Conveyor Belts 1

Transcript of Conveyor Belts 1

-

7/27/2019 Conveyor Belts 1

1/30

F o r t o p p e r f o r m a n c e , e n d u r a n c e a n d e c o n o m y

PHOENIX

CONVEYOR BELTSYSTEMSP R O G R A M O F C O N V E Y O R B E L T S

-

7/27/2019 Conveyor Belts 1

2/30

in conveying applications worldwide.

Dedication to all aspects of the manu-

facturing process and

the highest level of quality control

standards ensure that our prod-

ucts provide the best value to our

customers. With over 100 years

of experience and a multitude of

World Records, Phoenix Conveyor

Belt Systems GmbH continues to de-

monstrate its position as a global lea-

der in conveyor belt technology.

Phoenix has established a respected

global market presence based upon

innovative product design and cutting

edge technology. Our line of conveyor

belt products is developed from

engineered product designs that have

been tested and proven to provide the

highest level of product performance

PHOENIX CONVEYOR BELT

SYSTEMS GMBH

-

7/27/2019 Conveyor Belts 1

3/30

Manufacture of the first

co nveyor belt.

The b elts tens ion ca r-

rier initia lly c ons iste d of

fabric made from cotton

and rayon sta ple.

1904Manufacture of

the first steel-cord

co nveyor belt.

1956Introduc tion of the

P HOENOTEC a ctive

protection system,

co nsisting o f synthetic

individual cords.

1973

From the s ta rt of conveyor

belt production more than

100 yea rs a go...

Delivery of the w orlds

strongest generator-

operated conveyor

belt; with the highes t

dyna mic s plice fatigue

strength worldwide.

For the El Abra copper

mine.

1995Delivery of 5,500 m oftype St 4000 conveyorbelt for the Pierina goldmine in P eru, situatedat 4,200 m above s ealevel. It is the s teepes toverland co nveyor belt,w ith a n inclina tion of 18 .

1998

-

7/27/2019 Conveyor Belts 1

4/30

...to the mos t mod ern, high-

performa nce, conveyor belts foruse a bo ve a nd underground.

First delivery of

the w orlds hea viest

co nveyor belt;

with a we ight

of 52 metric tons.

1981Delivery of the worlds

strongest underground

conveyor belt PHOENCORD

St 7500 for the Prosper

Haniel mine.

1986elivery of the worldsst self-extinguishingeel-co rd c onveyorlt, for use und er-ound.

975The first P VG co nveyorbelt; with a PVC-impregnated ca rca ssand CR c overs.

1979

The long est c onveyo r

belt on earth is c onvey-

ing limes tone from a

mine loc a ted in India

ac ross the state border

to a cement plant in

Ba nglades h. The

single flight conveyor

is 17,000 m long.

2006The long es t pipe convey or

belt w orldw ide. The lates t

pathb reaking app lica tion

is a 16.4 km long b elt

(8,172 m center distance)

for the conveyance of

hot clinker from a cement

fac tory to the port on

the upper run of the con-

veyor, a nd c oa l and lime-stone from the p ort to the

fac tory on the bottom run.

2007elivery a nd as semb ly

the w orlds stronges t

nveyor belt the

HOENOCORD

7800, for the Los

elambres copper

ine.

999Delivery of the hea vies tco nveyor be lt reelsworldwide for thehighes t e levatedcopper mine worldwide Collahua si. Oneconveyor belt reel typeSt 6300 weighs 58 t.

2003

Internationalborder

India

Bangladesh

India

Bangladesh

Internationalborder

-

7/27/2019 Conveyor Belts 1

5/30

C ontents

2 P ro duc tio n pro gra m

Steel-cord conveyor belts

4 P HOENOC ORD

Textile conveyor belts

8 DUOFLEX

8 P OLYFLEX

10 UNIFLEX P VG , P VC

Special conveyor belts

12 P HOENOFLEX

12 P HOENAMID

13 MAG MA

14 P HOENOP IP E

15 P HOENOC ORD EOB

16 P HOENIX MVF-A

17 P HOENOTOP

Protection systems

for conveyor belts

18 P HOENOTEC

18 P HOENOC ARE S L

19 Belt splices

20 Testing centre

22 Service

-

7/27/2019 Conveyor Belts 1

6/30

2

PHOENOCORD PHOENOCORD

DUOFLEX POLYFLEX POLYFLEX

with PHOENOTEC

with PHOENOTEC

Steel-cord conveyor belts

Textile conveyor belts

P hoenix Conveyor Belt Systems

Gmb H is the technologica l lea der

worldwide for the construction

and produc tion of c onveyor belts.

