Copy of Hirarc

-

Upload

muhd-shafiq-ii -

Category

Documents

-

view

121 -

download

4

Transcript of Copy of Hirarc

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 1 of 13

1.0 Purpose

The purpose of this SOP is to provide a systematic and objective approach to assessing hazards and

their associated risks that will provide an objective measure of an identified hazard as well as provide

a method to control the risk. It is one of the general duties as prescribed under the Occupational

Safety and Health Act 1994 (Act 514) for the employer to provide a safe workplaces to their

employees and other related person.

2.0 Scope

This SOP outlines requirements associated with OSH workplace inspections, including training,

inspection checklists to be used and HIRARC report.

3.0 Definitions

Hazard means a source or a situation with a potential for harm in terms of human injury or ill health,

damage to property, damage to the environment or a combination of these.

Hazard identification means the identification of undesired events/conditions that lead to the

materialization of the hazard mechanism by which those undesired events could occur.

Inspection team / HIRARC Team means two or more people responsible for conducting the

workplace inspection

Risk means a combination of (i) the likelihood of an occurrence of a hazardous event with specified

period or in specified circumstances and (ii) the severity of injury or damage to the health of people,

property, environment or any combination of these caused by the event.

Risk assessment means the process of evaluating the risk to safety and health arising from hazards

at work.

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 2 of 13

Risk control means the process of implementing measures to control the risk associated with a

hazard.

Risk management means the total procedure associated with identifying a hazard, assessing the

risk, putting in place control measures, and reviewing the outcomes.

4.0 Responsibilities

4.1 Faculties/Divisional Management

Management in Faculties and Divisions/Departments, may, if requested, to assist the OSH

Committee to carry out workplace inspections and subsequent rectification of hazardous

conditions. Management and staff also have the responsibility to inform OSH Committee on

any potential hazards identified and/or the effectiveness of existing controls.

4.2 HIRARC Inspection Team

The inspection team is required to record workplace inspections findings as set out in this SOP

and to ensure hazards are controlled.

5.0 Workplace Safety Inspections

5.1 Inspection Frequency

The Occupational Safety and Health Act (OSHA) 1994 require the inspection of workplace to

be done at least once in every three months.

However, inspection frequency is determined by the level of risk associated with the workplace

(faculty, division, department, laboratory). A risk assessment should be conducted by the

Faculty/Division/Department/Laboratory controlling the area to determine the risk and the

frequency of inspections required.

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 3 of 13

After receiving risk assessment reports, an inspection schedule, appropriate for the level of

risk, should be developed by the HIRARC team, to program inspection throughout the year.

This schedule should be communicated back to the respective faculty, division, department

and laboratory.

5.2 HIRARC Inspection Team

It is recommended that those conducting workplace inspections attend HIRARC training and

have knowledge and/or experience of the workplace and hazards that may be present.

The inspection team should be comprised of at least an OSH Committee member, a

Department of Estates and Facilities (DEF) representative. Inspections team may also include

a person external to the area. The in charge personnel of the area should be present during

the inspection if required by the inspection team.

HIRARC Team should prepare the inspection schedule and discuss the areas to be inspected

and time allocated for inspection. Each inspection must be fully documented. The HIRARC

form (Appendix B) must be completed by the inspection team and signed by the in charge

personnel of the location and an agreement amongst team members involved in the

inspections on counter measures and recommendations, prior to submitting the report to the

OSH committee.

5.3 Staff Involvement

Staff (science/engineering/computer laboratory/workshop etc.) have valuable on-the-job

experience and can have skills in identifying the hazards associated with particular tasks. This

information is valuable during inspections and it is recommended that staff is involved in the

inspection process or given the opportunity to provide information to the inspection team by

being present during inspections. All staff are encouraged to provide information or/and report

any potential hazards to the OSH Secretariat.

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 4 of 13

5.4 Inspection Checklists

During inspection, checklists are used to assist in the identification of hazards. Any additional

hazard should be noted at the end of the checklist. An example of a checklist can be found in

Appendix D.

Faculty/Division/Department/Laboratory can include additional hazards in the checklist for their

units as long as OSH Secretariat is informed.

Inspection checklist is used to produce HIRARC report.

