Cracker Oven Reducing Gas Costs

-

Upload

andresfel47 -

Category

Documents

-

view

99 -

download

2

Transcript of Cracker Oven Reducing Gas Costs

1

Technical Paper Cracker Oven Gas Consumpti on June 2010

Introduction

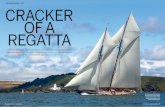

Cracker manufacturers worldwide have been baking their prod-ucts on Direct Gas Fired ovens since the 1930’s. Although elec-trical and mechanical components improved over the years, the basic concept of Direct Gas Fired (DGF) cracker ovens remains the same (Figure 1).

A cracker oven is ideally configured with a minimum of three (3) zones and a maximum of six (6) zones. These ovens typically vary in length from 30 m (100 ft) to 90 m (300 ft). Although produced by a number of equipment manufacturers, the basic principles of DGF oven designs are the same. A series of ribbon burners placed above and below the baking band produce the heat that bakes the product. The ribbon burners operate on a gas/air mixture, which combusts directly in the baking chamber.

The burners heat the wire mesh belt as well as the oven’s environment that, in turn, bakes the product. Exhaust is normally controlled via a series of adjustable dampers in each zone that regulate the exhaust and thus control the amount of water vapor released from the oven. All oven zones are generally the same except Zone 1 where a preheat section may be added to the return chamber of the oven to reheat the belt.

Understanding Cracker Oven Gas Consumption to Reduce

Energy CostsBy:

Joseph S Zaleski Jr.President, Reading Bakery Systems

Figure 1: Typical DGF Cracker Oven

2

There’s estimated to be 800 to 1,000 of these ovens operating in the cracker and biscuit industry worldwide.

Determining Energy Consumption

One of the more common ques-tions from cracker manufactur-ers operating DGF ovens is how to reduce fuel consumption. This is especially true in recent years, which have seen fuel prices rise at a faster past the ever. Gas con-sumption is the largest utility cost the manufacturer incurs on a cracker production line.

Cracker manufacturers usually know the monthly gas consumption of the factory but may not know the separate amount used by the ovens, boilers, heat exchangers and HVAC units. In order to determine if energy can be saved on any of these processes, one must know the energy presently being consumed.

Engineers design DGF ovens with enough burners to quickly heat the oven at start-up. The burners then settle back to a mid-level firing position for baking. At start-up, burners fire at maximum rate then drift back to a steady state condition of 50 to 70% of capacity during production.

To determine the specific gas consumption of their cracker oven, manufacturers can install fuel meters to measure the continued use of gas. These meters feed data to trending charts (Figure 2), which allow compi-lation of steady state gas usage during production. A key indicator of oven performance is the calculation of energy per unit weight of product being produced. This is normally expressed in KW-hr/kg or BTU/lb.

Every product has a unique energy value determined by the oven type, bake time, specific formula and room conditions. Products that entirely cover the baking band, such as soda crackers, provide the highest oven efficiencies. Round products, which may cover only 40% of the baking band, can require up to 25% more energy from the oven. The round cracker product itself does not necessarily require more energy; the oven heat losses remain the same for both crackers. Full sheeted crackers baking at 3 minutes produce more product than round crackers cov-ering only 60 to 70% of the belt baking at the same time.

Over the years, oven suppliers have collected “typical” expected values for energy consumption per unit weight of product. Table 1 shows a range of values collected for some of the most widely baked products in the industry. There are certainly exceptions to these values, as older inefficient ovens may require more energy and newer improved insu-lated ovens reduce energy consumption.

Line 2: Gas Usage

Figure 2: Cracker Oven Gas Trend Chart

Table 1: Gas Energy Values per Unit Product

Bread Snacks 0.32 - 0.45 KW-hr/kg 500 - 700 BTU/lb

Cookies 0.45 - 0.58 KW-hr/kg 700 - 900 BTU/lb

Round Crackers 0.65 - 0.77 KW-hr/kg 1,000 - 1,200 BTU/lb

Full Sheet Crackers 0.52 - 0.65 KW-hr/kg 800 - 1,000 BTU/lb

Tortilla Chips 0.71 - 0.84 KW-hr/kg 1,100 - 1,300 BTU/lb

Baked Potato Crisps 0.90 - 1.03 KW-hr/kg 1,400 - 1,600 BTU/lb

Pretzels 0.97 - 1.29 KW-hr/kg 1,500 - 2,000 BTU/lbPita Breads 1.61 - 1.93 KW-hr/kg 2,500 - 3,000 BTU/lb

3

In general, most products will fall into this range when baked on a typical tunnel oven.Once the total gas consumed by the oven is determined with a gas meter, the number needs to be bro-

ken down further to identify the areas consuming energy in the baking process. How much energy goes into the product and how much is attributed to oven losses? Once the breakdown is understood ways to improve the process and reduce energy can be determined. So, what consumes the heat in a DGF oven?