P hoenix conveyor belts ha ve been

operating in many countries around

the w orld for more tha n 100 yea rs.

Enduring and economical.

Production program

UNIFLEX PVC UNIFLEX PVG

-

7/27/2019 Conveyor Belts 1

7/30

-

7/27/2019 Conveyor Belts 1

8/30

10 mm running s ide

bonding plate

19 mm carrying side

P HOENOTEC

transverse reinforceme nt

stee l-cord tension c arrier

PHOENOCORD 1800 / St 7800-19T/10 X

are used to develop a large number of new belt

co nstructions to mee t the g row ing requirements .

The criteria to be c ons ide red a re: high d yna mic

efficiency; resista nce to rotting and co rros ion;

low elongation; meeting the fire-protection and

electros tatic s afety req uirements ; thermal sta bility

and chemica l resistance.

PHOENOCORD steel-cord conveyor belts:

Smallest elongation with long conveyor routes.

High breaking strength with highest capacity.

Long working life with the lowest need for maintenance.

Economical use above and below ground.

Phoenix has been developing and fabricating

ste el-cord co nveyor belts for more tha n 50 yea rs

already. A broad palette of steel-cord conveyor

belts up to a width of 3,200 m and individua l

lengths weighing up to 58 metric tons per unit are

manufactured o n the bas is o f a huge number of

materials. Deca des of knowledge and experience

4

PHOENOCORD

S teel-cord conveyor belts

-

7/27/2019 Conveyor Belts 1

9/30

9

-

7/27/2019 Conveyor Belts 1

10/30

6

1975 Phoenix supplied the worldsfirst self-extinguishing conveyor

belt, type PHOENOCORD St 4000.

1986 The worlds strongestconveyor belt with a breaking

strength of 8,200 N/mm was

installed in the Prosper-Haniel

mine by Phoenix. This 1,400 mm

wide, PHOENOCORD St 7500

could hold the weight of 3 Boeing

747s (Jumbo jets) without tearing.

1995 Phoenix supplied a 20 kmlong steel-cord conveyor belt for

the El Abra copper mine. The de-livery and commissioning of this

1,600 mm wide PHOENOCORD

St 6800 presented a challenge

for man and material. A total

of 56 splices were made under

extreme climatic conditions in

order to commission and endless

splice the belt.

1999 Phoenix was again ableto demonstrate its outstanding

performance worldwide, for thehighest strength conveyor belts.

The 24 km long and 1,800 mm

wide PHOENOCORD St 7800

with PHOENOTEC transverse

reinforcement runs in two tunnel

systems of the Los Pelambres

copper mine. Up to 25 MW of

energy is generated by the down-

hill conveyance of the ore.

PHOENOCORD

Phoenix has been the leading manufacturer

of high-strength c onveyor belts to mee t

dema nding c onditions o f use, for dec ad es.

Heightdifference1,310 m

TF 1

TF 2

Los Pelambres

feeding stationat 3,200 mabove sea level

Los Pelambres, Chile

S teel-ca ble c onveyor belts

-

7/27/2019 Conveyor Belts 1

11/30

-

7/27/2019 Conveyor Belts 1

12/30

carrying side cover

intermediate rubbe r

textile, tension carrier ply

running s ide cover

textile, tension carrier ply

DUOFLEX

and POLYFLEX

carrying side cover

textile, tension carrier ply

running s ide cover

carrying side cover

bonding rubber

synthetic cords

bonding rubber

textile tension

ca rrier p lies

running side co ver

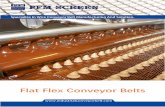

P hoenix co nveyor belts a re d es igned for the res pec tive a pplica tion.

Our application engineers are already advising the customer during the

planning of conveyor belt systems, in order to find an optimum solution.

8

Textile c onveyor beltsfor a bove ground

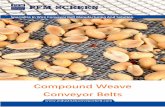

P hoenix manufactures a huge number of standa rd

conveyor belts besides steel tension carriers and

spe cial conveyor belts. The co vers c onsist of a nabrasion-resistant rubber quality, with high values

for strength a nd elonga tion. P hoenix co nveyor belts

usua lly ha ve so lid rubber ed ges . P hoenix offers

P HOENOTEC s ynthetic c ord trans verse reinforce-

ment to the user as an ac tive protection sys tem

a ga inst extreme impa cts . The belts a re endless

jointed b y mea ns o f well-know n splicing sys tems.S plicing ma terials of a cc la imed, spe cialized

companies can be used as well.

We would be glad to inform you

about special solutions.

POLYFLEXMultiply belt

with PHOENOTEC

transverse

reinforcement

POLYFLEXMultiply belt

DUOFLEXTwo-ply belt with

intermediate rubber

-

7/27/2019 Conveyor Belts 1

13/30

Phoenix is the major specialist for constructing and

producing conveyor belts of all types. Phoenix con-

veyor belts are supplied in various grades of covers,

which are adapted to special requirements and

conditions of use such as:q fire-protection safety,

q resistance to aggressive transported materials like

chemical mediums, fats and oils,q extreme abrasion

resistance with highly abrasive bulk materials.

9

-

7/27/2019 Conveyor Belts 1

14/30

UNIFLEX PVCUniflex PVC conveyor belts consist of a PVC-

impregnated solid woven traction carrier and

PVC covers. Uniflex PVC conveyor belts are

ideally suited for rough usage below ground,

and they meet the strictest safety regulations

for fire-protection.

UNIFLEX PVG

10

Phoenix achieved the first official approval

worldwide for this type of belt in the year

1979. The palette of conveyor belts was up

to a belt breaking strength of 3,500 N/mm.

Phoenix had already begun to develop self-

extinguishing textile conveyor belts with solidwoven tension carriers and rubber covers for

a wide range of strengths during the 1970s.

The P VC plas tomer and the CR elas tomer were

used as ba sic materials. A new g eneration of

belts wa s created, w hich a re d istinguished by

the follow ing features.

Durability by means of high

abrasion resistance.

Dynamically efficient

fatigue-resistant splices bymeans of vulcanization or

mechanical fastening.

High static and dynamic

tear-off resistance of the

tension carrier.

Resistance to ageing and

moisture.

High fire-protection safety

and low surface resistance.

UNIFLEX

Textile conveyorbelts for underground

A ge nera tion o f co nveyor belts for

high-performa nce co nveyance in

underground c oa l mines . With high

fire-protection sa fety.

-

7/27/2019 Conveyor Belts 1

15/30

11

The UNIFLEX PVG conveyor belt is constructed

from unconventional materials and it represents

one of the most interesting developments of

conveyor belts. In this respect UNIFLEX conveyor

belts have passed their test of suitability and

they are now given priority in fields of application

which were formerly reserved for steel-cord

conveyor belts only.

-

7/27/2019 Conveyor Belts 1

16/30

running side co ver

carrying side cover

bonding plate

steel-cord mesh

12

Phoenix Conveyor Belt Systems GmbH has

developed highly effective and high-performance

special conveyor belts for special duties in

systems engineering and conveyor technology.

Unlike conveyor belts which use individual steel cords

as the tension carrier, PHOENOFLEX conveyor belts

have a tension carrier that is made from steel cords

which are additionally interconnected with textile or

steel threads. PHOENOFLEX is typically used for high

temperatures such as when conveying hot bitumen.

PHOENOFLEX

The P HOENAMID c onvey or belt is a va ila ble for spe cial

applications which demand a combination of low

elongation, low weight and high strength, e.g. on

machine booms. Its tension carriers consist of aramid

cords. Special prerequisites of systems engineering

have to be met when using aramid c onveyor belts.

