035 1018044 .18.53 .38 1.22.31 .84 .75 1.47 2.09 1.59 .31 .06 .063/811018053 1018062 .29.66 .44 1.44.38 1.03.91 1.78 2.49 1.86 .38 .13 .067/161-1/21018071 1018080 .38.75 .50 1.69.44 1.161.062.03 2.91 2.13 .44 .13 .061/221018099 1018106 .71.81 .63 1.88.50 1.311.192.31 3.28 2.38 .50 .13 .065/83-1/41018115 1018124 1.501.06 .75 2.38.63 1.691.502.94 4.19 2.91 .69 .13 .063/44-3/41018133 1018142 2.321.25 .88 2.81.75 2.001.813.50 4.97 3.44 .81 .25 .067/86-1/21018151 1018160 3.491.44 1.003.31.88 2.282.094.03 5.83 3.81 .97 .25 .0618-1/21018179 1018188 5.001.69 1.133.751.002.692.384.69 6.56 4.53 1.06.25 .061-1/89-1/21018197 1018204 6.971.81 1.254.251.132.912.695.16 7.47 5.13 1.25.25 .061-1/4121018213 1018222 9.752.03 1.384.691.293.253.005.75 8.25 5.50 1.38.25 .061-3/813-1/21018231 1018240 13.252.25 1.505.251.423.633.316.38 9.16 6.13 1.50.25 .131-1/2171018259 1018268 17.252.38 1.635.751.543.883.636.88 10.00 6.50 1.62.25 .131-3/4251018277 1018286 29.462.88 2.007.001.845.004.198.86 12.34 7.75 2.25.25 .132351018295 1018302 45.753.25 2.257.752.085.754.819.97 13.68 8.75 2.40.25 .13G-213S-213 * NOTE: Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Strength is 6 times the Working Load Limit. Round pin shackles are not suitable for side loading applications. Nominal Size (in.) Working Load Limit (t)* Stock No. Weight Each (lbs.)Dimensions (in.) Tolerance +/- G-215S-215ABCDEFGKNGA 1/41/21018810 1018829 .10.47.31.25.25.97.62.911.591.34.06.06 5/163/41018838 1018847 .18.53.38.31.311.15.751.071.911.63.06.06 3/811018856 1018865 .25.66.44.38.381.42.921.282.311.86.13.06 7/161-1/21018874 1018883 .40.75.50.44.441.63 1.06 1.442.672.13.13.06 1/221018892 1018909 .50.81.63.50.501.81 1.18 1.663.032.38.13.06 5/83-1/41018918 1018927 1.211.06 .75.63.632.32 1.50 2.043.762.91.13.06 3/44-3/41018936 1018945 2.001.25 .88.81.752.75 1.81 2.404.533.44.25.06 7/86-1/21018954 1018963 3.281.441.00.97.883.20 2.10 2.865.333.81.25.06 18-1/21018972 1018981 4.751.691.13 1.00 1.00 3.69 2.38 3.245.944.53.25.06 1-1/89-1/21018990 1019007 6.301.811.25 1.25 1.13 4.07 2.68 3.616.785.13.25.06 1-1/4121019016 1019025 9.002.031.38 1.38 1.25 4.53 3.00 3.977.505.50.25.13 1-3/813-1/21019034 1019043 12.002.251.50 1.50 1.38 5.01 3.31 4.438.286.13.25.13 1-1/2171019052 1019061 16.152.381.63 1.62 1.50 5.38 3.62 4.879.056.50.25.13 1-3/4251019070 1019089 29.962.882.00 2.12 1.75 6.38 4.19 5.82 10.97 7.75.25.13 2351019098 1019105 43.253.252.25 2.36 2.10 7.25 5.00 6.82 12.74 8.75.25.13 19/10/2005G-215S-215 Copyright 2005 The Crosby Group, Inc. All Rights Reserved 19/10/2005Crosby Screw Pin Shackles Page 061SCREW PINANCHOR SHACKLES SCREW PINCHAIN SHACKLES l Capacities 1/3 thru 55 metric tons. l Forged - Quenched and Tempered, with alloy pin. l Working Load Limit permanently shown on every shackle. l Hot Dip galvanized or Self-Colored. l Fatigue Rated.l Shackles can be furnished proof tested with certificates to designated standards, such as ABS, DNV, Lloyds, or other certification. Charged for proof testing and certification available when requested at the time of order.l Shackles are Quenched and Tempered and can meet DNV impact requirements of 42 joules at -20C.l Crosby products meet or exceed all the requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, Crosby products meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B20.26. lLook for the Red Pin. . .the mark of genuine Crosby quality. G-209S-209G-210 S-210 Screw pin anchor shackles meet the performance requirements of Federal Specification RR-C-271D Type IVA, Grade A, Class 2, except for those provisions required of the contractor. For additional information, see page 349.Screw pin chain shackle meets the performance requirements of Federal Specifications RR-C271D Type IVB, Grade A, Class 2, except for those provisions required of the contractors. For additional information, see page 349.NominalSize (in.) Working Load Limit (t)* Stock No.Weight Each (lbs.)Dimensions (in.) Tolerance+/ - G-209S-209ABCDEFGHLMPCA 3/161/31018357.06.38.25.88.19.60.56.981.47.161.12.19.06.06 