Balance of Energy in the Oven

The First Law of Thermodynamics states that energy is always conserved in a process. The input energy must equal the output energy. Considering a cracker oven, the input energy, which is gas converted to heat, must equal the output energy consumed in the process.

The combustion process of the oven’s burners accounts for the energy going into the oven. Assuming the burners operate efficiently and at proper ratios, flow meters can measure the gas input to the oven. Gas flow can be converted to energy by using the standard tables for heat capacity of gases. For natural gas, the heat content of the gas varies between 9.8 and 10.9 KWh/m3 (950 and 1,050 BTU/ft3). The local gas company has the exact chemical makeup providing the specific heat capacity (or energy) for the local gas. Typically 10.3 KWh/m3 (1,000 BTU/ft3) is used as an average.

Determining the energy consumed by the process is not as easy as measuring gas flow however, it must equal the energy input to the process. There are four primary areas of gas consumption in an oven. First, the product requires energy to raise its temperature and remove the water. Second, the exhaust system removes energy by discharging heated air and water vapor from inside the oven. Third, the belt continu-ously circulates through the oven requiring energy to re-heat for each cycle. And finally the oven loses energy by the transmission of heat through the walls, floor (oven base) and ceiling (oven top) as well as the entrance and exit of the oven chamber (Figure 3).

Qbelt – Energy Out - Heat lost by the oven belt

Product In Product Out

Figure 3: Oven Heat Balance

Qgas – Energy In - Heat from the Gas Combusting

Qexh – Energy Out – Heated Exhaust Air is replaced with cooler make-up air

Qosr – Energy Out – Oven Surface Loses

Qproduct – Energy Out – Heat required for the product

4

The heat balance for the oven is as follows:

Energy into the Oven: Combustion of Gas Qgas

Energy Consumed: Drying the Product QproductEnergy Consumed: Heating the Belt QbeltEnergy Consumed: Heating the Makeup Air QmuairEnergy Consumed: Oven Surface Radiation losses Qosr

Qgas = Qproduct + Qbelt + Qmuair + Qosr

Product: Energy is consumed in stages during the baking process. In the first stage, the cracker dough absorbs heat from the air, belt and radiation. As the water in the cracker dough transfers phases from liq-uid to gas it undergoes an energy transformation process called Latent Heat of Vaporization. Water is now separated from the product as vapor and both product and vapor continue to absorb heat and increase in temperature to match the oven environment.

The product can be broken down and considered separately: dry materials and water. So the crackers go through the following energy changes:

Heat Required by Product: Qproduct

Sensible Heat for Dry Product: Qdryp= Mp cp (tp2 – tp1)Sensible Heat for Water in Product: Qwat= Mw cp (tw2 – tw1)Latent Heat of Evaporation: Qevap= Mw (H)Sensible Heat of Vapor: Qw vap= Mp cv (texh – tp) Mp, Mw, – Mass Flow of the Product and Watercp, cv – Specific Heat of the Product and Water VaporH – Energy of Vaporization – Converting Water to Vaportp2, tp1, tw2, tw1, texh, tp – Temperatures of the Process: [tp2] product at oven exit; [tp1] product at oven

entrance; [tw2] water at exit; [tw1] water at entrance; [texh] exhaust measured in oven stack; [tp] average product temperature in the oven.

Belt: For the baking belt, the coolest temperature is measured on the inlet roll stand just prior to the oven. Raw product is deposited on the belt at this location. The hottest temperature recorded for the belt is at the oven discharge as it carries product out of the oven. The belt continually loses heat until it returns to the oven inlet unless there is a pre-heat system on the belt. Pre-heat is additional energy consumed by the process. To determine the energy consumption of the belt, either sum all the losses of heat for the belt or just calculate how much energy the belt absorbs during the baking process. Since the belt travels a fixed cycle, the heat gained equals the heat lost.