PHOENAMID

PHOENAMID

PHOENOFLEX

aramid-cord tens ion ca rrier

running s ide cover

carrying side cover

bonding plate

P HOENOTEC trans verse reinforcement

Special conveyor belts

-

7/27/2019 Conveyor Belts 1

17/30

13

The MAG MA ge neration of c onvey or belts w a s

created in order to meet the g row ing req uirements

for heat-resistant conveyor belts. It is based on

ma ny yea rs of experience with conveying ho t bulk

ma terials a nd prac tica lly oriented te sting proc edures.

P hoenix used the la test te chnology in the field of

polymeric ma terials w hen d eveloping the program

of MAGMA conveyor belts.

MAGMA co nveyor belts a re us ed for a large numbe r

of conveyed materials like cement, slag, ash, mould-

ing sand, etc.

MAGMA ensures unproblematic transport at contin-

uous tempe ratures of up to 200 C with short-term

pea ks tha t a re c ons iderab ly higher. MAG MA co nveyor

belts c a n be supplied a s single-ply, two-ply a nd multi-

MAGMA

High-temperature conveyor belts

MAGMA

ply belts. MAGMA can also be used as a steel-cord

belt for conveya nce o ver great d ista nces . The belt

splices for MAG MA ca n be mad e w ith P hoenix

splicing materials or with commercial quality materials

that a re s ufficiently resista nt to high temperatures.

carrying side cover

textile tension carrier plies

running side co ver

-

7/27/2019 Conveyor Belts 1

18/30

14

PHOENOPIPE

The closed conveyor belt

P HOENOP IP E co nveyor belts a re p rima rily us ed where

bulk materials mus t be c onveyed a long horizonta l and

vertica l curves in confined s pa ce s. P HOENOP IP Es

special capability of adapting to topography allows

material to be conveyed through difficult terrain and

over long distances. PHOENOPIPEs important advan-

tages are protection of the conveyed material from

environmental influences like rain and wind as well

protec tion o f the environment b y a voiding d isc harge

of the conveyed ma terial such a s a sh from pow er

sta tions a nd gyps um. Inclined a ngles o f up to 35 c an

be overcome by using PHOENOPIPE. Cost reductions

are possible by shortening the conveyor route and

avoiding transfer stations.

Closed conveyor belts are gaining

increasing importance because

they meet the growing require-

ments for a clean environment.

The ability to maneuver through

more narrow curves possibly leads

to a shorter conveyor route since

transfer stations can be avoided.

frame

carrying idler

Uppe r run

Lowe r run

PHOENOPIPEconveyor belt

conveyed ma terial

-

7/27/2019 Conveyor Belts 1

19/30

15

The conveyor belt is deformed when

running over the carrying rollers,

which consumes energy. Bulges

form in front of the carrying rollers.

The ad vanta ge s of the energy-sa ving P HOENOCORD

EOB c onveyor belt res ult from the spe cial visc o-

elastic properties of the running side cover. Phoenix

scientists have simulated the deformation of con-

veyor belts on idlers in elaborate FEM simulations.

It wa s esta blished while d oing s o, that the greatest

deformation oc curs directly ab ove the laye r that runs

over the ca rrying idler. Externa l influential fa cto rs

like weather and the systems condition must be

co nsidered when a sc ertaining the e nergy req uire-

ment. Trans verse reinforce ment o n the running side

enables further energy savings to be achieved.

running direction

bottomcover

idler

transversereinforcement

steelcords

The covers EOB

quality with special

visco-elastic prop-

erties reduces this

deformation and

it helps to reduce

the drive energy.

running direction

idler

PHOENOCORD

EOBThe energy-optimized conveyor belt

The finite element graphic

shows part of a belt with

loads being applied by

indentation, while it runs

over the carrying idler.

PHOENOCORD EOB conveyor belts can

dramatically reduce energy consumption

by means of visco-elastic properties

of the covers. This is an important con-

tribution to increasing the economic

efficiency of long conveyor routes.

-

7/27/2019 Conveyor Belts 1

20/30

16

The MVF-A q ua lity w a s s pec ia lly d eveloped for

conveying copper ore. Copper ore is sharp-

edged and highly abrasive. In addition, the ore

is frequently sprayed with sulphuric acid in order

to lea ch out the meta l from t he o re. The MVF-A

q uality copes with these a gg ress ive mechanica l

and chemica l stress es, tha nks to its high

abrasion resistant and acid protected properties.

MVF-A conveyor beltsAcid protected conveyor belts

PHOENIX MVF-A

For the most aggressive

conditions of use in mining:

high abrasion resistant,

acid protected, wear

resistant and economical.

MVF-A running side

bonding plate

MVF-A carrying side

P HOENOTECtransverse reinforceme nt

stee l-cord tension c arrier

-

7/27/2019 Conveyor Belts 1

21/30

17

P HOENOTOP co ver belts a re use d in syste ms w here

the conveyed ma terial has to be protected. S pecial

tra nsversely rigid belts a re use d in this c a se .

P HOENOTOP co ver belts a re flexible in the long itudinal

direction so that they can be partially lifted off from

the steel construction when loading and unloading.

The co nveyed ma terial thus rema ins protecte d a s

much as poss ible w hen loa ding a nd unloa ding.

PHOENOTOP

COVER BELT

PHOENOTOP COVER BELT

cover

cover

transverse sta bilizingreinforcement

carcass

belt width

Transversely rigid cover belt

freely s uspended width

-

7/27/2019 Conveyor Belts 1

22/30

The w orking life a nd func tional ca pa bility of s tee l-

cord co nveyor belts d epends more on the impact

st res se s tha n ab ras ion. The P HOENOTEC reinforce-

ment system offers ac tive protection a ga inst da mag e

that is caused by high impact energies and slitting

by foreign bod ies . The P HOENOTEC sys tem c onsists

of highly elas tic, high-tensile polyamide co rds which

a re a ligned at right a ngles to the co nveyor belts

longitudinal axis.

P HOENOTEC is vulca nized into the co nveyo r belts

co vers (ca rrying or running side , o r both). The p itch

and diameter of the co rds are esta blished ac cording

to the respective requirements. It is particularly

recommended to equip conveyor belts with

P HOENOTEC w hen the da nge r of injuries exists

from g rea t discha rge heights or foreign b od ies .

PHOENOTEC

18

A da mag ed c onveyor belt ca n cause long a nd ex-

pens ive do wntimes. P HOENOCARE SL helps to

minimize the da ma ge that results from the belt being

s lit long itudina lly. The s ys tem is preferred in critic a l

a rea s like loa ding points w ith high impa ct energies.

P HOENOCARE SL co nsists of electroinductive con-

ducto r loops which a re vulca nized into the c a rrying o r

running side and spaced according to requirements.

Monitoring sensors are fitted in front of a critical area

a nd b ehind it. The integ ra ted co nducto r loops se rve

as electromagnetic transmitters, which are scanned

by the monitoring s ens ors. The c onvey or belt is

immediately halted when it is s lit by a foreign bod y,

and the electrical circuit is interrupted as a result in

order to prevent greate r da ma ge . The belt da ma ge

ca n thus be reduced to a few metres. In ad dition, the

conveyor belt ca n be eq uipped w ith a transponder

as the data carrier.

PHOENOCARE SL

sensor loop

Protective systems

for conveyor belts

-

7/27/2019 Conveyor Belts 1

23/30

19

Conveyor belt splices

Making the splice

As a rule, c onveyor belts a re s pliced on

the co nveyor belt sys tem on s ite, in order

to form an end les s b elt. B elt splices rep-

res ent a we ak point in the co nveyor belt

reg a rding s trength. Making belt s plice s

therefore demands special know-how,

experience and cleanest conditions.

Phoenix Conveyor Belt Systems not only

has a team of qualified engineers who

can precisely plan and execute this work

but a lso a great number of different, highly

mod ern vulca nizing p res ses for applica -

tions ab ove a nd unde rground. This service

is available to our customers worldwide.

One proof of performa nce a re the wo rlds

strongest belt splices which Phoenix

fabricated in Chile in 1999.

-

7/27/2019 Conveyor Belts 1

24/30

20

Tes ting centre forconveyor belts

Quality assurance

Testing apparatus for

ascertaining the dynamic

efficiency of steel

cord-to-rubber bonding

systems.

All of the P hoenix Groups prod uction

locations and subsidiaries meet

the ISO 9001 q ua lity sta nda rd. The

certifica tion a cc ording to ISO 9001

comprises quality assurance during

development, production, assembly

and distribution. It therefore com-

pletely covers a ll of the a rea s w hich

lea d to higher sta ndards of products

and services .

Phoenix Conveyor Belt Systems

GmbH fabricates according to all the

nationally releva nt q uality s tand a rds

like DIN, S AB S , MSHA, RMA, B S ,

AS, CSA, etc.

Phoenix Conveyor Belt

Systems has the most

modern testing centre

worldwide for developing

conveyor belts. Extensive

quality tests ensure the

technological lead of

Phoenix conveyor belts.

-

7/27/2019 Conveyor Belts 1

25/30

21

A horizontally arranged

tension-testing ma-

chine for conveyor belt

samples up to 10 m

long. The maximum

force amounts to 2,500

kN and the maximum

test frequency is 2 Hz.

Drum friction test rig

for analysing the fire-

protection behaviour

of conveyor belts during

drum slippage. The

drum temperature,

drive performance and

belt tension are con-

tinuously registered

during the test.

Impact and rip

testing rigs

(Phoenix system)

-

7/27/2019 Conveyor Belts 1

26/30

22

PHOENIXCONVEYOR BELT SYSTEMS

Service

Phoenix experts are advising about detailed matters

during the planning of c onveyo r belt s yste ms . They

thus c ontribute to ens uring that the b elt c omplies w ith

the operating conditions, that the belt's technological

aspects are considered, and that a customized beltco nstruction is a chieved for use . It is o bvious tha t

a dvice for our custome rs d oes not cea se w hen the

co nveyor belt is de livered . Our as se mbly engineers

co ordina te the p ulling-in proc ed ure a nd the a ss emb ly

seq uence ba sed on our extensive know -how.

Even after this s ta ge our service co ntinues through

inspec tions of the sys tems tha t co uld be ca rried out

by our specialists on request.

-

7/27/2019 Conveyor Belts 1

27/30

-

7/27/2019 Conveyor Belts 1

28/30

-

7/27/2019 Conveyor Belts 1

29/30

The content of this publication is provided for information only and without responsibility. Phoenix

C onveyor B elt Systems G mbH s obligations and responsibilities regarding its products are

governed solely by the agreements under which the products are sold. Unless otherwise agreed in

writing, the information contained herein does not become part o f these agreements. T his publica-

tion does not contain any guarantee or agreed quality of Phoenix C onveyor Belt Systems G mbH s

products or any warranty of merchantability, fitness for a particular purpose and non-infringement.

Phoenix C onveyor Belt Systems GmbH may make changes in the products or services described at

any time without notice. T his publication is provided on an as is basis. To the extent permitted by

law, P hoenix C onveyor Belt Systems Gm bH makes no warranty, express or implied, and assumes

no liability in connection with the use of the information contained in this publication. P hoenix C on-

veyor B elt Systems G mbH is not liable for any direct, indirect, incidental, consequential or punitive

damages arising out of the use of this publication. Information contained herein is not intended to

announce product availability anywhere in the world. 2008 Phoenix C onveyor Belt Systems

G mbH . A ll rights reserved.

-

7/27/2019 Conveyor Belts 1

30/30

008

PHOENIX CONVEYOR BELT

SYSTEMS GMBH

Hannoversche Strasse 88

D-21079 Hamburg, Germany

P hone + 49-40-7667-03

Fax + 49-40-7667-2411

E mail info@phoeni cbs com

PHOENIX CONVEYOR BELT

SYSTEMS GMBH

![Fms200904 Calc Methods Conveyor Belts 304 en[1]](https://static.fdocuments.net/doc/165x107/577cd7951a28ab9e789f584f/fms200904-calc-methods-conveyor-belts-304-en1.jpg)