Corbel

-

Upload

asraf-muidin -

Category

Documents

-

view

219 -

download

5

Transcript of Corbel

Corbel Design

fcu = 40 N/mm2 hcs R = 6 m

Cover, C = 25 mm hcs L = 6 m

fy = 460 N/mm2 Self Weight =

fyv = 250 N/mm2 hcs & top = 4.5 kN/m2

= 0.7 m 700 x 700 Service DL = 2.9 kN/m2

reaction,V = 675 kN beam =av = 75 mm sect1 = 5.772 kN/m

bend, r = 4 Ø sect2 = 2.688 kN/m= 64 mm DL = 52.86 kN/m

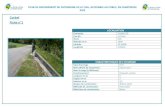

1) Corbel geometry LL = 3 kN/m2

LL = 18 kN/m= 16 mm thus, W = 102.8 kN/m= 12 mm beam , L = 9 m

= 400 mm

= 0.6fcu

= 24 N/mm2

= V/(0.6fculb)

= 70 mm

c) length of corbel. Lc

Lc = av + 0.5w + 2x cover + Ømain + Ølink + r

= 252 mm

says 250 mm l1 l2

d) depth of corbel 1/2w

av

= 450 mm

h1 = 351 mm > h/2 w= 70h1 225

b1 = 110.2 mm 450ok b2 139.8 mmnot ok

225

d = 417 mm > av

oknot ok

b) bearing width

length, lb

CORBEL DESIGN

Max/ bearing

stress

width of

bearing, w

column width

250Lc=

a) tension barlink size

assume depth of

corbel, h

e) check shear stress

v = V/ bd

= 2.31 N/mm2 < 0.8 √fcu

= 5.06 N/mm2

oknot ok

2) Corbel reinforcement

a) Main tie steel

Check if Fs > V/2

v/fcu = 0.36 (1-2av /d)

= 0.231

but v/fcu = 0.058 < 0.231

Thus, design for minimun tension

Fs = 0.5V

= 338 kN

Total tension = (Fs + T) T = 0 kN

= 338

v =

fcu

v/fcu = 0.058

av/d = 0.180

from chart z/d = 0.72

fs = 700 (z/d-0.55) / (1- z/d)

= 425 N/mm2

Hence As = 794.1 mm2

As min = 0.004 bd

= 417 mm2

3nos. of T 20 = 943 mm2

oknot ok

(0.4%bd min steel)

b) Check steel stress

(av/d)2 + (z/d)2

0.9 (z/d)(av/d)(1-z/d)

c) check bearing stress within bend

Fs' = (Fs + T) As req

nos. of bar As prov

= 49.76 kN

minimun bend radius

r = (Fs / Ø) x (1 + 2Ø / ab)

ab = 76.8 mm says 75 mm

r = 55 mm

aasumer = 4 Ø= 64

oknot ok

d) shear links

v = 2.31 N/mm2

100 As prov /bd= 0.50

400 / d = 0.96

fcu / 25 = 1.6

λm = 1.25

vc = 0.80 N/mm2

enhancedvc' = 2d vc / av

= 8.85 N/mm2> 0.8√fcu = 5.06

hence vc' = vc = 5.06

use calculated vc'

use 0.8√fcu

since v < vc ; no shear links required but provide

25% 0f main bar for confinemnet

Link = 236 mm2

2 nos. of T 16 = 402.3 mm2 oknot ok

2fcu

x

AS PROVIDED SHOULD GREATER

THAN AS MIN OR AS REQUIRED??

- to check shear stress formula, v=v/bd, b

equal width of column or depth of corbel

Projek :ILAJ

Loading Data

1. Dead load

Slab self weight

Ρconc = 24 kN/m3

205 H Core Slab = 2.7 kN/m2

Topping 75 = 1.8 kN/m2

mm 4.5 kN/m2

SDL

M & E = 0.25 kN/m2

Ceiling = 0.25 kN/m2

Screed = 1.2 kN/m2

Blockwall= 1.2 kN/m2

2.9 kN/m2

2. Live load

Imposed Load = 3 kN/m2

3. Calculate

Simply supported

Moment= wl2 / 8

Reaction= wl/2