The calculation for heat the belt is as follows:

Heat Required for the Baking Belt: Qbelt= Mb cb (tb2 – tb1)

Mb – Mass Flow of the Belt cb – Specific Heat of the Belttb2, tb1 – Temperatures of the Belt: (tb2] at exit; [tb1] at entrance

5

Surface Radiation: The heat lost to surface radiation requires a number of assumptions. The insulation and construction of the oven define the Heat Transfer Coefficient (U) used to calculate surface heat losses. This is similar in concept to how the insulation R values define how well a house holds heat. The more insulation and air entrapment a structure contains then the better overall R value of the structure.

The Heat Transfer Coefficient, however, is inverse of the R value. High R values mean lower heat transfer coefficients and thus less energy lost. In order to calculate heat lost through surface radiation, the oven surface areas must be calculated.

Heat Loss due to Oven Surface Area Radiation: Qosr = Uo Ao (to - tr)

Uo – Heat Transfer Coefficient Ao – Surface area of the Ovento, tr – Temperatures of the Oven and Room

Makeup Air: The exhaust system removes heated air and water vapor from the process. An ideal ex-haust system would only remove water vapor from the process without removing the heated air. However the water vapor and air are thoroughly mixed together so removing one gas removes the other. Water vapor is lighter than air and will stratify in the upper chambers of the oven. The art of baking is to remove enough water vapor from the process so as not to saturate the inside of the oven and make the drying process less efficient.

For maximum drying efficiency, all of the water vapor should be removed to allow the water to tran-sition more easily out of the product. This would be very inefficient from an energy standpoint but it achieves the fastest possible product drying curve. To determine the energy required for makeup air, the exhaust flow rate is needed as well as the air temperature of the room and the oven temperature.

Heat Required for Makeup Air: Qmair = Ma cpa (texh – tr)

Ma - Mass Flow of the Aircpa - Specific Heat of the Airtexh, tr – Temperatures of the Exhaust and Room

Determining the Energy Consumption of a Typical DGF Cracker Oven

Consider a cracker production line with a typical DGF oven that is 1 m wide with six zones extending 90 m in length (Figure 4). The line produces round snack crackers at the rate of 1,833 kg/hr (4,032 lbs/hr) of finished product.

The cracker dough is mixed with a moisture content of approximately 30%. The dough is then sheeted and cut into round shapes weighing 68 g (2.4 oz) for 18 pieces. Each raw cracker piece loses about 2% of its moisture in the sheeting process before it enters the oven.

The crackers bake in the oven for 2 minutes 32 seconds (2.58 minutes), after which the end-of-oven product moisture is 2.25%. The crackers now have a finished weight of 52.5 g (1.9 oz) for 18 pieces.

The DGF oven has an exposed surface area 582 m2 (6,265 ft2) to the room. The oven room is well ventilated with the average daily temperature of 35ºC (95ºF). The oven is sealed throughout except for where the belt and product enter and exit the oven. The open area at the entrance and exit of the oven are 0.185 m2 (2.0 ft2) each. The oven and

6

return chambers are fully insulat-ed (Figure 5). The Heat Transfer Coefficient for the oven is estimat-ed to be 3.0 W/m2 ºC (0.53 BTU/hr ft2 ºF).

A CB5 mesh belt transports the product through the oven and continuously cycles through an insulated return chamber below the oven. The insulated return has a preheat chamber to restore the belt temperature but it is not used for this product. The CB5 belt has a weight of 22.0 kg/m2 (4.5 lbs/ft2).

A meter measures the gas flow to the oven and reports it to the process control screen for graph-ing. The gas meter consistently reads 125 m3/hr (4,415 ft3/hr). The local gas company reports that the heat content of the gas is 10.6 KW-hr/m3 (1,020 BTU/ft3).

Table 2 contains the temperatures and exhaust settings as the oven bakes the cracker product. These are reference temperatures as measured at points in each zone.

To measure the actual environment tem-perature of the oven, a SCORPION® data logger with a temperature sensing bar was passed though the oven to determine the average temperature of the baking process. Since each zone is controlled separately, the temperatures vary throughout the bak-ing process. For simplicity of calculations,

1,450 mm (77 in)

1,715 mm (67.5 in)

Figure 5: Oven Cross Section

165 mm Mineral Wool Insulation

Fire Bricks above and Below Baking Belt

Insulated Belt Return

Zone 1: 48’ DGF

Zone 4: 48’ DGF

Zone 2: 48’ DGF

Zone 3: 48’ DGF

Zone 5: 48’ DGF

1 m (40 in) wide x 91 m (300 ft) long DGF Oven

Zone 6: 60’ DGF

Figure 4: Typical Cracker Oven

Temperature Exhaust Setting

Value ºC (ºF) Open %

Rate m3/hr (cfm)