1/41/21018375 1018384 .10.47.311.13.25.78.611.281.84.191.38.25.06.06 5/163/41018393 1018400 .19.53.381.22.31.84.751.472.09.221.66.31.06.06 3/811018419 1018428 .31.66.441.44.381.03.911.782.49.252.03.38.13.06 7/161-1/21018437 1018446 .38.75.501.69.441.16 1.062.032.91.312.38.44.13.06 1/221018455 1018464 .72.81.631.88.501.31 1.192.313.28.382.69.50.13.06 5/83-1/41018473 1018482 1.371.06 .752.38.631.69 1.502.944.19.443.34.69.13.06 3/44-3/41018491 1018507 2.351.25 .882.81.752.00 1.813.504.97.503.97.81.25.06 7/86-1/21018516 1018525 3.621.441.003.31.882.28 2.094.035.83.504.50.97.25.06 18-1/21018534 1018543 5.031.691.133.751.00 2.69 2.384.696.56.565.071.0625.06 1-1/89-1/21018552 1018561 7.411.811.254.251.16 2.91 2.695.167.47.635.591.25.25.06 1-1/4121018570 1018589 9.502.031.384.691.29 3.25 3.005.758.25.696.161.38.25.06 1-3/813-1/21018598 1018605 13.532.251.505.251.42 3.63 3.316.389.16.756.841.50.25.13 1-1/2171018614 1018623 17.202.381.635.751.54 3.88 3.636.8810.00.817.351.62.25.13 1-3/4251018632 1018641 27.782.882.007.001.84 5.00 4.198.8612.34 1.00 9.082.25.25.13 2351018650 1018669 45.003.252.257.752.08 5.75 4.819.9713.68 1.22 10.34 2.40.25.13 2-1/2551018678 1018687 85.754.132.75 10.50 2.71 7.25 5.69 12.87 17.84 1.38 13.00 3.13.25.25 19/10/2005G-209S-209 * NOTE: Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Strength is 6times the Working Load Limit. For Working Load Limit reduction due to side loading applications, see page 68. NominalSize (in.) WorkingLoad Limit (t)*Stock No. Weight Each (lbs.)Dimensions (in.) Tolerance +/- G-210S-210ABCDEFGKLMGA 1/41/210191501019169.11.47.31.25.25.97.62.971.59.191.43.06.06 5/163/410191781019187.17.53.38.31.311.15.751.071.91.221.71.06.06 3/8110191961019203.28.66.44.38.381.42.921.282.31.252.02.13.06 7/161-1/210192121019221.43.75.50.44.441.631.061.482.67.312.37.13.06 1/2210192301019249.59.81.63.50.501.811.181.663.03.382.69.13.06 5/83-1/4101925810192671.251.06 .75.63.632.321.502.043.76.443.34.13.06 3/44-3/4101927610192852.631.25 .88.81.752.751.812.404.53.503.97.25.06 7/86-1/2101929410193013.161.441.00.97.883.202.102.865.33.504.50.25.06 18-1/2101931010193294.751.691.131.001.003.692.383.245.94.565.13.25.06 1-1/89-1/2101933810193476.751.811.251.251.134.072.693.616.78.635.71.25.06 1-1/412101935610193659.062.031.381.381.254.533.003.977.50.696.25.25.13 1-3/813-1/21019374101938311.632.251.501.501.385.013.314.438.28.756.83.25.13 1-1/2171019392101940915.952.381.631.621.505.383.624.849.05.817.33.25.13 1-3/4251019418101942726.752.882.002.121.756.384.195.7810.971.009.06.25.13 2351019436101944542.313.252.252.362.107.255.006.7712.741.1310.35.25.13 2-1/2551019454101946371.754.122.752.632.639.385.688.0714.851.3813.00.25.25 G-210S-210 Copyright 2005 The Crosby Group, Inc. All Rights Reserved 19/10/2005Crosby Screw Pin Shackles Page 061SCREW PINANCHOR SHACKLES SCREW PINCHAIN SHACKLES l Capacities 1/3 thru 55 metric tons. l Forged - Quenched and Tempered, with alloy pin. l Working Load Limit permanently shown on every shackle. l Hot Dip galvanized or Self-Colored. l Fatigue Rated.l Shackles can be furnished proof tested with certificates to designated standards, such as ABS, DNV, Lloyds, or other certification. Charged for proof testing and certification available when requested at the time of order.l Shackles are Quenched and Tempered and can meet DNV impact requirements of 42 joules at -20C.l Crosby products meet or exceed all the requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, Crosby products meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B20.26. lLook for the Red Pin. . .the mark of genuine Crosby quality. G-209S-209G-210 S-210 Screw pin anchor shackles meet the performance requirements of Federal Specification RR-C-271D Type IVA, Grade A, Class 2, except for those provisions required of the contractor. For additional information, see page 349.Screw pin chain shackle meets the performance requirements of Federal Specifications RR-C271D Type IVB, Grade A, Class 2, except for those provisions required of the contractors. For