5.4 Preventive / Corrective Action

Once potential hazards or hazards are identified, measures should be taken to ensure the

hazards are controlled. Once an inspection is completed those items that require preventive /

corrective actions should be addressed. The HIRARC report should be sent to OSH

Secretariat within ten working days after the inspection is done. The Secretariat would ensure

that the reports are sent to an appropriate department/person for action. The Secretariat

should follow-up to verify that action has been taken or is completed and review the risk to

ensure that it has been eliminated or minimized.

Where a hazard presents an immediate risk to safety and health, the HIRARC team / Safety

and Health Officer should attempt to make the area safe and notify the area in charge

personnel for further action.

5.5 Inspection Reports / Documentation

Inspection report should consist of checklists and an HIRARC Form (inspection/hazard

summary). OSH Secretariat should disseminate the HIRARC report to the relevant

Dean/Director/HOD/Laboratory Officer.

A HIRARC Report should detail, but not limited to, the following:

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 5 of 13

Area inspected

Area supervisor

Inspection team

Area supervisor / Person in-charge

Hazard identification

Risk assessment

Risk control (Recommendations, action to be taken by, due date/status)

6.0 AppendicesAppendix A: Flowchart of HIRARC Process

Appendix B: HIRARC Form

Appendix C: HIRARC Form (Example)

Appendix D: Checklist (General Area)

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 6 of 13

Flowchart of HIRARC Process

Appendix A

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 7 of 13

HIRARC Team to complete/assess:a) scheduled building inspections after risk assessment is done,

b) identified potential hazards or hazards,c) any work activities.

Consultation with staff for specify work activities e.g. machine operation, chemicals

handling.

Identify Hazards from the information gathered.

Assessing the risk (high/medium/low) after hazard identification.

Develop control measures/action plan

Implement the control measures/action plan and follow up

Review

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 8 of 13

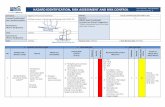

HIRARC FORM

Faculty/Location/Block Campus PK / K-V

Conducted by: Name:

Designation/Dept:

Name:

Designation/Dept:

Name:

Designation/Dept:

Date:(from… to…)

Time:

Next Review Date: Ref. No. for Follow Up Action:

Hazard Identification (HI)Risk

Assessment (RA)

Risk Control (RC)

No Hazard / Defect Identified and which can cause / effectRisk

(High/Medium/Low)

Recommended Control Measures Action By &Due Date/Status

1

2

3

Appendix B

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 9 of 13

HIRARC FORM (Example)

Faculty/Location/Block PE (CFS-PJ) Campus PK / K-V

Conducted by: Name: Benedict Tong

Designation/Dept: SHO/DSS

Name: Chu Ling Onn

Designation/Dept: Lecturer

Name: David Chan

Designation/Dept: Manager/DEF

Date:(from… to…)

2 Nov 2009 Time: 10 am to 2 pm

Next Review Date: 31 Nov 2009 Ref. No. for Follow Up Action:PE/4th Q 2009/1 (2, 3 and so on)

Hazard Identification (HI)Risk

Assessment (RA)#

Risk Control (RC)

No Hazard / Defect Identified and which can cause / effectRisk

(High/Medium/Low)

Recommended Control Measures Action By &Due Date/Status

1 No alarm, sprinkles, detectors, hydrants observed / no warnings during emergencies e.g. fire – may cause fatality

High Request the owner on

providing these facilities.DEF/

31 Dec 2009

2 No emergency numbers displayed. First aiderscontact nos. not available / delay in getting assistance during emergency e.g. first aid, ambulance, BOMBA services.

MediumEmergency numbers should be displayedat strategy locations. First aiders’ numbers should be displayed nearby or insidethe first aid kit

DSS31 Nov 2009

3 Spoiled chairs to be removed. (1st Floor) / obstruct escape during emergency.

Low To remove the chairs as soon as possibleDEF/

9 Nov 2009

Appendix C (i)

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 10 of 13

# Risk Assessment (High/Medium/Low) is derived from the table below:

Severity (S)

Likelihood (L) 1 2 3 4 5

5 5 10 15 20 25

4 4 8 12 16 20

3 3 6 9 12 15

2 2 4 6 8 10

1 1 2 3 4 5

High15-25

A HIGH risk requires immediate action to control the hazard as detailed in the hierarchy of control. Actions taken must be documented on the risk assessment form including date for completion.

Medium5-12

A MEDIUM risk requires a planned approach to controlling the hazard and applies temporary measure if required. Actions taken must be documented on the risk assessment form including date for completion.