Zone 1 100 2,040 (1,200) Top Burners 308 (588) Bottom Burners 235 (455) Pre-Heat 229 (444) Belt Temp Entering 163 (325)Zone 2 100 2,040 (1,200) Top Burners 277 (531) Bottom Burners 229 (444) Pre-Heat 260 (501)Zone 3 100 2,040 (1,200) Top Burners 246 (475) Bottom Burners 219 (427)Zone 4 100 2,040 (1,200) Top Burners 190 (374) Bottom Burners 156 (313)Zone 5 50 1,020 (600) Top Burners 251 (484) Bottom Burners 156 (313)Zone 6 50 1,020 (600) Top Burners 255 (492) Bottom Burners 212 (414) Belt Temperature Exiting 189 (370)

Table 2: Oven Conditions

7

use the average temperature inside the oven as the oven environment temperature. According to the Figure 6, the average oven environment temperature is approximately 200ºC (392ºF).

What is the total hourly consumption of gas energy used by the Oven?

According to the flow meter, the oven consumes 125 m3/hr (4,415 ft3/hr) of gas to produce 1,833 kg/hr (4,032 lbs/hr) of finished crackers. The local natural gas at the plant has an energy value of 10.6 KW-hr/m3 (1,020 BTU/ft3) when burned properly. For simplicity of calculations, assume the oven is set up correctly and that the burners are operating efficiently.

Calculated Hourly Gas Energy used by the Oven:

125 m3 gas/hr x 10.6 KW-hr/ m3 gas = 1,325 KW (4,521,088 BTU/hr)

What is the gas energy per unit weight of product produced?

Calculated Energy per unit weight of Product Produced:

1 hr/1,833 kg product x 125 m3 gas/hr x 10.6 KW-hr/m3 gas = 0.723 KW-hr/kg (1,122 BTU/lb)

Referring back to Table 1, a cracker process generally runs in the range of 0.52 to 0.77 KW-hr/kg (800 to 1,200 BTU/lb). At 0.723 KW-hr/kg, the cracker oven is operating within the typical range.

Figure 6: Oven Conditions

8

What is the calculated energy required to bake 1,833 kg/hr of Finished Crackers?

From the discussion on Heat Balance, the energy in must equal the energy out.

Qin = Qout

Qin = Energy in the Oven from the combustion of Gas

Qout = Energy consumed during the Baking Process (Product, Belt, Makeup Air and Oven Surface Radiation Losses)

Qout = Qproduct + Qbelt + Qmuair + Qosr

Heat Required by Product: Qproduct Sensible Heat for Dry Product: Qdryp= Mp cp (tp2 – tp1) Sensible Heat for Water in Product Qwat= Mw cp (tw2 – tw1) Latent Heat of Evaporation: Qevap= Mw (H) Sensible Heat of Vapor: Qw vap= Mp cv (texh – tp)

Heat Required for the Baking Belt: Qbelt= Mb cb (tb2 – tb1)

Heat Required for Makeup Air: Qmair = Ma cpa (texh – tr)

Heat Loss due to Oven Surface Area Radiation: Qosr = Uo Ao (to – tr)

From the information collected during a site survey at the bakery, the following basic process data was collected:

Product: Round Laminated Snack Cracker Bake Time: 2 min 32 sec (2.58 minutes)Oven Belt Speed: 36 m/minProduction: 1,833 kg/hr (4,032 lbs/hr) of finished productMixer Dough Moisture: 30%Oven Entrance Moisture: 28%End of Oven Moisture: 2.25%

Finished Production Rate: 1,833 kg/hr @ 2.25% MoistureDry Ingredients Rate: 1,792 kg/hr @ 0% MoistureDough Rate at Mixer: 2,560 kg/hr @ 30% MoistureDough Rate into Oven: 2,489 kg/hr @ 28% MoistureTotal Water in Dough: 2,560 kg/hr - 1,792 kg/hr = 768 kg/hrTotal Water in Dough at the Oven: 2,489 kg/hr - 1,792 kg/hr = 697 kg/hrWater Remaining in Finish Product: 1,833 kg/hr x 0.0225 = 41 kg/hr

9

Oven Dimensions: 1.72 m wide x 1.45 m high x 91 m longTotal Oven Surface Area: 582 m2

Oven Exhaust Capacity: 2,040 m3/hr (1200 cfm) for each Zone; Oven Inlet and Exit Open Area: 0.185 m3 eachBelt Type and weight: CB5 Carbon Steel Belt @ 22.0 kg/m2

The information in a Table 3 correlates each value with a meaning in the energy balance equations. In addition, the calculations call for standard engineering values, which can be found in Handbooks1.

Process ConditionsDesignation

(Units)Value

Mass Flow of the Dry Product: Mp (kg/hr) 1,792Mass Flow of Water in the Product at Oven Entrance: Mw (kg/hr) 697

Mass Flow of Water in the Product at Oven Exit: Mw (kg/hr) 41

Mass Flow of Water Evaporated in Oven: Mw evap (kg/hr) 656

Temperature of Product/ Water at Oven Entrance: tp1 & tw1 (ºC) 30

Temperature of Product/ Water at Oven Exit: tp2 & tw2 (ºC) 98Belt Temperature at Oven Entrance: tb1 (ºC) 180Belt Temperature at Oven Exit: tb2 (ºC) 225Air Density at Oven Temperature of 200ºC: ρa (kg/m3) 0.75Air Density at Oven Exhaust Temperature of 150ºC: ρa (kg/m3) 0.84Air Density of the Oven Room at a temperature of 30ºC: ρa (kg/m3) 1.13Temperature Average of the Product/Water in the Oven: tp ave (ºC) 64Average Temperature of the Oven: to (ºC) 200Temperature of the Room: tr (ºC) 35Temperature of the Exhaust (Estimated from Stack): texh (ºC) 150Specific Heat Capacity of the Water: cpw kJ/(kg ºC) 4.2

Specific Heat Capacity of the Dry Product (Cracker @ 2.5% Moisture): cpc kJ/(kg ºC) 1.57

Specific Heat Capacity of the Water Vapor: cpv kJ/(kg ºC) 2.0

Specific Heat Capacity of Air: cpa kJ/(kg ºC) 1.0Specific Heat Capacity of Carbon Steel Belt: cpb kJ/(kg ºC) 0.49Latent Heat of Evaporation: H kJ/kg 2,270

Heat Transfer Coefficient for the Oven/ Dryer: (Estimated) Uo W/(m2 ºC ) 3.0

Table 3: Oven Process Conditions and Parameters

10

Calculating the Energy Balance for the Oven

1. Heat Loss due to Oven Surface Area Radiation:

Qosr = Uo Ao (to - tr) = 3.0 W/m2 ºC x 582 m2 (200ºC - 35ºC) = 288.1 KW

2. Heat Required by Product

Sensible Heat for Dry Product: Qdryp = Mp cpc (tp2 – tp1) Qdryp= 1,792 kg/hr x 1hr/3,600 sec x 1.57 kJ/kg ºC x (98ºC - 30ºC) = 53.1 KW

Sensible Heat for Water: Qwat= Mw cpw (tw2 – tw1)

Qwat = 697 kg/hr x 1hr/3,600 sec x 4.2 kJ/kg ºC x (98ºC - 30ºC) = 55.3 KW

Latent Heat of Evaporation: Qevap = Mwevap (H)

Qevap = 656 kg/hr x 2,270 kJ/kg x 1 KW hr/3,600 kJ = 413.6 KW

Sensible Heat of Vapor: Qwvap = Mw cpv (texh – tp ave)

Qwvap = 656 kg/hr x 1hr/3,600 sec x 2.0 kJ/kg ºC x (150ºC - 64ºC) = 31.3 KW

Heat Required by the Product: = 53.1 + 55.3 + 413.6 + 31.3 = 553.3 KW

3. Heat Required for the Belt

Sensible Heat for Belt: Qbelt = Mb cpb (tb2 – tb1)

Qbelt = 36.0 m/min x 22.0 kg/m2 x 1.0m x 1min/60 sec x 0.49 kJ/kg ºC x (225ºC-180ºC) = 291.1 KW

4. Heat Required for Makeup Air to replace Exhausted Air and Air Leaks:

Qmair = Ma cpa (texh – tr) Exhaust Stack Flow: (4 x 2,040 m3/hr) + (2 x 1,020 m3/hr) = 10,200 m3/hr Air Leaking from Oven End: Estimated to be 170 m3/hr x opening of 0.37m2 = 63 m3/hr Total mass of air to be reheated (Ma): 10,263 m3/hr x 1 hr/ 60 min x 0.84 kg/m3 = 143.7 kg/min

Qmair = 143.7 kg/min x 1.0 kJ/kg ºC x (150ºC - 35ºC) = 16,526 kJ/min

Qmair = 16,526 kJ/min x 60 min/hr x 1 KW hr / 3,600 kJ = 275.4KW

11

Total Heat Required for Oven

Qoven = Qosr + (Qdryp + Qwat + Qevap + Qwvap) + Qbelt + Qmair

Qoven = 288.1 KW + 553.3 KW + 291.1 KW + 275.4 KW = 1,408 KW

Calculated Heat Required for the Cracker Oven:

1,408 KW (4,804,295 BTU/hr)

How does the calculated value compare to the measured value?

The calculated value can now be compared to the actual measured value by the gas meter:

Calculated Energy Consumption: 1,408 KW (4,804,295 BTU/hr)

Actual Energy Consumption: 1,325 KW (4,521,088 BTU/hr)

Close but not quite the same. Several reasons can explain the difference:• Oven Burners may not be burning perfectly, converting all of the gas energy to heat. The oven may

not be getting 10.6 KW-hr/m3 (1,020 BTU/ft3) from the combustion process as burners get fouled in the baking process.

• Estimates on the oven’s Heat Transfer Coefficient may be slightly off.• Measured Exhaust Flow rates may be slightly off.

However, the calculated rate is within 10% of the actual value. Therefore this information can be used to determine the magnitude of the four categories of oven energy consumption identified (Figure 7).

Summary: Identifying Opportunities to Save Energy in DGF Cracker Ovens

Product Heat: Heat required by the product remains a constant for a given formula. The only possible means to reduce the required product energy is to remove water from the formula. Usually removing wa-ter from a product negatively affects the product development and texture.

However one benefit of continuous mixing processes is that the thorough blending of water and flour can reduce water content of dough by 1 to 2%. Reducing the dough water content by 2% saves 3 to 4% of the overall oven energy requirement.

Oven Surface Heat: Surface heat losses are dependent on the insulating quality of the oven. In most cases, this is fixed based on the oven construction. However, a portion of this calculated heat loss is due to the oven room environment and temperature. The cooler the oven room, the more heat is transferred from

12

the oven; blowing cool air over the oven also increases the heat transfer. So there must be a balance between keeping the oven room tem-perature warm enough to minimize radiant heat transfer yet cool enough for people and electri-cal components to co-exist.

The ideal situation is an isolated oven room where people do not have to work continuously within the environment. Isolated oven room temperatures between 32 and 42ºC (90 and 110ºF) minimize radiant heat losses of ovens.

Oven Makeup Air: Removing water vapor is required in all baking ovens. Unfortunately, removing water vapor means removing heated air. If during the process of removing this water vapor and air, the two streams can be separated — discharge the water and save the heated air — a much more efficient process would result.

This is the function of a Makeup Air Heat Ex-changer. Cooler makeup air entering the oven is passed over the hotter tubes of exhausting air thus transferring energy to the makeup air stream. The tem-perature of the exhaust air decreases as the temperature of the makeup air increases. Using heat exchang-ers makes it possible to capture up to 50% of the energy required to heat the makeup air thus reducing overall energy consumption of the process by approximately 5 to 10%.

Oven Belt Heat: All tunnel ovens with belts traveling inside and outside the oven lose heat when out-side the oven. Reviewing the basic energy equation for the belt, there are two opportunities to reduce the energy lost by the belt. First, a well insulated oven return will maintain more heat in the belt during the return process yielding a higher oven entrance temperature.

Returning the belt back through the bottom of the oven chamber is even better. Higher temperatures inside the oven maintain a higher retention of belt heat.

Belt weight accounts for the other opportunity to reduce heat. Lower belt weights consume less energy. Consider changing heavy dense belts such as a CB5 belt (22.0 kg/m2) with a similar but lighter belt such as a CB3 belt (15.6.0 kg/m2). This can reduce overall oven energy consumption by approximately 5%.

Contact details

For more information contact, Reading Bakery Systems, Robesonia, PA, USA. Ph 610-693-5896, Email: [email protected]

References

Engineering Tool Box: www.engineeringtoolbox.com.Scorpion Oven Report. Midwest Bakery Producing Round Snack Crackers. May 2010.

Cracker Oven Energy Input

Belt Heat21% Product Heat

39%

Oven Surface Heat20%Make Up Air

Heat18%

Figure 7: Oven Energy Consumption