additional information, see page 349.NominalSize (in.) Working Load Limit (t)* Stock No.Weight Each (lbs.)Dimensions (in.) Tolerance+/ - G-209S-209ABCDEFGHLMPCA 3/161/31018357.06.38.25.88.19.60.56.981.47.161.12.19.06.06 1/41/21018375 1018384 .10.47.311.13.25.78.611.281.84.191.38.25.06.06 5/163/41018393 1018400 .19.53.381.22.31.84.751.472.09.221.66.31.06.06 3/811018419 1018428 .31.66.441.44.381.03.911.782.49.252.03.38.13.06 7/161-1/21018437 1018446 .38.75.501.69.441.16 1.062.032.91.312.38.44.13.06 1/221018455 1018464 .72.81.631.88.501.31 1.192.313.28.382.69.50.13.06 5/83-1/41018473 1018482 1.371.06 .752.38.631.69 1.502.944.19.443.34.69.13.06 3/44-3/41018491 1018507 2.351.25 .882.81.752.00 1.813.504.97.503.97.81.25.06 7/86-1/21018516 1018525 3.621.441.003.31.882.28 2.094.035.83.504.50.97.25.06 18-1/21018534 1018543 5.031.691.133.751.00 2.69 2.384.696.56.565.071.0625.06 1-1/89-1/21018552 1018561 7.411.811.254.251.16 2.91 2.695.167.47.635.591.25.25.06 1-1/4121018570 1018589 9.502.031.384.691.29 3.25 3.005.758.25.696.161.38.25.06 1-3/813-1/21018598 1018605 13.532.251.505.251.42 3.63 3.316.389.16.756.841.50.25.13 1-1/2171018614 1018623 17.202.381.635.751.54 3.88 3.636.8810.00.817.351.62.25.13 1-3/4251018632 1018641 27.782.882.007.001.84 5.00 4.198.8612.34 1.00 9.082.25.25.13 2351018650 1018669 45.003.252.257.752.08 5.75 4.819.9713.68 1.22 10.34 2.40.25.13 2-1/2551018678 1018687 85.754.132.75 10.50 2.71 7.25 5.69 12.87 17.84 1.38 13.00 3.13.25.25 G-209S-209 NominalSize (in.) WorkingLoad Limit (t)*Stock No. Weight Each (lbs.)Dimensions (in.) Tolerance +/- G-210S-210ABCDEFGKLMGA 1/41/210191501019169.11.47.31.25.25.97.62.971.59.191.43.06.06 5/163/410191781019187.17.53.38.31.311.15.751.071.91.221.71.06.06 3/8110191961019203.28.66.44.38.381.42.921.282.31.252.02.13.06 7/161-1/210192121019221.43.75.50.44.441.631.061.482.67.312.37.13.06 1/2210192301019249.59.81.63.50.501.811.181.663.03.382.69.13.06 5/83-1/4101925810192671.251.06 .75.63.632.321.502.043.76.443.34.13.06 3/44-3/4101927610192852.631.25 .88.81.752.751.812.404.53.503.97.25.06 7/86-1/2101929410193013.161.441.00.97.883.202.102.865.33.504.50.25.06 18-1/2101931010193294.751.691.131.001.003.692.383.245.94.565.13.25.06 1-1/89-1/2101933810193476.751.811.251.251.134.072.693.616.78.635.71.25.06 1-1/412101935610193659.062.031.381.381.254.533.003.977.50.696.25.25.13 1-3/813-1/21019374101938311.632.251.501.501.385.013.314.438.28.756.83.25.13 1-1/2171019392101940915.952.381.631.621.505.383.624.849.05.817.33.25.13 19/10/2005* NOTE: Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Strength is 6times the Working Load Limit. For Working Load Limit reduction due to side loading applications, see page 68. 1-3/4251019418101942726.752.882.002.121.756.384.195.7810.971.009.06.25.13 2351019436101944542.313.252.252.362.107.255.006.7712.741.1310.35.25.13 2-1/2551019454101946371.754.122.752.632.639.385.688.0714.851.3813.00.25.25 G-210S-210 Copyright 2005 The Crosby Group, Inc. All Rights Reserved 19/10/2005Crosby Bolt-Type Shackles Page 063 BOLT TYPE ANCHOR SHACKLESBOLT TYPE CHAIN SHACKLES l Working Load Limit permanently shown on every shackle. Capacities 1/3 thru 150 metric tons.l Forged Quenched and Tempered, with alloy pins. l Hot Dip galvanized or Self Colored.l Fatigue rated. l Crosby products meet or exceed all the requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, Crosby products meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B20.26.l Shackles 55 metric tons and smaller can be furnished proof tested with certificates to designated standards, such as ABS, DNV, Lloyds, or other certification.l Shackles 85 metric tons and larger can be provided as follows. Non Destructive Tested Serialized Pin and Bow Material Certification (Chemical) Certification must be requested at time of order. l Look for the Red Pin . . . the mark of genuine Crosby quality. G-2130 S-2130 G-2150 S-2150 BoltType Anchor shackles with thin head bolt - nut with cotter pin. Meets the performance requirements of Federal Specifications RR-C-271D Type IVA, Grade A Class 3, except for those provisions required of the contractor. For additional information, see page 349. Bolt Type Chain shackles. This hex head bolt - nut with cotter pin. Meets the performance requirements of Federal Specifications RR-C271D Type IVB, Grade A, Class 3, except for those provisions required of the contractors. For additional information, see page349.NominalSize (in.) Working Load Limit (t)*Stock No.Weight Each (lbs.)Dimensions (in.) Tolerance +/ - G-2130 S-2130ABCDEFHLNCA 3/161/31019464 .06.38.25.88.19.60.561.47.98.19.06.06 1/41/21019466 .11.47.311.13.25.78.611.841.28.25.06.06 5/163/41019468 .22.53.381.22.31.84.752.091.47.31.06.06 3/811019470 .33.66.441.44.381.03.912.491.78.38.13.06 7/161-1/21019471 .49.75.501.69.441.161.06 2.912.03.44.13.06 1/221019472 1019481 .79.81.641.88.501.311.19 3.282.31.50.13.06 5/83-1/41019490 1019506 1.681.06 .772.38.631.691.50 4.192.94.69.13.06 3/44-3/41019515 1019524 2.721.25 .892.81.752.001.81 4.973.50.81.25.06 7/86-1/21019533 1019542 3.951.441.023.31.882.282.09 5.834.03.97.25.06 18-1/21019551 1019560 5.661.691.153.751.002.692.38 6.564.691.06.25.06 1-1/89-1/21019579 1019588 8.271.811.254.251.132.912.69 7.475.161.25.25.06 1-1/4121019597 1019604 11.712.031.404.691.293.253.00 8.255.751.38.25.06 1-3/813-1/21019613 1019622 15.832.251.535.251.423.633.31 9.166.381.50.25.13 1-1/2171019631 1019640 20.802.381.665.751.533.883.6310.006.881.62.25.13 1-3/4251019659 1019668 33.912.882.047.001.845.004.1912.348.802.25.25.13 2351019677 1019686 52.253.252.307.752.085.754.8113.68 10.15 2.40.25.13 2-1/2551019695 1019702 98.254.132.80 10.502.717.255.6917.90 12.75 3.13.25.25 3 851019711 154.00 5.003.30 13.003.127.886.5021.50 14.62 3.62.25.25 3-1/2 1201019739 265.00 5.253.76 14.633.629.008.0024.88 17.02 4.38.25.25 4 1501019757 338.00 5.504.26 14.504.00 10.00 9.0025.68 18.00 4.56.25.25 G-2130S-2130 NominalSize (in.) Working Load Limit (t)* Stock No. Weight Each (lbs.)Dimensions (in.) Tolerance+/ - G-2150 S-2150 ABDFGKMPRGA 1/41/21019768.13.47.31.25.62.911.59.971.56.25.06.06 5/163/41019770.23.53.38.31.751.071.911.151.82.31.06.06 3/811019772.33.66.44.38.921.282.311.422.17.38.13.06 7/161-1/21019774.49.75.50.441.061.482.671.632.51.44.13.06 19/10/2005 * NOTE: Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Strengthis 6 times the Working Load Limit. For Working Load Limit reduction due to side loading applications, see page68. Individually Proof Tested with certification. Furnished in Anchor style only. Furnished with Round Head Bolts with welded handles.1/221019775 1019784.75.81.64.501.181.663.031.812.80.50.13.06 5/83-1/41019793 10198001.471.06 .77.631.502.043.762.323.56.63.13.06 3/44-3/41019819 10198282.521.25 .89.751.812.404.532.754.15.81.25.06 7/86-1/21019837 10198463.851.441.02.882.102.865.333.204.82.97.25.06 18-1/21019855 10198645.551.691.151.00 2.383.245.943.695.391.00.25.06 1-1/89-1/21019873 10198827.601.811.251.13 2.683.616.784.075.901.25.25.06 1-1/4121019891 101990810.812.031.401.25 3.003.977.504.536.691.38.25.06 1-3/813-1/21019917 101992613.752.251.531.38 3.314.438.285.017.211.50.25.13 1-1/2171019935 101994418.502.381.661.50 3.624.879.055.387.731.62.25.13 1-3/4251019953 101996231.402.882.041.75 4.195.82 10.97 6.389.332.12.25.13 2351019971 101998046.753.252.302.10 5.006.82 12.74 7.2510.41 2.36.25.13 2-1/2551019999 102000485.004.122.802.63 5.688.07 14.85 9.3813.58 2.63.25.25 3 851020013124.25 5.003.253.00 6.508.56 16.8711.00 15.13 3.50.25.25 G-2150S-2150 Copyright 2005 The Crosby Group, Inc. All Rights Reserved 19/10/2005Crosby Bolt-Type Shackles Page 063 BOLT TYPE ANCHOR SHACKLESBOLT TYPE CHAIN SHACKLES l Working Load Limit permanently shown on every shackle. Capacities 1/3 thru 150 metric tons.l Forged Quenched and Tempered, with alloy pins. l Hot Dip galvanized or Self Colored.l Fatigue rated. l Crosby products meet or exceed all the requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, Crosby products meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B20.26.l Shackles 55 metric tons and smaller can be furnished proof tested with certificates to designated standards, such as ABS, DNV, Lloyds, or other certification.l Shackles 85 metric tons and larger can be provided as follows. Non Destructive Tested Serialized Pin and Bow Material Certification (Chemical) Certification must be requested at time of order. l Look for the Red Pin . . . the mark of genuine Crosby quality. G-2130 S-2130 G-2150 S-2150 BoltType Anchor shackles with thin head bolt - nut with cotter pin. Meets the performance requirements of Federal Specifications RR-C-271D Type IVA, Grade A Class 3, except for those provisions required of the contractor. For additional information, see page 349. Bolt Type Chain shackles. This hex head bolt - nut with cotter pin. Meets the performance requirements of Federal Specifications RR-C271D Type IVB, Grade A, Class 3, except for those provisions required of the contractors. For additional information, see page349.NominalSize (in.) Working Load Limit (t)*Stock No.Weight Each (lbs.)Dimensions (in.) Tolerance +/ - G-2130 S-2130ABCDEFHLNCA 3/161/31019464 .06.38.25.88.19.60.561.47.98.19.06.06 1/41/21019466 .11.47.311.13.25.78.611.841.28.25.06.06 5/163/41019468 .22.53.381.22.31.84.752.091.47.31.06.06 3/811019470 .33.66.441.44.381.03.912.491.78.38.13.06 7/161-1/21019471 .49.75.501.69.441.161.06 2.912.03.44.13.06 1/221019472 1019481 .79.81.641.88.501.311.19 3.282.31.50.13.06 5/83-1/41019490 1019506 1.681.06 .772.38.631.691.50 4.192.94.69.13.06 3/44-3/41019515 1019524 2.721.25 .892.81.752.001.81 4.973.50.81.25.06 7/86-1/21019533 1019542 3.951.441.023.31.882.282.09 5.834.03.97.25.06 18-1/21019551 1019560 5.661.691.153.751.002.692.38 6.564.691.06.25.06 1-1/89-1/21019579 1019588 8.271.811.254.251.132.912.69 7.475.161.25.25.06 1-1/4121019597 1019604 11.712.031.404.691.293.253.00 8.255.751.38.25.06 1-3/813-1/21019613 1019622 15.832.251.535.251.423.633.31 9.166.381.50.25.13 1-1/2171019631 1019640 20.802.381.665.751.533.883.6310.006.881.62.25.13 1-3/4251019659 1019668 33.912.882.047.001.845.004.1912.348.802.25.25.13 2351019677 1019686 52.253.252.307.752.085.754.8113.68 10.15 2.40.25.13 2-1/2551019695 1019702 98.254.132.80 10.502.717.255.6917.90 12.75 3.13.25.25 3 851019711 154.00 5.003.30 13.003.127.886.5021.50 14.62 3.62.25.25 3-1/2 1201019739 265.00 5.253.76 14.633.629.008.0024.88 17.02 4.38.25.25 4 1501019757 338.00 5.504.26 14.504.00 10.00 9.0025.68 18.00 4.56.25.25 G-2130S-2130 NominalSize (in.) Working Load Limit (t)* Stock No. Weight Each (lbs.)Dimensions (in.) Tolerance+/ - G-2150 S-2150 ABDFGKMPRGA 1/41/21019768.13.47.31.25.62.911.59.971.56.25.06.06 5/163/41019770.23.53.38.31.751.071.911.151.82.31.06.06 3/811019772.33.66.44.38.921.282.311.422.17.38.13.06 7/161-1/21019774.49.75.50.441.061.482.671.632.51.44.13.06 19/10/2005 * NOTE: Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Strengthis 6 times the Working Load Limit. For Working Load Limit reduction due to side loading applications, see page68. Individually Proof Tested with certification. Furnished in Anchor style only. Furnished with Round Head Bolts with welded handles.1/221019775 1019784.75.81.64.501.181.663.031.812.80.50.13.06 5/83-1/41019793 10198001.471.06 .77.631.502.043.762.323.56.63.13.06 3/44-3/41019819 10198282.521.25 .89.751.812.404.532.754.15.81.25.06 7/86-1/21019837 10198463.851.441.02.882.102.865.333.204.82.97.25.06 18-1/21019855 10198645.551.691.151.00 2.383.245.943.695.391.00.25.06 1-1/89-1/21019873 10198827.601.811.251.13 2.683.616.784.075.901.25.25.06 1-1/4121019891 101990810.812.031.401.25 3.003.977.504.536.691.38.25.06 1-3/813-1/21019917 101992613.752.251.531.38 3.314.438.285.017.211.50.25.13 1-1/2171019935 101994418.502.381.661.50 3.624.879.055.387.731.62.25.13 1-3/4251019953 101996231.402.882.041.75 4.195.82 10.97 6.389.332.12.25.13 2351019971 101998046.753.252.302.10 5.006.82 12.74 7.2510.41 2.36.25.13 2-1/2551019999 102000485.004.122.802.63 5.688.07 14.85 9.3813.58 2.63.25.25 3 851020013124.25 5.003.253.00 6.508.56 16.8711.00 15.13 3.50.25.25 G-2150S-2150 Copyright 2005 The Crosby Group, Inc. All Rights Reserved 19/10/2005Crosby COLD-TUFF Fittings Page 066G-2130CT Bolt Type Anchor shackle with thin head bolt - nut with cotter pin. Meets the performance requirements of Federal Specification RR-C271D Type IVA, Grade A, Class 3, except for those provisions required of the contractor. G-2130CT & G-2140CT l Forged - Quenched and Tempered, with alloy bolt. - G-2130CT - Carbon Steel - G-2140CT - Alloy Steell Working Load Limit permanently shown on every shackle.lIndividually Serialized with Certification.l Fatigue Rated (G-2130CT only).l All sizes are individually proof tested to 2.0 times the Working Load Limit.lFinish is Inorganic Zinc Primer or Hot Dipped Galvanized.l Bow and Bolt are Certified to meet charpy impact testing of 31 ft-lbs. min. ave. at -4 F.l Individually Mag Inspected with certification.l Type Approval and certification in accordance with DNV Specification 2.7-1 Offshore Containers and DNV rules for Lifting Appliances - Loose Gear.l COLDTUFF shackles are suitable for use at -50F. G-2140CT G-2140 meets the performance requirements of Federal Specifications RR-C-271D, Type IVA, Grade B, Class 3 except for those provisions required of the ontractor. NominalShackle Size (in.)Working Load Limit *(tons)G-2130CT Stock No.G-2130CT Weight Each (lbs.)Dimensions (in.)Tolerance +/-A B C D E F H L N P A C3/4 4-3/4 1260568 2.72 1.25 .88 2.81 .75 2.00 1.81 4.97 3.50 .81 4.25 .06 .257/8 6-1/2 1260577 3.87 1.44 1.00 3.31 .88 2.28 2.09 5.83 4.03 .97 4.71 .06 .251 8-1/2 1260586 5.66 1.69 1.13 3.75 1.03 2.69 2.38 6.56 4.69 1.06 5.38 .06 .251-1/8 9-1/2 1260595 8.26 1.81 1.25 4.25 1.13 2.91 2.69 7.47 5.16 1.25 5.90 .06 .251-1/4 12 1260604 11.71 2.03 1.38 4.69 1.29 3.25 3.00 8.25 5.75 1.38 6.63 .06 .251-3/8 13-1/2 1260613 15.1 2.25 1.50 5.25 1.38 3.63 3.31 9.16 6.38 1.50 7.21 .13 .251-1/2 17 1260622 19.1 2.38 1.63 5.75 1.54 3.88 3.63 10.00 6.88 1.62 7.66 .13 .251-3/4 25 1260633 34.7 2.88 2.00 7.00 1.84 5.00 4.19 12.34 8.86 2.25 9.19 .13 .25NominalShackle Size (in.)Working Load Limit * (tons)G-2140CT Stock No.Weight Each (lbs.)Dimensions (ins.)Tolerance+/-A B C D E F H L N P A C1-1/2 30 1260801 20.8 2.38 1.63 5.75 1.54 3.88 3.63 10.00 6.88 1.62 7.66 .13 .251-3/4 40 1260812 33.9 2.88 2.00 7.00 1.84 5.00 4.19 12.34 8.86 2.25 9.19 .13 .252 55 1260823 52.0 3.25 2.25 7.75 2.08 5.75 4.81 13.68 9.97 2.40 10.16 .13 .252-1/2 85 1260834 96.0 4.12 2.75 10.50 2.72 7.25 5.69 17.84 12.87 3.12 12.94 .25 .253 120 1260843 178.0 5.00 3.25 13.00 3.11 7.88 6.50 21.50 14.36 3.62 16.50 .25 .253-1/2 150 1260852 265.0 5.25 3.75 14.63 3.62 9.00 8.00 24.62 16.50 4.12 19.00 .25 .254 175 1260861 338.0 5.50 4.25 14.5 4.10 10.00 9.00 25.69 18.42 4.56 19.75 .25 .254 3/4 200 1260870 450.0 7.25 4.75 15.62 4.50 11.00 10.50 29.25 21.00 6.00 20.50 .25 .255 250 1260889 600.0 8.50 5.00 20.00 4.50 13.00 12.00 35.00 24.50 6.50 21.97 .25 .2519/10/2005* NOTE: Maximum Proof Load is 2.0 times the Working Load Limit. 4-3/4t -175ft, Minimum Ultimate Load is 5.4 times the Working Load Limit. 200t and larger, Minimum Ultimate Load is 4 times the Working Load Limit. Furnished with Round Head Bolts with welded handle. Copyright 2005 The Crosby Group, Inc. All Rights Reserved 19/10/2005Crosby COLD-TUFF Fittings Page 066G-2130CT Bolt Type Anchor shackle with thin head bolt - nut with cotter pin. Meets the performance requirements of Federal Specification RR-C271D Type IVA, Grade A, Class 3, except for those provisions required of the contractor. G-2130CT & G-2140CT l Forged - Quenched and Tempered, with alloy bolt. - G-2130CT - Carbon Steel - G-2140CT - Alloy Steell Working Load Limit permanently shown on every shackle.lIndividually Serialized with Certification.l Fatigue Rated (G-2130CT only).l All sizes are individually proof tested to 2.0 times the Working Load Limit.lFinish is Inorganic Zinc Primer or Hot Dipped Galvanized.l Bow and Bolt are Certified to meet charpy impact testing of 31 ft-lbs. min. ave. at -4 F.l Individually Mag Inspected with certification.l Type Approval and certification in accordance with DNV Specification 2.7-1 Offshore Containers and DNV rules for Lifting Appliances - Loose Gear.l COLDTUFF shackles are suitable for use at -50F. G-2140CT G-2140 meets the performance requirements of Federal Specifications RR-C-271D, Type IVA, Grade B, Class 3 except for those provisions required of the ontractor. NominalShackle Size (in.)Working Load Limit *(tons)G-2130CT Stock No.G-2130CT Weight Each (lbs.)Dimensions (in.)Tolerance +/-A B C D E F H L N P A C3/4 4-3/4 1260568 2.72 1.25 .88 2.81 .75 2.00 1.81 4.97 3.50 .81 4.25 .06 .257/8 6-1/2 1260577 3.87 1.44 1.00 3.31 .88 2.28 2.09 5.83 4.03 .97 4.71 .06 .251 8-1/2 1260586 5.66 1.69 1.13 3.75 1.03 2.69 2.38 6.56 4.69 1.06 5.38 .06 .251-1/8 9-1/2 1260595 8.26 1.81 1.25 4.25 1.13 2.91 2.69 7.47 5.16 1.25 5.90 .06 .251-1/4 12 1260604 11.71 2.03 1.38 4.69 1.29 3.25 3.00 8.25 5.75 1.38 6.63 .06 .251-3/8 13-1/2 1260613 15.1 2.25 1.50 5.25 1.38 3.63 3.31 9.16 6.38 1.50 7.21 .13 .251-1/2 17 1260622 19.1 2.38 1.63 5.75 1.54 3.88 3.63 10.00 6.88 1.62 7.66 .13 .251-3/4 25 1260633 34.7 2.88 2.00 7.00 1.84 5.00 4.19 12.34 8.86 2.25 9.19 .13 .25NominalShackle Size (in.)Working Load Limit * (tons)G-2140CT Stock No.Weight Each (lbs.)Dimensions (ins.)Tolerance+/-A B C D E F H L N P A C1-1/2 30 1260801 20.8 2.38 1.63 5.75 1.54 3.88 3.63 10.00 6.88 1.62 7.66 .13 .251-3/4 40 1260812 33.9 2.88 2.00 7.00 1.84 5.00 4.19 12.34 8.86 2.25 9.19 .13 .252 55 1260823 52.0 3.25 2.25 7.75 2.08 5.75 4.81 13.68 9.97 2.40 10.16 .13 .252-1/2 85 1260834 96.0 4.12 2.75 10.50 2.72 7.25 5.69 17.84 12.87 3.12 12.94 .25 .253 120 1260843 178.0 5.00 3.25 13.00 3.11 7.88 6.50 21.50 14.36 3.62 16.50 .25 .253-1/2 150 1260852 265.0 5.25 3.75 14.63 3.62 9.00 8.00 24.62 16.50 4.12 19.00 .25 .254 175 1260861 338.0 5.50 4.25 14.5 4.10 10.00 9.00 25.69 18.42 4.56 19.75 .25 .254 3/4 200 1260870 450.0 7.25 4.75 15.62 4.50 11.00 10.50 29.25 21.00 6.00 20.50 .25 .255 250 1260889 600.0 8.50 5.00 20.00 4.50 13.00 12.00 35.00 24.50 6.50 21.97 .25 .2519/10/2005* NOTE: Maximum Proof Load is 2.0 times the Working Load Limit. 4-3/4t -175ft, Minimum Ultimate Load is 5.4 times the Working Load Limit. 200t and larger, Minimum Ultimate Load is 4 times the Working Load Limit. Furnished with Round Head Bolts with welded handle. Copyright 2005 The Crosby Group, Inc. All Rights Reserved 19/10/2005 Crosby Alloy Bolt Type Shackles Page 064* Note: Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Load is 4 times the Working Load Limit on 200 thru 400 metric Tons. For sizes 30 thru 175 metric Tons, Minimum Ultimate Load is 5.4 times the Working Load Limit. ** Cast Alloy Steel. Furnished with Round Head Bolts with welded handle.For Working Load Limit reduction due to side loading applications, see page 68. G-2140 / S-2140 ALLOY BOLT TYPE ANCHOR SHACKLES G-2140 meets the performance requirements of Federal Specification RR-C-271D, Type IVA, Grade B, Class 3, except for those provisions required of the contractor. For additional information, see page 349.l Quenched and Tempered.l Alloy bows, Alloy bolts.l Forged Alloy Steel 30 thru 175 metric tons. Cast Alloy Steel 200 thru 400 metric tons.l Working Load Limit is permanently shown on every shackle. l All sizes are individually proof tested to 2.0 times the Working Load Limit.l Pins are galvanized and painted red.l Certification must be requested at time of order. l Shackles are Quenched and Tempered and can meet DNV impact requirements of 42 joules at-20 C.l Crosby products meet or exceed all the requirements of ASME B30.26 including identifacation, ductility, design factor, proof load and temperature requirements. Importantly, Crosby products meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.l Shackles 200 metric tons and larger are provided as follows. l Non Destructive Tested l Serialized Pin and Bowl Material Certification (Chemical)l Magnetic Particle Inspected Nominal Shackle Size (in.)Working Load Limit * (t)Stock No.Weight Each (lbs.)Dimensions (in.) ToleranceG-2140 Galv.S-2140 S.C. A B C D E F G H J K L A E1-1/2 30 1021110 1021129 20.8 2.38 3.63 1.621.66 5.75 1.39 6.88 7.73 10.00 3.88 1.53 .13 .251-3/4 40 1021138 1021147 33.9 2.88 4.19 2.252.04 7.00 1.75 8.80 9.33 12.34 5.00 1.84 .13 .252 55 1021156 1021165 52.0 3.25 4.81 2.402.30 7.75 2.0010.15 10.4113.68 5.75 2.08 .13 .252-1/2 85 1021174 1021183 96.0 4.12 5.81 3.122.7110.502.6212.75 13.5817.70 7.25 2.71 .25 .253 120 1021192 - 178.0 5.00 6.50 3.623.3013.003.0014.62 15.1321.50 7.88 3.12 .25 .253-1/2 150 1021218 - 265.0 5.25 8.00 4.383.7614.633.7517.02 19.0024.88 9.00 3.62 .25 .254 175 1021236 - 338.0 5.50 9.00 4.564.0014.504.0018.00 19.7525.68 10.00 4.00 .25 .254-3/4 ** 200 1021414 - 450.0 7.2510.50 6.004.7515.693.7521.00 20.5929.25 11.00 4.50 .25 .255 ** 250 1021432 - 600.0 8.5012.00 6.505.0020.063.8824.50 22.0635.00 13.00 4.50 .25 .256 ** 300 1021450 - 775.0 8.3812.00 6.756.0019.566.4325.00 24.4435.25 13.00 5.00 .25 .257 ** 400 1021478 - 1102.0 8.2514.00 7.257.0022.566.5026.00 28.0640.25 13.00 6.00 .25 .25Copyright 2005 The Crosby Group, Inc. All Rights Reserved 19/10/2005Crosby Wide Body Shackles Page 065G-2160 "WIDE BODY" SHACKLES

Patented l All sizes Quenched and Tempered for maximum strength..l Forgedalloy steel from 30 through 300 metric tons. l Cast alloy steel from 400 through 1000 metric tons. l Sizes 400 tons and larger are tested to 1.33 times Working Load Limit.l All ratings are in metric tons, embossed on side of bow.l Bows and pins are furnished Dimetcoted. All pins are Dimetcoted then painted red.l Greatly improves wearability of wire rope slings. l Can be used to connect HIGH STRENGTH Synthetic Web Slings, HIGH STRENGTH Synthetic Round Slings or Wire Rope Slings. l Increase in shackle bow radius provides minimum 58% gain in sling bearing surface and eliminates need for a thimble. l Increases usable sling strength minimum of 15%. l Pin is non-rotating, with weld on handles for easier use (300t and larger). l All 2160 shackles are individually proof tested, Crosby certification available at time of order. l Crosby products meet or exceed all the requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, Crosby products meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26. l Shackles requiring ABS, DNV, Lloyds and other certifications are available upon special request and must be specified at time of order.l Shackles are produced in accordance with certified lifting appliance requirements. l Non Destructive Testingl Serialization / Identification l Material Testing (Physical / Chemical / Charpy)l Proof Testing 75 through 300 metric tons 400 through 1000 metric tons Page 1 : G-2140* Ultimate Load is 5 times the Working Load Limit. Forged Alloy Steel. Proof Load is 2 times the Working Load Limit.Cast Alloy Steel. Proof Load is 1.33 times the Working Load Limit. Working Load Limit * (metric tons)G-2160 Stock No.Weight Each (lbs.)Dimensions (in.)A B +/-.25C D +/-.02E G H J K P R 301021575 25 7.73 2.37 1.38 1.63 3.50 2.50 7.00 3.13 2.50 8.50 11.38 401021584 35 9.32 2.88 1.75 2.00 4.00 1.75 8.13 3.75 3.00 10.62 13.62 551021593 71 10.41 3.25 2.00 2.27 4.63 2.00 9.42 4.50 3.50 12.26 15.63 75 1021290 99 14.37 4.13 2.12 2.75 5.00 2.55 11.60 4.75 3.64 12.28 18.41 125 1021307 161 16.51 5.12 2.56 3.15 5.71 3.15 14.43 5.91 4.33 14.96 22.65 200 1021316 500 20.67 5.91 3.35 4.12 7.28 4.33 18.98 8.07 5.41 19.49 29.82 300 1021325 811 24.20 7.38 4.00 5.25 9.25 5.47 23.69 10.38 6.31 23.38 37.26 400 1021334 1041 30.06 8.66 5.16 6.30 11.81 6.30 22.71 12.60 7.28 27.17 38.78 500 1021343 1378 32.99 9.84 5.59 7.09 12.52 6.69 24.88 13.38 8.86 31.10 42.71 600 1021352 1833 35.39 10.83 6.04 7.87 13.78 7.28 27.64 14.56 9.74 34.06 47.24 700 1021361 2446 38.91 11.81 6.59 8.46 14.80 7.87 29.04 15.74 10.63 37.01 50.17 800 1021254 3016 43.50 12.80 7.19 9.06 15.75 8.27 29.62 16.54 10.92 38.39 52.09 900 1021389 3436 43.60 13.78 7.78 9.84 16.93 8.66 30.02 17.32 11.51 40.35 54.041000 1021370 4022 45.98 14.96 8.33 10.63 17.72 9.06 30.02 18.12 12.11 42.32 55.32Copyright 2005 The Crosby Group, Inc. All Rights Reserved Page 2 : G-2140