Low1-4

A risk identified as LOW may be considered as acceptable and further reduction may not necessary. However, if the risk can be resolved quickly and efficiently, control measures should be implemented and recorded.

Hence, risk can be calculated using the following formula:

L x S = Risk

L = Likelihood

S = Severity

Appendix C (ii)

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 11 of 13

Below is one of the examples of Likelihood:

Likelihood is an event likely to occur within the specific period or in specified circumstances.

Likelihood (L) Example Rating

Most likely The most likely result of the hazard / event being realized 5

Possible Has a good chance of occurring and is not unusual 4

Conceivable Might be occur at sometime in future 3

Remote Has not been known to occur after many years 2

Inconceivable Is practically impossible and has never occurred 1

Severity is outcome from an event such as severity of injury or health of people, or damage to property, or insult to environment, or any

combination of those caused by the event.

Severity (S) Example Rating

Catastrophic Numerous fatalities, irrecoverable property damage and productivity. 5

Fatal Approximately one single fatality, major property damage if hazard is realized 4

Serious Non-fatal injury, permanent disability 3

Minor Disabling but not permanent injury 2

Negligible Minor abrasions, bruises, cuts, first aid type injury 1

Appendix C (iii)

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 12 of 13

Source: Guidelines for Hazard Identification, Risk Assessment and Risk Control, 2008, DOSH, Ministry of Human Resources

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 13 of 13

GENERAL AREA INSPECTION CHECKLIST

Inspection Carried Out By :

Location : Inspection Date/ Time :

* Boxes to be ticked as items are satisfactory () or required action (X), or otherwise NA indicates the item is not applicable to this area.

No. Criteria/X or NA

Result of Inspection

1 Floors, Aisles, Walls, Ceilings, Stairs and Landings

a Do floors have even surfaces (no cracks or holes)?

b Are the floors and aisles clear of rubbish, materials and equipment?

c Are walkways clear of obstructions and trip hazards (e.g. electrical cords)?

d Are walls in good condition (no cracks or holes)?

e Are ceilings in good condition (no crack, sagging and water stain/water leaking)?

f Are stairs in good condition (no worn or broken treads)?

g Are handrails in good condition?

h Are non-skid strips in good condition?

i Are landings clear of obstructions?

2 Emergency Proceduresa Are emergency numbers

Appendix D

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 14 of 13

clearly displayed?b Are fire extinguishers located

in an easy to see location?c Have fire extinguishers been

serviced/tagged/expired?d Are fire extinguishers free

from obstruction (clearing at least 1 meter)?

e Are accesses to Hose Reel free from obstruction?

f Have the smoke detectors functioning/been tested?

g Have the fire alarm functioning/been tested?

h Are overhead sprinkler/detectors clear of obstructions, stores etc?

i Are emergency evacuation map easy to understand, up to date and clearly displayed?

j Are emergency evacuation instructions easy to understand and clearly displayed?

k Have emergency lighting units functioning/been tested?

l Are emergency exit stairs adequately lit?

m Are fire doors closed but not locked?

n Are exit signs in place and illuminated?

o Are exit doors marked and clearly visible?

p Can exit doors be opened from inside (no pad-locks)?

q Are exit corridors clear of obstructions (including outside of the building)?

r Are all fire hydrants visible and readily accessible (clearing at least 3 meter)?

s Have the fire hydrants functioning/been tested?

3 First Aida Are first aid kit and contents

clean and orderly and properly stocked (check expiry date)?

b Do ‘First Aid Kit’ signs

Universiti Tunku Abdul RahmanManual Title : HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL (HIRARC)

Procedure Number : QP-DSS-005 Rev No: 0 Effective Date: 07/04/2010 Page No: 15 of 13

indicate locations of kits and contact numbers of first aiders? Are the signs clearly displayed?

4 Electricala Are electrical items tested and

tagged and in date?b Are all power outlets and

switches in good condition (not broken)?

c Are all electric panels locked and surrounding 3 ft of space clear?

d Are extension leads / power boards used as designed (temporary or makeshift leads/power boards,double adaptors, overloading)?

5 Lighting / Othera Is there adequate lighting for

the work being carried out?b Is the drinking water from

water dispenser clean and safe to drink?

c Are waste bins routinely emptied?

Other Comments: